Abstract

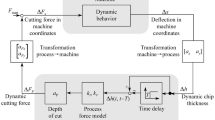

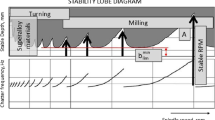

The research status and progress of the chatter stability in machining systems were systematically reviewed. Three types of chatter mechanisms and their interrelationships in machining processes were introduced. To establish a comprehensive and accurate chatter stability model, the factors that primarily influence chatter stability were discussed from two perspectives: system structure and machining processes. The methods for identifying dynamic parameters of the machining system, including modal parameters and contact stiffness, were summarized. The principle, advantages, shortcomings, and applications of chatter stability region solution methods, including the stability lobe diagram (SLD) methods, the frequency-domain methods, and the time-domain methods, were comprehensively analyzed. As the standard representation methods of stability analysis, SLD can be obtained based on control theory and machine learning techniques, respectively. The frequency-domain methods can be categorized into single-frequency methods and multi-frequency methods, while the time-domain methods encompass simulation time-domain methods and various discretization methods. In addition, the uncertainty analysis of the chatter stability was conducted for the first time, taking into account the uncertain parameters. The uncertainty analysis methods were outlined based on probability theory, interval number theory, and fuzzy set theory. On the above bases, the research challenges of the chatter stability in machining systems were summarized. Finally, its development trend has been prospected.

Similar content being viewed by others

Data availability

The data sets supporting the results of this article are included within the article and its additional files.

References

Ghorbani S, Rogov VA, Carluccio A, Belov PS (2019) The effect of composite boring bars on vibration in machining process. Int J Adv Manuf Technol 105(1–4):1157–1174. https://doi.org/10.1007/s00170-019-04298-6

Shvartsburg LE, Ivanova NA, Ryabov SA, Kulizade DI, Aksenov VA, Sorokina EA, Isaev AV (2021) Vibration in machining. Russ Eng Res 41(2):180–182. https://doi.org/10.3103/S1068798X21020179

Yuan L, Pan ZX, Ding DH, Sun SS, Li WH (2018) A review on chatter in robotic machining process regarding both regenerative and mode coupling mechanism. IEEE/ASME Trans Mechatron 23(5):2240–2251. https://doi.org/10.1109/tmech.2018.2864652

Quintana G, Ciurana D, Teixidor D, Ferrer I (2011) Experimental introduction to forced and self-excited vibrations in milling processes and identification of stability lobes diagrams. Mater Sci Forum 1369(692):24–32. https://doi.org/10.4028/www.scientific.net/MSF.692.24

Urbikain G, Olvera D, López de Lacalle LN, Beranoagirre A, Elías-Zuñiga A (2019) Prediction methods and experimental techniques for chatter avoidance in turning systems: a review. Appl Sci 9(21):1–18. https://doi.org/10.3390/app9214718

Qin L, Liu EL, Xing HW, Zhao LG (2019) Research progress on stability analysis of turning process. J Harbin Univ Sci Technol 9(21):1–18. https://doi.org/10.15938/j.jhust.2019.01.003

Zhu LD, Liu CF (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Sig Process 143(C):106840. https://doi.org/10.1016/j.ymssp.2020.106840

Lamraoui M, Barakat M, Thomas M, Badaoui ME (2015) Chatter detection in milling machines by neural network classification and feature selection. J Vib Control 21(7):1251–1266. https://doi.org/10.1016/j.ymssp.2020.106840

Inasaki I, Karpuschewski B, Lee HS (2001) Grinding chatter-origin and suppression. CIRP Ann Manuf Technol 50(2):515–534. https://doi.org/10.1016/S0007-8506(07)62992-8

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642. https://doi.org/10.1016/S0007-8506(07)60032-8

Pan JQ, Chen C, Liu ZB, Wang XB (2021) Multi-feature extraction and analysis for boring chatter monitoring. Int J Adv Manuf Technol 117(9–10):3129–3136. https://doi.org/10.1007/S00170-021-07191-3

Wang GF, Dong HY, Guo YJ, Ke YL (2017) Chatter mechanism and stability analysis of robotic boring. Int J Adv Manuf Technol 91(1–4):411–421. https://doi.org/10.1007/s00170-016-9731-9

Ozturk OM, Kilic ZM, Altintas Y (2018) Mechanics and dynamics of orbital drilling operations. Int J Mach Tools Manuf 129:37–47. https://doi.org/10.1016/j.ijmachtools.2018.03.001

Ma YC, Wan M, Yang Y, Zhang WH (2019) Dynamics of tapping process. Int J Mach Tools Manuf 140:34–47. https://doi.org/10.1016/j.ijmachtools.2019.02.002

Thaler T, Potočnik P, Bric I, Govekar E (2014) Chatter detection in band sawing based on discriminant analysis of sound features. Appl Acoust 77:114–121. https://doi.org/10.1016/j.apacoust.2012.12.004

Thaler T, Krese B, Govekar E (2015) Stability diagrams and chatter avoidance in horizontal band sawing. CIRP Ann Manuf Technol 64(1):81–84. https://doi.org/10.1016/j.cirp.2015.04.081

Liao WH, Zheng K, Sun LJ, Dong S, Zhang L (2021) Review on chatter stability in robotic machining for large complex components. Acta Aeronautica et Astronautica Sinica 43(1):026061. https://doi.org/10.7527/s1000-6893.2021.26061

Zheng ZP, Jin X, Sun YW, Zhang ZJ, Sun HC, Li QM (2020) Prediction of chatter stability for enhanced productivity in parallel orthogonal turn-milling. Int J Adv Manuf Technol 110(9):2377–2388. https://doi.org/10.1007/s00170-020-06015-0

Comak A, Altintas Y (2018) Dynamics and stability of turn-milling operations with varying time delay in discrete time domain. J Manuf Sci Eng 140(10):101013. https://doi.org/10.1115/1.4040726

Peng ZL, Zhang DY, Zhang XY (2020) Chatter stability and precision during high-speed ultrasonic vibration cutting of a thin-walled titanium cylinder. Chin J Aeronaut 02(11):1–15. https://doi.org/10.1016/j.cja.2020.02.011

Wang WK, Wan M, Zhang WH, Yang Y (2022) Chatter detection methods in the machining processes: a review. J Manuf Process 77:240–259. https://doi.org/10.1016/J.JMAPRO.2022.03.018

Myrsini N, Spyridon P, Anastasios K, Ilias G, Stefanos V, Ioannis K (2022) Infrastructure monitoring and quality diagnosis in CNC machining: a review. CIRP J Manuf Sci Technol 38:631–649. https://doi.org/10.1016/J.JMAPRO.2022.03.018

Wang YH, Wang M (2010) Advances on machining chatter suppression research. J Mech Eng 46(07):166–174. https://doi.org/10.3901/JME.2010.07.166

Fei JX, Xu FF, Lin B, Huang T (2020) State of the art in milling process of the flexible workpiece. Int J Adv Manuf Technol 109(5–6):1695–1725. https://doi.org/10.1007/s00170-020-05616-z

Honeycutt A, Schmitz TL (2018) Milling bifurcations: a review of literature and experiment. J Manuf Sci Eng 140(12):120801. https://doi.org/10.1115/1.4041325

Lu XH, Yang K, Luan YH, Hou PR, Gu H (2021) A review on chatter stability in thin-wall milling. J Vib Shock 40(08):50–61. https://doi.org/10.13465/j.cnki.jvs.2021.08.007

Lu XH, Wang FC, Wang H, Wang XX, Si LK (2016) A review about chatter stability analysis in milling process. J Vib Shock 35(01):74–82. https://doi.org/10.13465/j.cnki.jvs.2016.01.014

Wu G, Li GX, Pan WC, Raja I, Wang X, Ding SL (2021) A state-of-art review on chatter and geometric errors in thin-wall machining processes. J Manuf Process 68(PA):454–480. https://doi.org/10.1016/J.JMAPRO.2021.05.055

Lu SX, Guo S, Zhang JQ, Jiang QH, Zhou C, Zhang B (2022) Research progress on grindability of high performance difficult-to-machine materials. Surf Technol 51(03):12–42. https://doi.org/10.16490/j.cnki.issn.1001-3660.2022.03.002

Oliveira JFG, França TV, Wang JP (2008) Experimental analysis of wheel/workpiece dynamic interactions in grinding. CIRP Ann Manuf Technol 57(1):329–332. https://doi.org/10.1016/j.cirp.2008.03.096

Urbicain G, Palacios JA, Fernández A, Rodríguez A, Lacalle LNLde, Elías-Zúñiga A, (2013) Stability prediction maps in turning of difficult-to-cut materials. Pro Eng 63:514–522. https://doi.org/10.1016/j.proeng.2013.08.244

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Wang ZX, Liu XL, Li MY, Liang SY, Wang LC, Li YQ, Meng BY (2020) Intelligent monitoring and control technology of cutting chatter. J Mech Eng 56(24):1–23. https://doi.org/10.3901/JME.2020.24.001

Nam S, Hayasaka T, Jung H, Shamoto E (2020) Proposal of novel chatter stability indices of spindle speed variation based on its chatter growth characteristics. Precis Eng 62(C):121–133. https://doi.org/10.1016/j.precisioneng.2019.11.018

Sun C, Duan JC, Lan DX, Liu ZX, Xiu SC (2018) Prediction about ground hardening layers distribution on grinding chatter by contact stiffness. Arch Civil Mech Eng 18(4):1626–1642. https://doi.org/10.1016/j.acme.2018.06.010

Sun C, Deng YS, Lan DX, Xiu SC (2018) Modeling and predicting ground surface topography on grinding chatter. Procedia CIRP 71:364–369. https://doi.org/10.1016/j.procir.2018.05.042

Sun C, Liu ZX, Lan DX, Duan JC, Xiu SC (2018) Study on the influence of the grinding chatter on the workpiece’s microstructure transformation. Int J Adv Manuf Technol 96(9–12):3861–3879. https://doi.org/10.1007/s00170-018-1794-3

Zhang Z, Li HG, Liu XB, Zhang WY, Meng G (2018) Chatter mitigation for the milling of thin-walled workpiece. Int J Mech Sci 138–139:262–271. https://doi.org/10.1016/j.ijmecsci.2018.02.014

Tóth M, Sims ND, Curtis D (2019) An analytical study of wheel regeneration in surface grinding. Procedia CIRP 82:214–219. https://doi.org/10.1016/j.procir.2019.04.046

Thompson RA (1986) On the Doubly Regenerative stability of a grinder: the theory of chatter growth. J Eng Ind 108(2):75–82. https://doi.org/10.1115/1.3187054

Thompson RA (1992) On the doubly regenerative stability of a grinder: the effect of contact stiffness and wave filtering. J Eng Ind 114(1):53–60. https://doi.org/10.1115/1.2899758

Liu ZH, Payre G (2006) Stability analysis of doubly regenerative cylindrical grinding process. J Sound Vib 301(3):950–962. https://doi.org/10.1016/j.jsv.2006.10.041

Hahn RS (1954) On the theory of regenerative chatter in precision-grinding operations. Trans ASME 76(5):593–597. https://doi.org/10.1115/1.4014908

Arnold RN (1946) Cutting tools research: report of subcommittee on carbide tools: the mechanism of tool vibration in the cutting of steel. Proc Ins Mech Eng 154(1):261–284. https://doi.org/10.1243/PIME.PROC.1946.154.037.02

Grabec I (1986) Chaos generated by the cutting process. Phys Lett A 117(8):384–386. https://doi.org/10.1016/0375-9601(86)90003-4

Wiercigroch M, Krivtsov AM (2001) Frictional chatter in orthogonal metal cutting. Philos Trans Royal Soc A: Math Phys Eng Sci 359(1781):713–738. https://doi.org/10.1098/rsta.2000.0752

Wiercigroch M, Wahi P (2014) Modelling of frictional chatter in metal cutting. Int J Mech Sci 89:167–176. https://doi.org/10.1016/j.ijmecsci.2014.08.020

Huang Y, Wang TY, Zhang Y, Jiang YX (2008) Nonlinear analysis of frictional chatter mechanism in mechanical systems. Chin Mech Eng 19(14):1677-1680. JournalArticle/5aed14a3c095d710d4081adb

Wang A, Jin WY, Chen WK, Feng RC, Xu CW (2018) Bifurcation and chaotic vibration of frictional chatter in turning process. Adv Mech Eng 10(4):1–8. https://doi.org/10.1177/1687814018771262

Weremczuk A, Rusinek R (2017) Influence of frictional mechanism on chatter vibrations in the cutting process-analytical approach. Int J Adv Manuf Technol 89(9–12):2837–2844. https://doi.org/10.1007/s00170-016-9520-5

Yan Y, Xu J, Wiercigrocch M (2016) Regenerative and frictional chatter in plunge grinding. Nonlinear Dyn 86(1):283–307. https://doi.org/10.1007/s11071-016-2889-8

He FX, Liu Y, Liu K (2019) A chatter-free path optimization algorithm based on stiffness orientation method for robotic milling. Int J Adv Manuf Technol 101(9):2739–2750. https://doi.org/10.1007/s00170-018-3099-y

Tlusty J, Ismail F (1981) Basic non-linearity in machining chatter. CIRP Ann Manuf Technol 30(1):299–304. https://doi.org/10.1016/S0007-8506(07)60946-9

Gasparetto A (2001) Eigenvalue analysis of mode-coupling chatter for machine-tool stabilization. J Vib Control 7(2):181–197. https://doi.org/10.1177/107754630100700203

Gallina P, Trevisani A (2003) On the stabilizing and destabilizing effects of damping in wood cutting machines[J]. Int J Mach Tools Manuf 43(9):955–964. https://doi.org/10.1016/S0890-6955(03)00061-0

Badiola X, Iturrospe A, Abete JM, Arrazola PJ (2019) State-space analysis of mode-coupling workpiece chatter. Int J Adv Manuf Technol 103(5–8):2773–2781. https://doi.org/10.1007/s00170-019-03737-8

Pan ZX, Zhang H, Zhu ZQ, Wang JJ (2005) Chatter analysis of robotic machining process. J Mater Process Tech 173(3):301–309. https://doi.org/10.1016/j.jmatprotec.2005.11.033

Iturrospe A, Atxa V, Abete JM (2006) State-space analysis of mode-coupling in orthogonal metal cutting under wave regeneration. Int J Mach Tools Manuf 47(10):1583–1592. https://doi.org/10.1016/j.ijmachtools.2006.11.005

Zhang XJ, Xiong CH, Ding Y, Feng MJ, Xiong YL (2011) Milling stability analysis with simultaneously considering the structural mode coupling effect and regenerative effect. Int J Mach Tools Manuf 53(1):127–140. https://doi.org/10.1016/j.ijmachtools.2011.10.004

Ji YJ, Wang XB, Liu ZB, Wang HJ, Jiao L, Zhang L, Huang T (2018) Milling stability prediction with simultaneously considering the multiple factors coupling effects-regenerative effect, mode coupling, and process damping. Int J Adv Manuf Technol 97(5–8):2509–2527. https://doi.org/10.1007/s00170-018-2017-7

Dai YB, Li HK, Wei ZC (2019) Modeling method for chatter stability lobes of ball-end mill based on precise integration. J Vib Meas Diagn 39(03):525–530. https://doi.org/10.16450/j.cnki.issn.1004-6801.2019.03.010

Tlusty J, Polacek M (2007) The stability of the machine tool against self-excited vibration in machining. In: Proceedings of the ASME Production Engineering Research Conference. ASME, pp 465–474. https://doi.org/10.17973/MMSJ.2013_12_201314

Drobilek J, Polacek M, Bach P, Janota M (2019) Improved dynamic cutting force model with complex coefficients at orthogonal turning. Int J Adv Manuf Technol 103(5–8):2691–2705. https://doi.org/10.1007/s00170-019-03715-0

Xia Y, Wan Y, Luo XC, Liu ZQ, Song QH (2021) Milling stability prediction based on the hybrid interpolation scheme of the Newton and Lagrange polynomials. Int J Adv Manuf Technol 112(5–6):1501–1512. https://doi.org/10.1007/S00170-020-06420-5

Gao SH, Meng G, Long XH (2011) Study of milling stability with Hertz contact stiffness of ball bearings. Arch Appl Mech 81(8):1141–1151. https://doi.org/10.1007/s00419-010-0475-y

Tang YY, Zhang J, Tian H, Liu HG, Zhao WH (2023) Optimization method of spindle speed with the consideration of chatter and forced vibration for five-axis flank milling. Int J Adv Manuf Technol 125(7–8):3159–3169. https://doi.org/10.1007/S00170-023-10894-4

Tong X, Liu Q, Wang LQ, Sun PP (2023) A parameter optimization method for chatter stability in five-axis milling. Machines 11(1):79–79. https://doi.org/10.3390/MACHINES11010079

Xiong GL, Yi JM, Zeng C, Guo HK, Li LX (2003) Study of the gyroscopic effect of the spindle on the stability characteristics of the milling system. J Mater Process Tech 138(1):379–384. https://doi.org/10.1016/S0924-0136(03)00102-X

Movahhedy MR, Mosaddegh P (2005) Prediction of chatter in high speed milling including gyroscopic effects. Int J Mach Tools Manuf 46(9):996–1001. https://doi.org/10.1016/j.ijmachtools.2005.07.043

Sun SS, Tang WX, Huang HF, Xu XQ (2009) Dynamics and stability of milling process considering the gyroscopic effects. Adv Mater Res 849(76–78):624–629. https://doi.org/10.4028/www.scientific.net/AMR.76-78.624

Altıntas Y, Engin S, Budak E (1999) Analytical stability prediction and design of variable pitch cutters. J Manuf Sci Eng 121(2):173–178. https://doi.org/10.1115/1.2831201

Budak E (2003) An analytical design method for milling cutters with nonconstant pitch to increase stability, part I: theory. J Manuf Sci Eng 125(1):29–34. https://doi.org/10.1115/1.1536655

Budak E (2003) An analytical design method for milling cutters with nonconstant pitch to increase stability, part 2: application. J Manuf Sci Eng 125(1):35–38. https://doi.org/10.1115/1.1536656

Turner S, Merdol D, Altintas Y, Ridgway K (2006) Modelling of the stability of variable helix end mills. Int J Mach Tools Manuf 47(9):1410–1416. https://doi.org/10.1016/j.ijmachtools.2006.08.028

Dombovari Z, Stepan G (2012) The effect of helix angle variation on milling stability. J Manuf Sci Eng 134(5):1–6. https://doi.org/10.1115/1.4007466

Sellmeier V, Denkena B (2010) Stable islands in the stability chart of milling processes due to unequal tooth pitch. Int J Mach Tools Manuf 51(2):152–164. https://doi.org/10.1016/j.ijmachtools.2010.09.007

Otto A, Rauh S, Ihlenfeldt S, Radons G (2017) Stability of milling with non-uniform pitch and variable helix Tools. Int J Adv Manuf Technol 89(9–12):2613–2625. https://doi.org/10.1007/s00170-016-9762-2

Guo Y, Lin B, Wang WQ (2019) Optimization of variable helix cutter for improving chatter stability. Int J Adv Manuf Technol 104(5–8):2553–2565. https://doi.org/10.1007/s00170-019-03927-4

Zhao MX, Balachandran B (2001) Dynamics and stability of milling process. Int J Solids Struct 38(10):2233–2248. https://doi.org/10.1016/S0020-7683(00)00164-5

Balachandran B, Zhao MX (2000) A mechanics based model for study of dynamics of milling operations. Meccanica 35(2):89–109. https://doi.org/10.1023/A:1004887301926

Liu T, Deng ZH, Lv LS, She SL, Liu W, Luo CY (2020) Experimental analysis of process parameter effects on vibrations in the high-speed grinding of a camshaft. Strojniški Vestnik-J Mech Eng 66(3):175–183. https://doi.org/10.5545/sv-jme.2019.6294

Li HQ, Shin YC (2006) Wheel regenerative chatter of surface grinding. J Manuf Sci Eng 128(2):393–403. https://doi.org/10.1115/1.2137752

Yaser M, Keivan A (2022) Finite-amplitude stability in regenerative chatter: the effect of process damping nonlinearity and intermittent cutting in turning. J Sound Vib 537:117158. https://doi.org/10.1016/J.JSV.2022.117158

Balachandran B (2001) Nonlinear dynamics of milling processes. Philos Trans: Math Phys Eng Sci 359(1781):793–819. https://doi.org/10.1098/rsta.2000.0755

Banihasan M, Bakhtiari-Nejad F (2011) Chaotic vibrations in high-speed milling. Nonlinear Dyn 66(4):557–574. https://doi.org/10.1007/s11071-010-9935-8

Rahnama R, Sajjadi M, Park SS (2009) Chatter suppression in micro end milling with process damping. J Mater Process Tech 209(17):5766–5776. https://doi.org/10.1016/j.jmatprotec.2009.06.009

Afazov SM, Ratchev SM, Segal J, Popov AA (2012) Chatter modelling in micro-milling by considering process nonlinearities. Int J Mach Tools Manuf 56:28–38. https://doi.org/10.1016/j.ijmachtools.2011.12.010

Afazov SM, Zdebski D, Ratchev SM, Segal J, Liu S (2012) Effects of micro-milling conditions on the cutting forces and process stability. J M Process Tech 213(5):671–684. https://doi.org/10.1016/j.jmatprotec.2012.12.001

Jin XL, Altintas Y (2013) Chatter stability model of micro-milling with process damping. J Manuf Sci Eng 135(3):1–9. https://doi.org/10.1115/1.4024038

Song QH, Liu ZQ, Shi ZY (2014) Chatter stability for micromilling processes with flat end mill. Int J Adv Manuf Technol 71(5–8):1159–1174. https://doi.org/10.1007/s00170-013-5554-0

Eynian M, Magnevall M, Cedergren S, Wretland A, Lundblad M (2018) New methods for in-process identification of modal parameters in milling. Procedia CIRP 77:469–472. https://doi.org/10.1016/j.procir.2018.08.269

Pour M, Torabizadeh MA (2016) Improved prediction of stability lobes in milling process using time series analysis. J Intell Manuf 27(3):665–677. https://doi.org/10.1007/s10845-014-0904-9

Mithilesh KD, Asit BP, Atanu M (2017) Chatter and dynamic cutting force prediction in high-speed ball end milling. Mach Sci Technol 21(2):291–312. https://doi.org/10.1080/10910344.2017.1284560

Qu XT, Zang JH, Wang X (2018) Analysis and research on the modal experiment of series-parallel hybrid grinding and polishing machine. MATEC Web Conf 175:02018. https://doi.org/10.1051/matecconf/201817502018

Liu T, Deng ZH, Luo CY, Lv LS, Li CY, Wan LL (2021) Stability modeling and analysis of non-circular high-speed grinding with consideration of dynamic grinding depth. J Mech Eng 57(15):264–274. https://doi.org/10.3901/JME.2021.15.264

Eynian M (2019) In-process identification of modal parameters using dimensionless relationships in milling chatter. Int J Mach Tools Manuf 143:49–62. https://doi.org/10.1016/j.ijmachtools.2019.04.003

Kolář P, Janota M, Švéda J, Kozlok T (2021) Method for safe experimental testing of machine tool usable spindle power. MM Sci J 11:5167–5174. https://doi.org/10.17973/MMSJ.2021_11_2021176

Li XZ, Yue XB, Huang W, Dong XJ, Peng ZK (2019) Vibration response transmissibility and operational modal analysis methods: a review and comparative study. J Vib Shock 38(18):24–34+45. https://doi.org/10.13465/j.cnki.jvs.2019.18.004

Guo ML, Wei ZC, Wang MJ, Li SQ, Wang J, Liu SX (2020) Modal parameter identification of general cutter based on milling stability theory. J Intell Manuf 32:1–15. https://doi.org/10.1007/s10845-020-01569-y

Zaghbani I, Songmene V (2009) Estimation of machine-tool dynamic parameters during machining operation through operational modal analysis. Int J Mach Tools Manuf 49(12):947–957. https://doi.org/10.1016/j.ijmachtools.2009.06.010

Mao XY, Luo B, Li B, Cai H, Liu HQ, Pen FY (2014) An approach for measuring the FRF of machine tool structure without knowing any input force. Int J Mach Tools Manuf 86:62–67. https://doi.org/10.1016/j.ijmachtools.2014.07.004

Yin L, Li CH, Qin C, Peng YL, Gu JR, Zhang F, Li S, Song ZQ (2020) Identification method of modal parameters of machine tools under periodic cutting excitation. IEEE Access 8:120850–120858. https://doi.org/10.1109/access.2020.3006226

Yuan JC, Li JS, Wei W, Liu PK (2022) Operational modal identification of ultra-precision fly-cutting machine tools based on least-squares complex frequency-domain method. Int J Adv Manuf Technol 119:4385–4394. https://doi.org/10.1007/S00170-021-08469-2

Liu DS, Luo M, Zhang Z, Hu Y, Zhang DH (2022) Operational modal analysis based dynamic parameters identification in milling of thin-walled workpiece. Mech Syst Sig Process 167(PA):108469. https://doi.org/10.1016/J.YMSSP.2021.108469

Pedrammehr S, Farrokhi H, Rajab AKS, Pakzad S, Mahboubkhah M, Ettefagh MM, Sadeghi MH (2011) Modal analysis of the milling machine structure through FEM and experimental test. Adv Mater Res 383–390:6717–6721. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/AMR.383-390.6717

Pakzad S, Rajab AKS, Mahboubkhah M, Ettefagh MM (1936) Masoudi O (2012) Modal analysis of the surface grinding machine structure through FEM and experimental test. Adv Mater Res 566:353–356. https://doi.org/10.4028/www.scientific.net/AMR.566.353

Mahboubkhah M, Pakzad S, Arasi AG, Ettefagh MM (2017) Modal analysis of the vertical moving table of 4-DOF parallel machine tool by FEM and experimental test. J Vibroeng 19(7):5301–5309. https://doi.org/10.21595/jve.2017.18394

Ramos JC, Vinolas J, Nieto FJ (2001) A simplified methodology to determine the cutting stiffness and the contact stiffness in the plunge grinding process. Int J Mach Tools Manuf 41(1):33–49. https://doi.org/10.1016/S0890-6955(00)00062-6

Chi YL, Li HL (2016) Study on Contact stiffness and natural frequency cylindrical plunge grinding. Chin Mech Eng 27(10):1294–1298. https://doi.org/10.3969/j.issn.1004-132X.2016.10.003

Chi YL, Li HL, Chen X (2017) In-process monitoring and analysis of bearing outer race way grinding based on the power signal. Proc Inst Mech Eng Part B: J Eng Manuf 231(14):2622–2635. https://doi.org/10.1177/0954405416635032

An Q, Suo SF, Lin FY, Shi JW (2019) A novel micro-contact stiffness model for the grinding surfaces of steel materials based on cosine curve-shaped asperities. Materials 12(21):3561–3561. https://doi.org/10.3390/ma12213561

Liu Y, An Q, Shang DY, Bai L, Huang M, Huang SQ (2022) Research on normal contact stiffness of rough joint surfaces machined by turning and grinding. Metals 12(4):1–14. https://doi.org/10.3390/MET12040669

Zhang C, Yu WN, Yin L, Zeng Q, Chen ZX, Shao YM (2023) Modeling of normal contact stiffness for surface with machining textures and analysis of its influencing factors. Int J Solids Struct 262–263:112042. https://doi.org/10.1016/J.IJSOLSTR.2022.112042

Merritt HE (1965) Theory of self-excited machine-tool chatter: contribution to machine-tool chatter research-1. J Eng Ind 87(4):447–454. https://doi.org/10.1115/1.3670861

Tobias SA (1965) Machine tool vibration. Blackie and Sons Ltd Press, New York

Gao C (2020) Grinding force modeling and experimental analysis based on axial feed grinding of hard and brittle materials. Dissertation, Wenzhou University

Liu AM, Peng C, Liu JZ, Kruth JP, Vanherck P (2007) Diagnosis of chatter during high-speed milling and forecast of stable machining areas. J Mech Eng 01:164–169. https://doi.org/10.3321/j.issn:0577-6686.2007.01.027

Quintana G, Ciurana J, Teixidor D (2008) A new experimental methodology for identification of stability lobes diagram in milling operations. Int J Mach Tools Manuf 48(15):1637–1645. https://doi.org/10.1016/j.ijmachtools.2008.07.006

Zhang HB, Li L, Feng D, Li JG, Miao EM (2020) Fast drawing method of chatter lobe based on modal parameter and milling experiment. Tool Eng 54(11):108–111. https://doi.org/10.3969/j.issn.1000-008.2020.11.025

Peng C, Wang L, Liao TW (2015) A new method for the prediction of chatter stability lobes based on dynamic cutting force simulation model and support vector machine. J Sound Vib 354:118–131. https://doi.org/10.1016/j.jsv.2015.06.011

Friedrich J, Hinze C, Renner A, Verl A, Lechler A (2017) Estimation of stability lobe diagrams in milling with continuous learning algorithms. Robot Comput Integr Manuf 43:124–134. https://doi.org/10.1016/j.rcim.2015.10.003

Friedrich J, Torzewski J, Verl A (2018) Online learning of stability lobe diagrams in milling. Procedia CIRP 67:278–283. https://doi.org/10.1016/j.procir.2017.12.213

Denkena B, Bergmann B, Reimer S (2020) Analysis of different machine learning algorithms to learn stability lobe diagrams. Procedia CIRP 88(C):282–287. https://doi.org/10.1016/j.procir.2020.05.049

Ma YC, Yang JG (2015) Multi-sensor intelligent monitoring of high-speed grinding for brittle and hard materials. Appl Mech Mater 3844(741–741):309–314. https://doi.org/10.4028/www.scientific.net/AMM.741.309

Luo Z, Wang JW, Han QK, Wang DY (2021) Review on dynamics of the combined support-rotor system. J Mech Eng 57(07):44–60. https://doi.org/10.3901/JME.2021.07.044

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann Manuf Technol 44(1):357–362. https://doi.org/10.1016/S0007-8506(07)62342-7

Budak E, Ozlu E (2007) Analytical Modeling of chatter stability in turning and boring operations: a multi-dimensional approach. CIRP Ann Manuf Technol 56(1):401–404. https://doi.org/10.1016/j.cirp.2007.05.093

Ozlu E, Budak E (2007) Analytical modeling of chatter stability in turning and boring operations-part II: experimental verification. J Manuf Sci Eng 129(4):733–739. https://doi.org/10.1115/1.2738119

Bravo U, Altuzarra O, López de Lacalle LN, Sánchez JA, Campa FJ (2005) Stability limits of milling considering the flexibility of the workpiece and the machine. Int J Mach Tools Manuf 45(15):1669–1680. https://doi.org/10.1016/j.ijmachtools.2005.03.004

Wan M, Ma YC, Zhang WH, Yang Y (2015) Study on the construction mechanism of stability lobes in milling process with multiple modes. Int J Adv Manuf Technol 79(1–4):589–603. https://doi.org/10.1007/s00170-015-6829-4

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling-part I: general formulation. J Dyn Syst Meas Contr 120(1):22–30. https://doi.org/10.1115/1.2801317

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling-part II: application of the general formulation to common milling systems. J Dyn Syst Meas Contr 120(1):31–36. https://doi.org/10.1115/1.2801318

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466. https://doi.org/10.1115/1.1765139

Bachrathy D, Stepan G (2013) Improved prediction of stability lobes with extended multi frequency solution. CIRP Ann Manuf Technol 62(1):411–414. https://doi.org/10.1016/j.cirp.2013.03.085

Tang AJ, Liu ZQ (2009) Three-dimensional stability lobe and maximum material removal rate in end milling of thin-walled plate. Int J Adv Manuf Technol 43(1/2):33–39. https://doi.org/10.1007/s00170-008-1695-y

Wang MH, Gao L, Zhang YH (2014) Prediction of regenerative chatter in the high-speed vertical milling of thin-walled workpiece made of titanium alloy. Int J Adv Manuf Technol 72:707–716. https://doi.org/10.1007/s00170-014-5641-x

Yan BL, Zhu LD (2019) Research on milling stability of thin-walled parts based on improved multi-frequency solution. Int J Adv Manuf Technol 102(1):431–441. https://doi.org/10.1007/s00170-018-03254-0

Smith S, Tlusty J (1993) Efficient simulation programs for chatter in milling. CIRP Ann 42(1):463–466. https://doi.org/10.1016/S0007-8506(07)62486-X

Campomanes ML, Altintas Y (2003) An improved time domain simulation for dynamic milling at small radial immersions. J Manuf Sci Eng 125(3):416–422. https://doi.org/10.1115/1.1580852

Li HZ, Li XP, Chen XQ (2003) A novel chatter stability criterion for the modelling and simulation of the dynamic milling process in the time domain. Int J Adv Manuf Technol 22(9–10):619–625. https://doi.org/10.1007/s00170-003-1562-9

Schmitz TL, Medicus K, Dutterer B (2002) Exploring once-per-revolution audio signal variance as a chatter. Mach Sci Technol 6(2):215–233. https://doi.org/10.1081/MST-120005957

Li ZQ, Liu Q (2008) Solution and analysis of chatter stability for end milling in the time-domain. Chin J Aeronaut 21(2):169–178. https://doi.org/10.1016/S1000-9361(08)60022-9

Sims ND (2005) The self-excitation damping ratio: a chatter criterion for time-domain milling simulations. J Manuf Sci Eng 127(3):433–445. https://doi.org/10.1115/1.1948393

Rott O (2011) Simulation and stability of milling processes. University library of the Technical University Press, Berlin

Ma YC, Wan M, Zhang WH (2016) Time domain simulation of milling chatter stability. Mater Sci Forum 3901(836–837):94–98. https://doi.org/10.4028/www.scientific.net/MSF.836-837.94

Chen Y, Hou L, Liu WZ, Pu XJ (2021) Chatter stability prediction in low immersion milling based on time-domain simulation. Int J Adv Manuf Technol 57(03):98–106. https://doi.org/10.3901/JME.2021.03.098

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Meth Eng 55(5):503–518. https://doi.org/10.1002/nme.505

Insperger T, Stepan G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Meth Eng 61:117–141. https://doi.org/10.1002/nme.1061

Wan M, Zhang WH, Dang JW, Yang Y (2010) A unified stability prediction method for milling process with multiple delays. Int J Mach Tools Manuf 50(1):29–41. https://doi.org/10.1016/j.ijmachtools.2009.09.009

Wan M, Ma YC, Zhang WH, Yang Y (2015) Study on the construction mechanism of stability lobes in milling process with multiple modes. Int J Adv Manuf Technol 79:589–603. https://doi.org/10.1007/s00170-015-6829-4

Alvarez J, Zatarain M, Barrenetxea D, Ortega N, Gallego I (2013) Semi-discretization for stability analysis of in-feed cylindrical grinding with continuous workpiece speed variation. Int J Adv Manuf Technol 69(1–4):113–120. https://doi.org/10.1007/s00170-013-4993-y

Insperger T, Stépán G, Turi J (2007) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1):334–341. https://doi.org/10.1016/j.jsv.2007.11.040

Li ZW, Long XH, Meng G (2009) Stability analysis of milling process by semi-discretization method based on Magnus-Gaussian truncation. J Vib Shock 28(05):69–73205. https://doi.org/10.13465/j.cnki.jvs.2009.05.002

Jiang S, Sun Y, Yuan X, Liu W (2017) A second-order semi-discretization method for the efficient and accurate stability prediction of milling process. Int J Adv Manuf Technol 92(1–4):583–595. https://doi.org/10.1007/s00170-017-0171-y

Zhang CF, Yan ZH, Jiang XG (2021) Numerical integration scheme–based semi-discretization methods for stability prediction in milling. Int J Adv Manuf Technol 115:397–411. https://doi.org/10.1007/S00170-021-07069-4

Liu KN, Zhang Y, Gao XY, Yang WX, Sun W, Dai F (2021) Improved semi-discretization method based on predictor-corrector scheme for milling stability analysis. Int J Adv Manuf Technol 114(11-12):1–13. https://doi.org/10.1007/S00170-021-06747-7

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509. https://doi.org/10.1016/j.ijmachtools.2010.01.003

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) Second-order full-discretization method for milling stability prediction. Int J Mach Tools Manuf 50(10):926–932. https://doi.org/10.1016/j.ijmachtools.2010.05.005

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66. https://doi.org/10.1016/j.ijmachtools.2012.05.001

Liu YL, Zhang DH, Wu BH (2012) An efficient full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 63:44–48. https://doi.org/10.1016/j.ijmachtools.2012.07.008

Tang XW, Pen FY, Yan R, Gong YT, Li YT, Jiang LL (2017) Accurate and efficient prediction of milling stability with updated full-discretization method. Int J Adv Manuf Technol 88(9–12):2357–2368. https://doi.org/10.1007/s00170-016-8923-7

Yan ZH, Wang XB, Liu ZB, Wang DQ, Jia L, Ji YJ (2017) Third-order updated full-discretization method for milling stability prediction. Int J Adv Manuf Technol 92(5–8):2299–2309. https://doi.org/10.1007/s00170-017-0243-z

Ji YJ, Wang XB, Liu ZB, Wang HJ, Yan ZH (2018) An updated full-discretization milling stability prediction method based on the higher-order Hermite-Newton interpolation polynomial. Int J Adv Manuf Technol 95(5):2227–2242. https://doi.org/10.1007/s00170-017-1409-4

Wu Y, You YP, Jiang JJ (2020) New predictor-corrector methods based on piecewise polynomial interpolation for milling stability prediction. Mach Sci Technol 24(5):688–718. https://doi.org/10.1080/10910344.2020.1752235

Huang C, Yang WA, Cai X, Liu W, You Y (2020) An efficient third-order full-discretization method for prediction of regenerative chatter stability in milling. Shock Vib 2020:1–16. https://doi.org/10.1155/2020/9071451

Ji YJ, Wang LY, Song Y, Wang HJ, Liu ZB (2022) Investigation of robotic milling chatter stability prediction under different cutter orientations by an updated full-discretization method. J Sound Vib 536:117150. https://doi.org/10.1016/J.JSV.2022.117150

Ozoegwu CG (2014) Least squares approximated stability boundaries of milling process. Int J Mach Tools Manuf 79:24–30. https://doi.org/10.1016/j.ijmachtools.2014.02.001

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9. https://doi.org/10.1016/j.ijmachtools.2015.02.007

Yan ZH, Wang XB, Liu ZB, Wang DQ, Ji YJ, Jiao L (2017) Orthogonal polynomial approximation method for stability prediction in milling. Int J Adv Manuf Technol 91(9–12):4313–4330. https://doi.org/10.1007/s00170-017-0067-x

Li MZ, Zhang GJ, Huang Yu (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71(1–2):187–199. https://doi.org/10.1007/s11071-012-0651-4

Niu JB, Ding Y, Zhu LM, Ding H (2014) Runge-Kutta methods for a semi-analytical prediction of milling stability. Nonlinear Dyn 76(1):289–304. https://doi.org/10.1007/s11071-013-1127-x

Li ZQ, Yang ZK, Peng YR, Zhu F, Ming XZ (2016) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol 86(1–4):943–952. https://doi.org/10.1007/s00170-015-8207-7

Bayly PV, Halley JE, Mann BP, Davies MA (2003) Stability of interrupted cutting by temporal finite element analysis. Trans ASME-J Manuf Sci Eng 125:220–225. https://doi.org/10.1115/1.1556860

Sims ND, Mann BP, Huyanan S (2008) Analytical prediction of chatter stability for variable pitch and variable helix milling tools. J Sound Vib 317(3):664–686. https://doi.org/10.1016/j.jsv.2008.03.045

Mann BP, Edes BT, Easley SJ, Young KA, Ma K (2008) Chatter vibration and surface location error prediction for helical end mills. Int J Mach Tools Manuf 48(3):350–361. https://doi.org/10.1016/j.ijmachtools.2007.10.003

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):1–9. https://doi.org/10.1115/1.4004136

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Milling stability analysis using the spectral method. Sci Chin Technol Sci 54(12):3130–3136. https://doi.org/10.1007/s11431-011-4611-x

Zhang XJ, Xiong CH, Ding Y, Xiong YL (2011) Variable-step integration method for milling chatter stability prediction with multiple delays. Sci Chin Technol Sci 54(12):3137–3154. https://doi.org/10.1007/s11431-011-4599-2

Ding Y, Zhu LM, Zhang XJ, Ding H (2013) Stability analysis of milling via the differential quadrature method. J Manuf Sci Eng 135(4):044502. https://doi.org/10.1115/1.4024539

Zhang Z, Li HG, Meng G, Li C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47. https://doi.org/10.1016/j.ijmachtools.2015.09.002

Zhang XJ, Xiong CH, Ding Y, Ding H (2017) Prediction of chatter stability in high speed milling using the numerical differentiation method. Int J Adv Manuf Technol 89(9–12):2535–2510. https://doi.org/10.1007/s00170-016-8708-z

Qin CJ, Tao JF, Liu CJ (2017) Stability analysis for milling operations using an Adams-Simpson-based method. Int J Adv Manuf Technol 92(1–4):969–979. https://doi.org/10.1007/s00170-017-0186-4

Qin CJ, Tao JF, Li L, Liu CJ (2017) An Adams-Moulton-based method for stability prediction of milling processes. Int J Adv Manuf Technol 89(9–12):3049–3058. https://doi.org/10.1007/s00170-016-9293-x

Dai YB, Li HK, Xing XY, Hao BT (2018) Prediction of chatter stability for milling process using precise integration method. Precis Eng 52:152–157. https://doi.org/10.1016/j.precisioneng.2017.12.003

Li HK, Dai YB, Fan ZF (2019) Improved precise integration method for chatter stability prediction of two-DOF milling system. Int J Adv Manuf Technol 101(5):1235–1246. https://doi.org/10.1007/s00170-018-2981-y

Zhi HY, Zhang TS, Du J, Yan XG (2020) An efficient full-discretization method for milling stability prediction. Int J Adv Manuf Technol 107:1–13. https://doi.org/10.1007/s00170-020-05290-1

Dong XF, Qiu ZZ (2020) Stability analysis in milling process based on updated numerical integration. Mech Syst Sig Process 137(C):106435. https://doi.org/10.1016/j.ymssp.2019.106435

Xia Y, Wan Y, Su GS, Du J, Zhang PR, Xu CH (2022) An improved numerical integration method for prediction of milling stability using the Lagrange-Simpson interpolation scheme. Int J Adv Manuf Technol 120(11–12):8105–8115. https://doi.org/10.1007/S00170-022-09245-6

Liu WC, Yang WA, Chen YX, You YP (2022) A novel precise integration-based updated numerical integration method for milling stability prediction. Int J Adv Manuf Technol 124(7–8):2109–2126. https://doi.org/10.1007/S00170-022-10372-3

Junior MV, Baptista EA, Araki L, Smith S, Schmitz T (2018) The role of tool presetting in milling stability uncertainty. Proc Manuf 26:164–172. https://doi.org/10.1016/j.promfg.2018.07.023

Liu Y, Li TX, Liu K, Zhang YM (2016) Chatter reliability prediction of turning process system with uncertainties. Mech Syst Signal Process 66–67:232–247. https://doi.org/10.1016/j.ymssp.2015.06.030

Feng JL, Sun ZL, Sun HZ, Chai XD (2015) Investigation of the milling chatter and its probability. Modul Mach Tool Autom Manuf Tech 12:8–11. https://doi.org/10.13462/j.cnki.mmtamt.2015.12.003

Huang XZ, Hu S, Zhang YM (2017) On the calculation method for the reliability of chatter stability in CNC milling. J Northe Univ (Nat Sci) 38(05):675–679. https://doi.org/10.3969/j.issn.1005-3026.2017.05.014

Huang XZ, Xu YC, Zhang YM, Tan XF (2016) Simulation of chatter stability reliability in turning machining monte carlo method. J Vib Meas Diagn 36(03):484–487+603. https://doi.org/10.16450/j.cnki.issn.1004-6801.2016.03.012

Löser M, Otto A, Ihlenfeldt S, Radons G (2018) Chatter prediction for uncertain parameters. Adv Manuf 6(3):319–333. https://doi.org/10.1007/s40436-018-0230-0

Zhang N, Shi YY, Chen Z, Chen HX, Liu J, Zhao P (2021) Chatter reliability prediction of overall leaf disc side milling. J Northw Polytech Univ 39(01):111–118. https://doi.org/10.1051/jnwpu/20213910111

Jiang GJ, Wu DW, Zhang N, Wu JX, Wang Y (2020) Chatter reliability prediction of side milling aero-engine blisk. J Mech Sci Technol 34(10):1–9. https://doi.org/10.1007/s12206-020-2211-z

Sun C, Niu Y, Liu WY, Xiu S (2017) Study on the surface topography considering grinding chatter based on dynamics and reliability. Int J Adv Manuf Technol 92(9–12):1–14. https://doi.org/10.1007/s00170-017-0385-z

Huang XZ, Zhang YM, Lv CM (2016) Probabilistic analysis of dynamic stability for milling process. Nonlinear Dyn 86(3):2105–2114. https://doi.org/10.1007/s11071-016-3019-3

Huang XZ, Zhang YM, Lv CM (2016) Probabilistic analysis of chatter stability in turning. Int J Adv Manuf Technol 87(9–12):3225–3232. https://doi.org/10.1007/s00170-016-8672-7

Liu Y, Meng LL, Liu K, Zhang YM (2016) Chatter reliability of milling system based on first-order second-moment method. Int J Adv Manuf Technol 87(1–4):1–9. https://doi.org/10.1007/s00170-016-8523-6

Liu Y, He FX (2019) Study on the chatter Stability of robotic milling based on the probability method. J Northe Univ (Nat Sci) 40(05):683–687. https://doi.org/10.12068/j.issn.1005-3026.2019.05.015

Liu Y, Wang ZY, Liu K, Zhang YM (2017) Chatter stability prediction in milling using time-varying uncertainties. Int J Adv Manuf Technol 89(9–12):2627–2636. https://doi.org/10.1007/s00170-016-9856-x

Li K, He SP, Liu HQ, Mao XY, Li B, Luo B (2020) Bayesian uncertainty quantification and propagation for prediction of milling stability lobe. Mech Syst Sig Process 138(C):106532. https://doi.org/10.1016/j.ymssp.2019.106532

Duncan GS, Kurdi MH, Schmitz TL (2006) Uncertainty propagation for selected analytical milling stability limit analyses. North American Manufacturing Research Conference, Florida

Zhang XM, Zhu LM, Zhang D, Ding H, Xiong YL (2012) Numerical robust optimization of spindle speed for milling process with uncertainties. Int J Mach Tools Manuf 61:9–19. https://doi.org/10.1016/j.ijmachtools.2012.05.002

Sims ND, Manson G, Mann B (2009) Fuzzy stability analysis of regenerative chatter in milling. J Sound Vib 329(8):1025–1041. https://doi.org/10.1016/j.jsv.2009.10.024

Hamann D, Walz NP, Fischer A, Hanss M, Eberhard P (2018) Fuzzy arithmetical stability analysis of uncertain machining systems. Mech Syst Signal Process 98:534–547. https://doi.org/10.1016/j.ymssp.2017.05.012

Yan Y, Xu J, Wiercigroch M (2017) Regenerative chatter in a plunge grinding process with workpiece imbalance. Int J Adv Manuf Technol 89(9–12):2845–2862. https://doi.org/10.1007/s00170-016-9830-7

Ding WF, Cao Y, Zhao B, Xu JH (2022) Research status and future prospects of ultrasonic vibration-assisted grinding technology and equipment. Journal of Mechanical Engineering 58(09):244–269. https://doi.org/10.3901/JME.2019.01.189

Sonia P, Jain JK, Saxena KK (2021) Influence of ultrasonic vibration assistance in manufacturing processes: a review. Mater Manuf Process 36(13):1451–1475. https://doi.org/10.1080/10426914.2021.1914843

Funding

This work was supported by the Special Fund for the Construction of Hunan Innovative Province (grant no. 2022GK4025), Hunan Provincial Innovation Foundation for Postgraduate (grant no. CX20221043), and the Natural Science Foundation of Hunan Province (grant no. 2020JJ4309).

Author information

Authors and Affiliations

Contributions

Xianyang Zhang and Linlin Wan provided ideas for the paper; Xianyang Zhang collected data and wrote the paper. Linlin Wan and Xiaoru Ran provided guidance and advice on the whole frame of the paper.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors agree to participate to this study.

Consent for publication

All authors agree to publish to this paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, X., Wan, L. & Ran, X. Research progress on the chatter stability in machining systems. Int J Adv Manuf Technol 131, 29–62 (2024). https://doi.org/10.1007/s00170-024-13050-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13050-8