Abstract

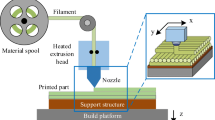

Fused deposition modeling (FDM) additive manufacturing (AM) printers frequently take significant trial and error to achieve desired dimensions, which has been fairly well investigated in the literature. What remains largely unexplored is the ability of a printer to match a desired primary natural frequency of a part. This can be critical when it comes to using printed parts as replacement parts in a moving system where a drastic change in a part’s natural frequency may appreciably change the dynamics of the system. This work uses iterative learning control (ILC) to create printed bars that match both desired dimensions and primary natural frequencies. Multiple case studies are presented and the best results were reprinted to investigate their repeatability and transferability. Dimensional error when using an ILC algorithm was comparable to that when deploying the default settings. Conversely, significant improvements in reducing warp and matching desired primary natural frequencies were found. These improvements were maintained when the output was printed on another machine in the same environment, indicating promise for deployment in a mass production setting. These results show that the presented ILC algorithm is capable of reducing error in both warp and desired primary natural frequency for simple parts on desktop FDM printers and lay the groundwork for further investigation with commercial grade and metal additive processes.

Similar content being viewed by others

Availability of data and materials

Data available upon request.

Code Availability

Code available upon request.

References

Liu P, Huang SH, Mokasdar A, Zhou H, Hou L (2014) The impact of additive manufacturing in the aircraft spare parts supply chain: supply chain operation reference (scor) model based analysis. Prod Plan Control 25:1169–1181. https://doi.org/10.1080/09537287.2013.808835

Khajavi SH, Partanen J, Holmström J (2014) Additive manufacturing in the spare parts supply chain. Comput Ind 65(1):50–63. https://doi.org/10.1016/j.compind.2013.07.008

McCann R, Obeidi MA, Hughes C, McCarthy E, Egan DS, Vijayaraghavan RK, Joshi AM, Garzon VA, Dowling DP, Mcnally PJ, Brabazon D (2021) In-situ sensing, process monitoring and machine control in laser powder bed fusion: a review. Additive Manufacturing 45. https://doi.org/10.1016/j.addma.2021.102058

Tian X, Li Y, Ma D, Han J, Xia L (2021) Closed-loop control of silicone extrusion-based additive manufacturing based on machine vision. In: ASME manufacturing science and engineering conference, pp 1–7

Qin Q, Huang J, Yao J (2019) A real-time adaptive look-ahead speed control algorithm for FDM-based additive manufacturing technology with Hbot kinematic system. Rapid Prototyp J 25(6):1095–1107. https://doi.org/10.1108/RPJ-11-2018-0291/full/html

Zhao J, Perkins E, Li XF, Bond A, Marghitu D (2021) Nonlinear vibratory properties of additive manufactured continuous carbon fiber reinforced polymer composites. Int J Adv Manuf Technol 117:1077–1089. https://doi.org/10.1007/s00170-021-07456-x

Funke L, Opara M (2022) Using iterative learning control to improve the accuracy of desktop fused deposition modeling printers: an experimental case study. ASME International Manufacturing Science and Engineering Conference

Funke L, Hylton B, Brown K, Sommer M (2020) Investigating how additively manufactured parts in traditionally manufactured systems affect the system dynamic properties. ASME International Design Engineering Technical Conferences

Sohoni VN, Whitesell J (1986) Automatic linearization of constrained dynamical models. Am Soc Mech Eng J Mech, Transm Autom Des 108(85):300–304

Kim BS, Eom SM, Yoo HH (2009) Design variable tolerance effects on the natural frequency variance of constrained multi-body systems in dynamic equilibrium. J Sound Vib 320(3):545–558. https://doi.org/10.1016/j.jsv.2008.08.015

Fernandez-Vicente M, Calle W, Ferrandiz S, Conejero A (2016) Effect of infill parameters on tensile mechanical behavior in desktop 3d printing. 3D Print Addit Manuf 3, 183–192. https://doi.org/10.1089/3dp.2015.0036

Ouhsti M, Haddadi BE, Belhouideg S (2018) Effect of printing parameters on the mechanical properties of parts fabricated with open-source 3d printers in PLA by fused deposition modeling. Mech Mech Eng 22:895–907. https://doi.org/10.2478/mme-2018-0070

Dizon JRC, Espera AH, Chen Q, Advincula RC (2018) Mechanical characterization of 3D-printed polymers. Addit Manuf 20:44–67. https://doi.org/10.1016/j.addma.2017.12.002

Jerez-Mesa R, Travieso-Rodriguez JA, Llumá-Fuentes J, Gomez-Gras G, Puig D (2017) Fatigue lifespan study of PLA parts obtained by additive manufacturing. Procedia Manuf 13:872–879. https://doi.org/10.1016/j.promfg.2017.09.146

Christiyan J, Chandrasekhar U, Venkateswar K (2016) A study on the inluence of process parameters on the mechanical properties of 3D printed ABS composite. IOP Conf Ser Mater Sci Eng 114. https://doi.org/10.1088/1757-899X/114/1/012109

Shergill K, Chen Y, Bull S (2023) An investigation into the layer thickness effect on the mechanical properties of additively manufactured polymers: PLA and ABS. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-11270-y

Dawoud M, Taha I, Ebeid SJ (2016) Mechanical behaviour of abs: an experimental study using FDM and injection moulding techniques. J Manuf Process 21:39–45. https://doi.org/10.1016/j.jmapro.2015.11.002

Daly M, Tarfaoui M, Chihi M, Bouraoui C (2023) FDM technology and the effect of printing parameters on the tensile strength of ABS parts. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-11486-y

Sukindar NA, Dahan AAA, Shaharuddin SIS, Halim NFHA (2021) Performance of low-cost 3D printer in medical application. In: ASME manufacturing science and engineering conference, pp 1–9

Ruiz C, Jafari D, Subramanian VV, Vaneker THJ, Ya W, Huang Q (2022) Prediction and control of product shape quality for wire and arc additive manufacturing. J Manuf Sci Eng 144. https://doi.org/10.1115/1.4054721

Elkholy A, Quinn P, Mhurchadha SMU, Raghavendra R, Kempers R (2022) Characterization and analysis of the thermal conductivity of alsi10mg fabricated by laser powder bed fusion. J Manuf Sci Eng 144. https://doi.org/10.1115/1.4054491

Porter Q, Li M, Pei Z, Ma C (2022) Binder jetting additive manufacturing: the effect of feed region density on resultant densities. J Manuf Sci Eng 144. https://doi.org/10.1115/1.4054453

Budinoff HD, Sun Y, McMains S (2020) Comparison of real-time geometric analyses to predict warping deformation in fused filament fabrication. In: ASME manufacturing science and engineering conference pp 1–10

Wu H, Wang Y, Yu Z (2016) In situ monitoring of FDM machine condition via acoustic emission. Int J Adv Manuf Technol 84:1483–1495. https://doi.org/10.1007/s00170-015-7809-4

Nathaphan S, Trutassanawin W (2021) Effects of process parameters on compressive property of FDM with ABS. Rapid Prototyp J 27(5)

Bristow DA, Tharayil M, Alleyne AG (2006) A survey of iterative learning control: a learning-based method for high-performance tracking control. IEEE Control Syst Mag (June), 96–114

Funke LW, Schmiedeler JP (2018) Control of final part dimensions in polymer extrusion using a variable-geometry die. ASME J Manuf Sci Eng 140(8):081001–8

Rafajłowicz W, Jurewicz P, Reiner J, Rafajłowicz E (2019) Iterative learning of optimal control for nonlinear processes with applications to laser additive manufacturing. IEEE Trans Autom Control 27(6):2647–2654. https://doi.org/10.1109/All

Hoelzle DJ, Alleyne AG, Wagoner Johnson AJ (2008) Iterative learning control for robotic deposition using machine vision. Am Control Conf 4541–4547

Armstrong AA, Alleyne AG, Johnson AJW (2020) 1D and 2D error assessment and correction for extrusion-based bioprinting using process sensing and control strategies. Biofabrication 12:045023

Armstrong AA, Alleyne AG (2021) A multi-input single-output iterative learning control for improved material placement in extrusion-based additive manufacturing. Control Eng Pract 111. https://doi.org/10.1016/j.conengprac.2021.104783

Hoelzle DJ, Barton KL (2015) On spatial iterative learning control via two dimensional convolution: stability analysis and computational efficiency. Trans Control Syst Technol 24(4):1504-1512

Wang Z, Pannier CP, Barton K, Hoelzle DJ (2018) Application of robust monotonically convergent spatial iterative learning control to microscale additive manufacturing. Mechatronics 56:157–165. https://doi.org/10.1016/j.mechatronics.2018.09.003

Afkhami Z, Pannier C, Aarnoudse L, Hoelzle D, Barton K (2021) Spatial iterative learning control for multi-material three- dimensional structures. ASME Lett Dyn Syst Control 1:1–7. https://doi.org/10.1115/1.4046576

Aarnoudse L, Pannier C, Afkhami Z, Oomen T, Barton K (2019) Multi-layer spatial iterative learning control for micro-additive manufacturing. Int Fed Autom Control-PapersOnLine 52(15):97–102. https://doi.org/10.1016/j.ifacol.2019.11.657

Adib AA, Hoelzle DJ (2022) Hybrid control of flowrate in microextrusion-based direct-write additive manufacturing. IEEE Control Syst Lett 6:97–102. https://doi.org/10.1109/LCSYS.2021.3049897

Afkhami Z, Hoelzle D, Barton K (2021) Higher-order spatial iterative learning control for additive manufacturing. Proceedings of the IEEE Conference on Decision and Control 2021-December, pp 6547–6553. https://doi.org/10.1109/CDC45484.2021.9682875

Afkhami Z, Hoelzle D, Barton K (2022) Synthesis of model predictive control and iterative learning control for topography regulation in additive manufacturing. Int Fed Autom Control-PapersOnLine 55:500–507. https://doi.org/10.1016/j.ifacol.2022.07.361

Funding

This work was supported by two grants from the Ohio Space Grant Consortium (OSGC) Faculty Research Initiation Grant Proposal (FRIGP). Support was also provided by Ohio Northern University (ONU) summer research grants and Evans Fellowships (from ONU) supported the students involved in this project.

Author information

Authors and Affiliations

Contributions

All authors contributed significantly to the work in the order provided.

Corresponding author

Ethics declarations

Ethic approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Funke, L.W., Lamison, C., Hylton, J.B. et al. Characterization and control of primary natural frequency of FDM ABS prints through printer parameters and STL file manipulation. Int J Adv Manuf Technol 129, 2139–2151 (2023). https://doi.org/10.1007/s00170-023-12378-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12378-x