Abstract

Double-electrode gas metal arc welding (DE-GMAW) was recently developed to control the current through the workpiece at a desired level when the welding productivity was increased. A novel welding method entitled consumable double electrode with a single arc GMAW (consumable DESA-GMAW) was proposed to further enhance the welding productivity by replacing the non-consumable electrode in DE-GMAW with a consumable electrode. The consumable DESA-GMAW system can work stably with appropriate welding parameters. In this paper, the effects of control variables including the voltage of the main power source and slave power source as well as the wire feed speed of the main wire and bypass wire on the current distribution between the workpiece and bypass wire were studied. The effects of the variables on arc behavior and metal transfer process were also studied. The ratio of the current through the bypass wire to the main wire can be increased by decreasing the main power source voltage, increasing the slave power source, or increasing the main wire feed speed. However, a higher ratio obtained by modifying a single control parameter may negatively influence the regular metal transfer process.The ratio of the current through the workpiece to the main filler wire can be most effectively decreased with a combination of relatively lower main power source voltage and higher slave power source voltage.

Similar content being viewed by others

References

Li KH, Zhang YM, Xu P, Yang FQ (2008) High-strength steel welding with consumable double-electrode gas metal arc welding. Weld J 87:57s–64s

Ma GH, Zhang YM (2012) A novel DE-GMAW method to weld steel tubes on simplified condition. Int J Adv Manuf Technol 63:147–153

Wu CS, Hu ZK, Zhang YM (2009) Suppression of weld-bead defects and increase in the critical welding speed during high-speed arc welding. Proc Inst Mech Eng B-J Eng Manuf 223:751–757

Wu CS, Hu ZH, Zhong LM (2012) Prevention of humping bead associated with high welding speed by double-electrode gas metal arc welding. Int J Adv Manuf Technol 63:573–581

Lu Y, Chen SJ, Shi Y, Li XR, Chen JS, Kvidahl L, Zhang YM (2014) Double-electrode arc welding process: Principle, variant, control and developments. J Manuf Process 16:93–108

Shi Y, Han RH, Huang JK, Yan S (2014) Numerical and experimental study of temperature field for double electrode gas metal arc welding. J Manuf Sci E-T ASME

Li XR, Zhang YM, Kvidahl L (2013) Penetration depth monitoring and control in submerged arc welding. Weld J 92:48s–56s

Lu Y, Zhang YM, Kvidahl L (2013) Heat input reduction in fillet welding using bypass and root opening. Weld J 92:390s–400s

Shi Y, Shao L, Huang J, Gu Y (2013) Effects of Si and Mg elements on the microstructure of aluminum-steel joints produced by pulsed DE-GMA welding-brazing. Mater Sci Technol 29:1118–1124

Zhang YM, Jiang M, Lu W (2004) Double electrode improve GMAW heat input control. Welding J 83:39–41

Li KH, Chen JS, Zhang YM (2007) Double-electrode GMAW process and control. Weld J 86:231C237

Li KH, Zhang YM (2007) Metal transfer in double-electrode gas metal arc welding. J Manuf Sci Eng-Trans ASME 129:991–999

Wang ZZ, Zhang YM (2007) Image processing algorithm for automated monitoring of metal transfer in double-electrode GMAW. Meas Sci Technol 18:2048–2058

Li KH, Wu CS (2009) Mechanism of metal transfer in DE-GMAW. J Mater Sci Technol 25:415–418

Shao Y, Wang ZZ, Zhang YM (2011) Monitoring of liquid droplets in laser-enhanced GMAW. Int J Adv Manuf Technol 57:203–214

Wang XW, Huang Y, Zhang YM (2013) Droplet transfer model for laser-enhanced GMAW. Int J Adv Mannuf Technol 64:207–217

Wang ZZ, Huang Y, Zhang YM (2013) Unsupervised droplet identification during the pulsed laser enhanced GMAW process. Int J Adv Manuf Technol 67(5-8):1449–1457

Wu CS, Zhang MX, Li KH, Zhang YM (2007) Numerical analysis of double electrode gas metal arc welding process. Comp Mater Sci 39:416–423

Li KH, Zhang YM (2008) Consumable double-electrode GMAW Part I: the process. Weld J 87:11sC17s

Li KH, Zhang YM (2008) Consumable double-electrode GMAW part II: Monitoring, modeling, and control. Weld J 87:44sC50s

Li KH, Zhang YM (2010) Interval model control of consumable double-electrode gas metal arc welding process. IEEE T Autom Sci Eng 7:826–839

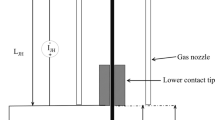

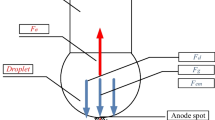

Wei HL, Li H, Yang LJ, Gao Y (2013) Consumable double electrode with a single arc GMAW. Int J Adv Manuf Technol 68:1539–1550

Park HJ, Kim DC, Kang MJ (2012) The arc phenomenon by the characteristic of EN ratio in AC pulse GMAW. Int J Adv Manuf Technol 66:867–875

Kah P, Suoranta R, Martikaine J (2013) Advanced gas metal arc welding processes. Int J Adv Manuf Technol 67:655–674

Rao ZH, Zhou J, Tsai HL (2012) Determination of equilibrium wire-feed-speeds for stable gas metal arc welding. Int J Heat Mass Transfer 55:6651–6664

Hu J, Tsai HL (2006) Effects of current on droplet generation and arc plasma in gas metal arc welding. J Appl Phys 100:053304

Palani PK, Murugan N (2005) Selection of parameters of pulsed current gas metal arc welding. J Mater Process Technol 172:1–10

Kim YS, Eagar TW (1993) Metal transfer in pulsed current gas metal arc welding. Welding J 72:s279–s287

Lancaster (1986) The physics of welding, 2nd edn. Pergamon, New York

Wang F, Hou WK, Hu SJ, Kannatey-Asibu E, Schultz WW, Wang PC (2003) Modeling and analysis of metal transfer in gas metal arc welding. J Phys D Appl Phys 36:1143–1152

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, H.L., Li, H., Gao, Y. et al. Welding process of consumable double electrode with a single arc GMAW. Int J Adv Manuf Technol 76, 435–446 (2015). https://doi.org/10.1007/s00170-014-6300-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6300-y