Abstract

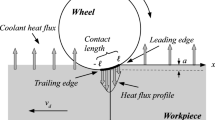

In the present study, the general solutions for a transient state as well as for the temperature rise formed everywhere in the workpiece due to a rectangular-shaped moving plane heat source arising at the grinding zone are derived. The present analysis starts from a point heat source solution by applying the method of separation of variables to a three-dimensional heat conduction problem. Because the workpiece moving velocity is quite small, the convective term related to the workpiece velocity is first excluded from the heat conduction equation. This workpiece velocity effect will be included in the model by slightly modifying the coordinate variable in the sliding direction shown in the solution of the point heat source. Therefore, the general three-dimensional solution of the stationary temperature rise can be expressed in an integral form as a function of the product value of the unknown initial condition and the particular solution of temperature rise. The unknown initial temperature rise in the solution can be replaced by the point heat source due to frictional that multiplying the product of the Dirac delta functions defined for three directions. Using the definition of the Dirac delta function, the temperature rise solution for a point heat source can thus be obtained. This solution is further extended to obtain the moving and uniform heat sources arising in a rectangular grinding zone. A comparison among the experimental result and the theoretical results predicted by the present model and Jaeger’s model [Jaeger JC (1942) Proc Roy Soc, NSW 76:203–224.] show that the present model is quite accurate and is generally superior to Jaeger’s model; it can be applied to predict the three-dimensional temperature rise distributions in the workpiece.

Similar content being viewed by others

References

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. Proc Roy Soc, NSW 76:203–224

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. 2nd edn. Oxford Univ Press, Oxford, pp 255–281

Trigger KJ, Chao BT (1951) An analytical evaluation of metal-cutting temperatures. Trans ASME 73:55–58

Chao BT, Trigger KJ (1951) Cutting temperatures and metal cutting phenomena. Trans ASME 73:777–787

Bowden FP, Thoma PH (1953) Surface temperatures of sliding solids. Proc Roy Soc, A 223:29–39

Barber JR (1967) Distribution of heat between sliding surfaces. J Mech Eng Sci 9:351–354

Cameron A, Gordon AN, Symm GT (1964) Contact temperatures in rolling/sliding surfaces. Proc Roy Soc, pp 45–61

Gecim B, Winer WO (1985) Transient temperatures in the vicinity of an asperity contact. J of Tribology, Trans ASME 107:333–342

Ling FF (1959) A quasi-iterative method for computing interface temperature distributions. zeitschrift fur angewandte mathematik X:461–474

Ling FF, Ng CW (1962) On temperatures at the interfaces of bodies in sliding contact. Proc of Fourth US Nat Conger, Appl Mech, ASME 4:1343–1349, New York

Ling FF (1973) Surface mechanics. Wiley, New York

Rosenthal D (1935) Theoretical study of the heat cycle during arc welding. 2-mem Congres National des Sciences, Brussels, pp 1277–1292 (in French)

Rosenthal D (1941) Mathematical theory of heat distribution during welding and cutting. Weld Res Supplement, pp 220s–234s

Rosenthal D, Schmerber R (1938) Thermal study of arc welding — experimental verification of theoretical formulas. Weld Res Supplement, pp 2–8

Rosenthal D (1946) The theory of moving sources of heat and its application to metal treatments. Trans ASME 80:849–866

Blok H (1937) Theoretical study of temperature rise at surfaces of actual contact under oiliness lubricating conditions. Proc of the General Discussion on Lubrication and Lubricants, Inst of Mech Engrs 2:222–235, London

Blok H (1955) The dissipation of frictional heat. Appl Sci Res Section A5:151–181

Tian X, Kennedy FE (1994) Maximum and average flash temperatures in sliding contact. J Tribology, Trans ASME 116:167–174

Bos J, Moes H (1995) Frictional heating of tribological contacts. J Tribology, Trans ASME 117:171–217

Hou ZB, Komanduri R (2000) General solutions for stationary/moving plane heat source problem in manufacturing and tribology. Int J Heat Mass Transfer 43:1679–1698

Outwater JO, Shaw MC (1952) Surface temperature in grinding. Trans ASME 74:73–86

Des Ruisseaux NR, Zerkle RD (1970) Thermal analysis of the grinding process. J Eng for Ind, Trans ASME 92:428–434

Malkin S (1974) Thermal aspects of grinding: Part 2 Surface temperatures and workpiece burn. J Eng for Ind, Trans ASME 96:1184–1191

Lavine AS (1988) A simple model for convective cooling during the grinding process. J Eng for Ind, Trans ASME 110:1–6

Ramanath S, Shaw MC (1988) Abrasive grain temperature at the beginning of a cut in fine grinding. J Eng for Ind, Trans ASME 110:15–18

Rowe WB, Pettit JA, Boyle A, Moruzzi JL (1988) Avoidance of thermal damage in grinding and prediction of the damage threshold. Annals CIRP 37(1):327–330

Shaw MC (1990) A simplified approach to workpiece temperatures in fine grinding. Annals CIRP 39(1):345–347

Sato K (1961) Grinding temperature. Bull Japan Soc of Grindign Eng 1:21–33

Kato T, Fujii H (1999) Energy partition in conventional surface grinding. J Manuf Sci Eng, Trans ASME 121:393–398

Littman WE, Wulff J (1955) The influence of the grinding process on the structure of hardened steel. Trans ASME 47:692–714

Takazawa K (1966) Effects of grinding variables on surface structure of hardened steels. Bull Japan Soc Prec Eng 2:14–18

Saver WJ (1972) Thermal aspect of surface grinding. New Developments in Grinding, Proc Int Grinding Conference, Carnegie Press, pp 391–411

Werner PG, Younis, MA, Schlingensiepen R (1980) Creep feed - an effective method to reduced work surface temperature in high-hfficiency grinding processes. Proc 8th North American Metalworking Research Conference, pp 312–319

Beck JV (1962) Thermocouple temperature disturbances in low conductivity materials. J Heat Transfer, Trans ASME 84:124–132

Attia MH, Kops L (1993) Distortion in the thermal field around inserted thermocouples in experimental interfacial studies-Part 3: Experimental and umerical verification. J Eng for Ind, Trans ASME 115:444–449

Ueda T, Hosokawa A, Yamamoto A (1986) Measurement of grinding temperature using infrared radiation pyrometer with optical fiber. J Eng for Ind, Trans ASME 108:247–251

Hebbar, Rajadasa R, Chandrasekhar S, Farris TN (1992) Ceramic grinding temperatures. J American Ceramic Soc 75:2742–2748

Kato T, Fujii H (1996) PVD film method for measuring the temperature distribution in cutting tools. J Eng for Ind, Trans ASME 118:117–122

Kato T, Fujii H (1997) Temperature measurement of workpiece in surface grinding by PVD film method. J Manuf Sci Eng, Trans ASME 119:689–694

Matsuo T, Shibahara H, Ohbuchi Y (1987) Curvature in surface grinding of thin workpiece with superabrasive wheels. Ann CIRP 36(1):231–234

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuo, W.L., Lin, J.F. General temperature rise solution for a moving plane heat source problem in surface grinding. Int J Adv Manuf Technol 31, 268–277 (2006). https://doi.org/10.1007/s00170-005-0200-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-005-0200-0