Abstract

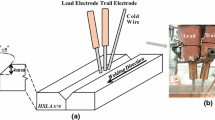

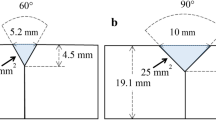

The addition of a cold wire in conventional tandem submerged arc welding (TSAW), i.e., the CWTSAW process, is proposed to improve the productivity of pipeline manufacturing by increasing welding travel speed and deposition rate, while retaining adequate joint geometry without increasing the welding heat input. In addition to increasing productivity, incorporating a cold wire in the TSAW process improves the fracture toughness by refining the microstructure of the weld heat-affected zone (HAZ). In the present work, the influence of cold-wire addition on the heat input, productivity and properties of an X70 microalloyed steel welded by CWTSAW is investigated. Charpy impact testing and microhardness testing were utilized to investigate the mechanical properties of the HAZ. Scanning electron microscopy (SEM) and tint etching optical microscopy (TEOM) were used to correlate the microstructure alterations with the properties. The low-temperature fracture toughness of the HAZ was improved by 38% when a cold wire was fed at 25.4 cm/min in the conventional TSAW process with a heat input of 22.1 kJ/cm. This improvement was attributed to a reduction in the prior austenite grain (PAG) size and martensite-austenite (M-A) constituent fraction as a result of the reduction in the effective heat input (7.5% reduction) by cold wire addition. The amount of heat input reduction is a function of the cold wire addition rate and the nominal welding heat input. The increase in travel speed and deposition rate of welding by addition of a cold wire at 58 cm/min in the TSAW process with a heat input of 23.2 kJ/cm was 26 and 12%, respectively.

Similar content being viewed by others

References

Viano DM, Ahmed NU, Schumann GO et al (2013) Influence of heat input and travel speed on microstructure and mechanical properties of double tandem submerged arc high strength low alloy steel weldments. Sci Technol Weld Join 5:26–34. doi:10.1179/stw.2000.5.1.26

Zhang YQ, Zhang HQ, Li JF, Liu WM (2009) Effect of heat input on microstructure and toughness of coarse grain heat affected zone in Nb microalloyed HSLA steels. J Iron Steel Res Int 16:73–80. doi:10.1016/S1006-706X(10)60014-3

Pepin JT (2009) Effects of submerged arc weld (SAW) parameters on bead geometry and notch-toughness for X70 and X80 linepipe steels. MSc Thesis, University of Alberta

Fabricator (2010) Improving productivity with submerged arc welding (Technical Report). Fabr Manuf Assoc Intl, IL, 1-4

Moeinifar S, Kokabi AH, Hosseini HRM (2011) Role of tandem submerged arc welding thermal cycles on properties of the heat affected zone in X80 microalloyed pipe line steel. J Mater Process Technol 211:368–375. doi:10.1016/j.jmatprotec.2010.10.011

Kiran DV, Alam SA, De A (2013) Development of process maps in two-wire tandem submerged arc welding process of HSLA steel. J Mater Eng Perform 22:988–994. doi:10.1007/s11665-012-0381-2

Thomas PD, Craig LA (1986) Automatic submerged arc welding with metal powder additions to increase productivity and maintain quality. Newport News Shipbuilding, Washington

Pepin J, Penniston C, Henein H et al (2012) Using semipenetration ratio to characterise effects of waveform variables on bead profile and heat affected zone with single electrode submerged arc welding. Can Metall Q 51:284–293. doi:10.1179/1879139512Y.0000000018

Mruczek MF, Konkol PJ (2006) Cold wire feed submerged arc welding: technical report. Advanced Technology Institute (ATI), Johnstown

ESAB (2013) Submerged arc welding (Technical Handbook), TX, 1–94

Massey S (2012) Increasing productivity with submerged arc welding. Columbus

Beidokhti B, Kokabi AH, Dolati A (2014) A comprehensive study on the microstructure of high strength low alloy pipeline welds. J Alloys Compd 597:142–147. doi:10.1016/j.jallcom.2014.01.212

Farhat H (2007) Effects of multiple wires and welding speed on the microstructures and properties of submerged arc welded X80 steel. PhD Diss. Univ. Saskatchewan

Mruczek MF, Konkol PJ (2005) Twin-arc and cold-wire-feed submerged-arc welding of HSLA-100 steel. Conf Proceedings, Am Weld Soc

Mohammadijoo M, Kenny S, Collins L et al (2016) Influence of cold-wire tandem submerged arc welding parameters on weld geometry and microhardness of microalloyed pipeline steels. Int J Adv Manuf Technol. doi:10.1007/s00170-016-8910-z

Mohammadijoo M, Kenny S, Collins L et al (2016) Effect of cold-wire addition in the TSAW process on microstructure and mechanical properties of the HAZ of X70 microalloyed pipeline steel. Am Soc Mech Eng 3:1–9. doi:10.1115/IPC2016-64549

ASTM (2012) E23-12C: standard test methods for notched bar impact testing of metallic materials. ASTM International, PA

ASTM (2012) E384: standard test method for knoop and vickers hardness of materials. ASTM Int. doi:10.1520/E0384-11E01.2

ASTM (2011) E3-11: standard guide for preparation of metallographic specimens. ASTM Int. doi:10.1520/E0003-11.2

LePera FS (1979) Improved etching technique for the determination of percent martensite in high-strength dual-phase steels. Metallography 12:263–268. doi:10.1016/0026-0800(79)90041-7

ASTM (2011) E562-11: standard test method for determining volume fraction by systematic manual point count. ASTM Int. doi:10.1520/E0562-11.2

Rigdal S, Karlsson L, Östgren L (2002) Synergic cold wire (SCW™) submerged arc welding. ESAB Weld Cut J 57:26–31. doi:10.1007/978-3-319-26324-3

Ramakrishnan M,Muthupandi V (2013) Application of submerged arc welding technology with cold wire addition for drum shell long seam butt welds of pressure vessel components. Int J Adv Manuf Technol 65:945–956. doi:10.1007/s00170-012-4230-0

Adarsh Narang V (2005) Heat transfer analysis in steel structures. Master Thesis, Worcester Polytechnic Institute, MA, USA

Rokhlin SI, Guu AC (1993) A study of arc force, pool depression, and weld penetration during gas tungsten arc welding. Weld Res Suppl 72:381 s–390 s

Adonyi Y, Richardson W, Baeslack WA (1992) Investigation of arc force effects in subsurface GTA welding. Weld Res Suppl 71:321 s– 699 330 s

Halmoy E (1979) The pressure of the arc acting on the weld pool. Arc physics and weld pool behavior. The Welding Institute, Cambridge

Converti J (1981) Plasma-jets in arc welding. PhD Thesis, Massachusetts Institute of Technology

Connor LP, O’Brien RL (1987) Welding handbook: welding technology. American Welding Society, Miami

Bavaria agglomerated welding flux BF6.5. Technical Report. Bavaria Schweisstechnik, Germany. 6.5:1–4

Easterling KE (1992) Introduction to the physical metallurgy of welding. Butterworth-Heinemann Ltd, Oxford

Poorhaydari K, Patchett BM, Ivey DG (2005) Estimation of Cooling Rate in the Welding of Plates with Intermediate Thickness. Weld Res 149 s–155 s

Xia ZH, Wan XL, Tao XL, Wu KM (2012) Effect of heat input on toughness of coarse-grained heat-affected zone of an ultra low carbon acicular ferrite steel. Adv Mater Res 538–541:2003–2008. doi:10.4028/www.scientific.net/AMR.538-541.2003

Yu L, Wang HH, Hou TP et al (2014) Characteristic of martensite-austenite constituents in coarse grained heat affected zone of HSLA steel with varying Al contents. Sci Technol Weld Join 19:708–714. doi:10.1179/1362171814Y.0000000246

Li X, Ma X, Subramanian SV et al (2014) Influence of prior austenite grain size on martensite-austenite constituent and toughness in the heat affected zone of 700 MPa high strength linepipe steel. Mater Sci Eng A 616:141–147. doi:10.1016/j.msea.2014.07.100

Li X, Fan Y, Ma X et al (2015) Influence of martensite-austenite constituents formed at different intercritical temperatures on toughness. Mater Des 67:457–463. doi:10.1016/j.matdes.2014.10.028

Davis CL, King JE (1993) Effect of cooling rate on intercritically reheated microstructure and toughness in high strength low alloy steel. Mater Sci Technol 9:8–15

Davis CL, King JE (1994) Cleavage initiation in the intercritically reheated coarse-grained heat-affected zone : part I. Fractographic evidence. Metall Mater Trans A 25:563–573. doi:10.1007/BF02651598

Reichert JM, Garcin T, Militzer M, Poole WJ (2014) A new approach using EBSD to quantitatively distinguish complex transformation products along the HAZ in X80 linepipe steel. Conf Proceedings, 9th Int. Pipeline Conf, Calgary, AB, Canada. doi:10.1115/IPC2014-33668

Gharibshahiyan E, Honarbakhsh A, Parvin N, Rahimian M (2011) The effect of microstructure on hardness and toughness of low carbon welded steel using inert gas welding. Mater Des 32:2042–2048. doi:10.1016/j.matdes.2010.11.056

Yang HS, Bhadeshia HKDH (2009) Austenite grain size and the martensite-start temperature. Scr Mater 60:493–495. doi:10.1016/j.scriptamat.2008.11.043

Garcia-Junceda A, Capdevila C, Caballero FG et al (2008) Dependence of martensite start temperature on fine austenite grain size. Scr Mater 58:134–137. doi:10.1016/j.scriptamat.2007.09.017

Lee S-J, Lee Y-K (2005) Effect of austenite grain size on martensitic transformation of a low alloy steel. Mater Sci Forum 475–479:3169–3172

Bhadeshia HKDH (2013) About calculating the characteristics of the martensite-austenite constituent. In: Int. Semin. Weld. High Strength Pipeline Steels. The Minerals, Metals and Materials Society, The Minerals, Metals and Materials Society (TMS), USA, pp 99–106

Yan P, Bhadeshia HKDH (2015) The austenite-ferrite transformation in enhanced-niobium, low-carbon steel. Mater Sci Technol 31:1066–1076. doi:10.1179/1743284714Y.0000000673

Matsuda F, Ikeuchi K, Fukada Y et al (1995) Review of mechanical and metallurgical investigations of M-A constituents in welded joint in Japan.Pdf. Transcations JWRI 24:1–24

Kim BC, Lee S, Kim NJ, Lee DY (1991) Microstructure and local brittle zone phenomena in high-strength low-alloy steel welds. Metall Mater Trans A 22:139–149

Shome M (2007) Effect of heat-input on austenite grain size in the heat-affected zone of HSLA-100 steel. Mater Sci Eng A 445–446:454–460. doi:10.1016/j.msea.2006.09.085

Somekawa H, Mukai T (2006) Fracture toughness in an extruded ZK60 magnesium alloy. Mater Trans 47:995–998

Lan L, Qiu C, Zhao D (2012) Analysis of martensite – austenite constituent and its effect on toughness in submerged arc welded joint of low carbon bainitic steel. J Mater Sci 47:4732–4742. doi:10.1007/s10853-012-6346-x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadijoo, M., Collins, L., Henein, H. et al. Evaluation of cold wire addition effect on heat input and productivity of tandem submerged arc welding for low-carbon microalloyed steels. Int J Adv Manuf Technol 92, 817–829 (2017). https://doi.org/10.1007/s00170-017-0150-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0150-3