Abstract

In this work, the results of the enzymatic oxidation of TMP-fibers (thermomechanical pulp) and a well-structured lignin model compound, the dehydropolymer (DHP), were investigated by different 14C and 13C methods, caused by a Laccase–Mediator-System (LMS). These methods are the nuclear magnetic resonance spectroscopy (13C-NMR) with DHP (unmarked) and the determination of the 14CO2 release of 14C-marked DHP and TMP-fibers. The 13C-NMR measurements were chosen to analyze the structural changes of the LMS-treated DHP model compounds and TMP-fibers qualitatively and quantitatively. The data of 14CO2 release give an explanation of the demethylation of DHP and TMP-fibers. The effect of the LMS is shown by comparing the results in respect of DHP and TMP-fibers, which were only treated with laccase and of an inactivated LMS as the control. Comparing the results of the 13C-NMR method, in particular the use of the Mediator during the enzymatical treatment, showed significant changes in the structure of the DHP. Also, the TMP-fibers were materially influenced by the LMS. The analysis of the 14CO2 release data of the 14C-marked DHP and TMP-fibers revealed that the rate of 14CO2 increases in the 14C-2 atom as well as in the O14CH3 group within the first hour of Laccase–Mediator incubation. Therefore, the 14CO2 release from the DHP was higher than from the TMP-fibers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Besides Ligninperoxidases (E.C. 1.11.1.7.) and Manganperoxidases (E.C. 1.11.1.13.), Laccases (Polyphenoloxidases; E.C. 1.10.3.2.) are the most important lignin-degrading and lignin-polymerizing enzymes (Thurston 1994). In nature, laccases are generated by many fungi, especially white-rot fungi (mostly basidiomycetes), plants, and some bacteria (Mayer and Staples 2002; Claus 2003, 2004; Baldrian 2006; Hoegger et al. 2006). Laccases are used in many technical processes such as in the biobleaching in the pulp and paper industry (Gutierrez et al. 2009; Zhang et al. 2007) and the textile industry (Galante and Formantici 2003). Those are mostly commercial laccases from saprophytic basiomycetes like the white-rot fungi Trametes, Pleurotus, or Agaricus species, which release high amounts of extra cellular enzymes (Minussi et al. 2002; Xu 2005; Rühl et al. 2007). Some former works report on the high potential of laccases for industrial applications (Wagenführ 1988; Wagenführ et al. 1989; Call and Mücke 1997; Couto and Toca-Herrera 2006; Riva 2006; Mikolasch and Schauer 2009). A disadvantage of the application of laccase is its low redox potential. Because of this low redox potential, laccases need a free phenolic group at the aromatic rings of the lignin for oxidation that normally inhibits their application in the lignin biotechnology because in natural lignin, the most phenolic groups are substituted during the radical reaction of the lignin synthesis (Lenowicz et al. 2001; Rochefort et al. 2004). Bourbonnais and Paice (1990) were the first who could show that, after the addition of low-molecular redox compounds (the Mediator), laccase is able to attack also non-phenolic lignin connections and to fasten and intensify the reactions. This is explained by the ability of the little Mediator molecules to reach the smaller reaction locations of the lignin, which are not accessible by the larger laccase molecules as well as the new reaction mechanisms which can be implemented by the Mediators during the enzymatic modification of the lignin (Bourbonnais and Paice 1992; Bourbonnais et al. 1995; Call and Mücke 1994). Thus, the Laccase–Mediator-System (LMS) offers an improvement on the low redox potential laccases.

In view of this, Mediators play a new and important role in the biochemistry of lignin degradation (Call and Mücke 1997; Goodell et al. 1997; Crestini and Argyropoulos 2001; Crestini et al. 2003). Mediators like 1-hydroxybenzotriazole, acetosyringone, and syringaldehyde were successfully adopted in combination with laccases in the biochemical bleaching of paper pulp and in the degradation of textile fibers. In contrast, the Mediator p-coumaric acid, for example, was less suitable for such applications (Moreira et al. 1998; Pandey et al. 2000; Lund and Felby 2001; Camarero et al. 2004; Chakar and Ragauskas 2004; Rochefort et al. 2004; Hakala et al. 2005; Ibarra et al. 2006; Camarero et al. 2007; Gutiérrez et al. 2007; Vivekanand et al. 2008). A positive effect of the Mediator 4-hydroxy benzoic acid (HBA) in the modifying of paper is described by Chandra et al. (2004). The LMS for the production of wooden fiberboards was first applied in Euring (2008) and then in Kharazipour and Euring (2010).

In this work, some positive effects of the HBA during the enzymatic oxidation of TMP-fibers (TMP = thermomechanical pulp) are described and verified by synthetic labeled lignin models.

Materials and methods

For the 13C-NMR determination, unlabeled TMP-fibers from the wood species Picea sp. and Pinus spec. were used. For the other method to determine the 14CO2 release, the lignin of TMP-fibers was 14C marked in vivo by the method of Freudenberg and Reichert (1954), Freudenberg (1968) and Trojanowski and Hüttermann (1987).

For the DHP synthesis, coniferyl alcohol was used together with peroxidase from horseradish (Applichem) with an activity of 260 U/mg (Purpurogalin) and H2O2 according to Freudenberg′s “Zutropfverfahren” (1968).

For the 13C-NMR spectroscopy, the DHP was not labeled. For the 14CO2 measurments, the DHP was labeled with 14C in CH3-groups and in side chain-C-2 using the procedure described by Trojanowski and Hüttermann (1987).

The laccase for these studies was used from the genetically modified fungi Aspergillus sp. from Novozym, Denmark (Novozym 51003, E.C. 1.10.3.2). The activity of the laccase was routinely determined by monitoring the oxidation of diammonium salt of 2.2′-azinobis-3-ethylbenzothiazoline-6-sulfonic acid (ABTS) (Matsumura et al. 1986). The activity of the pure laccase was about 2200 U/ml (ABTS).

The Mediator 4-hydroxy benzoic acid (HBA) from Applichem had a purity of 99% and solubility of 9 g/l in water.

The reaction buffer was the McIlvain buffer, containing 0.2 M dipotassium hydrogen phosphate (K2HPO4) from AppliChem, 0.1 M citric acid monohydrate (C6H8O7 * H2O) from AppliChem and H2Obidest to dissolve both reagents. The pH value of this buffer was adjusted to 6.

TMP-fibers and DHP treatment with the LMS for 13C-NMR studies

For the 13C-NMR measurements, either 5 g TMP-fibers or 5 g DHP and 150 ml McIlvain buffer (pH 6), containing 200 U/ml laccase and 10 mM HBA, were incubated for 4, 60, and 180 h under constant shaking. In comparison, the same amount of the compounds was used without the Mediator to explain any effect of this Mediator.

As control samples, the TMP-fibers/DHP was incubated in McIlvain buffer with inactivated LMS. After the incubation times, the samples of TMP-fibers and DHP were washed with bidistilled water using a centrifuge with 12,000g. After that, the TMP-fibers and DHP were dried in a vacuum oven at 105°C for 12 h. After the drying process, the samples were measured by the 13C-NMR method using a Bruker Avance 400 MHz WB.

14C labeled DHP and TMP-fibers

As mentioned before, for the determination of 14CO2 emission, the TMP-fibers and DHP were 14C marked in the C-2 atom and in 14CH3 methoxyl groups.

The lignin degradation was monitored using a modified radiorespirometric method based on Haider and Trojanowski (1975).

Each sample was placed in a glass flask and incubated in a vacuum in 7 ml McIlvain buffer, containing either 200 U/ml laccase and 10 mM HBA or only 200 U/ml laccase and inactivated LMS (control). The incubation solution was stirred and kept at between 30 and 45°C using a water bath for a total of 6 h.

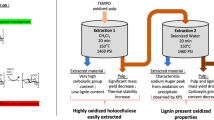

The 14CO2 released from 14C atoms and 14CH3 methoxyl groups was trapped in 2 ml 10% (w/v) NaOH, and the radioactivity was measured in the liquid scintillation counter C 400 (Fig. 1). The data were collected every hour.

Radiorespirometric method for TMP-fibers and DHP based on Haider and Trojanowski (1975)

Results and discussion

13C-NMR spectroscopy

Table 1 shows the amounts of aromatic groups in TMP-fibers and DHP treated with laccase and LMS, respectively, at different incubation times. Besides the region of aromatic groups (160–95 ppm), many other regions in the 13C-NMR spectra have been detected—such as aliphatic C compounds (45–10 ppm), methoxyl groups (60–45 ppm), and COOH/C=O groups (220–160 ppm). Those were present especially in TMP-fibers carbohydrates (95–10 ppm). By analyzing all these regions, the most noticeable differences appeared in the aromatic groups which are displayed in the Table. The differences between the values of detected aromatic groups in TMP-fibers and DHP are explained by the constituents of both materials. While DHP is a pure lignin model compound, TMP-fibers consist of many other components, such as cellulose, hemicelluloses, and extractives. For example, DHP does not contain carbohydrates, whereas TMP-fibers contain 78% of carbohydrates in relation to the other compounds. Therefore, the amount of aromatic groups in TMP-fibers is much lower than in DHP.

Nonetheless, during analysis of the 13C-NMR spectra, it was shown that under the influence of the LMS, after 4 h of incubation, the aromatic groups (160–95 ppm) were noticeably degraded and transferred into the incubation solution. Prior to the incubation, with the LMS, 19.8% aromatic groups were found in the TMP-fibers and 58.1% in the DHP. After 4 h of incubation, just 13.9% were found in the TMP-fibers and 48.5% in DHP. In comparison, when using only laccase, after 4 h of incubation, the percentage of aromatic compounds in the TMP-fibers was of 18.3% and 52.9% in the DHP. At longer incubation times, a lower degradation value of aromatic groups was noticed. After 60 h of incubation, the aromatic compounds had a percentage of 13.0 in TMP-fibers and 47.9 in DHP, and after 180 h of incubation, a value of 12.8% (TMP-fibers) and 47.2% (DHP).

In reference to the other detected regions of the 13C-NMR spectra during the complete incubation test for methoxyl groups (60–45 ppm), no essential changes were found due to a low degradation rate of methoxyl by the LMS. Equally low degradation values were recognized for aliphatic compounds. Apart from that, the percentile rate of COOH/C=O bonds was increased marginally from 0.7 to 1.3% in TMP-fibers and from 1.4 to 2.9% in DHP after 180 h of incubation. The increase of COOH/C=O bonds is caused by a structural change of TMP-fibers and DHP during the laccase degradation, which forces the formation of these bonds. Additionally, COOH/C=O bonds do not pass into the solution and can be released by the degradation and conversion of aromatic compounds. In the evaluation of the samples based on 13C-NMR spectroscopy, it was found that laccase, especially laccase in a system with Mediator, affects chemical changes on the TMP-fibers and DHP. A lower absorption rate of the TMP-fibers and DHP treated with LMS during the 13C-NMR measurements implied that the lignin-oxidized effect of laccase was increased by the Mediator HBA. Particularly, close to the aromatic compounds the oxidation of the TMP-fibers and DHP must have been strongly supported by the Mediator. Furthermore, side chains (hydroxyl groups and ether groups) of the hydrocarbons were absorbed less after 4 h of incubation.

Also Milstein et al. (1993) recognized a clear chemical change in the lignin structure—mainly a release of aromatic hydrocarbons.

In contrast to the results of this paper, Kharazipour et al. (1997) performed 13C-NMR measurements with lignin which was already dissolved in fiber suspension by incubation of the wood surface with laccase only. In that paper, the TMP-fibers were analyzed by themselves with the LMS.

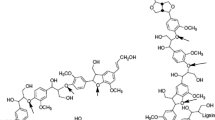

In Fig. 2, the changes are illustrated, in comparison with the NMR spectra of the control sample of DHP (points): the DHP sample (broken line), which was incubated for 4 h with laccase, and the LMS-treated DHP (continuous line).

Degradation tests of 14C marked DHP and TMP wood fibers

Analysis of the results showed that incubation supported by a LMS causes an oxidation and degradation of C-2 chains and CH3 groups and additionally a 14CO2 emission in all TMP-fibers and DHP samples as early as within the first 2 h. In comparison with TMP-fibers, higher emission rates emerged for DHP samples (Figs. 3 and 4). The measured 14CO2 emission of the CH3 groups of the DHPs, which was treated with the LMS, was at 1.6% after 2 h of incubation; for the TMP-fibers, the value was below 1.0%. After 3 and 4 h of incubation for all treated samples, the maximal 14CO2 emission was achieved. Afterward, a more or less continuous behavior for the illustrated incubation time was recognized (Fig. 4). It became obvious that reactions between laccase or the LMS and the TMP-fibers or the DHP proceeded within a few hours faster than in the tests by Haider et al. (1985) and Iimura et al. (1995). The faster degradation rate of the DHP lignin model in comparison with TMP-fibers is presumably closely related to the simpler structure of DHP, which is already a simple polymer. Consequently, the C atoms are easier to reach for the LMS. A lower 14CO2 emission was counted for the TMP-fibers because other components besides lignin are inside of them, i.e., hemicelluloses, cellulose, and extractives.

The most essential aspect during the 14CO2 emission was the different degradation rates of the C-2 chains and CH3- groups and the different treatments (LMS or only laccase). Again it becomes obvious that by application of a Mediator, a more intensive and accelerated lignin activation and degradation will be possible. This is an interesting aspect for the industrial production of wood fiber–based materials, which are made of TMP-fibers that can form a fiber to fiber bond by the cross-linking molecules (Yamaguchi et al. 1992; Kharazipour and Hüttermann 1993, 1998; Kharazipour et al. 1993, 1994; Kharazipour et al. 1997; Kharazipour 1996; Hüttermann et al. 2001; Felby et al. 1997, 2002; Widsten 2002; Kües et al. 2007; Euring 2008).

Conclusion

This article illustrates coherencies between the influence of the LMS on both TMP-fibers and dehydropolymers (DHP). Furthermore, it provides insights into the oxidation mechanisms of the laccase enzyme in interaction with a Mediator in the lignin structure. The results showed that the use of a LMS can increase the lignin degradation rates, which were measured by a nuclear magnetic resonance spectroscopy (13C-NMR) and which were caused by a 14CO2 emission. Further investigations could show to what extent the LMS can be optimized. By a higher activation, and therefore a more intensive lignin degradation, the system could be used in different biochemical and technological applications, i.e., for paper bleaching, in the textile industry, or for the production of wood fiber products.

References

Baldrian P (2006) Fungal laccases—occurrence and properties. FEMS Microbiol Rev 30:215–242

Bourbonnais R, Paice MG (1990) Oxidation of non-phenolic substrates. An expanded role for laccase in lignin biodegradation. FEBS Lett 267:99–102

Bourbonnais R, Paice MG (1992) Demethylation and delignification of kraft pulp by Trametes versicolor laccase in the presence of ABTS. Appl Microbiol Biotechnol 36:823–827

Bourbonnais R, Paice MG, Reid ID, Lanthier P, Yaguchi M (1995) Lignin oxidation by laccase isozymes from Trametes versicolor and role of the mediator 2, 2′-Azinobis(3-Ethylbenzthiazoline-6-sulfonate) in Kraft lignin depolymerization. Appl Environ Microbiol 61(5):1876–1880

Call HP, Mücke I (1994) Die enzymatische Bleiche mit dem Laccase-Mediator System (LMS): Labor- und Pilotversuche. In: Miletzky F, Borchers B, Baumgarten HL (Hrsg.) (eds) Enzymtechnik in der Papierindustrie. München, PTS, pp 51–59

Call HP, Mücke I (1997) History overview and applications of mediated lignolytic systems, especially laccase-mediator-systems (Lignozym-process). J Biotechnol 53:163–202

Camarero S, Ibarra D, Martinez MJ, Martinez AT (2004) Lignin-derived compounds as efficient laccase mediators for decolorization of different types of realcitrant dyes. Appl Environ Microbiol 2005:1775–1784

Camarero S, Ibarra D, Martínez AT, Romero J, Gutiérrez A, del Rio JC (2007) Paper pulp delignification using laccase and natural mediators. Enzyme Microb Technol 40:1264–1271

Chakar FS, Ragauskas AJ (2004) Biobleaching chemistry of laccase-mediator systems on high-lignin-content kraft pulps. Can J Chem 82:344–352

Chandra RP, Felby C, Ragauskas AJ (2004) Improving laccase-facilitated grafting of 4-hydroxybenzoic acid to high–kappa kraft pulps. J Wood Chem Technol 24:69–81

Claus H (2003) Laccases and their occurrence in prokaryotes. Arch Microbiol 179:145–150

Claus H (2004) Laccases: structure reactions, distribution. Micron 35:93–96

Couto SR, Toca-Herrera JL (2006) Laccases in the textile industry. Biotechnol Mol Biol Rev 1(4):115–120

Crestini C, Argyropoulos DS (2001) On the role of 1-Hydroxybenzotriazole as mediator in the laccase oxidation of residual kraft lignin. oxidative delignification chemistry: fundamentals and catalysis, ACS Symposium Series No. 785, Argyropoulos DS (ed) Washington, ACS Books, 2001, Chapter 23, pp 373–390

Crestini C, Jurasek L, Argyropoulos DS (2003) On the mechanism of the laccase-mediator system in the oxidation of lignin. Chem Eur J 9:5371–5378

Euring M (2008) Einsatz von Mediatoren bei der enzymatischen Aktivierung der fasereigenen Bindekräfte zur Herstellung von enzymgebundenen, bindemittelfreien Holzwerkstoffe. Dissertation, Fakultät für Forstwissenschaften und Waldökologie, Georg-August Universität Göttingen, 211 Seiten

Felby C, Nielsen PO, Oelsen LH, Skibsted LH (1997) Identification and quantification of radical reaction intermediates by electron spin resonance spectrometry of laccase-catalyzed oxidation of wood fibres from beech. Appl Microbiol Biotechnol 48:459–464

Felby C, Hassigboe J, Lund M (2002) Pilot-scale production of fiberboards made by laccase oxidized wood fibres: board properties and evidence for cross-linking of lignin. Enz Microbial Technol 31:736–741

Freudenberg K (1968) The constitution and biosynthesis of lignin. In: Freudenberg K, Neish AC (eds) Constitution and biosynthesis of lignin. Springer, Berlin, pp 82–92

Freudenberg K, Reichert M (1954) Die Anwendung radioaktiver Isotope bei der Erforschung des Lignins, V. Chem Ber 87(12):1834–1840

Galante YM, Formantici C (2003) Enzyme applications in detergency and in manufacturing industries. Curr Org Chem 7(13):1399–1422

Goodell B, Jellison J, Liu J, Daniel G, Paszczynski A, Fekete F, Krishnamurthy S, Jun L, Xu G (1997) Low molecular weight chelators and phenolic compounds isolated from wood decay fungi an their role in the fungal biodegradation of wood. J Biotechnol 53:133–162

Gutierrez A, del Rio JC, Martinez AT (2009) Microbial and enzymatic control of pitch in the pulp and paper industry. Appl Microbiol Biotechnol 82:1005–1018

Gutiérrez A, Rencoret J, Ibarra D, Molina S, Camarero S, Romero J, Del Rio JC, Martínez AT (2007) Removal of lipophilic extractives from paper pulp by laccase and lignin-derived phenols as natural mediators. Environ Sci Technol 41:4124–4129

Haider K, Trojanowski J (1975) Decomposition of specifically 14C-labelled phenols and dehydropolymers of coniferyl alcohol as models for lignin degradation by soft and white rot fungi. Arch Microbiol 105:33–41

Haider K, Kern H, Ernst L (1985) Intermediate steps of microbial lignin degradation as elucidated by 13C NMR spectroscopy of specifically 13C-enriched DHP-lignins. Holzforschung 39:23–32

Hakala TK, Lundell T, Galkin S, Maijala P, Kalkkinen N, Hatakka A (2005) Manganese peroxidises laccases and oxalic acid from the selective white-rot fungus Physisporinus rivulosus grown on spruce wood chips. Enzyme Microb Technol 36:461–468

Hoegger PJ, Kilaru S, James T, Thacker J, Kües U (2006) Phylogenetic comparison and classification of laccase and related multi-copper oxidase protein sequences. FEBS J 273:2308–2326

Hüttermann A, Mai C, Kharazipour A (2001) Modification of lignin for the production of new compounded materials. Appl Microbiol Biotechnol 55:387–394

Ibarra D, Camarero S, Romero J, Martinez MJ, Martinez AT (2006) Integrating Laccase-mediator treatment into an industrial-type sequence for totally chlorine-free bleaching of eucalypt kraft pulp. J Chem Technol Biotechnol 81:1159–1165

Iimura Y, Katayama Y, Kawai S, Morohoshi N (1995) Degradation and solubilization of 13C-, 14C-side chain labeled synthetic lignin (dehydrogenative polymerizate) by laccase III of Colorius versicolor. Biosci Biotech Biochem 59(5):903–905

Kharazipour A (1996) Enzyme von Weißfäulepilzen als Grundlage für die Herstellung von Bindmitteln für Holzwerkstoffe. Sauerländer′s Verlag Frankfurt/Main

Kharazipour A, Euring M (2010) Verwendung von Mediatoren bei der Herstellung von Faserplatten. Patent DE 10 2008 038 398 A1

Kharazipour A, Hüttermann A (1993) Enzymatische Behandlung von Holzfasern als Weg zu vollständig bindemittelfreien Holzwerkstoffen. In Hüttermann, A., Kharazipour, A (Herausgeber): Die pflanzliche Zellwand als Vorbild für Holzwerkstoffe, naturorientierte Herstellung von Span- und Faserplatten. Stand der Technik und Perspektiven. pp 83–98, J. D. Sauerländer′s Verlag, Frankfurt/Main

Kharazipour A, Hüttermann A (1998) Biotechnological production of wood composites. In: Bruce A, Palfreyman JW (eds) Forest products biotechnology. Taylor and Francis, London, pp 141–150

Kharazipour A, Hüttermann A, Kühne G, Rong M (1993) Verfahren zur Herstellung von bindemittelfreien Formkörpern. DE-Patent 4305411

Kharazipour A, Hüttermann A, Kühne G, Rong M (1994) Verfahren zum Verkleben von Holzfragmenten und nach dem Verfahren hergestellte Formkörper. EU-Patent 94103099

Kharazipour A, Hüttermann A, Lüdemann HD (1997) Enzymatic activation of wood fibres as a mean for the production of wood composites. J Adhes Sci Technol 11:419–427

Kües U, Bohn C, Euring M, Müller C, Polle A, Kharazipour A (2007) Enzymatically modified wood in panel board production. In: Kües U (ed) Wood production, wood technology, and biotechnological impacts. Universitätsverlag Göttingen. Chapter 18, pp 433–468

Lenowicz A, Cho N-S, Luterek J, Wilkolazka A, Woitas-Wasilewska M, Matuzewskas A, Hofrichter M, Wesenberg D, Rogalski J (2001) Fungal laccase: properties and activity on lignin. J Basic Microbiol 41:185–227

Lund M, Felby C (2001) Wet strength improvement of unbleached Kraft pulp through laccase catalyzed oxidation. Enzyme Microbial Technol 28:760–765

Matsumura E, Yamamoto E, Numata A, Kawano T, Shin T, Murao S (1986) Structures of the laccase-catalysed oxidation products of hydroxybenzoic acids in the presence of ABTS. Japan society for bioscience, biotechnology and agrochemistry. Agric Biol Chem 50(5):1355–1357

Mayer AM, Staples RC (2002) Laccase: new functions for an old enzyme. Phytochemistry 60:551–565

Mikolasch A, Schauer F (2009) Fungal laccases as tools for the synthesis of new hybrid molecules and biomaterials. Appl Microbiol Biotechnol 82:605–624

Milstein O, Hüttermann A, Majcherczyk A, Schulze K, Fründ R, Lüdemann H-D (1993) Transformation of lignin-related compounds with laccase in organic solvents. J Biotechnol 30:37–47

Minussi RC, Pastore GM, Duran N (2002) Potential applications of laccase in the food industry. Trends Food Sci Technol 13:205–216

Moreira MT, Palma C, Feijoo G, Lema JM (1998) Strategies for the continuous production of ligninolytic enzymes in fixed and fluidised bed bioreactors. J Biotechnol 66:27–39

Pandey A, Soccol CR, Mitchell D (2000) New developments in solid state fermentation: I-bioprocesses and products. Process Biochem 35:1153–1169

Riva S (2006) Laccases: blue enzymes for green chemistry. Trends Biotechnol 24(5):219–226

Rochefort D, Leech D, Bourbonnais R (2004) Electron transfer mediator systems for bleaching of paper pulp. Green Chem 6:14–24

Rühl M, Kilaru S, Navarro-Gonzales M, Hoegger PJ, Kharazipour A, Kües U (2007) Production of laccase and other enzymes for the wood industry. In: Kües U (ed) Wood production, wood technology, and biotechnological impacts. Universitätsverlag Göttingen. Chapter 19, pp 469–509

Thurston CF (1994) The structure and function of fungal laccases. Microbiology 140:19–26

Trojanowski J, Hüttermann A (1987) Screening of wood inhabiting fungi for their capacity to degrade and solubilize 14C-labelled lignin. Microbios 50:91–97

Vivekanand V, Dwivedi P, Sharma A, Sabharwal N, Singh RP (2008) Enhanced delignification of mixed wood pulp by Aspergillus fumigatus laccase mediator system. World J Microbiol Biotechnol 24:2799–2804

Wagenführ A (1988) Praxisrelevante Untersuchungen zur Nutzung biotechnologischer Wirkprinzipien bei der Holzwerkstoffherstellung. Dissertation, TU Dresden

Wagenführ A, Pecina H, Kühne G (1989) Enzymatische Hackschnitzelmodifizierung für die Holzwerkstoffherstellung. Holztechnologie 30, pp 262–265

Widsten P (2002) Oxidation of Wood Fibers for the Manufacture of Medium-Density Fiberboards (MDF), Dissertation, Helsinki University of Technology Laboratory of Paper Technology, Reports, Series A 15, Espoo 2002

Xu F (2005) Applications of oxidoreductases: recent progress. Ind Biotechnol 1:38–50

Yamaguchi H, Maeda Y, Sakata I (1992) Applications of phenol dehydrogenative polymerisation by laccase to bonding among woody-fibers. Mokuzai Gakkaishi 38(10):931–937

Zhang AP, Qin MH, Sun RC, Xu QH, Fu YJ, Liu CF (2007) Characterization of Masson pine stone groundwood pulp modified with Laccase/mediator system. Cell Chem Technol 41(1):63–75

Acknowledgment

Markus Euring is supported by the Deutsche Forschungsgemeinschaft (DFG), grant EU 124/2-1.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Euring, M., Trojanowski, J., Horstmann, M. et al. Studies of enzymatic oxidation of TMP-fibers and lignin model compounds by a Laccase–Mediator-System using different 14C and 13C techniques. Wood Sci Technol 46, 699–708 (2012). https://doi.org/10.1007/s00226-011-0439-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-011-0439-6