Abstract

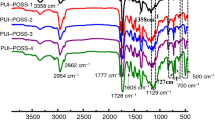

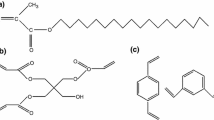

A kind of polyurethane rubber (PU)/n-octadecane (n-OD)@silicon dioxide (SiO2)-polymethyl acrylate (PHEMA) form-stable phase change material (PCM) was fabricated in this paper. n-OD@SiO2-PHEMA microcapsules were prepared in one-pot, through interfacial hydrolysis polycondensation of alkoxy silanes and radical polymerization of HEMA. Then, n-OD@SiO2-PHEMA microcapsules were added into PU matrix to obtain PU/n-OD@SiO2-PHEMA composites. SiO2-PHEMA hybrid shell not only provides a shelter for core material, but also increases interfacial bonding between microcapsules with PU and effectively improves the mechanical properties of composites. The morphologies, chemical compositions and crystal structures of microcapsules and composites were characterized by SEM, TEM, FT-IR and XRD methods. The thermal and mechanical properties of the microcapsules and composites were characterized by differential scanning calorimetry and mechanical performance tests. The results show that the thermal and mechanical properties of PU/n-OD@SiO2-PHEMA composites were better than those of neat PU. The PU/n-OD@SiO2-PHEMA composites endow the microcapsules with improved thermal reliability and leakage proof property. The composites were found as form-stable PCM with low leakage rate. The phase change latent heat of the PU/n-OD@SiO2-PHEMA composites was up to 85.1 J/g and the composites can be used for thermal energy storage.

Similar content being viewed by others

References

Patil SB, Basavarajappa PS, Ganganagappa N, Jyothi MS, Raghu AV, Reddy KR (2019) Barium titanate nanostructures for photocatalytic hydrogen generation and photodegradation of chemical pollutants. Int J Hydrog Energy 44:13022–13039

Srinivas M, Reddy C, Venkata R, Kakarla RR, Shetti NP, Reddy MS, Anjanapura VR (2019) Novel co and Ni metal nanostructures as efficient photocatalysts for photodegradation of organic dyes. Mater Res Express 6:125502

Jyothi MS, Reddy KR, Naveen S, Raghu AV (2019) Nanocarbons-supported and polymers-supported titanium dioxide nanostructures as effificient photocatalysts for remediation of contaminated wastewater and hydrogen production. Nanophotocatal Environ Appl 30:83–105

Reddy KR, Jyothi MS, Raghu AV, Sadhu V, Naveen S, Aminabhavi TM (2020) Nanocarbons-supported and polymers-supported titanium dioxide nanostructures as efficient photocatalysts for remediation of contaminated wastewater and hydrogen production. Nanophotocatal Environ Appl. https://doi.org/10.1007/978-3-030-12619-3_6

Shwetharani R, Chandan HR, Sakar M, Balakrishna GR, Reddy KR, Raghu AV (2020) Recent advances in non-metals-doped TiO2 nanostructured photocatalysts for visible-light driven hydrogen production, CO2 reduction and air purification. Int J Hydrog Energy 45:18289–18308

Jinendra U, Kumar J, Nagabhushana BM, Raghu AV, Bilehal D (2019) Photocatalytic semiconductor thin films for hydrogen production and environmental applications. Green Mater 7:137–142

Karthik KV, Reddy CV, Reddy KR, Ravishankar R, Sanjeev G, Kulkarni RV (2019) Barium titanate nanostructures for photocatalytic hydrogen generation and photodegradation of chemical pollutants. J Mater Sci Mater Electron 30:20646–20653

Jinendra U, Bilehal D, Nagabhushana BM, Reddy KR, Reddy CV, Raghu AV (2019) Facile synthesis of CoFe2O4 nanoparticles and their application in removal of malachite green dye. Mater Sci Energy Technol 2:657–666

Pielichowska K, Pielichowski K (2014) Phase change materials for thermal energy storage. Prog Mater Sci 65:67–123

Zhang N, Yuan Y, Cao X, Du Y, Zhang Z, Gui Y (2018) Latent heat thermal energy storage systems with solid-liquid phase change materials: a review. Adv Eng Mater 20:1700753

Giro-Paloma J, Martínez M, Cabeza LF, Fernández AI (2016) Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): a review. Renew Sustain Energy Rev 53:1059–1075

Latibari ST, Mehrali M, Mehrali M, Afifi ABM, Mahlia TMI (2015) Akhiani AR facile synthesis and thermal performances of stearic acid/titania core/shell nanocapsules by sol–gel method. Energy 85:635–644

Geng X, Li W, Yin Q, Wang Y, Han N, Wang N (2018) Design and fabrication of reversible thermochromic microencapsulated phase change materials for thermal energy storage and its antibacterial activity. Energy 159:857–869

Geng X, Li W, Wang Y, Lu J, Wang J, Wang N (2018) Reversible thermochromic microencapsulated phase change materials for thermal energy storage application in thermal protective clothing. Appl Energy 217:281–294

Wang Y, Xia TD, Feng HX, Zhang H (2011) Stearic acid/polymethylmethacrylate composite as form-stable phase change materials for latent heat thermal energy storage. Renew Energy 36:1814–1820

Qiu X, Li W, Song G, Chu X, Tang G (2012) Microencapsulated n-octadecane with different methylmethacrylate-based copolymer shells as phase change materials for thermal energy storage. Energy 46:188–199

Alkan C, Sari A, Karaipekli A (2011) Preparation, thermal properties and thermal reliability of microencapsulated n-eicosane as novel phase change material for thermal energy storage. Energy Convers Manag 52:687–692

Yoo Y, Martinez C, Youngblood JP (2017) Synthesis and characterization of microencapsulated phase change materials with poly(urea−urethane) shells containing cellulose nanocrystals. ACS Appl Mater Interfaces 9:31763–31776

Mochane MJ, Luyt AS (2012) Preparation and properties of polystyrene encapsulated paraffin wax as possible phase change material in a polypropylene matrix. Thermochim Acta 544:63–70

Jiang Z, Yang W, He F, Xie C, Fan J, Wu J (2018) Modified phase change microcapsules with calcium carbonate and graphene oxide shells for enhanced energy storage and leakage prevention. ACS Sustain Chem Eng 6:5182–5191

Liang SE, Li QB, Zhu YL, Chen KP, Tian CR, Wang JH (2015) Nanoencapsulation of n-octadecane phase change material with silica shell through interfacial hydrolysis and polycondensation in miniemulsion. Energy 93:1684–1692

Fortuniak W, Slomkowski S, Chojnowski J, Kurjata J, Tracz A, Mizerska U (2013) Synthesis of a paraffin phase change material microencapsulated in a siloxane polymer. Colloid Polym Sci 291:725–733

Zhu Y, Qin Y, Liang S, Chen K, Tian C, Wang J (2019) Graphene/SiO2/n-octadecane nanoencapsulated phase change material with flower like morphology, high thermal conductivity, and suppressed supercooling. Appl Energy 250:98–108

Zhu Y, Qin Y, Wei C, Liang S, Luo X, Wang J (2018) Nanoencapsulated phase change materials with polymer-SiO2 hybrid shell materials: compositions, morphologies, and properties. Energy Convers Manag 164:83–92

Umair MM, Zhang Y, Iqbal K, Zhang S, Tang B (2019) Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage—a review. Appl Energy 235:846–873

Karaman S, Karaipekli A, Sarı A, Biçer A (2011) Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells 95:1647–1653

Tang B, Wang L, Xu Y, Xiu J, Zhang S (2016) Hexadecanol/phase change polyurethane composite as form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells 144:1–6

Guo Y, Yang W, Jiang Z, He F, Zhang K, He R (2019) Silicone rubber/paraffin@silicon dioxide form-stable phase change materials with thermal energy storage and enhanced mechanical property. Sol Energy Mater Sol Cell 196:16–24

Rostami M, Ranjbar Z, Mohseni M (2010) Investigating the interfacial interaction of different aminosilane treated nano silicas with a polyurethane coating. Appl Surf Sci 257:899–904

Nam K-H, Seo K, Seo J, Khan SB, Han H (2015) Ultraviolet-curable polyurethane acrylate nanocomposite coatings based on surface-modified calcium carbonate. Prog Org Coat 85:22–30

Król P, Król B, Kozakiewicz J, Zapotoczny S, Pilch-Pitera B, Kozdra S (2015) Composites prepared from polyurethanes modified with silicone-acrylic nanopowders. Prog Org Coat 81:72–79

Wu T, Liu Y, Li N, Huang G-W, Qu C-B, Xiao H-M (2019) Cryogenic mechanical properties of epoxy resin toughened by hydroxyl-terminated polyurethane. Polym Test 74:45–56

Do T, Ko YG, Chun Y, Choi US (2015) Encapsulation of phase change material with water-absorbable shell for thermal energy storage. ACS Sustain Chem Eng 3:2874–2881

Raghu AV, Gadaginamath GS, Aminabhavi TM (2005) Synthesis and characterization of novel polyurethanes based on 1,3-bis(hydroxymethyl) benzimidazolin-2-one and 1,3-bis(hydroxymethyl) benzimidazolin-2-thione hard segments. J Appl Polym Sci 98:2236–2244

Raghu AV, Gadaginamath GS, Priya M, Seema P, Jeong HM, Aminabhavi TM (2008) Synthesis and characterization of novel polyurethanes based on N1, N4-bis[(4-hydroxyphenyl) methylene] succinohydrazide hard segment. J Appl Polym Sci 110:2315–2320

Suhas DP, Jeong HM, Aminabhavi TM, Raghu AV (2014) Preparation and characterization of novel polyurethanes containing 4,40-{oxy-1,4-diphenyl bis(nitromethylidine)}diphenol schiff base diol. Polym Eng Sci 54:24–32

Acknowledgements

The research is especially grateful for the sponsored by Support Program (Industrial) of Changzhou Science and Technology (CE20200014, CE20170029), Jiangsu Province Graduate Cultivation Innovation Project, Double ‘Ten Hundred and Thousand’ Project of Wujin District Science and Technology Bureau, the Top-notch Academic Programs Project of Jiangsu Higher Education Institutions (TAPP), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), Jiangsu Chenguang Paint Co., Ltd., Changzhou, Jiangsu and Shenzhen Basic Research Project (JCYJ20170818114324998).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, X., Chen, Y., Jiang, J. et al. Polyurethane/n-octadecane@silicon dioxide-polyhydroxyethyl methacrylate form-stable phase change materials with enhanced mechanical properties and thermal energy storage. Polym. Bull. 79, 3867–3889 (2022). https://doi.org/10.1007/s00289-021-03677-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03677-y