Abstract

Polylactic acid is a polyester polymer, which is recyclable and renewable as well. Membrane made of polylactic acid is acquiring attention nowadays due to its superior properties and versatility in application. This review primarily explains various synthesis routes of polylactic acid membrane and its applications. Sometimes, in membrane synthesis, polylactic acid is used with some other copolymers such as caprolactam, ethylene glycol to obtain the required functionality or property for its specific application. Some copolymers that find it helpful with polylactic acid for membrane synthesis are also discussed here with its specificity and enhanced properties. In this review, precise and detailed PLA membrane structure and its degradation mechanism is discussed.

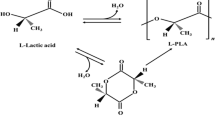

Graphical abstract

Similar content being viewed by others

References

Kang IJ, Yoon SH, Lee CH (2002) Comparison of the filtration characteristics of organic and inorganic membranes in a membrane-coupled anaerobic bioreactor. Water Res 36(7):1803–1813. https://doi.org/10.1016/S0043-1354(01)00388-8

Lin YS, Kumakiri I, Nair BN, Alsyouri H (2007) MICROPOROUS INORGANIC MEMBRANES. 31(2). https://doi.org/10.1081/SPM-120017009, https://doi.org/10.1081/SPM-120017009

Verweij H (2012) Inorganic membranes. Curr Opin Chem Eng 1(2):156–162. https://doi.org/10.1016/J.COCHE.2012.03.006

Baker RW (2000) Membrane technology. Kirk-Othmer Encycl Chem Technol. https://doi.org/10.1002/0471238961.1305130202011105.A01

Suhas DP, Aminabhavi TM, Raghu AV (2014) Para-toluene sulfonic acid treated clay loaded sodium alginate membranes for enhanced pervaporative dehydration of isopropanol. Appl Clay Sci 101:419–429. https://doi.org/10.1016/j.clay.2014.08.017

Magalad VT, Gokavi GS, Nadagouda MN, Aminabhavi TM (2011) Pervaporation separation of water-ethanol mixtures using organic-inorganic nanocomposite membranes. J Phys Chem C 115(30):14731–14744. https://doi.org/10.1021/jp201185g

Strathmann H (2001) Membrane separation processes: Current relevance and future opportunities. AIChE J 47(5):1077–1087. https://doi.org/10.1002/aic.690470514

Suhas DP, Aminabhavi TM, Raghu AV (2014) Mixed matrix membranes of H-ZSM5-loaded poly(vinyl alcohol) used in pervaporation dehydration of alcohols: influence of silica/alumina ratio. Polym Eng Sci 54(8):1774–1782. https://doi.org/10.1002/PEN.23717

Suhas DP, Raghu AV, Jeong HM Aminabhavi TM (2013) Graphene-loaded sodium alginate nanocomposite membranes with enhanced isopropanol dehydration performance via a pervaporation technique. RSC Adv 3(38):17120–17130. https://doi.org/10.1039/C3RA42062K

McHugh AJ (2005) The role of polymer membrane formation in sustained release drug delivery systems. J Control Release 109(1–3):211–221. https://doi.org/10.1016/j.jconrel.2005.09.038

Asad A, Sameoto D, Sadrzadeh M (2020) Overview of membrane technology. In: Nanocomposite membranes for water and gas separation, pp 1–28. https://doi.org/10.1016/b978-0-12-816710-6.00001-8

Carothers WH (1929) Studies on polymerization and ring formation. I. An introduction to the general theory of condensation polymers. J Am Chem Soc 51(8):2548–2559

Lowe CE (1954) Preparation of high molecular weight polyhydroxyacetic ester. United states Patent Office, pp 2–4

Martin AM (1996) Fermentation processes for the production of lactic acid. Lactic acid bacteria, pp 269–301. https://doi.org/10.1007/978-3-642-61462-0_12

Datta R, Tsai SP (1997) Lactic acid production and potential uses: a technology and economics assessment. ACS Symp Ser 666:223–236. https://doi.org/10.1021/BK-1997-0666.CH012

Piemonte V, Gironi F (2012) Kinetics of hydrolytic degradation of PLA. J Polym Environ 21(2):313–318. https://doi.org/10.1007/S10924-012-0547-X

Elsawy MA, Kim KH, Park JW, Deep A (2017) Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sustain Energy Rev 79:1346–1352. https://doi.org/10.1016/J.RSER.2017.05.143

Rashkov I, Manolova N, Li SM, Espartero JL, Vert M (1996) Synthesis, characterization, and hydrolytic degradation of PLA/PEO/PLA triblock copolymers with short poly(l-lactic acid) chains. Macromolecules 29(1):50–56. https://doi.org/10.1021/MA950530T

Fukuda N, Tsuji H, Ohnishi Y (2002) Physical properties and enzymatic hydrolysis of poly(l-lactide)–CaCO3 composites. Polym Degrad Stab 78(1):119–127. https://doi.org/10.1016/S0141-3910(02)00125-8

Datta R, Tsai S, Bonsignore P, Moon S, Frank JR (1995) And lactic acid derivatives, vol 16, pp 221–231

Martin O, Avérous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42(14):6209–6219. https://doi.org/10.1016/S0032-3861(01)00086-6

Tiersch TR, Monroe WT (2016) Three-dimensional printing with polylactic acid (PLA) thermoplastic offers new opportunities for cryobiology. Cryobiology 73(3):396–398. https://doi.org/10.1016/j.cryobiol.2016.10.005

Li G et al (2020) Synthesis and biological application of polylactic acid. Molecules (Basel, Switzerland) 25(21). https://doi.org/10.3390/molecules25215023

Cohn D, Younes H (1988) Biodegradable PEO/PLA block copolymers. J Biomed Mater Res 22(11):993–1009. https://doi.org/10.1002/jbm.820221104

Athanasiou KA, Niederauer GG, Agrawal CM (1996) Sterilization, toxicity, biocompatibility and clinical applications of polylactic acid/polyglycolic acid copolymers. Biomaterials 17(2):93–102. https://doi.org/10.1016/0142-9612(96)85754-1

Yu X, Liu F, Wang L, Xiong Z, Wang Y (2015) Robust poly(lactic acid) membranes improved by polysulfone-g-poly(lactic acid) copolymers for hemodialysis. RSC Adv 5(95):78306–78314. https://doi.org/10.1039/c5ra15816h

Konstantinos Avgoustakis (2004) Pegylated poly(lactide) and poly(lactide-co-glycolide) nanoparticles: preparation, properties and possible applications in drug delivery. Curr Drug Deliv 1(4):13. [Online]. http://www.ingentaconnect.com/content/ben/cdd/2004/00000001/00000004/art00002

Fu SJ, Zhang PH (2019) Surface modification of polylactic acid and poly (D, L-lactide-co-glycolide) biodegradable materials via chitosan-coating treatment: a new approach for developing novel antibacterial acupoint catgut embedding materials. Text Res J 89(13):2583–2594. https://doi.org/10.1177/0040517518798649

Sivalingam G, Madras G (2004) Thermal degradation of binary physical mixtures and copolymers of poly(ε-caprolactone), poly(D, L-lactide), poly(glycolide). Polym Degrad Stab 84(3):393–398. https://doi.org/10.1016/j.polymdegradstab.2003.12.008

Robert P, Mauduit J, Frank RM, Vert M (1993) Biocompatibility and resorbability of a polylactic acid membrane for periodontal guided tissue regeneration. Biomaterials 14(5):353–358. https://doi.org/10.1016/0142-9612(93)90054-6

Abdal-Hay A, Sheikh FA, Lim JK (2013) Air jet spinning of hydroxyapatite/poly(lactic acid) hybrid nanocomposite membrane mats for bone tissue engineering. Colloids Surf, B 102:635–643. https://doi.org/10.1016/j.colsurfb.2012.09.017

Bin Ma H et al (2012) Preparation and cytocompatibility of polylactic acid/hydroxyapatite/graphene oxide nanocomposite fibrous membrane. Chinese Sci Bull 57(23):3051–3058. https://doi.org/10.1007/s11434-012-5336-3

Zhu L, Liu F, Yu X, Xue L (2015) Poly(lactic acid) hemodialysis membranes with poly(lactic acid)-block-poly(2-hydroxyethyl methacrylate) copolymer as additive: preparation, characterization, and performance. ACS Appl Mater Interfaces 7(32):17748–17755. https://doi.org/10.1021/acsami.5b03951

Li D, Frey MW, Baeumner AJ (2006) Electrospun polylactic acid nanofiber membranes as substrates for biosensor assemblies. J Membr Sci 279(1–2):354–363. https://doi.org/10.1016/j.memsci.2005.12.036

Wang X et al (2021) Performance adjustable porous polylactic acid-based membranes for controlled release fertilizers. J Appl Polym Sci 138(2):1–12. https://doi.org/10.1002/app.49649

Xiong Z, Lin H, Zhong Y, Qin Y, Li T, Liu F (2017) Robust superhydrophilic polylactide (PLA) membranes with a TiO2 nano-particle inlaid surface for oil/water separation. J Mater Chem A 5(14):6538–6545. https://doi.org/10.1039/C6ta11156d

Selatile MK, Ojijo V, Sadiku R, Ray SS (2020) Development of bacterial-resistant electrospun polylactide membrane for air filtration application: Effects of reduction methods and their loadings. Polym Degrad Stab 178:109205. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2020.109205

Nicosia A et al (2015) Air filtration and antimicrobial capabilities of electrospun PLA/PHB containing ionic liquid. Sep Purif Technol 154:154–160. https://doi.org/10.1016/J.SEPPUR.2015.09.037

Qin Y et al (2020) Mechanically robust Janus poly(lactic acid) hybrid fibrous membranes toward highly efficient switchable separation of surfactant-stabilized oil/water emulsions. ACS Appl Mater Interfaces 12(45):50879–50888. https://doi.org/10.1021/acsami.0c15310

Sabbatier G et al (2015) Design, degradation mechanism and long-term cytotoxicity of poly(l -lactide) and poly(lactide-co-ε-caprolactone) terpolymer film and air-spun nanofiber scaffold. Macromol Biosci 15(10):1392–1410. https://doi.org/10.1002/mabi.201500130

Fryczkowski R, Fryczkowska B, Biniaś W, Janicki J (2013) Morphology of fibrous composites of PLA and PVDF. Compos Sci Technol 89:186–193. https://doi.org/10.1016/j.compscitech.2013.10.005

Feng J (2017) Preparation and performance control of poly(lactic acid) fiber/polyurethane composite porous biomimetic-aligned scaffolds. J Ind Text 46(6):1297–1318. https://doi.org/10.1177/1528083715624257

Datta R, Henry M (2006) Lactic acid: recent advances in products, processes and technologies—a review. J Chem Technol Biotechnol 81(7):1119–1129. https://doi.org/10.1002/JCTB.1486

Singhvi MS, Zinjarde SS, Gokhale DV (2019) Polylactic acid: synthesis and biomedical applications. J Appl Microbiol 127(6). Blackwell Publishing Ltd, pp. 1612–1626. https://doi.org/10.1111/jam.14290

Miyoshi R, Hashimoto N, Koyanagi K, Sumihiro Y, Sakai T (1996) Biodegradable poly(lactic acid) with high molecular weight. Int Polym Proc 11(4):320–328. https://doi.org/10.3139/217.960320

Miyoshi R, Hashimoto N, Koyanagi K, Sumihiro Y, Sakai T (1996) Biodegradable poly(lactic acid) with high molecular weight: Preparation by continuous melt-polycondensation process combined with reactive processing technology. Int Polym Proc 11(4):320–328. https://doi.org/10.3139/217.960320/HTML

Achmad F, Yamane K, Quan S, Kokugan T (2009) Synthesis of polylactic acid by direct polycondensation under vacuum without catalysts, solvents and initiators. Chem Eng J 151(1–3):342–350. https://doi.org/10.1016/J.CEJ.2009.04.014

Nagahata R, Sano D, Suzuki H, Takeuchi K (2007) Microwave-assisted single-step synthesis of poly(lactic acid) by direct polycondensation of lactic acid. Macromol Rapid Commun 28(4):437–442. https://doi.org/10.1002/MARC.200600715

Ovitt TM, Coates GW (1999) Stereoselective ring-opening polymerization of meso-lactide: synthesis of syndiotactic poly(lactic acid). J Am Chem Soc 121(16):4072–4073. https://doi.org/10.1021/JA990088K

Boua-In K, Chaiyut N, Ksapabutr B (2010) Preparation of polylactide by ring-opening polymerisation of lactide. Optoelectron Adv Mater—Rapid Commun 4:1404–1407

Cheng Y, Deng S, Chen P, Ruan R (2009) Polylactic acid (PLA) synthesis and modifications: a review. Front Chem China 2009 4:3 4(3):259–264. https://doi.org/10.1007/S11458-009-0092-X

Lopes MS, Jardini AL, Filho RM (2014) Synthesis and characterizations of poly (lactic acid) by ring-opening polymerization for biomedical applications. Chem Eng Trans 38:331–336. https://doi.org/10.3303/CET1438056

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci (Oxford) 33(8):820–852. https://doi.org/10.1016/j.progpolymsci.2008.05.004

Kulkarni RK, Moore EG, Hegyeli AF, Leonard F (1971) Biodegradable poly(lactic acid) polymers. J Biomed Mater Res 5(3):169–181. https://doi.org/10.1002/jbm.820050305

Granados-Hernández MV et al (2018) In vitro and in vivo biological characterization of poly(lactic acid) fiber scaffolds synthesized by air jet spinning. J Biomed Mater Res—Part B Appl Biomater 106(6):2435–2446. https://doi.org/10.1002/jbm.b.34053

Chanes-cuevas OA, Arellano-sánchez U, Álvarez-gayosso CA (2020) Synthesis of PLA/SBA-15 composite scaffolds for bone tissue engineering 2. Exp Sect 23(5)

Zhou H, Tang Y, Wang Z, Zhang P, Zhu Q (2018) Cotton-like micro- and nanoscale poly(lactic acid) nonwoven fibers fabricated by centrifugal melt-spinning for tissue engineering. RSC Adv 8(10):5166–5179. https://doi.org/10.1039/c7ra07453k

An Tran NH, Brünig H, Hinüber C, Heinrich G (2014) Melt spinning of biodegradable nanofibrillary structures from poly(lactic acid) and poly(vinyl alcohol) blends. Macromol Mater Eng 299(2):219–227. https://doi.org/10.1002/mame.201300125

Persson M, Cho SW, Skrifvars M (2013) The effect of process variables on the properties of melt-spun poly(lactic acid) fibres for potential use as scaffold matrix materials. J Mater Sci 48(8):3055–3066. https://doi.org/10.1007/s10853-012-7022-x

Cui L, Zhang N, Cui W, Zhang P, Chen X (2015) A novel nano/micro-fibrous scaffold by melt-spinning method for bone tissue engineering. J Bionic Eng 12(1):117–128. https://doi.org/10.1016/s1672-6529(14)60106-2

Chung S, Gamcsik MP, King MW (2011) Novel scaffold design with multi-grooved PLA fibers. Biomed Mater 6(4). https://doi.org/10.1088/1748-6041/6/4/045001

Zhang T et al (2020) Solution blow spinning of polylactic acid to prepare fibrous oil adsorbents through morphology optimization with response surface methodology. J Polym Environ 28(3):812–825. https://doi.org/10.1007/s10924-019-01617-6

Li R et al (2020) Polycaprolactone/poly(L-lactic acid) composite micro/nanofibrous membrane prepared through solution blow spinning for oil adsorption. Mater Chem Phys 241:122338. https://doi.org/10.1016/j.matchemphys.2019.122338

Oliveira JE et al (2013) Development of poly(lactic acid) nanostructured membranes for the controlled delivery of progesterone to livestock animals. Mater Sci Eng, C 33(2):844–849. https://doi.org/10.1016/j.msec.2012.10.032

Bonan RF et al (2017) Poly(lactic acid)/poly(vinyl pyrrolidone) membranes produced by solution blow spinning: structure, thermal, spectroscopic, and microbial barrier properties. J Appl Polym Sci 134(19). https://doi.org/10.1002/app.44802

Medeiros ES, Glenn GM, Klamczynski AP, Orts WJ, Mattoso LHC (2009) Solution blow spinning: a new method to produce micro- and nanofibers from polymer solutions. J Appl Polym Sci 113(4):2322–2330. https://doi.org/10.1002/app.30275

da S. Parize DD et al (2017) Solution blow spun nanocomposites of poly(lactic acid)/cellulose nanocrystals from Eucalyptus kraft pulp. Carbohydr Polym 174:923–932. https://doi.org/10.1016/j.carbpol.2017.07.019

Kamyar N et al (2018) Exploiting inherent instability of 2D black phosphorus for controlled phosphate release from blow-spun poly(lactide- co-glycolide) nanofibers. ACS Appl Nano Mater 1(8):4190–4197. https://doi.org/10.1021/acsanm.8b00938

Ye B et al (2020) Solution-blow spun PLA/SiO2 nanofiber membranes toward high efficiency oil/water separation. J Appl Polym Sci 137(37):1–9. https://doi.org/10.1002/app.49103

Tomecka E, Wojasinski M, Jastrzebska E, Chudy M, Ciach T, Brzozka Z (2017) Poly(L-lactic acid) and polyurethane nanofibers fabricated by solution blow spinning as potential substrates for cardiac cell culture. Mater Sci Eng, C 75:305–316. https://doi.org/10.1016/j.msec.2017.02.055

Cerna Nahuis LE, Alvim Valente C, de Freitas Oliveira D, de Souza Basso NR, Antonio Malmonge J (2019) Preparation and characterization of polymeric microfibers of PLGA and PLGA/PPy composite fabricated by solution blow spinning. Macromolecular Symposia 383(1). https://doi.org/10.1002/masy.201800030

Bienek DR, Hoffman KM, Tutak W (2016) Blow-spun chitosan/PEG/PLGA nanofibers as a novel tissue engineering scaffold with antibacterial properties. J Mater Sci—Mater Med 27(9):0–1. https://doi.org/10.1007/s10856-016-5757-7

Lin Xu X et al (2016) Solution blowing of chitosan/PLA/PEG hydrogel nanofibers for wound dressing. Fibers Polym 17(2):205–211. https://doi.org/10.1007/s12221-016-5800-9

Ahmed FE, Lalia BS, Hashaikeh R (2015) A review on electrospinning for membrane fabrication : challenges and applications. DES 356:15–30. https://doi.org/10.1016/j.desal.2014.09.033

Xue J, Wu T, Dai Y, Xia Y (2019) Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 119(8):5298–5415. https://doi.org/10.1021/acs.chemrev.8b00593

Yue M et al (2015) Switchable hydrophobic/hydrophilic surface of electrospun poly (L-lactide) membranes obtained by CF4 microwave plasma treatment

Tasselli F (2004) Membrane preparation techniques, no. c, pp 1–3. https://doi.org/10.1007/978-3-642-40872-4

Figoli A, Marino T, Galiano F (2016). Polymeric membranes in biorefinery. https://doi.org/10.1016/B978-0-08-100451-7.00002-5

Wang H et al (2019) Effect of temperature on the morphology of poly (lactic acid) porous membrane prepared via phase inversion induced by water droplets. Int J Biol Macromol 133:902–910. https://doi.org/10.1016/j.ijbiomac.2019.04.145

Figoli A et al (2014) Towards non-toxic solvents for membrane preparation: a review. Green Chem 16(9):4034–4059. https://doi.org/10.1039/c4gc00613e

Kim JF (2020) Recent progress on improving the sustainability of membrane fabrication. J Membr Sci Res 6(3):241–250. https://doi.org/10.22079/JMSR.2019.106501.1260

Chinyerenwa AC et al (2018) Structure and thermal properties of porous polylactic acid membranes prepared via phase inversion induced by hot water droplets. Polymer 141:62–69. https://doi.org/10.1016/j.polymer.2018.03.011

Do AV, Khorsand B, Geary SM, Salem AK (2015) 3D printing of scaffolds for tissue regeneration applications. Adv Healthcare Mater 4(12):1742–1762. https://doi.org/10.1002/adhm.201500168

Choi WJ et al (2020) Rapid development of dual porous poly(lactic acid) foam using fused deposition modeling (FDM) 3D printing for medical scaffold application. Mater Sci Eng, C 110:110693. https://doi.org/10.1016/j.msec.2020.110693

Rosenzweig DH, Carelli E, Steffen T, Jarzem P, Haglund L (2015) 3D-printed ABS and PLA scaffolds for cartilage and nucleus pulposus tissue regeneration. Int J Mol Sci 16(7):15118–15135. https://doi.org/10.3390/ijms160715118

Serra T, Planell JA, Navarro M (2013) High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater 9(3):5521–5530. https://doi.org/10.1016/j.actbio.2012.10.041

Zhang HY, Jiang HB, Ryu JH, Kang H, Kim KM, Kwon JS (2019) Comparing properties of variable pore-sized 3D-printed PLA membrane with conventional PLA membrane for guided bone/tissue regeneration. Materials 12(10):1–11. https://doi.org/10.3390/MA12101718

Heo DN, Castro NJ, Lee SJ, Noh H, Zhu W, Zhang LG (2017) Enhanced bone tissue regeneration using a 3D printed microstructure incorporated with a hybrid nano hydrogel. Nanoscale 9(16):5055–5062. https://doi.org/10.1039/c6nr09652b

Xing R, Huang R, Qi W, Su R, He Z (2018) Three-dimensionally printed bioinspired superhydrophobic PLA membrane for oil-water separation. AIChE J 64(10):3700–3708. https://doi.org/10.1002/aic.16347

Shuai C, Yang B, Peng S, Li Z (2013) Development of composite porous scaffolds based on poly(lactide-co- glycolide)/nano-hydroxyapatite via selective laser sintering. Int J Adv Manuf Technol 69(1–4):51–57. https://doi.org/10.1007/s00170-013-5001-2

Zhou WY, Lee SH, Wang M, Cheung WL, Ip WY (2008) Selective laser sintering of porous tissue engineering scaffolds from poly(L-lactide)/carbonated hydroxyapatite nanocomposite microspheres. J Mater Sci—Mater Med 19(7):2535–2540. https://doi.org/10.1007/s10856-007-3089-3

Duan B, Wang M, Zhou WY, Cheung WL, Li ZY, Lu WW (2010) Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering. Acta Biomater 6(12):4495–4505. https://doi.org/10.1016/j.actbio.2010.06.024

Jung Y et al (2005) A poly(lactic acid)/calcium metaphosphate composite for bone tissue engineering. Biomaterials 26(32):6314–6322. https://doi.org/10.1016/j.biomaterials.2005.04.007

Singha S, Hedenqvist MS (2020) A review on barrier properties of poly(lactic acid)/clay nanocomposites. Polymers 12(5). https://doi.org/10.3390/POLYM12051095

Guo P et al (2020) Facile fabrication of methylcellulose/PLA membrane with improved properties. Coatings 10(5). https://doi.org/10.3390/COATINGS10050499

Pearce G (2007) Introduction to membranes: Membrane selection. Filtr Sep 44(3):35–37. https://doi.org/10.1016/S0015-1882(07)70083-6

Wang Z, Yu W, Zhou C (2015) Preparation of polyethylene microporous membranes with high water permeability from thermally induced multiple phase transitions. Polymer 56:535–544. https://doi.org/10.1016/j.polymer.2014.11.032

Luo F, Fortenberry A, Ren J, Qiang Z (2020) Recent progress in enhancing poly(lactic acid) stereocomplex formation for material property improvement. Front Chem 8(August):1–8. https://doi.org/10.3389/fchem.2020.00688

Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey MC (2019) Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol 125:307–360. https://doi.org/10.1016/j.ijbiomac.2018.12.002

Jem KJ, Tan B (2020) The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv Ind Eng Polym Res 3(2):60–70. https://doi.org/10.1016/j.aiepr.2020.01.002

Zong X, Ran S, Kim KS, Fang D, Hsiao BS, Chu B (2003) Structure and morphology changes during in vitro degradation of electrospun poly(glycolide-co-lactide) nanofiber membrane. Biomacromolecules 4(2):416–423. https://doi.org/10.1021/bm025717o

Chen Y, Lin J, Wan Y, Fei Y, Wang H, Gao W (2012) Preparation and blood compatibility of electrospun PLA/curcumin composite membranes. Fibers Polym 13(10):1254–1258. https://doi.org/10.1007/s12221-012-1254-x

Xiong Z, Liu F, Lin H, Li J, Wang Y (2016) Covalent bonding of heparin on the crystallized poly(lactic acid) (PLA) membrane to improve hemocompability via surface cross-linking and glycidyl ether reaction. ACS Biomater Sci Eng 2(12):2207–2216. https://doi.org/10.1021/acsbiomaterials.6b00413

Luo H, Hu J, Dou Y, Yang Y, Hou J (2020) Rapid visual alcohol dipstick based on transparent detection of hierarchical structured PLA/PVDF electrospun nanofibrous membrane. Compos Commun 22. https://doi.org/10.1016/j.coco.2020.100516

Wang Y, Qian J, Liu T, Xu W, Zhao N, Suo A (2017) Electrospun PBLG/PLA nanofiber membrane for constructing in vitro 3D model of melanoma. Mater Sci Eng, C 76:313–318. https://doi.org/10.1016/j.msec.2017.03.098

Katsoufidou K, Yiantsios SG, Karabelas AJ (2005) A study of ultrafiltration membrane fouling by humic acids and flux recovery by backwashing: experiments and modeling. J Membr Sci 266(1–2):40–50. https://doi.org/10.1016/J.MEMSCI.2005.05.009

Moriya A, Maruyama T, Ohmukai Y, Sotani T, Matsuyama H (2009) Preparation of poly(lactic acid) hollow fiber membranes via phase separation methods. J Membr Sci 342(1–2):307–312. https://doi.org/10.1016/j.memsci.2009.07.005

Dasari A, Quirós J, Herrero B, Boltes K, García-Calvo E, Rosal R (2012) Antifouling membranes prepared by electrospinning polylactic acid containing biocidal nanoparticles. J Membr Sci 405–406:134–140. https://doi.org/10.1016/J.MEMSCI.2012.02.060

Xiong Z, Lin H, Liu F, Yu X, Wang Y, Wang Y (2016) A new strategy to simultaneously improve the permeability, heat-deformation resistance and antifouling properties of polylactide membrane via bio-based β-cyclodextrin and surface crosslinking. J Membr Sci 513:166–176. https://doi.org/10.1016/j.memsci.2016.04.036

Shen P, Moriya A, Rajabzadeh S, Maruyama T, Matsuyama H (2013) Improvement of the antifouling properties of poly (lactic acid) hollow fiber membranes with poly (lactic acid)-polyethylene glycol-poly (lactic acid) copolymers. Desalination 325:37–39. https://doi.org/10.1016/j.desal.2013.06.012

Vargas-Villagran H et al (2011) Non-woven membranes electrospun from polylactic acid incorporating silver nanoparticles as biocide. Mater Res Soc Symp Proc 1376(December 2014):78–83. https://doi.org/10.1557/opl.2012.285

Jiang S, Lv J, Ding M, Li Y, Wang H, Jiang S (2016) Release behavior of tetracycline hydrochloride loaded chitosan/poly(lactic acid) antimicrobial nanofibrous membranes. Mater Sci Eng, C 59:86–91. https://doi.org/10.1016/j.msec.2015.10.005

Lin K et al (2020) Selective laser sintered nano-HA/PDLLA composite microspheres for bone scaffolds applications. Rapid Prototyp J 26(6):1131–1143. https://doi.org/10.1108/RPJ-06-2019-0155

Carfi Pavia F, Conoscenti G, Greco S, la Carrubba V, Ghersi G, Brucato V (2018) Preparation, characterization and in vitro test of composites poly-lactic acid/hydroxyapatite scaffolds for bone tissue engineering. Int J Biol Macromol 119:945–953. https://doi.org/10.1016/j.ijbiomac.2018.08.007

Han J et al (2018) Hydroxyapatite nanowires modified polylactic acid membrane plays barrier/osteoinduction dual roles and promotes bone regeneration in a rat mandible defect model. J Biomed Mater Res—Part A 106(12):3099–3110. https://doi.org/10.1002/jbm.a.36502

Saini P, Arora M, Kumar MNVR (2016) Poly(lactic acid) blends in biomedical applications. Adv Drug Deliv Rev 107:47–59. https://doi.org/10.1016/j.addr.2016.06.014

Liu S, Qin S, He M, Zhou D, Qin Q, Wang H (2020) Current applications of poly(lactic acid) composites in tissue engineering and drug delivery Shan. Compos Part B Eng 199(May):108238. https://doi.org/10.1016/j.compositesb.2020.108238

le Marec PE et al (2014) Influence of melt processing conditions on poly(lactic acid) degradation: Molar mass distribution and crystallization. Polym Degrad Stab 110:353–363. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2014.10.003

Gaona LA, Gómez Ribelles JL, Perilla JE, Lebourg M Hydrolytic degradation of PLLA/PCL microporous membranes prepared by freeze extraction. Polym Degrad Stab 97(9):1621–1632. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2012.06.031

Dias JC, Ribeiro C, Sencadas V, Botelho G, Ribelles JLG, Lanceros-Mendez S (2012) Influence of fiber diameter and crystallinity on the stability of electrospun poly(l-lactic acid) membranes to hydrolytic degradation. Polym Testing 31(6):770–776. https://doi.org/10.1016/J.POLYMERTESTING.2012.05.007

Gorrasi G, Pantani R Hydrolysis and biodegradation of poly(lactic acid). Adv Polym Sci 279(May 2017):119–151. https://doi.org/10.1007/12_2016_12

Li S, McCarthy S (1999) Influence of crystallinity and stereochemistry on the enzymatic degradation of poly(lactide)s. Macromolecules 32(13):4454–4456. https://doi.org/10.1021/ma990117b

Vert M, Mauduit J, Li S (1994) Biodegradation of PLA/GA polymers: increasing complexity 15(15):1209–1213

Ranjbar-Mohammadi M, Prabhakaran MP, Bahrami SH, Ramakrishna S (2016) Gum tragacanth/poly(l-lactic acid) nanofibrous scaffolds for application in regeneration of peripheral nerve damage. Carbohydr Polym 140(December 2017):104–112. https://doi.org/10.1016/j.carbpol.2015.12.012

Naseem R, Zhao L, Liu Y, Silberschmidt VV (2017) Experimental and computational studies of poly-L-lactic acid for cardiovascular applications: recent progress. Mech Adv Mater Mod Process 3(1). https://doi.org/10.1186/s40759-017-0028-y

Miyajima M, Koshika A, Okada J, Ikeda M (1999) Mechanism of drug release from poly(l-lactic acid) matrix containing acidic or neutral drugs. J Control Release 60(2–3):199–209. https://doi.org/10.1016/S0168-3659(99)00083-8

Santos LG et al (2013) Electrospun membranes of poly(lactic acid) (PLA) used as scaffold in drug delivery of extract of sedum dendroideum. J Nanosci Nanotechnol 13(7):4694–4702. https://doi.org/10.1166/jnn.2013.7194

Agarwal M, Koelling KW, Chalmers JJ (1998) Characterization of the degradation of polylactic acid polymer in a solid substrate environment

Ghorpade VM, Gennadios A, Hanna MA (2001) Laboratory composting of extruded poly(lactic acid) sheets. Biores Technol 76(1):57–61. https://doi.org/10.1016/S0960-8524(00)00077-8

Lunt J (1998) Large-scale production, properties and commercial applications of polylactic acid polymers. Polym Degrad Stab 59(1–3):145–152. https://doi.org/10.1016/S0141-3910(97)00148-1

Karamanlioglu M, Houlden A, Robson GD (2014) Isolation and characterisation of fungal communities associated with degradation and growth on the surface of poly(lactic) acid (PLA) in soil and compost. Int Biodeterior Biodegrad 95(PB):301–310. https://doi.org/10.1016/J.IBIOD.2014.09.006

da S. D et al (2018) Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem Eng J (Lausanne, Switzerland: 1996) 340:9–14. https://doi.org/10.1016/J.CEJ.2018.01.010

Yu H, Huang N, Wang C, Tang Z (2003) Modeling of poly(L-lactide) thermal degradation: theoretical prediction of molecular weight and polydispersity index

Kopinke F, Remmler M, Mackenzie K, Milder M (1996) Thermal decomposition of biodegradable polyesters-11. Poly(lactic acid)

Ozdemir E, Hacaloglu J (2016) Thermal degradation of polylactide and its electrospun fiber. Fibers Polym 2016 17:1 17(1):66–73. https://doi.org/10.1007/S12221-016-5679-5

Bonan RF et al (2017) Poly(lactic acid)/poly(vinyl pyrrolidone) membranes produced by solution blow spinning: structure, thermal, spectroscopic, and microbial barrier properties. J Appl Polym Sci 134(19):1–9. https://doi.org/10.1002/app.44802

Ozdemir E, Lekesiz TO, Hacaloglu J (2016) Polylactide/organically modified montmorillonite composites; effects of organic modifier on thermal characteristics. Polym Degrad Stab 134:87–96. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2016.09.028

Yuzay IE, Auras R, Soto-Valdez H, Selke S (2010) Effects of synthetic and natural zeolites on morphology and thermal degradation of poly(lactic acid) composites. Polym Degrad Stab 95(9):1769–1777. https://doi.org/10.1016/J.POLYMDEGRADSTAB.2010.05.011

Dai X, Cao Y, Shi X, Wang X (2016) Non-isothermal crystallization kinetics, thermal degradation behavior and mechanical properties of poly(lactic acid)/MOF composites prepared by melt-blending methods. RSC Adv 6(75):71461–71471. https://doi.org/10.1039/C6RA14190K

Sencadas V et al (2012) Thermal properties of electrospun poly(lactic acid) membranes. J Macromol Sci Part B Phys 51(3):411–424. https://doi.org/10.1080/00222348.2011.597325

Effect of molecular weight and crystallinity on poly(lactic acid) mechanical properties—Perego—1996—Journal of Applied Polymer Science - Wiley Online Library. https://onlinelibrary.wiley.com/doi/abs/https://doi.org/10.1002/(SICI)1097-4628(19960103)59:1%3C37::AID-APP6%3E3.0.CO;2-N. Accessed 29 Jun 2021

Botelho G, Machado AV, Araújo A, Lema Botelho G, Silva M, Machado AV (2013) UV stability of poly(lactic acid) nanocomposites. https://doi.org/10.17265/2161-6221/2013.02.001

Sakai W, Kinoshita M, Nagata M, Tsutsumi N (2001) ESR studies of photosensitized degradation of poly(L-lactic acid) via photoionization of dopant

Gupta MC, Deshmukh VG (1983) Radiation effects on poly(lactic acid)

Blasi P (2019) Poly(lactic acid)/poly(lactic-co-glycolic acid)-based microparticles: an overview. J Pharm Investig 49(4). Springer Netherlands, pp 337–346. https://doi.org/10.1007/s40005-019-00453-z

Liu S et al (2019) Enhanced surface hydrophilicity of polylactic acid sutures treated by lipase and chitosan. Text Res J 89(16):3291–3302. https://doi.org/10.1177/0040517518811936

Kamaly N, Yameen B, Wu J, Farokhzad OC (2016) Degradable controlled-release polymers and polymeric nanoparticles: mechanisms of controlling drug release. Chem Rev 116(4). American Chemical Society, pp 2602–2663. https://doi.org/10.1021/acs.chemrev.5b00346.

Robert PM, Frank RM (1994) Periodontal guided tissue regeneration with a new resorbable polylactic acid membrane. J Periodontol 65(5):414–422. https://doi.org/10.1902/jop.1994.65.5.414

Gao A, Liu F, Xue L (2014) Preparation and evaluation of heparin-immobilized poly (lactic acid) (PLA) membrane for hemodialysis. J Membr Sci 452:390–399. https://doi.org/10.1016/j.memsci.2013.10.016

Chung S, Gamcsik MP, King MW (2011) Novel scaffold design with multi-grooved PLA fibers. Biomed Mater 6(4):45001. https://doi.org/10.1088/1748-6041/6/4/045001

Bettahalli NMS, Steg H, Wessling M, Stamatialis D (2011) Development of poly(l-lactic acid) hollow fiber membranes for artificial vasculature in tissue engineering scaffolds. J Membr Sci 371(1–2):117–126. https://doi.org/10.1016/j.memsci.2011.01.026

Miyajima M, Koshika A, Okada J, Ikeda M (1999) Effect of polymer/basic drug interactions on the two-stage diffusion-controlled release from a poly(l-lactic acid) matrix. J Control Release 61(3):295–304. https://doi.org/10.1016/S0168-3659(99)00149-2

Miyajima M, Koshika A, Okada J, Kusai A, Ikeda M (1998) Factors influencing the diffusion-controlled release of papaverine from poly (l-lactic acid) matrix. J Control Release 56(1–3):85–94. https://doi.org/10.1016/S0168-3659(98)00076-5

Zhu LJ, Liu F, Yu XM, Gao AL, Xue LX (2015) Surface zwitterionization of hemocompatible poly(lactic acid) membranes for hemodiafiltration. J Membr Sci 475:469–479. https://doi.org/10.1016/j.memsci.2014.11.004

Zare S, Kargari A (2020) The 11th international chemical engineering congress & exhibition (IChEC 2020) Fouman, Iran, no. IChEC, pp 15–17

Wang Z, Pan Z (2015) Preparation of hierarchical structured nano-sized/porous poly(lactic acid) composite fibrous membranes for air filtration. Appl Surf Sci 356:1168–1179. https://doi.org/10.1016/j.apsusc.2015.08.211

Cao Q et al (2020) Electrospun bead-in-string fibrous membrane prepared from polysilsesquioxane-immobilising poly(lactic acid) with low filtration resistance for air filtration. J Polym Res 27(1). https://doi.org/10.1007/s10965-019-1919-x

Li H, Wang Z, Zhang H, Pan Z (2018) Nanoporous PLA/(Chitosan Nanoparticle) composite fibrous membranes with excellent air filtration and antibacterial performance. Polymers 10(10):10–12. https://doi.org/10.3390/polym10101085

Liu Z, Zhao J, Li W, Xing J, Xu L, He J (2019) Humidity-induced porous poly(lactic acid) membrane with enhanced flux for oil–water separation. Adsorpt Sci Technol 37(5–6):389–400. https://doi.org/10.1177/0263617418816200

Su Y, Zhao Y, Zheng W, Yu H, Liu Y, Xu L (2020) Asymmetric Sc-PLA membrane with multi-scale microstructures: wettability, antifouling, and oil–water separation. ACS Appl Mater Interfaces 12(49):55520–55526. https://doi.org/10.1021/acsami.0c17545

Zhu C, Jiang W, Hu J, Sun P, Li A, Zhang Q (2020) Polylactic acid nonwoven fabric surface modified with stereocomplex crystals for recyclable use in oil/water separation. ACS Appl Polym Mater 2(7):2509–2516. https://doi.org/10.1021/acsapm.9b01197

Yamaoka T et al (2013) Elastic/adhesive double-layered PLA-PEG multiblock copolymer membranes for postoperative adhesion prevention. Polym Degrad Stab 98(11):2168–2176. https://doi.org/10.1016/j.polymdegradstab.2013.08.026

Tanaka T, Lloyd DR (2004) Formation of poly(L-lactic acid) microfiltration membranes via thermally induced phase separation. J Membr Sci 238(1–2):65–73. https://doi.org/10.1016/j.memsci.2004.03.020

Tanaka T, Ueno M, Watanabe Y, Kouya T, Taniguchi M, Lloyd DR (2011) Poly(L-lactic acid) microfiltration membrane formation via thermally induced phase separation with drying. J Chem Eng Jpn 44(7):467–475. https://doi.org/10.1252/jcej.11we030

Tanaka T et al (2012) Formation of depth filter microfiltration membranes of poly(l-lactic acid) via phase separation. J Membr Sci 396:101–109. https://doi.org/10.1016/j.memsci.2012.01.002

Hwang C, Park S, Kang IG, Kim HE, Han CM (2020) Tantalum-coated polylactic acid fibrous membranes for guided bone regeneration. Mater Sci Eng C 115(March):111112. https://doi.org/10.1016/j.msec.2020.111112

Liang JW, Prasad G, Wang SC, Wu JL Lu SG (2019) Enhancement of the oil absorption capacity of poly(lactic acid) nano porous fibrous membranes derived via a facile electrospinning method. Appl Sci (Switzerland) 9(5). https://doi.org/10.3390/app9051014

Yu Q et al (2020) Preparation and characterization of solvent-free fluids reinforced and plasticized polylactic acid fibrous membrane. Int J Biol Macromol 161:122–131. https://doi.org/10.1016/j.ijbiomac.2020.06.027

JY-TK Ming-Ju Chen, Kreuter (1996) Nanoparticles and microparticles for drug and vaccine delivery. J Anat 189 (Pt 3, no. Ii):503–505. https://doi.org/10.1002/bit

Ye J, Wang S, Lan W, Qin W, Liu Y (2018) Preparation and properties of polylactic acid-tea polyphenol-chitosan composite membranes. Int J Biol Macromol 117(2017):632–639. https://doi.org/10.1016/j.ijbiomac.2018.05.080

Yamaoka T et al (2013) Elastic/adhesive double-layered PLA-PEG multiblock copolymer membranes for postoperative adhesion prevention. Polym Degrad Stab 98(11):2168–2176. https://doi.org/10.1016/j.polymdegradstab.2013.08.026

Moriya A, Shen P, Ohmukai Y, Maruyama T, Matsuyama H (2012) Reduction of fouling on poly ( lactic acid ) hollow fiber membranes by blending with poly ( lactic acid )– polyethylene glycol – poly ( lactic acid ) triblock copolymers. J Membr Sci 415–416:712–717. https://doi.org/10.1016/j.memsci.2012.05.059

Zhu L, Liu F, Yu X, Xue L (2015) Poly(lactic acid) hemodialysis membranes with poly(lactic acid)- block -poly(2-hydroxyethyl methacrylate) copolymer as additive: preparation, characterization, and performance. https://doi.org/10.1021/acsami.5b03951

Wei Q, Wei W, Tian R, yan Wang L, Su ZG, Ma GH (2008) Preparation of uniform-sized PELA microspheres with high encapsulation efficiency of antigen by premix membrane emulsification. J Colloid Interface Sci 323(2):267–273. https://doi.org/10.1016/j.jcis.2008.04.058

Xu X, Zhong W, Zhou S, Trajtman A, Alfa M (2010) Electrospun PEG—PLA nanofibrous membrane for sustained release of hydrophilic antibiotics. https://doi.org/10.1002/app

Zebiri H et al (2021) Synthesis of PLA–poly(ether urethane)–PLA copolymers and design of biodegradable anti-adhesive membranes for orthopaedic applications. J Mater Chem B 9(3):832–845. https://doi.org/10.1039/D0TB02545C

Gindt BP et al (2016) Nanoporous polysulfone membranes via a degradable block copolymer precursor for redox flow batteries. J Mater Chem A 4(11):4288–4295. https://doi.org/10.1039/c6ta00698a

Galiano F et al (2019) Preparation and characterization of green polylactic acid (PLA) membranes for organic/organic separation by pervaporation. Clean Technol Environ Policy 21(1):109–120. https://doi.org/10.1007/s10098-018-1621-4

Le Phuong HA, Izzati Ayob NA, Blanford CF, Mohammad Rawi NF, Szekely G (2019) Nonwoven membrane supports from renewable resources: bamboo fiber reinforced poly(lactic acid) composites. ACS Sustain Chem Eng 7(13):11885–11893. https://doi.org/10.1021/acssuschemeng.9b02516

Liu L, Jin TZ, Coffin DR, Hicks KB (2009) Preparation of antimicrobial membranes: coextrusion of poly(lactic acid) and nisaplin in the presence of plasticizers. J Agric Food Chem 57(18):8392–8398. https://doi.org/10.1021/jf902213w

Munteanu BS, Aytac Z, Pricope GM, Uyar T, Vasile C (2014) Polylactic acid (PLA)/Silver-NP/VitaminE bionanocomposite electrospun nanofibers with antibacterial and antioxidant activity. J Nanopart Res 16(10):1–12. https://doi.org/10.1007/s11051-014-2643-4

Wang Z, Zhao C, Pan Z (2015) Porous bead-on-string poly(lactic acid) fibrous membranes for air filtration. J Colloid Interface Sci 441(November):121–129. https://doi.org/10.1016/j.jcis.2014.11.041

Li L, Hashaikeh R, Arafat HA (2013) Development of eco-efficient micro-porous membranes via electrospinning and annealing of poly (lactic acid). J Membr Sci 436:57–67. https://doi.org/10.1016/j.memsci.2013.02.037

Zou F, Sun X, Wang X (2019) Elastic, hydrophilic and biodegradable poly (1, 8-octanediol-co-citric acid)/polylactic acid nanofibrous membranes for potential wound dressing applications. Polym Degrad Stab 166:163–173. https://doi.org/10.1016/j.polymdegradstab.2019.05.024

Abe GL et al (2020) Fabrication of novel poly(lactic acid/caprolactone) bilayer membrane for GBR application. Dent Mater 36(5):626–634. https://doi.org/10.1016/j.dental.2020.03.013

Chen K et al (2018) Strong and biocompatible poly(lactic acid) membrane enhanced by Ti3C2Tz (MXene) nanosheets for Guided bone regeneration. Mater Lett 229:114–117. https://doi.org/10.1016/j.matlet.2018.06.063

Binotto JP et al (2020) Poly (Lactic acid) membrane and Sedum dendroideum extract favors the repair of burns in rats. Acta Cirurgica Brasileira 35(3). https://doi.org/10.1590/s0102-865020200030000002

Liu Z et al (2021) A flexible fibrous membrane based on copper( ii ) metal–organic framework/poly(lactic acid) composites with superior antibacterial performance. Biomater Sci 9(10):3851–3859. https://doi.org/10.1039/d1bm00164g

Wang Z, Pan Z, Wang J, Zhao R (2016) A novel hierarchical structured poly(lactic acid)/titania fibrous membrane with excellent antibacterial activity and air filtration performance. J Nanomater 2016. https://doi.org/10.1155/2016/6272983

Chala TF, Wu CM, Chou MH, Guo ZL (2018) Melt electrospun reduced tungsten oxide /polylactic acid fiber membranes as a photothermal material for light-driven interfacial water evaporation. ACS Appl Mater Interfaces 10(34):28955–28962. https://doi.org/10.1021/acsami.8b07434

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest by any of the authors for this review article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

More, N., Avhad, M., Utekar, S. et al. Polylactic acid (PLA) membrane—significance, synthesis, and applications: a review. Polym. Bull. 80, 1117–1153 (2023). https://doi.org/10.1007/s00289-022-04135-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04135-z