Abstract

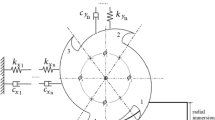

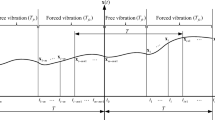

This paper analyzes the stability of milling with variable pitch cutter and tool runout cases characterized by multiple delays, and proposes a new variable-step numerical integration method for efficient and accurate stability prediction. The variable-step technique is emphasized here to expand the numerical integration method, especially for the low radial immersion cases with multiple delays. First, the calculation accuracy of the numerical integration method is discussed and the variable-step algorithm is developed for milling stability prediction for single-delay and multiple-delay cases, respectively. The milling stability with variable pitch cutter is analyzed and the result is compared with those predicted with the frequency domain method and the improved full-discretization method. The influence of the runout effect on the stability boundary is investigated by the presented method. The numerical simulation shows that the cutter runout effect increases the stability boundary, and the increasing stability limit is verified by the milling chatter experimental results in the previous research. The numerical and experiment results verify the validity of the proposed method.

Similar content being viewed by others

References

Stépán G. Retarded Dynamical Systems: Stability and Characteristic Functions. New York: Longman Scientific & Technical New York, 1989

Kline W, DeVor R. The effect of runout on cutting geometry and forces in end milling. Int J Mach Tool Design & Res, 1983, 23(2–3): 123–140

Altintas Y, Engin S, Budak E. Analytical stability prediction and design of variable pitch cutters. J Manuf Sci Eng, 1999, 121(2): 173–178

Olgac N, Sipahi R. Dynamics and stability of variable-pitch milling. J Vib Contl, 2007, 13(7): 1031–1043

Sims N D, Mann B, Huyanan S. Analytical prediction of chatter stability for variable pitch and variable helix milling tools. J Sound Vib, 2008, 317(3–5): 664–686

Wan M, Zhang W, Dang J, et al. A unified stability prediction method for milling process with multiple delays. Int J Mache Tools Manuf, 2010, 50(1): 29–41

Ding Y, Zhu L, Zhang X, et al. A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf, 2010, 50(5): 502–509

Ding Y, Zhu L, Zhang X, et al. Numerical integration method for prediction of milling stability. J Manuf Sci Eng, Trans ASME, 2011, 133, 031005

Butcher E, Bobrenkov O, Bueler E, et al. Analysis of milling stability by the Chebyshev collocation method: Algorithm and optimal stable immersion levels. J Comp Nonlinear Dyn, 2009, 4(3): 1–12

Zhang X, Xiong C, Ding Y. Improved Full-Discretization Method for Milling Chatter Stability Prediction with Multiple Delays, in Intelligent Robotics and Applications. Heidelberg: Springer. 2010. 541–552

Bayly P V, Halley J E, Mann B P, et al. Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng, Trans ASME, 2003, 125(2): 220–225

Insperger T, Stepan G, Turi J. On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib, 2008, 313(1–2): 334–341

Insperger T. Full-discretization and semi-discretization for milling stability prediction: Some comments. Int J Mach Tools Manuf, 2010, 50(7): 658–662

Ding Y, Zhu L, Zhang X, et al. Second-order full-discretization method for milling stability prediction. Int J Mach Tools Manuf, 2010, 50(10): 926–932

Insperger T, Stépán G., Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Num Meth Eng, 2004, 61(1): 117–141

Yang W Y, Cao W, Chung T-S, et al. Applied Numerical Methods Using MatLab. Hoboken, N.J.: Wiley-Interscience, 2005

Farkas M. Periodic Motions. New York: Springer-Verlag, 1994

Campomanes M L. Dynamics of milling flexible structures. Master Thesis, The University of British Columbia. 1998

Arizmendi M, Fernandez J, Gil A, et al. Identification of tool parallel axis offset through the analysis of the topography of surfaces machined by peripheral milling. Int J Mach Tools Manuf, 2010, 50(12): 1097–1114

Liang S, Wang J. Milling force convolution modeling for identification of cutter axis offset. Int J Mach Tools Manuf, 1994, 34(8): 1177–1190

Armarego E, Deshpande N. Computerized end-milling force predictions with cutting models allowing for eccentricity and cutter deflections. CIRP Ann—Manuf Technol, 1991, 40(1): 25–29

Wan M, Zhang W H, Dang J W, et al. New procedures for calibration of instantaneous cutting force coefficients and cutter runout parameters in peripheral milling. Int J Mach Tools Manuf, 2009, 49(14): 1144–1151

Wang J J J, Zheng C. Identification of cutter offset in end milling without a prior knowledge of cutting coefficients. Int J Mach Tools Manuf, 2003, 43(7): 687–697

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (I): Third-order approximation of tool envelope surface. Sci China Tech Sci, 2010, 53(7): 1904–1912

Zhu L M, Ding H, Xiong Y L. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (II): Tool positioning strategy. Sci China Tech Sci, 2010, 53(7): 1904–1912

Ding H, Zhu L M. Global optimization of tool path for five-axis flank milling with a cylindrical cutter. Sci China Tech Sci, 2009, 52(8): 2449–2459

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Xiong, C., Ding, Y. et al. Variable-step integration method for milling chatter stability prediction with multiple delays. Sci. China Technol. Sci. 54, 3137–3154 (2011). https://doi.org/10.1007/s11431-011-4599-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4599-2