Abstract

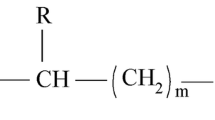

The benefits of biotechnology are not limited to genetic engineering, but it also displays its great impact on industrial uses of crops (e.g., biodegradable plastics). Polyhydroxyalkanoates (PHAs) make a diverse class of bio-based and biodegradable polymers naturally synthesized by numerous microorganisms. However, several C3 and C4 plants have also been genetically engineered to produce PHAs. The highest production yield of PHAs was obtained with a well-known C3 plant, Arabidopsis thaliana, upto 40% of the dry weight of the leaf. This review summarizes all biotechnological mechanisms that have been adopted with the goal of increasing PHAs production in bacteria and plant species alike. Moreover, the possibility of using some methods that have not been applied in bioplastic science are discussed with special attention to plants. These include producing PHAs in transgenic hairy roots and cell suspension cultures, making transformed bacteria and plants via transposons, constructing an engineered metabolon, and overexpressing of phaP and the ABC operon concurrently. Taken together, that biotechnology will be highly beneficial for reducing plastic pollution through the implementation of biotechnological strategies is taken for granted.

Similar content being viewed by others

Data Availability

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

References

RameshKumar S, Shaiju P, O’Connor KE (2020) Bio-based and biodegradable polymers—State-of-the-art, challenges and emerging trends. Curr Opin Green Sustain Chem 21:75–81. https://doi.org/10.1016/j.cogsc.2019.12.005

Masood F, Yasin T, Hameed A (2014) Polyhydroxyalkanoates—what are the uses? Current challenges and perspectives. Crit Rev Biotechnol 35:514–521. https://doi.org/10.3109/07388551.2014.913548

Coppola G, Gaudio MT, Lopresto CG, Calabro V, Curcio S, Chakraborty S (2021) Bioplastic from renewable biomass: A facile solution for a greener environment. Earth Syst Environ 5:231–251. https://doi.org/10.1007/s41748-021-00208-7

Kosseva MR, Rusbandi R (2018) Trends in the biomanufacture of polyhydroxyalkanoates with focus on downstream processing. Int J Biol Macromol 107:762–778. https://doi.org/10.1016/j.ijbiomac.2017.09.054

Serna CP, Filho JF (2015) Biodegradable zein-based blend films: structural, mechanical and barrier properties. Food Technol Biotechnol 53:348–353. https://doi.org/10.17113/ftb.53.03.15.3725

Perotto G, Ceseracciu L, Simonutti R, C. Paul U, Guzman-Puyol S, Tran TN, S. Bayer I, Athanassiou A, (2018) Bioplastics from vegetable waste: Via an ecofriendly water-based process. Green Chem 20:894–902. https://doi.org/10.1039/C7GC03368K

Bezirhan Arikan E, Bilgen HD (2019) Production of bioplastic from potato peel waste and investigation of its biodegradability. Int Adv Res Eng J 3:93–97. https://doi.org/10.35860/iarej.420633

Azieyanti NA, Amirul A, Othman SZ, Misran H (2020) Mechanical and morphology studies of bioplastic-based banana peels. J Phys Conf Ser 1529:032091. https://doi.org/10.1088/1742-6596/1529/3/032091

Ebrahimian F, Karimi K, Kumar R (2020) Sustainable biofuels and bioplastic production from the organic fraction of municipal solid waste. Waste Manag 116:40–48. https://doi.org/10.1016/j.wasman.2020.07.049

Ryder K, Ali MA, Billakanti J, Carne A (2020) Evaluation of dairy co-product containing composite solutions for the formation of bioplastic films. J Polym Environ 28:725–736. https://doi.org/10.1007/s10924-019-01635-4

Cinar SO, Chong ZK, Kucuker MA, Wieczorek N, Cengiz U, Kuchta K (2020) Bioplastic production from microalgae: A review. Int J Environ Res Public Health 17:3842. https://doi.org/10.3390/ijerph17113842

Luengo JM, Garcia B, Sandoval A, Naharro G, Olivera ER (2003) Bioplastics from microorganisms. Curr Opin Microbiol 6:251–260. https://doi.org/10.1016/s1369-5274(03)00040-7

Soto G, Stritzler M, Lisi C, Alleva K, Pagano ME, Ardila F, Mozzicafreddo M, Cuccioloni M, Angeletti M, Ayub ND (2011) Acetoacetyl-CoA thiolase regulates the mevalonate pathway during abiotic stress adaptation. J Exp Bot 15:5699–5711. https://doi.org/10.1093/jxb/err287

Muneer F, Rasul J, Azeem F, Siddique MH, Zubair M, Nadeem M (2020) Microbial Polyhydroxyalkanoates (PHAs): Efcient replacement of synthetic polymers. J Polym Environ 28:2301–2323. https://doi.org/10.1007/s10924-020-01772-1

Meng DC, Shen R, Yao H, Chen JC, Wu Q, Chen GQ (2014) Engineering the diversity of polyesters. Curr Opin Biotechnol 29:24–33. https://doi.org/10.1016/j.copbio.2014.02.013

Steinbuchel A, Hein S (2001) Biochemical and molecular basis of microbial synthesis of polyhydroxyalkanoates in microorganisms. Adv Biochem Eng Biotechnol 71:24–33. https://doi.org/10.1007/3-540-40021-43

Budde FC, E. Mahan A, Lu J, Rha CK, J. Sinskey A, (2010) Roles of multiple acetoacetyl Coenzyme A reductases in polyhydroxybutyrate biosynthesis in Ralstonia eutropha H16. J Bacteriol 192:5319–5328. https://doi.org/10.1128/JB.00207-10

Pötter M, Steinbüchel A (2005) Poly(3-hydroxybutyrate) granule-associated proteins: impacts on poly(3-hydroxybutyrate) synthesis and degradation. Bio-macromolecules 6:552–560. https://doi.org/10.1021/bm049401n

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555. https://doi.org/10.1016/S0079-6700(00)00035-6

Choi SY, Cho IJ, Lee Y, Kim YJ, Kim KJ, Lee SY (2020) Microbial polyhydroxyalkanoates and nnonnatural polyesters. Adv Mater 32:1–37. https://doi.org/10.1002/adma.201907138

Vicente D, Proença DN, Morais PV (2023) The role of bacterial polyhydroalkanoate (PHA) in a sustainable future: A review on the biological diversity. Int J Environ Res Public Health 20:1–37. https://doi.org/10.3390/ijerph20042959

Yashavanth PR, Das M, Maiti SK (2021) Recent progress and challenges in cyanobacterial autotrophic production of polyhydroxybutyrate (PHB), a bioplastic. J Environ Chem Eng 9:1–11. https://doi.org/10.1016/j.jece.2021.105379

Zhang X, Lin Y, Wu Q, Wang Y, Chen GQ (2019) Synthetic biology and genome-editing tools for improving PHA metabolic engineering. Trends Biotechnol 7:689–700. https://doi.org/10.1016/j.tibtech.2019.10.006

Kumar M, Rathour R, Singh R, Sun Y, Pandey A, Gnansounou E, Lin KYA, Tsang CWD, Thakur IS (2020) Bacterial polyhydroxyalkanoates: Opportunities, challenges, and prospects. J Clean Prod 264:1–90. https://doi.org/10.1016/j.jclepro.2020.121500

Penloglou G, Chatzidoukas C, Kiparissides C (2012) Microbial production of polyhydroxybutyrate with tailor-made properties: an integrated modelling approach and experimental validation. Biotechnol Adv 30:329–337. https://doi.org/10.1016/j.biotechadv.2011.06.021

Domski GJ, Rose JM, Coates GW, Bolig AD, Brookhart M (2007) Living alkene polymerization: new methods for the precision synthesis of polyolefins. Prog Polym Sci 32:30–92. https://doi.org/10.1016/j.progpolymsci.2006.11.001

Park SJ, Kim TW, Kim MK, Lee SY, Lim SC (2012) Advanced bacterial polyhydroxyalkanoates: towards a versatile and sustainable platform for unnatural tailor-made polyesters. Biotechnol Adv 30:1196–1206. https://doi.org/10.1016/j.biotechadv.2011.11.007

Laycock B, Halley P, Pratt S, Werker A, Lant P (2013) The chemomechanical properties of microbial polyhydroxyalkanoates. Prog Polym Sci 38:536–583. https://doi.org/10.1016/j.progpolymsci.2012.06.003

Tanadchangsaeng N, Yu J (2012) Microbial synthesis of polyhydroxybutyrate from glycerol: gluconeogenesis, molecular weight and material properties of biopolyester. Biotechnol Bioeng 109:2808–2818. https://doi.org/10.1002/bit.24546

Liu H, Kumar V, Jia L, Sarsaiya S, Kumar D, Juneja A, Zhang Z, Sindhu R, Binod P, Bhatia SK, Awasthi MK (2021) Biopolymer poly-hydroxyalkanoates (PHA) production from apple industrial waste residues: A review. Chemosphere 284:1–9. https://doi.org/10.1016/j.chemosphere.2021.131427

Jensen PE, Scharff LB (2019) Engineering of plastids to optimize the production of high-value metabolites and proteins. Curr Opin Biotechnol 59:8–15. https://doi.org/10.1016/j.copbio.2019.01.009

Li T, Ye J, Shen R, Zong Y, Zhao X, Lou C, Chen GQ (2016) Semirational approach for ultrahigh poly(3-hydroxybutyrate) accumulation in Escherichia coli by combining one-step library construction and high-throughput screening. ACS Synth Biol 5:1308–1317. https://doi.org/10.1021/acssynbio.6b00083

Shen R, Yin J, Ye JW, Xiang RJ, Ning ZY, Chen HWZ, GQ, (2018) Promoter engineering for enhanced P(3HB-co-4HB) production by Halomonas bluephagenesis. ACS Synth Biol 7:1897–1906. https://doi.org/10.1021/acssynbio.8b00102

Escapa IF, del Cerro C, García JL, Prieto MA (2013) The role of GlpR repressor in Pseudomonas putida KT2440 growth and PHA production from glycerol. Environ Microbiol 15:93–110. https://doi.org/10.1111/j.1462-2920.2012.02790.x

Hernández-Eligio A, Moreno S, Castellanos M, Castañeda M, Nuñez C, Muriel-Millán LF, Espín G (2012) RsmA post-transcriptionally controls PhbR expression and polyhydroxybutyrate biosynthesis in Azotobacter vinelandii. Microbiology 158:1953–1963. https://doi.org/10.1099/mic.0.059329-0

Lagares A, Borella GC, Linne U, Becker A, Valverde C (2017) Regulation of polyhydroxybutyrate accumulation in Sinorhizobium meliloti by the transencoded small RNA MmgR. J Bacteriol 199:e00776-e816. https://doi.org/10.1128/JB.00776-16

Pyla R, Kim TJ, Silva JL, Jung YS (2009) Overproduction of poly-b-hydroxybutyrate in the Azotobacter vinelandii mutant that does not express small RNA ArrF. Appl Microbiol Biotechnol 84:717–724. https://doi.org/10.1007/s00253-009-2002-z

Hernández-Eligio A, Castellanos M, Moreno S, Espín G (2011) Transcriptional activation of the Azotobacter vinelandii polyhydroxybutyrate biosynthetic genes phbBAC by PhbR and RpoS. Microbiology 157:3014–3023. https://doi.org/10.1099/mic.0.051649-0

Matsusaki H, Manji S, Taguchi K, Kato M, Fukui T, Doi Y (1998) Cloning and molecular analysis of the poly(3-hydroxybutyrate) and poly(3- hydroxybutyrate-co-3-hydroxyalkanoate) biosynthesis genes in Pseudomonas sp. strain 61–3. J Bacteriol 180:6459–6467. https://doi.org/10.1128/jb.180.24.6459-6467.1998

Osanai T, Oikawa A, Numata K, Kuwahara A, Iijima H, Doi Y, Saito K, Hirai MY (2014) Pathway-level acceleration of glycogen catabolism by a response regulator in the cyanobacterium Synechocystis species PCC 6803. Plant Physiol 164:1831–1841. https://doi.org/10.1104/pp.113.232025

Jiang XR, Chen GQ (2016) Morphology engineering of bacteria for bio-production. Biotechnol Adv 34:435–440. https://doi.org/10.1016/j.biotechadv.2015.12.007

Elhadi D, Lv L, Jiang XR, Wu H, Chen GQ (2016) CRISPRi engineering E. coli for morphology diversification. Metab Eng 38:358–369. https://doi.org/10.1016/j.ymben.2016.09.001

Zhang XC, Guo Y, Liu X, Chen XG, Wu Q, Chen GQ (2018) Engineering cell wall synthesis mechanism for enhanced PHB accumulation in E. coli. Metab Eng 45:32–42. https://doi.org/10.1016/j.ymben.2017.11.010

Tan D, Wu Q, Chen JC, Chen GQ (2014) Engineering Halomonas TD01 for low-cost production of polyhydroxyalkanoates. Metab Eng 26:34–47. https://doi.org/10.1016/j.ymben.2014.09.001

Chen Y, Chen XY, Du HT, Zhang X, Ma YM, Chen JC, Ye JW, Jiang XR, Chen GQ (2019) Chromosome engineering the TCA cycle in Halomonas bluephagenesis for production of copolymers of 3-hydroxybutyrate and 3-hydroxyvalerate (PHBV). Metab Eng 54:69–82. https://doi.org/10.1016/j.ymben.2019.03.006

Chen KK, Liu S, Ma JL, Zhang DX, Shi ZP, Du GC, Chen J (2012) Deletion combined with saturation mutagenesis of N-terminal residues in transglutaminase from Streptomyces hygroscopicus results in enhanced activity and thermostability. Process Biochem 47:2329–2334. https://doi.org/10.1016/j.procbio.2012.09.013

Hida K, Hanes J, Ostermeier M (2007) Directed evolution for drug and nucleic acid delivery. Adv Drug Delivery Rev 59:1562–1578. https://doi.org/10.1016/j.addr.2007.08.022

Taguchi S, Nakamura H, Hiraishi T, Yamato I, Doi Y (2002) In vitro evolution of a polyhydroxybutyrate synthase by intragenic suppression-type mutagenesis. J Biochem 131:801–806. https://doi.org/10.1093/oxfordjournals.jbchem.a003168

Takase K, Taguchi S, Doi Y (2003) Enhanced synthesis of poly(3-hydroxybutyrate) in recombinant Escherichia coli by means of error-prone PCR mutagenesis, saturation mutagenesis and in vitro recombination of the type II polyhydroxyalkanoate synthase gene. J Biochem 133:139–145. https://doi.org/10.1093/jb/mvg015

Hiraishi T, Hirahara Y, Doi Y, Maeda M, Taguchi S (2006) Effects of mutations in the substrate-binding domain of poly[(R)-3-hydroxybutyrate] (PHB) depolymerase from Ralstonia pickettii T1 on PHB degradation. Appl Environ Microbiol 2:7331–7338. https://doi.org/10.1128/aem.01187-06

Tan LT, Hiraishi T, Sudesh K, Maeda M (2013) Directed evolution of poly[(R)-3-hydroxybutyrate] depolymerase using cell surface display system: functional importance of asparagine at position. Appl Microbiol Biotechnol 97:4859–4871. https://doi.org/10.1007/s00253-012-4366-8

Hiraga K, Arnold FH (2003) General method for sequence-independent site-directed chimeragenesis. J Mol Biol 330:287–296. https://doi.org/10.1016/S0022-2836(03)00590-4

Niamsiri N, Delamarre SC, Kim YR, Batt CA (2004) Engineering of chimeric class II polyhydroxyalkanoate synthases. Appl Environ Microbiol 70:6789–6799. https://doi.org/10.1128/AEM.70.11.6789-6799.2004

Matsumoto K, Takase K, Yamamoto Y, Doi Y, Taguchi S (2009) Chimeric enzyme composed of polyhydroxyalkanoate (PHA) synthases from Ralstonia eutropha and Aeromonas caviae enhances production of PHAs in recombinant Escherichia coli. Biomacromolecules 10:682–685. https://doi.org/10.1021/bm801386j

Chilton MD, Que Q (2003) Targeted integration of T-DNA into the tobacco genome at double-stranded breaks: new insights on the mechanism of T-DNA integration. Plant Physiol 133:956–965. https://doi.org/10.1104/pp.103.026104

Mlynarova L, Hricova A, Loonen A, Nap JP (2003) The presence of a chromatin boundary appears to shield a transgene in tobacco from RNA silencing. Plant Cell 15:2203–2217. https://doi.org/10.1105/tpc.012070

Hirsch DC, Springer MN (2016) Transposable element influences on gene expression in plants. Gene Regul Mech 1860:157–165. https://doi.org/10.1016/j.bbagrm.2016.05.010

Ivics Z, Izsvák Z (2010) The expanding universe of transposon technologies for gene and cell engineering. Mob DNA 1:1–25. https://doi.org/10.1186/1759-8753-1-25

Malachowa N, DeLeo FR (2010) Mobile genetic elements of Staphylococcus aureus. Cell Mol Life Sci 124:2836–2840. https://doi.org/10.1007/s00018-010-0389-4

Quesneville H (2020) Twenty years of transposable element analysis in the Arabidopsis thaliana genome. Mob DNA 27:11–28. https://doi.org/10.1186/s13100-020-00223-x

Fischer R, Vasilev N, Twyman RM, Schillberg S (2015) High-value products from plants: the challenges of process optimization. Curr Opin Biotechnol 32:156–162. https://doi.org/10.1016/j.copbio.2014.12.018

Barbulova A, Apone F, Colucci G (2015) Plant cell cultures as source of cosmetic active ingredients. Cosmetics 1:94–104. https://doi.org/10.3390/cosmetics1020094

GutierrezValdes NT, Häkkinen S, Lemasson C, Guillet M, OksmanCaldentey KM, Ritala A, Cardon F (2020) Hairy root cultures—A versatile tool with multiple applications. Front Plant Sci 3:11–33. https://doi.org/10.3389/fpls.2020.00033

Hashemi SM, Naghavi MR (2016) Production and gene expression of morphinan alkaloids in hairy root culture of Papaver orientale L. using abiotic elicitors. Plant Cell Tissue Organ Cult 125:31–41. https://doi.org/10.1007/s11240-015-0927-8

Sharafi A, Hashemi Sohi H, Mousavi A, Azadi P, Razavi K, Ntui VO (2013) A reliable and efficient protocol for inducing hairy roots in Papaver bracteatum. Plant Cell Tissue Organ Cult 113:1–9. https://doi.org/10.1007/s11240-012-0246-2

Sharifzadeh Naeini M, Naghavi MR, Bihamta MR, Sabokdast M, Salehi M (2020) Production of some benzylisoquinoline alkaloids in Papaver armeniacum L. hairy root cultures elicited with salicylic acid and methyl jasmonate. In Vitro Cell Dev Biol 57:261–271. https://doi.org/10.1007/s11627-020-10123-7

Menzel G, Harloff HJ, Jung C (2003) Expression of bacterial poly(3- hydroxybutyrate) synthesis genes in hairy roots of sugar beet (Beta vulgaris L.). Appl Microbiol Biotechnol 60:571–576. https://doi.org/10.1007/s00253-002-1152-z

Moscatiello R, Baldan B, Navazio L (2013) Plant cell suspension cultures. In: Maathuis F (ed) Plant Mineral Nutrients, 1st edn. Humana Press, Totowa, pp 77–93

Poirier Y, Somerville C, Schechtman LA, Satkowski MM, Noda I (1995) Synthesis of high-molecular-weight poly([R]-(-)-3-hydroxybutyrate) in transgenic Arabidopsis thaliana plant cells. Int J Biol Macromol 17:7–12. https://doi.org/10.1016/0141-8130(95)93511-u

Hahn JJ, Eschenlauer AC, Sleytr UB, Somers DA, Srienc F (1999) Peroxisomes as sites for synthesis of polyhydroxyalkanoates in transgenic plants. Biotechnol Prog 15(1053):1057. https://doi.org/10.1021/bp990118n

Karimi AK, Naghavi MR, Peyghambari SA, Rasoulnia A (2021) Inulin content and expression of related genes in different tissues and cell suspension culture of Taraxacum kok-saghyz. In Vitro Cell Dev 57:1009–1017. https://doi.org/10.1007/s11627-021-10180-6

Salehi M, Karimzadeh G, Naghavi MR (2019) Synergistic effect of coronatine and sorbitol on artemisinin production in cell suspension culture of Artemisia annua L. cv. Anamed Plant Cell Tissue Organ Cult 137:587–597. https://doi.org/10.1007/s11240-019-01593-8

Jørgensen K, Rasmussen AN, Morant M, Nielsen AH, Bjarnholt N, Zagrobelny M, Bak S, Møller BL (2005) Metabolon formation and metabolic channeling in the biosynthesis of plant natural products. Curr Opin Plant Biol 8:280–291. https://doi.org/10.1016/j.pbi.2005.03.014

Cameron K, Najmudin S, Alves VD, Bayer EA, Smith SP, Bule P, Waller H, Ferreira LMA, Gilbert HJ, Fontes CMGA (2015) Cell-surface attachment of bacterial multienzyme complexes involves highly dynamic protein-protein anchors. J Biol Chem 290:13578–13590. https://doi.org/10.1074/jbc.M114.633339

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochemie 86:807–815. https://doi.org/10.1016/j.biochi.2004.09.017

Rakus D, Pasek M, Krotkiewski H, Dzugaj A (2004) Interaction between muscle aldolase and muscle fructose 1,6-bisphosphatase results in the substrate channeling. Biochemistry 43(43):14948–14957. https://doi.org/10.1021/bi048886x

Farrow SC, Hagel JM, Beaudoin GAW, Burns DC, Facchini PJ (2015) Stereochemical inversion of (S)-reticuline by a cytochrome P450 fusion in opium poppy. Nat Chem Biol 11:728–732. https://doi.org/10.1038/nchembio.1879

Jia F, Narasimhan B, Mallapragada S (2014) Materials-based strategies for multi-enzyme immobilization and co-localization: a review. Biotechnol Bioeng 111:209–222. https://doi.org/10.1002/bit.25136

Wu F, Pelster LN, Minteer SD (2015) Krebs cycle metabolon formation: Metabolite concentration gradient enhanced compartmentation of sequential enzymes. Chem Commun 51:1244–1247. https://doi.org/10.1039/C4CC08702J

Laursen T, Møller BL, Bassard JE (2015) Plasticity of specialized metabolism as mediated by dynamic metabolons. Trends Plant Sci 20:20–32. https://doi.org/10.1016/j.tplants.2014.11.002

Winkel BSJ (2004) Metabolic channeling in plants. Annu Rev Plant Biol 55:85–107. https://doi.org/10.1146/annurev.arplant.55.031903.141714

Chen X, L. Zaro J, Shen WC, (2013) Fusion protein linkers: Property, design and functionality. Adv Drug Deliv Rev 65:1357–1369. https://doi.org/10.1016/j.addr.2012.09.039

Agapakis CM, Ducat DC, Boyle PM, Wintermute EH, Way JC, Silver PA (2010) Insulation of a synthetic hydrogen metabolism circuit in bacteria. J Biol Eng. https://doi.org/10.1186/1754-1611-4-3

Brodelius M, Lundgren A, Mercke PE, Brodelius P (2002) Fusion of farnesyldiphosphate synthase and epi-aristolochene synthase, a sesquiterpene cyclase involved in capsidiol biosynthesis in Nicotiana tabacum. Eur J Biochem 269:3570–3577. https://doi.org/10.1046/j.1432-1033.2002.03044.x

Castellana M, Wilson MZ, Xu Y, Joshi P, Cristea IM, Rabinowitz JD, Gitai Z, S. Wingreen N, (2014) Enzyme clustering accelerates processing of intermediates through metabolic channeling. Nat Biotechnol 32:1011–1018. https://doi.org/10.1038/nbt.3018

Pötter M, Müller H, Steinbüchel A (2005) Influence of homologous phasins (PhaP) on PHAs accumulation and regulation of their expression by the transcriptional repressor PhaR in Ralstonia eutropha H16. Microbiology 151:825–833. https://doi.org/10.1099/mic.0.27613-0

York GM, Junker BH, Stubbe J, Sinskey AJ (2002) The Ralstonia eutropha PhaR protein couples synthesis of the PhaP phasin to the presence of polyhydroxybutyrate in cells and promotes polyhydroxybutyrate production. J Bacteriol 184:59–66. https://doi.org/10.1128/JB.184.1.59-66.2002

Bohmert K, Balbo I, Kopka J, Mittendorf V, Nawrath C, Poirier Y, Tischendorf G, Trethewey RN, Willmitzer L (2000) Transgenic Arabidopsis plants can accumulate polyhydroxybutyrate to up to 4% of their fresh weight. Planta 211:841–845. https://doi.org/10.1007/s004250000350

Kourtz L, Dillon K, Daughtry S, Madison LL, Peoples O, Snell KD (2005) A novel thiolase-reductase gene fusion promotes the production of polyhydroxybutyrate in Arabidopsis. Plant Biotechnol J 111:485–488. https://doi.org/10.1111/j.1467-7652.2005.00136.x

Lössl A, Bohmert K, Harloff H, Eibl C, Mühlbauer S, Koop HU (2005) Inducible trans-activation of plastid transgenes: expression of the R. eutropha phb operon in transplastomic tobacco. Plant Cell Physiol 46:1462–1471. https://doi.org/10.1093/pcp/pci157

Matsumoto K, Nagao R, Murata T, Arai Y, Kichise T, Nakashita H, Taguchi S, Shimada H, Doi Y (2011) Improved polyhydroxybutyrate (PHB) production in transgenic tobacco by enhancing translation efficiency of bacterial PHB biosynthetic genes. J Biosci Bioeng 111:485–488. https://doi.org/10.1016/j.jbiosc.2010.11.020

John ME (1997) Cotton crop improvement through genetic engineering. Crit Rev Biotechnol 17:185–208. https://doi.org/10.3109/07388559709146613

Schnell J, Treyvaud-Amiguet V, Arnason J, Johnson D (2012) Expression of polyhydroxybutyric acid as a model for metabolic engineering of soybean seed coats. Transgenic Res 21:895–899. https://doi.org/10.1007/s11248-011-9575-x

Saruul P, Srienc F, Somers DA, Samac DA (2002) Production of a biodegradable plastic polymer, poly-β-hydroxybutyrate, in transgenic alfalfa. Crop Sci 42:919–927. https://doi.org/10.2135/cropsci2002.9190

Endo N, Yoshida K, Akiyoshi M, Manji S (2006) Hybrid fiber production: a wood and plastic combination in transgenic rice and Tamarix made by accumulating poly-3-hydroxybutyrate. Plant Biotechnol 23:99–109. https://doi.org/10.5511/plantbiotechnology.23.99

Romano A, van der Plas LHW, Witholt B, Eggink G, Mooibroek H (2005) Expression of poly-3®hydroxyalkanoate (PHA) polymerase and acyl-CoA-transacylase in plastids of transgenic potato leads to the synthesis of a hydrophobic polymer, presumably medium-chain-length PHAs. Planta 220:455–464. https://doi.org/10.1007/s00425-004-1349-8

Houmiel KL, Slater S, Broyles D, Casagrande L, Colburn S, Gonzalez K (1999) Poly(beta-hydroxybutyrate) production in oilseed leukoplasts of Brassica napus. Planta 209:547–550. https://doi.org/10.1007/s004250050760

Wróbel-Kwiatkowska M, Skórkowska-Telichowska K, Dymińska L, Mączka M, Hanuza J, Szopa J (2009) Biochemical, mechanical, and spectroscopic analyses of genetically engineered flax fibers producing bioplastic (poly-β-hydroxybutyrate). Biotechnol Prog 25:1489–1498. https://doi.org/10.1002/btpr.194

Dalton DA, Ma C, Shrestha S, Kitin P, Strauss SH (2011) Trade-offs between biomass growth and inducible biosynthesis of polyhydroxybutyrate in transgenic poplar. Plant Biotechnol J 9:759–767. https://doi.org/10.1111/j.1467-7652.2010.00585.x

Parveez GKA, Bahariah B, Ayub NH, Masani MAM, Rasid OA, Tarmizi AH, Ishak Z (2015) Production of polyhydroxybutyrate in oil palm (Elaeis guineensis Jacq.) mediated by microprojectile bombardment of PHB biosynthesis genes into embryogenic calli. Front Plant Sci 11:596–598. https://doi.org/10.3389/fpls.2015.00598

Patterson N, Tang J, Cahoon EB, Jaworski JG, Wang W, Peoples OP, Snell KD (2011) Generation of high polyhydroxybutryate producing oilseeds. US Patent No US9181559B2. Washington, DC: U.S. Patent and Trademark Office

Mitsky TA, Slater S, Reiser SE, Hao M, Houmiel KL (2003) Multigene expression vectors for the biosynthesis of products via multienzyme biological pathways. US Patent No US6448473B1. Washington, DC: U.S. Patent and Trademark Office

Somleva M, Chinnapen H, Ali A, Snell KD, Peoples OP, Patterson N, Tang J, Bohmert-Tatarev K (2012) Increasing carbon flow for polyhydroxybutyrate production in biomass crops. US Patent No US 2012/0060413 A1. Washington, DC: U.S. Patent and Trademark Office

McQualter RB, Petrasovits LA, Gebbie LK, Schweitzer D, Blackman DM, Chrysanthopoulos P, Hodson MP, Plan MR, Riches JD, Snell KD, Brumbley SM, Nielsen LK (2014) The use of an acetoacetyl-CoA synthase in place of a β-ketothiolase enhances poly-3-hydroxybutyrate production in sugarcane mesophyll cells. Plant Biotechnol J 10:569–557. https://doi.org/10.1111/pbi.12298

Funding

The authors declare that no funds, grants, or other support were received during the preparation of the manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. The first draft of the manuscript was written by ZA and the other author commented on the previous versions of the manuscript. All authors read and approved the submitted version.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical Approval

This manuscript has not been previously published and is not under consideration in the same or substantially similar form in any other peer-reviewed journals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aghaali, Z., Naghavi, M.R. Biotechnological Approaches for Enhancing Polyhydroxyalkanoates (PHAs) Production: Current and Future Perspectives. Curr Microbiol 80, 345 (2023). https://doi.org/10.1007/s00284-023-03452-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00284-023-03452-4