Abstract

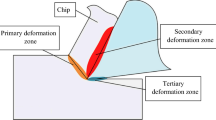

Heat generation during the machining process is an important issue which can accelerate wear of tools and also affect machining accuracy and surface quality of finished workpieces. Thermal damage due to lack of cutting fluid is a severe problem in dry cutting. As a result, different cooling technologies were proposed to reduce thermal damage and prolong tool life. However, there are less studies about the development of cooling technologies for dry cutting tools. In this thesis, an overview of cooling technologies for dry cutting tools, especially the internal cooling, is mainly discussed. Two main approaches, namely heat exchanger and heat pipe, which could have more potential in cooling for dry cutting tools are summarized. A new utilization of the pulsating heat pipe which could be the future research hotspot in cooling for dry cutting tools as a result of its feature is introduced.

Similar content being viewed by others

References

Childs THC, Maekawa K, Obikawa T, Yamane Y (2001) Metal machining theory and applications. Butterworth Heinemann, Oxford

Deng JX, Song WL, Zhang H (2009) Design, fabrication and properties of a self-lubricated tool in dry cutting. Int J Mach Tools Manuf 49(1):66–72

Klocke F, Eisenblaetter G (1997) Dry cutting. CIRP Ann Manuf Technol 46(2):519–526

Sreejith PS, Ngoi BKA (2000) Dry machining: machining of the future. J Mater Process Technol 101(1):287–291

Sun X, Bateman R, Cheng K, Ghani SC (2012) Design and analysis of an internally cooled smart cutting tool for dry cutting. Proc Inst Mech Eng B J Eng Manuf 226(4):585–591

Sharma VS, Dogra M, Suri NM (2009) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49(6):435–453

Deng JX, Ai X, Li ZQ (1996) Friction and wear behavior of Al2O3/TiB2 composite against cemented carbide in various atmospheres at elevated temperature. Wear 195(1–2):128–132

Lugscheider E, Barwulf S, Barimani C (1999) Properties of tungsten and vanadium oxides deposited by MSIP–PVD process for self-lubricating applications. Surf Coat Technol 120–121:458–464

Fox-Rabinovich GS, Yamamoto K, Kovalev AI, Veldhuis SC, Ning L, Shuster LS, Elfizy A (2008) Wear behavior of adaptive nano-multilayered TiAlCrN/NbN coatings under dry high performance machining conditions. Surf Coat Technol 202(10):2015–2022

Lei ST, Devarajan S, Chang ZH (2009) Study of micropool lubricated cutting tool in machining of mild steel. J Mater Process Technol 209(3):1612–1620

Noritaka K, Hiroshi S, Hideki M, Noboru M, Isao H (2009) Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis Eng 33(3):248–254

Obikawa T, Kamio A, Takaoka H, Osada A (2011) Micro-texture at the coated tool face for high performance cutting. Int J Mach Tools Manuf 51(12):966–972

Bouzakis KD, Michailidis N, Skordaris G, Bouzakis E, Biermann D, MSaoubi R (2012) Cutting with coated tools: coating technologies, characterization methods and performance optimization. CIRP Ann Manuf Technol 61(2):703–723

Scheerer H, Hoche H, Broszeit E, Schramm B, Abele E, Berger C (2005) Effects of the chromium to aluminum content on the tribology in dry machining using (Cr, Al)N coated tools. Surf Coat Technol 200(1–4):203–207

Bobzin K, Lugscheider E, Nickel R, Bagcivan N, Krämer A (2007) Wear behavior of Cr1−xAlxN PVD-coatings in dry running conditions. Wear 263(7–12):1274–1280

Tao SY, Yin ZJ, Zhou XM, Ding CX (2010) Sliding wear characteristics of plasma-sprayed Al2O3 and Cr2O3 coatings against copper alloy under severe conditions. Tribol Int 43(1–2):69–75

Liu JY, Han RD, Sun YF (2005) Research on experiments and action mechanism with water vapor as coolant and lubricant in Green cutting. Int J Mach Tools Manuf 45(6):687–694

Fan YH, Hao ZP, Lin JQ, Yu ZX (2015) New observations on tool wear mechanism in machining Inconel 718 under water vapor + air cooling lubrication cutting conditions. J Clean Prod 90:381–387

Perri GM, Bräunig M, Gironimo GD, Putz M, Tarallo A, Wittstock V (2016) Numerical modelling and analysis of the influence of an air cooling system on a milling machine in virtual environment. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8322-5

Evans C (1991) Cryogenic diamond turning of stainless steel. CIRP Ann 40(1):571–575

Dhar NR, Paul S, Chattopadhyay AB (2002) Role of cryogenic cooling on cutting temperature turning steel. J Manuf Sci Eng Trans ASME 124(1):146–154

Bordin A, Imbrogno S, Rotella G, Bruschi S, Ghiotti A, Umbrello D (2015) Finite element simulation of semi-finishing turning of electron beam melted Ti6Al4V under dry and cryogenic cooling. Procedia CIRP 31:551–556

Ahmed MI, Ismail AF, Abakr YA, Amin AN (2007) Effectiveness of cryogenic machining with modified tool holder. J Mater Process Technol 185(1–3):91–96

Wang FB, Wang YQ, Hou B, Zhang JB, Li YP (2016) Effect of cryogenic conditions on the milling performance of aramid fiber. J Adv Manuf Technol 83(1):429–439

Lee I, Bajpai V, Moon S, Byun J, Lee Y, Park HW (2015) Tool life improvement in cryogenic cooled milling of the preheated Ti-6Al-4V. J Adv Manuf Technol 79(1):665–673

Kheireddine AH, Ammouri AH, Lu T, Dillon OW Jr, Hamade RF, Jawahir IS (2015) An experimental and numerical study of the effect of cryogenic cooling on the surface integrity of drilled holes in AZ31BMg alloy. J Adv Manuf Technol 78(1):269–279

Akincioğlu S, Gökkaya H, Uygur İ (2016) The effects of cryogenic-treated carbide tools on tool wear and surface roughness of turning of Hastelloy C22 based on Taguchi method. J Adv Manuf Technol 82(1):303–314

Akincioğlu S, Gökkaya H, Uygur İ (2015) A review of cryogenic treatment on cutting tools. J Adv Manuf Technol 78(9):1609–1627

Gill SS, Singh H (2010) Cryoprocessing of cutting tool materials—a review. Int J Adv Manuf Technol 48(1):175–192

Gill SS, Singh J, Singh R, Singh H (2011) Metallurgical principles of cryogenically treated tool steels—a review on the current state of science. Int J Adv Manuf Technol 54(1):59–82

Çiçek A, Kıvak T, Uygur İ, Ekici E, Turgut Y (2012) Performance of cryogenically treated M35 HSS drills in drilling of austenitic stainless steels. Int J Adv Manuf Technol 60(1):65–73

Dogra M, Sharma VS, Sachdeva A, Suri NM, Dureja JS (2011) Performance evaluation of CBN, coated carbide, cryogenically treated uncoated/coated carbide inserts in finish-turning of hardened steel. Int J Adv Manuf Technol 57(5):541–553

Yong AYL, Seah KHW, Rahman M (2007) Performance of cryogenically treated tungsten carbide tools in milling operations. Int J Adv Manuf Technol 32(7):638–643

Vadivel K, Rudramoorthy R (2009) Performance analysis of cryogenically treated coated carbide inserts. Int J Adv Manuf Technol 42(3):222–232

Gill SS, Singh J, Singh H, Singh R (2012) Metallurgical and mechanical characteristics of cryogenically treated tungsten carbide (WC–Co). Int J Adv Manuf Technol 58(1):119–131

Fallenstein F, Aurich JC (2014) CFD based investigation on internal cooling of twist drills. Procedia CIRP 14:293–298

Rozzi JC, Sanders JK, Chen WB (2011) The experimental and theoretical evaluation of an indirect cooling system for machining. J Heat Transf. doi:10.1115/1.4002446

Shu SR, Ding H, Chen SJ, Cheng K (2012) FEM-based design and analysis of a smart cutting tool with internal cooling for cutting temperature measurement and control. Appl Mech Mater 217–219:1874–1879

Shu SR, Cheng K, Ding H, Chen SJ (2013) An innovative method to measure the cutting temperature in process by using an internally cooled smart cutting tool. J Manuf Sci Eng Trans ASME. doi:10.1115/1.4025742

Minton T, Ghani S, Sammler F, Bateman R, Fürstmann P, Roeder M (2013) Temperature of internally-cooled diamond-coated tools for dry-cutting titanium. Int J Mach Tools Manuf 75:27–35

Zhang CL, Zhang S, Yan XF, Zhang Q (2016) Effects of internal cooling channel structures on cutting forces and tool life in side milling of H13 steel under cryogenic minimum quantity lubrication condition. J Adv Manuf Technol 83(5):975–984

Jen TC, Gutierrez G, Eapen S, Barber G, Zhao H, Szuba PS, Labataille J, Manjunathaiah J (2002) Investigation of heat pipe cooling in drilling applications, Part I: preliminary numerical analysis and verification. Int J Mach Tools Manuf 42(5):643–652

Judd RL, Mackenzie HS, Elbestawi MA (1995) An investigation of a heat pipe cooling system for use in turning on a lathe. Int J Adv Manuf Technol 10(6):357–366

Haq AN, Tamizharasan T (2006) Investigation of the effects of cooling in hard turning operations. Int J Adv Manuf Technol 30(9):808–816

Chiou RY, Lu L, Chen JSJ, North MT (2007) Investigation of dry machining with embedded heat pipe cooling by finite element analysis and experiments. Int J Adv Manuf Technol 31(9):905–914

Liang L, Quan YM, Ke ZY (2011) Investigation of tool-chip interface temperature in dry turning assisted by heat pipe cooling. Int J Adv Manuf Technol 54(1):35–43

Zhu L, Jen TC, Yin CL, Kong XL, Yen YH (2012) Experimental analyses to investigate the feasibility and effectiveness in using heat pipe-embedded drills. Int J Adv Manuf Technol 58(9):861–868

Zhu L, Jen TC, Yin CL, Kong XL, Yen YH (2013) Investigation of the feasibility and effectiveness in using heat pipe-embedded drills by finite element analysis. Int J Adv Manuf Technol 64(5):659–668

Zhu L, Jen TC, Yin CL, Kong XL, Yen YH (2012) Experimental analyses to investigate the feasibility and effectiveness in using heat-pipe embedded end-mills. Int J Adv Manuf Technol 60(5):497–504

Zhu L, Peng SS, Yin CL, Jen TC, Cheng X, Yen YH (2014) Cutting temperature, tool wear, and tool life in heat-pipe-assisted end-milling operations. Int J Adv Manuf Technol 72(5):995–1007

Shu SR, Chen SJ, Cheng K (2011) Investigation of a novel green internal cooling in turning application. Proc Int Conf Electr Mech Eng Inf Technol 3:1156–1159

Sameer K, Pradipta KP, Frédéric L, Jocelyn B (2010) Local hydrodynamics of flow in a pulsating heat pipe: a review. Front Heat Pipes. doi:10.5098/fhp.v1.2.3003

Wu Z, Deng JX, Su C, Luo C, Xia D (2014) Performance of the micro-texture self-lubricating and pulsating heat pipe self-cooling tools in dry cutting process. Int J Refract Met Hard Mater 45:238–248

Wu Z, Yang Y, Luo C (2016) Design, fabrication and dry cutting performance of pulsating heat pipe self-cooling tools. J Clean Prod. doi:10.1016/j.jclepro.2016.02.129

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Z., Yang, Y., Su, C. et al. Development and prospect of cooling technology for dry cutting tools. Int J Adv Manuf Technol 88, 1567–1577 (2017). https://doi.org/10.1007/s00170-016-8842-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8842-7