Abstract

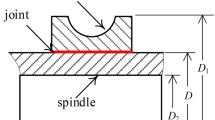

Motorized spindle is an inevitable choice of precision machine, but it has a prominent heat problem for its specific configuration of build-in motor. The paper proposed temperature distribution and thermal deformation modeling and a thermal-structural coupling simulation analysis method for a motorized spindle system from a vertical machining center. In order to establish an accurate finite element model, the boundary condition of joint thermal contact resistance (TCR) was taken into account. The paper detailed on how to obtain the TCR value which is related to the machine tool parameters by means of experimental and theoretical methods, and carried out a simulation experiment for the purpose of acquiring a quantitative analysis of the TCR influence on the temperature results. In order to verify the effectiveness of the TCR relevant methods, the experiment was carried out. The agreement between the experimental results and the simulation results showed that the proposed method can more accurately simulate the thermal characteristics of the motorized spindle.

Similar content being viewed by others

References

Brinksmeier E, Mutlugünes Y, Klocke F, Aurich JC, Shore P, Ohmori H (2010) Ultra-precision grinding. CIRP Ann Manuf Technol 59(2):652–671. https://doi.org/10.1016/j.cirp.2010.05.001

Abele E, Altintas Y, Brecher C (2010) Machine tool spindle units. CIRP Ann Manuf Technol 59(2):781–802. https://doi.org/10.1016/j.cirp.2010.05.002

Mayr J, Jedrzejewski J, Uhlmann E, Donmez MA, Knapp W, Härtig F, Wendt K, Moriwaki T, Shore P, Schmitt R, Brecher C, Würz T, Wegener K (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791. https://doi.org/10.1016/j.cirp.2012.05.008

Bossmanns B, Tu JF (1999) A thermal model for high speed motorized spindles. Int J Mach Tools Manuf 39(9):1345–1366. https://doi.org/10.1016/S0890-6955(99)00005-X

Kuo WL, Lin JF (2006) General temperature rise solution for a moving plane heat source problem in surface grinding. Int J Adv Manuf Technol 31(3-4):268–277. https://doi.org/10.1007/s00170-005-0200-0

Chen Y, Zhang LC, Arsecularatne JA, Montross C (2006) Polishing of polycrystalline diamond by the technique of dynamic friction, part 1: prediction of the interface temperature rise. Int J Mach Tool Manu 46(6):580–587. https://doi.org/10.1016/j.ijmachtools.2005.07.018

Yan JY, Yang JG (2009) Application of synthetic grey correlation theory on thermal point optimization for machine tool thermal error compensation. Int J Adv Manuf Technol 43(11–12):1124–1132. https://doi.org/10.1007/s00170-008-1791-z

Li JW, Zhang WJ, Yang GS (2009) Thermal-error modeling for complex physical systems: the-state-of-arts review. Int J Adv Manuf Technol 42(1-2):168–179. https://doi.org/10.1007/s00170-008-1570-x

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review part II: thermal errors. Int J Mach Tool Manu 40(9):1257–1284. https://doi.org/10.1016/S0890-6955(00)00010-9

Wang LP, Wang HT, Li TM, Li FC (2015) A hybrid thermal error modeling method of heavy machine tools in z-axis. Int J Adv Manuf Technol 80(1–4):389–400. https://doi.org/10.1007/s00170-015-6988-3

Chen JS, Hsu WY (2003) Characterizations and models for the thermal growth of a motorized high speed spindle. Int J Mach Tool Manu 43(11):1163–1170. https://doi.org/10.1016/S0890-6955(03)00103-2

Adbulshahed AM, Longstaff AP, Fletcher S (2015) Thermal error modelling of machine tools bases on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl Math Model 39(7):1837–1852. https://doi.org/10.1016/j.apm.2014.10.016

Liu H, En MM, Wei XY, Zhuang XD (2017) Robust modeling method for thermal error of CNC machine tools based on ridge regression algorithm. Int J Mach Tool Manu 113:35–48. https://doi.org/10.1016/j.ijmachtools.2016.11.001

Gomez-Acedo E, Olarra A, Orive J (2013) Methodology for the design of a thermal distortion compensation for large machine tools based in state-space representation with Kalman filter. Int J Mach Tool Manu 75:100–108. https://doi.org/10.1016/j.ijmachtools.2013.09.005

Feng WL, Li ZH, Gu QY, Yang JG (2015) Thermally induced positioning error modelling and compensation based on thermal characteristic analysis. Int J Mach Tool Manu 93:26–36. https://doi.org/10.1016/j.ijmachtools.2015.03.006

Liu K, Sun MJ, Zhu TJ, Wu YL, Liu Y (2016) Modeling and compensation for spindle's radial thermal drift error on a vertical machining center. Int J Mach Tool Manu 105:58–67. https://doi.org/10.1016/j.ijmachtools.2016.03.006

Jiang S, Min X (2012) Thermal design of the vertical machining centre headstock by the forced cooling method. Proc Inst Mech Eng C J Mech Eng Sci 226(3):738–751

Sun LJ, Ren MJ, Hong HB, Yin YH (2017) Thermal error reduction based on thermodynamics structure optimization method for an ultra-precision machine tool. Int J Adv Manuf Technol 88(5–8):1267–1277. https://doi.org/10.1007/s00170-016-8868-x

Zhao HT, Yang JG, Shen JH (2007) Simulation of thermal behavior of a CNC machine tool spindle. Int J Mach Tool Manu 47(6):1003–1010

Holkup T, Cao H, Kolár (2010) Thermo-mechanical model of spindles. CIRP Ann Manuf Technol 59(1):365–368. https://doi.org/10.1016/j.cirp.2010.03.021

Zahedi A, Movahhedy MR (2012) Thermo-mechanical modeling of high speed spindles. Scientia Iranica B 19(2):282–293. https://doi.org/10.1016/j.scient.2012.01.004

Creighton E, Honegger A, Tulsian A (2010) Analysis of thermal errors in a high-speed micro-milling spindle. Int J Mach Tool Manu 50(4):386–393. https://doi.org/10.1016/j.ijmachtools.2009.11.002

Uhlmanna E, Hu J (2012) Thermal modelling of a high speed motor spindle. Procedia CIRP 1:313–318. https://doi.org/10.1016/j.procir.2012.04.056

Liu T, Gao WG, Zhang DW, Zhang YF, Chang WF, Liang CM, Tian YL (2017) Analytical modeling for thermal errors of motorized spindle unit. Int J Mach Tool Manu 112:53–70. https://doi.org/10.1016/j.ijmachtools.2016.09.008

Zhang JF, Feng PF, Chen C (2013) A method for thermal performance modeling and simulation of machine tools. Int J Adv Manuf Technol 68(5–8):1517–1527. https://doi.org/10.1007/s00170-013-4939-4

Zhao CL, Guan XS (2012) Thermal analysis and experimental study on the spindle of the high-speed machining center. AASRI Procedia 1:207–212. https://doi.org/10.1016/j.aasri.2012.06.032

Lu ZS, Ma BH (2009) Thermal model of hydrostatic motorized spindle. J Syst Simul 21(2):352–356

Jiang S, Zheng Y (2009) An analytical model of thermal contact resistance based on the Weierstrass–Mandelbrot fractal function. Proc Inst Mech Eng C J Mech Eng Sci 224:959–967

Jeng YR, Chen JT, Cheng CY (2003) Theoretical and experimental study of a thermal contact conductance model for elastic, elastoplastic and plastic deformation of rough surfaces. Tribol Lett 14(4):251–259. https://doi.org/10.1023/A:1022632801251

Mian NS (2010) Efficient machine tool thermal error modelling strategy for accurate offline assessment. Doctoral thesis, University of Huddersfield

Fang B, Gu TQ, Ye DP, Luo TZ (2016) An improved thermo-mechanical model for vertical machining center. Int J Adv Manuf Technol 87(9–12):2581–2592. https://doi.org/10.1007/s00170-016-8651-z

ISO 230-3 (2007) Test code for machine tools—part 3: determination of thermal effects. Genf, Schwitzerland

Tan B, Mao XY, Liu HQ, Li B, He SP, Peng FY, Yin L (2014) A thermal error model for large machine tools that considers environmental thermal hysteresis effects. Int J Mach Tools Manuf 82-83:11–20. https://doi.org/10.1016/j.ijmachtools.2014.03.002

Mian NS, Fletcher S, Longstaff AP (2013) Efficient estimation by FEA of machine tool distortion due to environmental temperature perturbations. Precis Eng 37(2):372–379

Acknowledgements

The authors gratefully acknowledge the financial support provided by the Science and Technology Commission of Shanghai Municipality (Grant No. 15110502300).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Y., Li, H., Li, T. et al. An accurate thermal performance modeling and simulation method for motorized spindle of machine tool based on thermal contact resistance analysis. Int J Adv Manuf Technol 96, 2525–2537 (2018). https://doi.org/10.1007/s00170-018-1593-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1593-x