Abstract

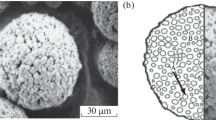

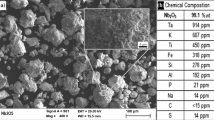

Despite the development of numerous coating techniques and materials, today’s anti-biofouling applications require coatings that are facile and mechanically robust in nature. Studies on the hydrophobicity of rare-earth oxides have risen due to their unusual chemical properties; ytterbium oxide is one such oxide substance. In this study, spray combustion was used to create a hydrophobic coating of ytterbium oxide (Yb2O3) on a stainless steel (SS) substrate, which was then vacuum-treated. GI-XRD analysis confirmed the sesquioxide cubic crystalline structure of Yb2O3. FESEM images displayed an underneath wavy morphological coating with discrete particles on the surface. The thickness and roughness were ~12 and ~0.17 µm, respectively. When 5 and 10 N loads were applied, the coating showed better scratch hardness than uncoated SS. Water contact angle (WCA) <10° indicated superhydrophilicity in the fabricated coating. After vacuum treatment, it became hydrophobic, and the WCA was 128°; because of the increment in the relative area fraction of the C–H bond. The proportion of area covered by blue–green algae (Phormidium sp.) on vacuum-treated Yb2O3 coating was only 3% compared to uncoated SS samples, 80%.

Similar content being viewed by others

References

Alexander B T, Philseok K, Stefan K, Caitlin H, Onye A and Joanna A 2015 Nat. Commun. 6 1

Callow J A and Callow M E 2011 Nat. Commun. 2 1

Yebra D M, Kiil S and Dam-Johansen K 2004 Prog. Org. Coat. 50 75

Hochbaum A I and Aizenberg J 2010 Nano Lett. 10 3717

Scott C, Fletcher R L and Bremer G B 1996 Biofouling 10 161

Hotos G N 2021 J. Mar. Sci. Eng. 9 798

Bhattacharya A, Srinivasa Rao R and Ghanashyam Krishna M 2007 Sens. Actuator. A Phys. 134 348

Gisele A, Rajeev D, Hyuk-Min K, Adam T P and Kripa K V 2013 Nat. Mater. 12 315

Zidong G, Ao L, You M, Caixuan F, Byoungchul S, Guoxia L et al 2017 Ceram. Int. 43 15194

Xu P, Pershin L, Mostaghimi J and Coyle T W 2018 Mater. Lett. 211 24

Xu P, Coyle T W, Pershin L and Mostaghimi J 2018 J. Colloid Interface Sci. 523 35

Xu P, Meng G, Pershin L, Mostaghimi J and Coyle T W 2021 J. Mater. Sci. Technol. 62 107

Xu P, Coyle T W, Pershin L and Mostaghimi J 2018 Mater. Des. 160 974

Xu P, Coyle T W, Pershin L and Mostaghimi J 2019 J. Therm. Spray Technol. 28 242

Wang B, Yu X, Guo P, Huang W, Zeng L, Zhou N et al 2016 Adv. Electron. Mater. 2 1500427

Yu X, Smith J, Zhou N, Zeng L, Guo P, Xia Y et al 2015 Proc. Natl. Acad. Sci. USA 112 3217

Vardhan R V, Manjunatha M and Mandal S 2020 IOP SciNotes 1 024806

Adeleke S A, Ramesh S, Bushroa A R, Ching Y C, Sopyan I, Malequeet M A et al 2018 Ceram. Int. 44 1802

Sarraf M, Zalnezhad E, Bushroa A R, Hamouda A M S, Baradaran S, Nasiri-Tabrizi B et al 2014 Appl. Surf. Sci. 321 511

Misra D, Shariff S M, Mukhopadhyay S and Chatterjee S 2018 Ceram. Int. 44 4248

Sinha S K, Song T, Wan X and Tong Y 2009 Wear 266 814

Beegan D, Chowdhury S and Laugier M T 2007 Surf. Coat. Technol. 201 5804

Chakraborty H, Sinha A, Mukherjee N, Ray D and Chattopadhyay P P 2013 Mater. Lett. 93 137

Augustin A, Huilgol P, Udupa K R and Bhat K U 2016 J. Mech. Behav. Biomed. Mater. 63 352

Li B, Ding R, Shen Y, Hu Y and Guo Y 2012 Mater. Des. 35 25

Wu Y, Wu L, Yao W, Jiang B, Wu J, Chen Y et al 2021 Electrochim. Acta 374 137913

Lee D, Choi S, Moon M and Shon M 2021 Bull. Korean Chem. Soc. 42 626

Callow M E, Callow J A and Wendt D E 2007 in P Zarras, T Wood, B Richey and B C Benicewicz (eds) New Developments in Coatings Technology (Washington: ACS Publications) 962 91

Efimenko K, Finlay J, Callow M E, Callow J A and Genzeret J 2009 ACS Appl. Mater. Interfaces 1 1031

Xie C, Guo H, Zhao W and Zhang L 2020 Langmuir 36 2396

Dowling D P, Nwankire C E, Riihimäki M, Keiski R and Nylen U 2010 Surf. Coat. Technol. 205 1544

Gudipati C S, Finlay J A, Callow J A, Callow M E and Wooley K L 2005 Langmuir 21 3044

Tesler A B, Kim P, Kolle S, Howell C, Ahanotu O and Aizenberg J 2015 Nat. Commun., Article ID 8649 doi:https://doi.org/10.1038/ncomms9649

Clare A S, Gerhart D J, Rittschof D, Bonaventura J, Smith C and Hadfield M G 1992 Biofouling 6 181

Lim C S, Dickinson G H, Sommer S, Teo S L, Bodkhe R B, Webster D C et al 2015 J. Coat. Technol. Res. 12 533

Pan J, Peng Q, Zhang G, Xie Q, Gong X, Qian P et al 2021 J. Mater. Sci. Technol. 84 200

Bloomfield N J, Wei S, Woodham B, Wilkinson P and Robinson A P 2021 Sci. Rep. 11 2739

Pedersen M L, Weinell C E, Ulusoy B and Dam-Johansen K 2022 J. Coat. Technol. Res. 19 1127

Romeu M J, Morais J, Gomes L C, Silva R, Vasconcelos V and Mergulhao F J M 2023 FEMS Microbiol. Ecol. 99 1

MacMullen J, Zhang Z, Dhakal H N, Radulovic J, Karabela A, Tozzi G et al 2014 Int. Biodeterior. Biodegradation 93 54

Barberousse H, Ruot B, Yéprémian C and Boulon G 2007 Build. Environ. 42 2555

Zhou W, Cheng Y, Li Y, Wan Y, Liu Y, Lin X et al 2012 Appl. Biochem. Biotechnol. 167 214

Karle S S, Praveen L L, Vardhan R V, Mandal S 2023 Mater. Today: Proc. https://doi.org/10.1016/j.matpr.2023.08.261

Recipe for standard BG-11 media. Available: www.protocols.io (accessed on 28 October 2021)

Ashwini S and Manjula S 2018 J. Algal Biomass Util. 9 86

Rai S and Rajashekhar M 2015 J. Coast. Life Med. 3 857

Chen C, Kelder E M, Van D P and Schoonman J 1996 J. Mater. Chem. 6 765

Vardhan R V, Kumar S and Mandal S 2022 Surf. Interface Anal. 54 510

Padalia B D, Lang W C, Norris P R, Watson L M and Fabian D J 1977 Proc. R Soc. Lond. Ser. A 354 269

Oh J, Orejon D, Park W, Cha H, Sett S, Yokoyama Y et al 2022 iScience 25 103691

Kaladharan P, Zacharia P U and Vijayakumaran K 2011 J. Mar. Biol. Assoc. 53 121

Mridula R M and Rajesh K M 2002 Bangladesh J Fish. Res. 6 165

Acknowledgements

This work is supported by the Science and Engineering Research Board (SERB), Department of Science and Technology (CRG/2021/001084). We would like to thank Prof K Narayan Prabhu, Department of Metallurgical and Materials Engineering, for providing access to the water contact angle measuring facility and Prof N K Udayashankar, Department of Physics, for providing access to the vacuum furnace facility, NITK Surathkal, India. We would also like to thank the Department of Metallurgical and Materials Engineering, NITK Surathkal, India.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karle, S.S., Kailasam, K., Vardhan, R.V. et al. Anti-biofouling evaluation of vacuum-assisted hydrophobic ytterbium oxide (Yb2O3) coating on stainless steel by facile spray combustion. Bull Mater Sci 47, 98 (2024). https://doi.org/10.1007/s12034-024-03159-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-024-03159-7