Abstract

This paper studies self-excited vibrations, regenerative and frictional chatters, in a plunge grinding process. In consideration of lateral and torsional workpiece movements, a dynamic model with four degrees of freedom is proposed, which involves state-dependent time delays and Stribeck effect for regenerative and frictional effects, respectively. With this model, by linearising contact angle, regenerative grinding depth, frictional velocity and the state-dependent delays, eigenvalue analysis yields stability diagrams for the grinding, where boundaries for both regenerative and frictional instabilities are determined. Then, near the boundaries, simulations and bifurcation analyses are performed to reveal patterns of chatter onset. Bifurcation diagrams show coexistence of stable grinding and the regenerative chatter near the regenerative boundary, and a sudden switch between the stable and the frictionally unstable on the frictional boundary. Moreover, simulation results also show various dynamical properties in the grinding chatters, such as effect of losing contact and stick–slip motion.

Similar content being viewed by others

References

Altintas, Y., Weck, M.: Chatter stability of metal cutting and grinding. CIRP Ann. Manuf. Technol. 53(2), 619–642 (2004). doi:10.1016/S0007-8506(07)60032-8

Armstrong-Hlouvry, B.: Control of Machines with Friction. Kluwer Academic Press, Hingham, MA (1991)

Armstrong-Hlouvry, B., Dupont, P., De Wit, C.C.: A survey of models, analysis tools and compensation methods for the control of machines with friction. Automatica 30(7), 1083–1138 (1994). doi:10.1016/0005-1098(94)90209-7

Chung, K.W., Liu, Z.: Nonlinear analysis of chatter vibration in a cylindrical transverse grinding process with two time delays using a nonlinear time transformation method. Nonlinear Dyn. 66, 441–456 (2011). doi:10.1007/s11071-010-9924-y

Durgumahanti, U.S.P., Singh, V., Rao, P.V.: A new model for grinding force prediction and analysis. Int. J. Mach. Tools Manuf. 50(3), 231–240 (2010). doi:10.1016/j.ijmachtools.2009.12.004

Ermentrout, B.: Simulating, Analyzing, and Animating Dynamical Systems: A Guide to XPPAUT for Researchers and Students. Society for Industrial and Applied Mathematics, Philadelphia (2002)

Grabec, I.: Chaos generated by the cutting process. Phys. Lett. A 117(8), 384–386 (1986). doi:10.1016/0375-9601(86)90003-4

Hastings, W.F., Mathew, P., Oxley, P.L.B.: A machining theory for predicting chip geometry, cutting forces etc. from work material properties and cutting conditions. Proc. R. Soc. Lond. A Math. Phys. Sci. 371(1747), 569–587 (1980)

Hesterman, D., Stone, B.: Improved model of chatter in grinding, including torsional effects. J. Multi-body Dyn. 216, 169–180 (2002)

Kim, P., Jung, J., Lee, S., Seok, J.: Stability and bifurcation analyses of chatter vibrations in a nonlinear cylindrical traverse grinding process. J. Sound Vib. 332(15), 3879–3896 (2013). doi:10.1016/j.jsv.2013.02.009

Li, H.Q., Shin, Y.C.: A time-domain dynamic model for chatter prediction of cylindrical plunge grinding processes. ASME J. Manuf. Sci. Eng. 128(2), 404–415 (2006). doi:10.1115/1.2118748

Lichun, L., Jizai, F., Peklenik, J.: A study of grinding force mathematical model. CIRP Ann. Manuf. Technol. 29(1), 245–249 (1980). doi:10.1016/S0007-8506(07)61330-4

Litak, G., Schubert, S., Radons, G.: Nonlinear dynamics of a regenerative cutting process. Nonlinear Dyn. 69(3), 1255–1262 (2012). doi:10.1007/s11071-012-0344-z. Nonlinear Dyn

Liu, X., Vlajic, N., Long, X., Meng, G., Balachandran, B.: Nonlinear motions of a flexible rotor with a drill bit: stick-slip and delay effects. Nonlinear Dyn. 72(1–2), 61–77 (2013). doi:10.1007/s11071-012-0690-x

Liu, X., Vlajic, N., Long, X., Meng, G., Balachandran, B.: Coupled axial-torsional dynamics in rotary drilling with state-dependent delay: stability and control. Nonlinear Dyn. 78(3), 1891–1906 (2014). doi:10.1007/s11071-014-1567-y

Liu, X., Vlajic, N., Long, X., Meng, G., Balachandran, B.: State-dependent delay influenced drill-string oscillations and stability analysis. J. Vib. Acoust. 136(5), 051008 (2014). doi:10.1115/1.4027958

Liu, Y., Pavlovskaia, E., Hendry, D., Wiercigroch, M.: Vibro-impact responses of capsule system with various friction models. Int. J. Mech. Sci. 72, 39–54 (2013). doi:10.1016/j.ijmecsci.2013.03.009

Liu, Z.H., Payre, G.: Stability analysis of doubly regenerative cylindrical grinding process. J. Sound Vib. 301(2), 950–962 (2007). doi:10.1016/j.jsv.2006.10.041

Mannan, M.A., Drew, S.J., Stone, B.J.: Torsional vibration effects in grinding. Ann. CIRP 49, 249–252 (2000)

Nayfeh, A.H.: Order reduction of retarded nonlinear systems—the method of multiple scales versus center-manifold reduction. Nonlinear Dyn. 51, 483–500 (2008). doi:10.1007/s11071-007-9237-y

Nayfeh, A.H., Balachandran, B.: Applied Nonlinear Dynamics: Analytical, Computational, and Experimental Methods. Wiley, Weinheim (2004)

Rowe, W.B.: Principles of Modern Grinding Technology. William Andrew, Burlington, MA (2009)

Rusinek, R., Kecik, K., Warminski, J., Weremczuk, A.: Dynamic model of cutting process with modulated spindle speed. AIP Conf. Proc. 1493(1), 805–809 (2012). doi:10.1063/1.4765580

Rusinek, R., Wiercigroch, M., Wahi, P.: Influence of tool flank forces on complex dynamics of cutting process. Int. J. Bifurc. Chaos 24(09), 1450,115 (2014). doi:10.1142/S0218127414501156

Rusinek, R., Wiercigroch, M., Wahi, P.: Modelling of frictional chatter in metal cutting. Int. J. Mech. Sci. 89, 167–176 (2014). doi:10.1016/j.ijmecsci.2014.08.020

Rusinek, R., Wiercigroch, M., Wahi, P.: Orthogonal cutting process modelling considering tool-workpiece frictional effect. Procedia CIRP 31, 429–434 (2015). doi:10.1016/j.procir.2015.03.033

Thompson, R.A.: On the doubly regenerative stability of a grinder. ASME J. Eng. Ind. 96(1), 275–280 (1974). doi:10.1115/1.3438310

Thompson, R.A.: On the doubly regenerative stability of a grinder: the combined effect of wheel and workpiece speed. ASME J. Eng. Ind. 99(1), 237–241 (1977). doi:10.1115/1.3439144

Thompson, R.A.: On the doubly regenerative stability of a grinder: the mathematica analysis of chatter growth. ASME J. Eng. Ind. 108(2), 83–92 (1986). doi:10.1115/1.3187055

Thompson, R.A.: On the doubly regenerative stability of a grinder: the theory of chatter growth. ASME J. Eng. Ind. 108(2), 75–82 (1986). doi:10.1115/1.3187054

Thompson, R.A.: On the doubly regenerative stability of a grinder: the effect of contact stiffness and wave filtering. ASME J. Eng. Ind. 114(1), 53–60 (1992). doi:10.1115/1.2899758

Weck, M., Hennes, N., Schulz, A.: Dynamic behaviour of cylindrical traverse grinding processes. CIRP Ann. Manuf. Technol. 50(1), 213–216 (2001). doi:10.1016/S0007-8506(07)62107-6

Werner, G.: Influence of work material on grinding forces. CIRP Ann. Manuf. Technol. 27(1), 243–248 (1978)

Wiercigroch, M., Budak, E.: Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 359(1781), 663–693 (2001). doi:10.1098/rsta.2000.0750

Wiercigroch, M., Krivtsov, A.M.: Frictional chatter in orthogonal metal cutting. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 359(1781), 713–738 (2001). doi:10.1098/rsta.2000.0752

Yan, Y., Xu, J.: Suppression of regenerative chatter in a plunge-grinding process by spindle speed. ASME J. Manuf. Sci. Eng. 135(4), 041019 (2013). doi:10.1115/1.4023724

Yan, Y., Xu, J., Wang, W.: Nonlinear chatter with large amplitude in a cylindrical plunge grinding process. Nonlinear Dyn. 69(4), 1781–1793 (2012). doi:10.1007/s11071-012-0385-3

Yan, Y., Xu, J., Wiercigroch, M.: Chatter in a transverse grinding process. J. Sound Vib. 333(3), 937–953 (2014). doi:10.1016/j.jsv.2013.09.039

Yuan, L., Keskinen, E., Jarvenpaa, V.M.: Stability analysis of roll grinding system with double time delay effects. In: Ulbrich, H., Gunthner, W. (eds.) Proceedings of IUTAM Symposium on Vibration Control of Nonlinear Mechanisms and Structures, vol. 130, pp. 375–387. Springer (2005)

Acknowledgments

This research is supported by National Natural Science Foundation of China under Grant Nos. 11572224 and 11502048 and Fundamental Research Funds for the Central Universities under Grant No. ZYGX2015KYQD033.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Coefficient of the discrete model

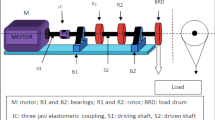

In Fig. 1, the workpiece is spatial–temporal continuum. Thus, kinetic energy of the grinding system is

In Eq. (41), the first and the second terms are translational kinetic energy of the workpiece and the disc, while the third and the forth terms represent rotational kinetic energy of the workpiece and the disc, respectively. The last term is the translational kinetic energy of the wheel. In consideration of linear elasticity of the workpiece, potential energy of the grinding is given by

where G and E are the shear and Young’s modulus of the workpiece material and \(I_o=\pi r_\text {w}^4/2\), \(I_x=\pi r_\text {w}^4/4\) and \(I_y=\pi r_\text {w}^4/4\) are the area moment of inertia of cross section of the workpiece. Given inherent material damping and interfacial damping of the grinding, the dissipation function is obtained as [14]

where \(c_\text {w}\) and \(c_\text {t}\) are the equivalent viscous damping coefficients with respect to the bending and torsional motion of the workpiece and \(c_\text {g}\) is the damping coefficient of the wheel.

To discretize the dynamic model of the grinding, the bending displacement field of the workpiece in the x direction can be defined as

where \(a_{xi}\) and \(b_{xi}\) (\(i=0,1,2,3\)) are functions of time. Corresponding to the model presented in Fig. 1, the boundary conditions with respect to \(X_\text {w}(t,S)\) are

where \(X_\text {p}(t)=X_\text {w}(t,P)\) represents the horizontal displacement of the disc. Considering Eq. (44), solving Eq. (45) yields

Symmetrically, the vertical bending deformation of the workpiece is given by

where \(Y_\text {p}(t)=Y_\text {w}(t,P)\). Similarly, the torsional displacement field \(\phi (t,S)\) of the workpiece can be defined as

where coefficients \(a_{\phi i}\) and \(b_{\phi i}\) (\(i=0,1\)) are functions of time. Its boundary conditions are

Solving Eqs. (48) and (49) yields

Next, to obtain the governing equation of the grinding process, one can use Lagrange’s equations

where the Lagrange L is \(L=T-V\), \(q_i\) represents generalised coordinates \(X_\text {g}(t)\), \(X_\text {p}(t)\), \(Y_\text {p}(t)\) and \(\phi _\text {p}(t)\) and \(Q_{q_i}\) stands for generalised force with respect to \(q_i\), respectively. Then, substituting Eqs. (41), (42), (43), (46), (47) and (50) into Eq. (51) yields Eq. (2), where the coefficients are given as follows:

Appendix 2: Coefficient matrices

In Eq. (33), the matrices \(\mathbf {M}\), \(\mathbf {C}\), \(\mathbf {K}\) and \(\mathbf {A}\) are

where

The matrix, \(\mathbf {D}\), introduced in Eq. (34) is

where

\(\mathbf {D_\text {w}}\) is

where

\(\mathbf {D_\text {g}}\) is

where

\(\mathbf {D_\text {v}}\) is

where

Appendix 3: Continuation

The continuation scheme is illustrated in Fig. 17. As shown, to start the continuation algorithm, two adjacent solutions (the ith and the \(i+1\)st solutions) are required. Then, the initial guess for the third one (the \(i+2\)nd) is given by using a relaxation parameter r; thereafter, the guess is corrected by Newton–Raphson iteration. If the iteration does not converge, the relaxation parameter is decreased for a new prediction of the third solution. On the contrary, the convergent solution is accepted so long as it is located in the predefined region. Lastly, the algorithm goes to next loop (\(i=i+1\)) if \(i<\)max_steps, or the loop is ended when sufficient solutions are obtained.

Extended stability diagram for Fig. 7a (\(p=0.1\) and \(\nu =0.006\)). More specifically, regenerative and frictional stabilities for \(v_\text {f0}<0\) (\(\omega _\text {g}r_\text {g}<\omega _\text {g}r_\text {w}\)) are investigated. In addition, Arrows V (\(\tau _\text {w0}=14.2\) and \(\kappa _\mu \in [1.1, 2]\)) and VI (\(\tau _\text {w0}=15\) and \(\kappa _\mu \in [1.1, 2]\)) are marked for further analysis

Appendix 4: Grinding dynamics for \(v_\text {f0}<0\)

Sections 3 and 4 discuss the grinding stability and the grinding dynamics for positive frictional velocity (\(v_\text {f0}>0\)). Besides, due to the non-smoothness in the frictional coefficient given in Eq. (14) and Fig. 6, one would be curious about the grinding dynamics for negative frictional velocity (\(v_\text {f0}<0\)). In that case, the frictional coefficient in Eqs. 19 and 32 is transformed into

and

Before the analysis, it should be remarked that this is only a mathematical problem, because a high rotary speed for the wheel (\(\omega _\text {g}r_\text {g}>\omega _\text {w}r_\text {p}\)) is always required for cutting the workpiece. However, this discussion is still valuable for us to understand the relationship between our model and a real grinding process in application.

As an example, Fig. 18 extends Fig. 7a to \(\tau _\text {w0}=10\). It is seen that the stability boundaries are discontinuous at \(\tau _\text {w0}=20\), where \(k_\text {f0}\) is non-smooth for zero frictional velocity. Moreover, Fig. 18 illustrates another difference between the regenerative and the frictional instabilities: the regenerative boundaries move downwards uniformly for the decrease of \(\tau _\text {w0}\), but the frictional boundaries reach the lowest point near \(\tau _\text {w0}=20\), where the Stribeck effect is more significant than any other places. Next, to represent the grinding dynamics for \(v_\text {f0}<0\), Arrows V (\(\tau _\text {w0}=14.2\) and \(\kappa _\mu \in [1.1, 2]\)) and VI (\(\tau _\text {w0}=15\) and \(\kappa _\mu \in [1.1, 2]\)) are marked for further bifurcation analysis.

For \(\kappa _\mu \) increasing along Arrow V, a regenerative boundary is crossed before it reaches a frictional one. Therefore, the corresponding bifurcation pattern in Fig. 19 is similar to that along Arrow I, which is depicted in Fig. 12. However, the bifurcation diagram for \(\min (v_\text {f})\) presents some new features when the frictional chatter is incurred. Here, as shown in Fig. 19f, the frictional velocity of the chatter motion keeps negative and the corresponding \(\min (v_\text {f})\) recorded in Fig. 19b cluster round two locations. One indicates the smallest velocities and located at the bottom of the bifurcation diagram, and another is due to the stick motion and sited at the top of the bifurcation diagram.

Bifurcation diagrams with respect to Arrow V marked in Fig. 18. In addition, time series or phase portraits for \(\kappa _\nu =1.4\) and 1.8 are plotted as well

The bifurcation pattern along Arrow VI is plotted in Fig. 20. As seen, this is similar to those in Figs. 13 and 14. As the increase of \(\kappa _\mu \), the frictional chatter is firstly promoted before the regenerative chatter. Still, the frictional chatter is of negative frictional velocity, and the distribution of \(min(v_\text {f})\) is split by the frictional chatter. In addition, the periodic frictional vibration plotted in Fig. 20e is twisted, so that two maximums of the grinding depth (\(\max (d_\text {g})\)) are recorded.

Bifurcation diagrams with respect to Arrow VI marked in Fig. 18. In addition, time series or phase portraits for \(\kappa _\nu =1.3\), 1.5 and 1.8 are plotted as well

Rights and permissions

About this article

Cite this article

Yan, Y., Xu, J. & Wiercigroch, M. Regenerative and frictional chatter in plunge grinding. Nonlinear Dyn 86, 283–307 (2016). https://doi.org/10.1007/s11071-016-2889-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-016-2889-8