Abstract

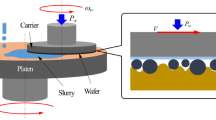

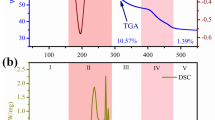

In the chemical mechanical polishing (CMP) process, chemical action is generally determined by pH regulator and oxidant in the polishing slurry. In this paper, tungsten (W) polished by CMP was examined, and the material removal mechanism was discussed. The influence of pH values and hydrogen peroxide (H2O2) concentrations on surface quality and material removal rate (MRR) were closely investigated. The MRR obtained from the CMP test indicates that the removal rate of W by the H2O2 oxidant reaches 34.10 μm/h under acidic pH conditions and the H2O2 oxidant improves the polishing rate of W. The obtained potentiodynamic polarization results show that the passivation layer formed under the H2O2 action cannot prevent the further corrosion of the slurry to the sample, but W can stably generate a tungsten trioxide (WO3) passivation layer under acidic conditions. XPS data confirm that the formation and dissolution of tungsten oxide passivation layers with different compositions are the main causes of these results. By analyzing the different morphologies (corrosion pits, grain boundaries, etc.) formed after tungsten chemical mechanical polishing (W-CMP), the deformation and removal mechanisms involved in the process are more deliberately exposed. This study enriches the understanding of the corrosion damage and material removal mechanisms of pure tungsten during CMP and contributes to the efficient and high-precision manufacturing of W components.

Similar content being viewed by others

References

Zhang P, Yang JF, Qiu HD (2022) Material removal rate of double-faced mechanical polishing of 4H-SiC substrate. Int J Adv Manuf Technol 118(11–12):3983–3993. https://doi.org/10.1007/s00170-021-08186-w

Tarek K, Abderrazek D, Khemissi BM, Cherif DM, Lilia C, Nouredine O (2020) Comparative study between cyclostationary analysis, EMD, and CEEMDAN for the vibratory diagnosis of rotating machines in industrial environment. Int J Adv Manuf Technol 109(9–12):2747–2775. https://doi.org/10.1007/s00170-020-05848-z

Gu DD, Guo M, Zhang HM, Sun YX, Wang R, Zhang L (2020) Effects of laser scanning strategies on selective laser melting of pure tungsten. Int J Extrem Manuf 2(2). https://doi.org/10.1088/2631-7990/ab7b00

Yuan S, Fan X (2019) Developments and perspectives on the precision forming processes for ultra-large size integrated components. Int J Extrem Manuf 1(2). https://doi.org/10.1088/2631-7990/ab22a9

Wu YC, Hou QQ, Luo LM, Zan X, Zhu XY, Li P, Xu Q, Cheng JG, Luo GN, Chen JL (2019) Preparation of ultrafine-grained/nanostructured tungsten materials: an overview. J Alloy Compd 779:926–941. https://doi.org/10.1016/j.jallcom.2018.11.279

Zhang Z, Meng Y, Guo D, Kang R, Gao H (2010) Nanoscale machinability and subsurface damage machined by CMP of soft-brittle CdZnTe crystals. Int J Adv Manuf Technol 47(9–12):1105–1112. https://doi.org/10.1007/s00170-009-2225-2

Zhang Y, Zhou Z, Lv Y, Wang JL, Shao L, Lqbal A (2013) Wear behavior of natural diamond tool in cutting tungsten-based alloy. Int J Adv Manuf Technol 69(1–4):329–335. https://doi.org/10.1007/s00170-013-5045-3

Tan XY, Luo LM, Chen HY, Zhu XY, Zan X, Luo GN, Chen JL, Li P, Cheng JG, Liu DP, Wu YC (2015) Mechanical properties and microstructural change of W-Y2O3 alloy under helium irradiation. Sci Rep 5. https://doi.org/10.1038/srep12755

Kim SC (2021) Development of air pressure mirroring particle dispersion method for producing high-density tungsten medical radiation shielding film. Sci Rep 11(1). https://doi.org/10.1038/s41598-020-79819-5

Guo J, Shi XL, Song CP, Niu L, Cui HL, Guo XG, Tong Z, Yu N, Jin ZJ, Kang RK (2021) Theoretical and experimental investigation of chemical mechanical polishing of W-Ni-Fe alloy. Int J Extrem Manuf 3(2). https://doi.org/10.1088/2631-7990/abefb8

Tso PL, Hsu R (2007) Estimating chemical mechanical polishing pad wear with compressibility. Int J Adv Manuf Technol 32(7–8):682–689. https://doi.org/10.1007/s00170-005-0386-1

Kaufman FB, Thompson DB, Broadie RE, Jaso MA, Guthrie WL, Pearson DJ, Small MB (1991) Chemical-mechanical polishing for fabricating patterned W metal features as chip interconnects. J Electrochem Soc 138(11):3460–3465. https://doi.org/10.1149/1.2085434

Stein DJ, Hetherington DL, Cecchi JL (1999) Investigation of the kinetics of tungsten chemical mechanical polishing in potassium iodate-based slurries-I. Role of alumina and potassium iodate. J Electrochem Soc 146(1):376–81. https://doi.org/10.1149/1.1391617

Kneer EA, Raghunath C, Mathew V, Raghavan S, Jeon JS (1997) Electrochemical measurements during the chemical mechanical polishing of tungsten thin films. J Electrochem Soc 144(9):3041–3049. https://doi.org/10.1149/1.1837956

Song C, Yang Y, Liu Y, Luo ZY, Yu JK (2015) Study on manufacturing of W-Cu alloy thin wall parts by selective laser melting. Int J Adv Manuf Technol 78(5–8):885–893. https://doi.org/10.1007/s00170-014-6689-3

Chen HY, Xu Q, Wang JH, Li P, Yuan JL, Lyu BH, Wang JH, Tokunaga K, Yao G, Luo LM, Wu YC (2022) Effect of surface quality on hydrogen/helium irradiation behavior in tungsten. Nucl Eng Technol 54(6):1947–1953. https://doi.org/10.1016/j.net.2021.12.006

Cao ZC, Wang M, Yan SQ, Zhao CY, Liu HT (2023) Surface integrity and material removal mechanism in fluid jet polishing of optical glass. J Mater Proces Technol 311. https://doi.org/10.1016/j.jmatprotec.2022.117798

Chen WJ, Gu LN, Han JY, Ge SW, Hua XJ, Hu P, Bai R, Zhang W, Chang T, Wang KS (2022) The effect of heat treatment and different degrees of deformation on the microstructure and mechanical properties of pure Mo sheets. Metals 12(12). https://doi.org/10.3390/met12122189

Sun YX, Gu DD, Dai DH, Guo M, Ge Q, Shi XY, Li YZ, Le GM, Yao MX (2020) Thermal behavior and microstructure evolution mechanism of W-20% Fe alloy fabricated by laser metal deposition. Int J Mech Sci 183:105772. https://doi.org/10.1016/j.ijmecsci.2020.105772

Wang K, Zan X, Yu M, Pantleon WG, Luo LM, Zhu XY, Li P, Wu YC (2017) Effects of thickness reduction on recrystallization process of warm-rolled pure tungsten plates at 1350 degrees C. Fusion Eng Des 125:521–525. https://doi.org/10.1016/j.fusengdes.2017.03.140

Kneer EA, Raghunath C, Raghavan S, Jeon JS (1996) Electrochemistry of chemical vapor deposited tungsten films with relevance to chemical mechanical polishing. J Electrochem Soc 143(12):4095–4100. https://doi.org/10.1149/1.1837342

Anik M, Osseo-asare K (2002) Effect of pH on the anodic behavior of tungsten. J Electrochem Soc 149(6):B224–B233. https://doi.org/10.1149/1.1471544

Paul E (2001) Application of a CMP model to tungsten CMP. J Electrochem Soc 148(6):G359–G363. https://doi.org/10.1149/1.1372223

Luo H, Ajmal KM, Liu W, Yamamura K, Deng Hui (2021) Polishing and planarization of single crystal diamonds:state-of-the-art and perspectives. Int J Extrem Manuf 3(2). https://doi.org/10.1088/2631-7990/abe915

Anik M (2006) Effect of concentration gradient on the anodic behavior of tungsten. Corros Sci 48(12):4158–4173. https://doi.org/10.1016/j.corsci.2006.03.014

Stein DJ, Hetherington D, Guilinger T, Cecchi JL (1998) In situ electrochemical investigation of tungsten electrochemical behavior during chemical mechanical polishing. J Electrochem Soc 145(9):3190–3196. https://doi.org/10.1149/1.1838785

Lim G, Lee JH, Kim J, Lee HW, Hyun SH (2004) Effects of oxidants on the removal of tungsten in CMP process. Wear 257(9–10):863–868. https://doi.org/10.1016/j.wear.2004.02.007

Coetsier CM, Testa F, Carretier E, Ennahali M, Laborie B, Mouton-arnaud C, Fluchere O, Moulin P (2011) Static dissolution rate of tungsten film versus chemical adjustments of a reused slurry for chemical mechanical polishing. Appl Surf Sci 257(14):6163–6170. https://doi.org/10.1016/j.apsusc.2011.02.023

Ralston KD, Fabijanic D, Birbilis N (2011) Effect of grain size on corrosion of high purity aluminium. Electrochim Acta 56(4):1729–1736. https://doi.org/10.1016/j.electacta.2010.09.023

Lillard RS, Kanner GS, Butt DP (1998) The nature of oxide films on tungsten in acidic and alkaline solutions. J Electrochem Soc 145(8):2718–2725. https://doi.org/10.1149/1.1838704

Lim JH, Park JH, Park JG (2013) Effect of iron(III) nitrate concentration on tungsten chemical-mechanical-planarization performance. Appl Surf Sci 282:512–517. https://doi.org/10.1016/j.apsusc.2013.06.003

Funding

This work is supported by the National Natural Science Foundation of China (Grant no. 52275467, 51905485, and U20A20293), the Natural Science Foundation of Zhejiang Province (LY21E050011), the Institute for Frontiers and Interdisciplinary Sciences, Zhejiang University of Technology (2022JCY09), and the Fundamental Research Funds for the Provincial Universities of Zhejiang (RF-A2022002).

Author information

Authors and Affiliations

Contributions

Conceptualization, L.W. and H.C.; methodology, W.H. and S.Z; software, F.P.; validation, F.P., W.H., and C.Y.; formal analysis, S.C.; investigation, F.P. and Y.M.; resources, L.W.; data curation, Z.W.; writing—original draft preparation, L.W. and H.C.; writing—review and editing, C.Y., Y.M., and H.C.; visualization, B.L. and J.L; supervision, Z.W.; project administration, S.C.; funding acquisition, H.C. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Peng, F., Chen, H. et al. The influence of pH and H2O2 on surface quality and material removal rate during W-CMP. Int J Adv Manuf Technol 127, 4097–4110 (2023). https://doi.org/10.1007/s00170-023-11805-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11805-3