Abstract

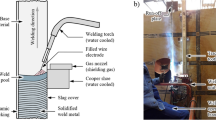

The pipeline industry has undertaken an essential upgrade of well-established X70 pipeline steel in heavy gauge pipes to fill the demand of increased operating pressures. A developed welding process, cold wire tandem submerged arc welding (CWTSAW), with improved deposition rate and travel speed can meet this upgrade. Currently, the effect of CWTSAW process parameters and bevel design on the change in weld geometry and properties of the weld and heat-affected zone (HAZ) in heavy gauge X70 pipe is not well understood. In this article, a series of weld trials were conducted on heavy gauge (19.1 mm) X70 steel plates to investigate the effect of cold wire feed speed, heat input, and bevel design on the reinforcement size, coarse-grained heat-affected zone (CGHAZ) area, ratio of weld shapes, and micro-hardness of the weld and HAZ. The results showed that the cold wire feed speed significantly influenced the micro-hardness profiles, and bevel design was the dominant factor influencing the reinforcement size and CGHAZ area. In addition, empirical equations of micro-hardness profiles of the CWTSAW samples were developed using nonlinear regression analysis. The phase fraction and morphology of martensite-austenite (MA) constituents were analyzed using optical microscopy and scanning electron microscopy. The microstructural results indicated lower MA fractions with fine and dispersed MA constituents obtained in the CGHAZ of the CWTSAW samples than for conventional tandem submerged arc welding samples. This can be interpreted as the reason for the lower hardness in the CGHAZ of the CWTSAW samples.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Code availability

Not applicable.

Abbreviations

- ACSQ:

-

Square wave alternating current

- ANOVA:

-

Analysis of variance

- AR:

-

Aspect ratio

- BA:

-

Bevel area

- BD:

-

Bevel design

- BM:

-

Base metal

- BTA:

-

Bead toe angle

- BW:

-

Bead width

- BW1/2 :

-

Bead width at half of penetration

- CGHAZ:

-

Coarse grained heat-affected zone

- CWFS:

-

Cold wire feed speed

- CWTSAW:

-

Cold wire tandem submerged arc welding

- DCEP:

-

Direct current electrode positive

- DIL:

-

Dilution

- FGHAZ:

-

Fine grained heat-affected zone

- ICHAZ:

-

Inter-critical heat-affected zone

- LBZ:

-

Localized brittle zone

- MA:

-

Martensite-austenite

- OM:

-

Optical microscopy

- PA:

-

Penetration area

- PD:

-

Penetration depth

- RA:

-

Reinforcement area

- S/N:

-

Signal-to-noise

- SAW:

-

Submerged arc welding

- SE:

-

Secondary electron

- SEM:

-

Scanning electrode microscopy

- SPR:

-

Semi-penetration ratio

- TMCP:

-

Thermo-mechanical controlled processing

- TOMR:

-

Three-order multiple regression

- TS:

-

Travel speed

- TSAW:

-

Tandem submerged arc welding

- V :

-

Voltage

- VL:

-

Voltage of the lead electrode

- VT:

-

Voltage of the trail electrode

- WM:

-

Weld metal

- DF:

-

Degrees of freedom

- F :

-

Variance ratio

- R 2 :

-

Coefficient of determination

- SS:

-

Sum of squares

- \(\eta\) :

-

Arc efficiency

- \(\rho\) :

-

Effective contribution

References

Collins LE, Dunnett K, Hylton T, Ray A (2018) Development of heavy gauge X70 helical line pipe. In Proceedings of the 2018 12th International Pipeline Conference (IPC), Calgary, Alberta, Canada

Weman K (2012) Welding Processes Handbook (2nd Edition) - 10.4.2 welding parameters and weld quality, Woodhead Publishing in Materials. In Weman K (ed) Welding Processes Handbook (2nd Edition). Woodhead Publishing, Paperback ISBN: 9780857095107, eBook ISBN: 9780857095183, pp 105–106

Bortsov AN, Shabalov IP, Velichko AA et al (2013) Features of multi-electrode submerged-arc welding in the production of high-strength thick-walled pipes. Metallurgist 57:310–319. https://doi.org/10.1007/s11015-013-9730-0

Moeinifar S, Kokabi AH, Madaah Hosseini HR et al (2010) Influence of four wires tandem submerged arc welding process on heat affected zone properties in high strength pipeline steel. Proc Int Conf Mech Ind Manuf Technol MIMT 85–89. https://doi.org/10.1115/1.859544.paper14

Far SM (2012) Influence of thermal simulated and real tandem submerged arc welding process on the microstructure and mechanical properties of the coarse grained heat affected zone. Appl Mech Mater 110–116:3191–3198. https://doi.org/10.4028/www.scientific.net/AMM.110-116.3191

Mruczek MF, Parker D (2006) Cold wire feed submerged arc welding. Concurrent Technologies Corporation, Johnstown, PA

Mohammadijoo M, Kenny S, Collins L et al (2017) Influence of cold-wire tandem submerged arc welding parameters on weld geometry and microhardness of microalloyed pipeline steels. Int J Adv Manuf Technol 88:2249–2263. https://doi.org/10.1007/s00170-016-8910-z

Mannarsamy R, Shrivastava SK, Thakor P, Chauhan G, Joshi SK, Korada R (2015) Establishment of cold wire addition technology in multiwire submerged arc welding for line pipe manufacturing to improve the weldment quality. ASME 2015 India Oil Gas Pipeline Conf 1–11

Júnior RC, Esteves L, Santos NF et al (2019) Influence of heat input and cold wire feeding rate on pitting corrosion resistance of submerged arc welding duplex stainless steel welds. J Mater Eng Perform 28:1969–1976. https://doi.org/10.1007/s11665-019-03967-7

Mohammadijoo M, Collins L, Lazor R et al (2018) Influence of cold-wire submerged arc welding on the toughness of microalloyed steel. Weld J 97:338s–352s. https://doi.org/10.29391/2018.97.029

Mohammadijoo M, Collins L, Henein H, Ivey DG (2017) Evaluation of cold wire addition effect on heat input and productivity of tandem submerged arc welding for low-carbon microalloyed steels. Int J Adv Manuf Technol 92:817–829. https://doi.org/10.1007/s00170-017-0150-3

Ishigami A, Roy MJ, Walsh JN, Withers PJ (2017) The effect of the weld fusion zone shape on residual stress in submerged arc welding. Int J Adv Manuf Technol 90:3451–3464. https://doi.org/10.1007/s00170-016-9542-z

Taguchi G (1993) Taguchi on robust technology development: bringing quality engineering upstream. ASME Press ISBN-10:0791800288. https://doi.org/10.1115/1.800288

Tarng YS, Yang WH (1998) Application of the Taguchi method to the optimization of the submerged arc welding process. Mater Manuf Process 13:455–467. https://doi.org/10.1080/10426919808935262

Sarkar A, Roy J, Majumder A, Saha SC (2014) Optimization of welding parameters of submerged arc welding using analytic hierarchy process (AHP) based on Taguchi technique. J Inst Eng Ser C 95:159–168. https://doi.org/10.1007/s40032-014-0114-4

Roy RK (2010) Primer on the Taguchi method (2nd edition) - 6. Analysis of Variance (ANOVA). In: Roy RK (ed) Primer on the Taguchi Method, 2nd ed. Soc Manuf Eng (SME)

Mathews P (2004) Chapter 8 linear regression. In: Design of Experiments with MINITAB. American Society for Quality (ASQ), pp 273–346

Mason RL, Gunst RF, Hess JL (2003) Analysis of nested designs and designs for process improvement. In Statistical Design and Analysis of Experiments - With Applications to Engineering and Science, 2nd Editio. pp 423–458

ASTM (2017) E3–11: Stardard guide for preparation of metallographic specimens. 11:1–17

ASTM (2017) E384–17: Standard test method for microindentation hardness of materials. ASTM Int 1–40

Mohammadijoo M, Henein H, Ivey DG (2016) Microstructural characterization of the HAZ in welded microalloyed steels. In: Microscopy Society of Canada 2016 MSC/SMC 43rd Annual Meeting. Edmonton, Alberta, Canada

Reisgen U, Dilthey U, Aretov I (2008) SAW cold wire technology - economic alternative for joining hot crack sensitive nickel-base alloys. Hot Crack Phenom Welds II:215–237. https://doi.org/10.1007/978-3-540-78628-3_12

Murugan N, Parmar RS, Sud SK (1993) Effect of submerged arc process variables on dilution and bead geometry in single wire surfacing. J Mater Process Tech 37:767–780. https://doi.org/10.1016/0924-0136(93)90135-S

Shahverdi Shahraki H, Mozafari H (2015) Modeling and optimizing of submerged arc welding process by Taguchi design of experiments in presence of magnesium oxide nano-particles. Appl Mech Mater 763:52–57. https://doi.org/10.4028/www.scientific.net/amm.763.52

O’Brien A (2004) Welding handbook. Volume 2: welding processes, part 1 - 6.5 process variables. In 9th Editio. Am Weld Soc (AWS) ISBN:9780871717290/0871717298, pp 278–282, ISBN:9780871717290/0871717298

Pepin J, Penniston C, Henein H et al (2012) Using semipenetration ratio to characterize effects of waveform variables on bead profile and heat affected zone with single electrode submerged arc welding. Can Metall Q 51:284–293. https://doi.org/10.1179/1879139512Y.0000000018

Sun Z, Pan D, Kuo M (2002) High Productivity cladding with non-consumable electrode arc processes. In: 6’th International Trendsin Welding Research Conference Proceedings, 15–19 April 2002, Pine Mountain, GA, USA. ASM Int 436–441

Chen J, Schwenk C, Wu CS, Rethmeier M (2012) Predicting the influence of groove angle on heat transfer and fluid flow for new gas metal arc welding processes. Int J Heat Mass Transf 55:102–111. https://doi.org/10.1016/j.ijheatmasstransfer.2011.08.046

Huang Y, Yu H, Zhang J, Ren C (2019) Study on arc physical characteristics of GPCA-TIG welding under different angles of V groove. Eng Res Express 1:015032. https://doi.org/10.1088/2631-8695/ab3c04

Ribic B, Tsukamoto S, Rai R, DebRoy T (2011) Role of surface-active elements during keyhole-mode laser welding. J Phys D Appl Phys. https://doi.org/10.1088/0022-3727/44/48/485203

Kannan PR, Muthupandi V, Devakumaran K (2018) On the effect of temperature coefficient of surface tension on shape and geometry of weld beads in hot wire gas tungsten arc welding process. Mater Today Proc 5:7845–7852. https://doi.org/10.1016/j.matpr.2017.11.465

Gowthaman K, Saiganesh J, Rajamanikam C (2013) Determination of submerged arc welding process parameters using Taguchi method and regression analysis. In 2013 International Conference on Energy Efficient Technologies for Sustainability. IEEE, Nagercoil, India, pp 842–847

Luo X, Chen X, Wang T et al (2018) Effect of morphologies of martensite–austenite constituents on impact toughness in intercritically reheated coarse-grained heat-affected zone of HSLA steel. Mater Sci Eng A 710:192–199. https://doi.org/10.1016/j.msea.2017.10.079

Mohammadijoo M, Valloton J, Collins L et al (2018) Characterization of martensite-austenite constituents and micro-hardness in intercritical reheated and coarse-grained heat affected zones of API X70 HSLA steel. Mater Charact 142:321–331. https://doi.org/10.1016/j.matchar.2018.05.057

Acknowledgements

The authors would like to acknowledge the Natural Sciences and Engineering Research Council (NSERC) of Canada, Evraz Inc. NA and TC Energy Corp. for providing financial support. Special thanks are also in order for the Research and Development Division of Evraz Inc. NA for providing welding equipment and technical assistance to conduct welding tests.

Funding

This research was financially supported by the Natural Sciences and Engineering Research Council (NSERC) of Canada, Evraz Inc. NA and TC Energy Corp.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

ANOVA tables (Table 9), average signal-to-noise (S/N) ratio (Table 10), and empirical equations from TOMR analysis.

Developed empirical equations from TOMR analysis:

Rights and permissions

About this article

Cite this article

Ren, T., Mohammadijoo, M., Wiskel, J. et al. Effect of cold wire addition in tandem submerged arc welding on weld geometry and micro-hardness of heavy gauge X70 steel. Int J Adv Manuf Technol 121, 7607–7625 (2022). https://doi.org/10.1007/s00170-022-09698-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09698-9