Abstract

The aramid fiber composite materials were processed by CNC milling machine in dye cutting and liquid nitrogen cryogenic conditions. The milling qualities and forces were analyzed, and cutting mechanism was discussed. The results show that with the increase of spindle speed, the better surface quality is only obtained in restrained 5000 r/min for the dye cutting, but in cryogenic conditions, the speed may be bigger. And at the same speed, the cryogenic ones are all more excellent than the dye ones. The cutting forces are generally lower for cryogenic than the dry ones at the same speed. The measuring instrument and material performance parameters from reference errors are the main error reason between model prediction and experimental measurements. Moreover, with the decrease of temperature, from tensile to shear fracture, the change of chip breaking improves the milling quality. In cryogenic condition, cutting force decrease and temperature drop have played a positive role for the improvement of the material cutting defects.

Similar content being viewed by others

References

Kececi E, Asmatulu R (2014) Effects of moisture ingression on polymeric laminate composites and its prevention via highly robust barrier films. Int J Adv Manuf Technol 73(9–12):1657–1664

Azmi AI, Lin RJT, Bhattacharyya D (2013) Machinability study of glass fibre-reinforced polymer composites during end milling. Int J Adv Manuf Technol 64(1–4):247–261

Soutis C (2005) Fibre reinforced composites in aircraft construction. Progress in aerospace. Sciences 41(2):143–151

Al-Sulaiman FA, Yilbas BS, Karakas FC (2008) Laser hole cutting in Kevlar modeling and quality assessment. Int J Adv Manuf Technol 38(11–12):1125–1136

El-Taweel TA, Abdel-Maaboud AM, Azzam BS (2009) Parametric studies on the CO2 laser cutting of Kevlar-49 composite. Int J Adv Manuf Technol 40(9–10):907–917

Shuaib AN, AI-Sulaiman FA, Hamid F (2004) Machinability of Kevlar-49 composite laminates while using standard TiN coated HSS drills. Mach Sci Technol 8(3):449–467

Al-Sulaiman FA, Yilbas BS, Ahsan M (2009) CO2 laser cutting of Kevlar laminate: influence of assisting gas pressure. Int J Adv Manuf Technol 45(1–2):62–70

Botelho EC, Silva RA, Pardini LC (2006) A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater Res 9(3):247–256

Jeremy G, Aaran J, Mohammad M, James S (2005) Low velocity impact of combination Kcvlar/carbon fiber sandwich composites. Compos Struct 69(4):396–406

Azmi AI, Lin RJT, Bhattacharyya D (2013) Tool wear prediction models during end milling of glass fibre-reinforced polymer composites. Int J Adv Manuf Technol 67(1–4):701–718

Kim J, Mai Y (1991) Effects of interfacial coating and temperature on the fracture behaviours of unidirectional Kevlar and carbon fibre reinforced epoxy resin composites. J Mater Sci 26(17):4702–4720

Grubb DT, Li Z (1994) Single-fibre polymer composites. J Mater Sci 29(1):203–212

Bunsell AR (1975) Tensile and fatigue behaviour of Kevlar-49 (PRD-49) fibre. J Mater Sci 10(8):1300–1308

Wan YZ, Chen GC, Huang Y (2005) Characterization of three-dimensional braided carbon/Kevlar hybrid composites for orthopedic usage. Mater Sci Eng A398(1–2):227–232

Santhanakrishnan G, Krishnamurthy R, Malhotra SK (1988) Machinability characteristics of fibre reinforced plastics composites. J Mech Work Technol 17:195–204

Shi W, Liu HL, Zhang JB, Liu YD (2013) Research on cutting defects of aramid fiber composites. Chin Plastic 27(4):71–74

Zhuang Y (2013) Study on the combined machining technology of sawing and grinding for aramid composites. Master degree thesis of Dalian University of Technology:39–48

Zhang B, Sun B, Dang JK (2011) Study of stock removing process about aramid paper honeycomb composite. Hi-Tech Fiber Applic 36(6):22–25

Won MS, Dharan CKH (2002) Drilling of aramid and carbon fiber polymer composites. Trans ASME 124(11):778–783

Bhattacharyya D, Allen MN, Mander SJ (1993) Cryogeric machining of Kevlar composites. Mater Manuf Process 8(6):631–651

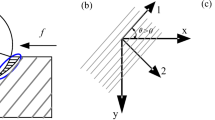

Zhang LC, Zhang HJ, Wang XM (2001) A force prediction model for cutting unidirectional fibre-reinforced plastics. Mach Sci Technol 5(3):293–305

Arola D, Ramulu M (1997) Orthogonal cutting of fiber-reinforced composites: a finite element analysis. Int J Mech Sci 39:597–613

Zhang L (2001) Solid mechanics for engineers. Macmillan Press, Basingstoke, pp 102–156

Sohei S, Keiji Okamoto KK (1988) The effect of water-absorption and cryogenic temperature on the strength of ArFRP. Mater Sci Res Int 4(4):287–293

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Wang, Y., Hou, B. et al. Effect of cryogenic conditions on the milling performance of aramid fiber. Int J Adv Manuf Technol 83, 429–439 (2016). https://doi.org/10.1007/s00170-015-7574-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7574-4