Abstract

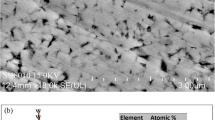

This study experimentally verifies the feasibility and effectiveness of heat-pipe cooling in end-milling operations. The basic idea is to embed a heat-pipe at the center of an end-mill with the evaporator close to the tool tip, and the condenser at the tool end. Thus, most of heat generated on the end-mill tip can be quickly removed dependent on convection heat transfer by means of heat-pipe. The end-milling experiments were carried out on a CNC vertical machining center under three different cooling conditions, including dry milling, fluid cooling, and heat-pipe cooling. The work material was AISI 1040 steel, and hard alloy was chosen for the cutting tool material. Flank wear is considered as the criterion for tool failure and the wear was measured using a Hisomet II Toolmaker's microscope. The tests were conducted until the end-mill was rejected when maximum flank wear equal to 0.30 mm was recorded. The results validate that heat-pipe-assisted cooling in end-milling processes can effectively perform thermal management comparable to the fluid cooling used pervasively in the manufacturing industry, increasing the service life of the end-mill.

Similar content being viewed by others

References

Johnson D (1996) Why cutting tools fail. Tooling & Production. Huebcore Communications Inc.

Trent E, Wright P (2000) Metal cutting. Butterworth/Heinemann, Oxford

Stephenson DA, Agapiou JS (2006) Metal cutting theory and practice. CRC Taylor & Francis, Boca Raton

Jen TC, Chen YM, Gutierrez G (2002) Investigation of heat-pipe cooling in drilling applications Part I: preliminary numerical analysis and verification. Int J Mach Tool Manufact 42:643–652

Chiou RY, Lu L, Chen JS-J, North MT (2007) Investigation of dry machining with embedded heat-pipe cooling by finite element analysis and experiments. Int J Adv Manuf Tech 31:905–914

Judd R-L, Aftab K, Elbestawi MA (1995) An investigation of a heat-pipe cooling system for use in turning on a lathe. Int J Adv Manuf Tech 10:357–366

Ding Y, Hong SY (1998) Improvement of chip breaking in machining low carbon steel by cryogenically pre-cooling the workpiece. J Manuf Sci Eng 120:76–83

Hung NP, Yeo SH, Oon BE (1997) Effect of cutting fluid on the machinability of metal matrix composites. J Mater Process Tech 67:157–161

Daniels T, Al-Jumaily F (1975) Investigation of the factor affecting the performance of a rotating heat-pipe. Int J Heat Mass Tran 18:961–973

Gutierrez, G (2002) Investigation of heat-pipes for drilling applications, Ph.D. Thesis, University of Wisconsin, Milwaukee.

Sreejith PS, Ngoi BKA (2000) Dry machining: machining of the future. J Mater Process Tech 101:287–291

Peterson GP (1994) An introduction to heat-pipes: modeling, testing, and applications. Wiley, New York

Jen, T.C, Jadhav, R (2003) Thermal management of a heat-pipe drill-A FEM analysis. Proceedings of NHTC03: ASME Summer Heat Transfer conference, 15–24, Las Vegas, Nevada, USA

Jen TC, Gutierrez G, Jadhav R (2002) Progress report for the heat-pipe drill temperatures simulations and experimental measurement, at Lamb Technicon Machining Systems. Warren, Michigan

Kalpakjian S, Schmid SR (2004) Manufacturing engineering and technology. 4th ed. Prentice Hall International

Lu L (2003) Investigation of embedded heat-pipe in cutting tools for dry machining. Masters thesis, Temple University, Philadelphia, Pennsylvania

Acknowledgments

The authors would like to thank the financial support for the project from EPA-STAR grant through RD833357.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Jen, TC., Yin, CL. et al. Experimental analyses to investigate the feasibility and effectiveness in using heat-pipe embedded end-mills. Int J Adv Manuf Technol 60, 497–504 (2012). https://doi.org/10.1007/s00170-011-3629-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3629-3