Abstract

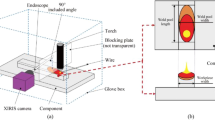

Pulsed laser-enhanced gas metal arc welding (GMAW) is an innovative arc welding process developed recently at the University of Kentucky. It uses the recoil pressure force generated by a pulsed laser to provide an additional force to reduce the needed electromagnetic detaching force (which is produced by the current) to assure the detachment of the droplet and the arc stability. The reduction in the current needed to detach droplets and maintain the arc stability improves the controllability of the most widely used arc welding process—GMAW—and its application range. To accurately control the detachment of the droplets, the force generated by the pulsed laser needs to be computed. Since this force is proportional to the distance from the center of the droplet to the welding wire, the problem can thus be changed to compute the distance between the droplet and the wire. To compute this distance, image processing method is the most effective way. Hence, different well-known image processing algorithms are implemented to address this problem and their performances are evaluated in this paper. Considering the robustness, processing speed, and automation, none of the evaluated image processing methods produce an acceptable result. To solve this specific problem, a novel image processing method is proposed. It is unsupervised and fast. Experimental results indicate that this proposed method can also achieve adequate computation accuracy.

Similar content being viewed by others

References

Huang Y, Zhang YM (2010) Laser enhanced GMAW. Weld J 89(9):181s–188s

Huang Y, Zhang YM (2011) Laser enhanced metal transfer: part I, system and observations. Weld J 90(10):183s–190s

Huang Y, Zhang YM (2011) Laser enhanced metal transfer: part II, analysis and influence factors. Weld J 90(11):205s–210s

Huang Y (2011) Control of metal transfer at given arc variables. Ph.D Dissertation, University of Kentucky

Bae KY, Lee TH, Ahn KC (2002) An optical sensing system for seam tracking and weld pool control in gas metal arc welding of steel pipe. J Mater Process Technol 120:458–465

Song HS, Zhang YM (2008) Measurement and analysis of three dimensional specular gas tungsten weld pool surface. Weld J 87(4):85s–95s

Mnich C, Al-Bayat F (2004) In situ weld pool measurement using stereovision. Japan–USA Symposium on Flexible Automation. Denver, Colorado

Zhao DB, Yi JQ (2003) Extraction of three-dimensional parameters for weld pool surface in pulsed GTAW with wire filler. J Manuf Sci Eng 125:493–503

Wang ZZ, Zhang YM (2009) Brightness-based selection and edge detection-based enhancement separation algorithm for low-resolution metal transfer images. IEEE Trans Automat Sci Eng 6(1):181–187

Wang ZZ, Zhang YM (2007) Image processing algorithm for automated monitoring of metal transfer in double-electrode GMAW. Meas Sci Tech 18:2048–2058

Xu CY, Prince JL (1998) Snakes, shapes, and gradient vector flow. IEEE Trans Image Process 7(3):359–369

Walker RF, Jackway PT (2003) Genetic algorithm optimization of adaptive multi-scale GLCM features. Int J Pattern Recogn Artif Intell 17(1):17–39

Gonzalez RC, Woods RE (1993) Digital image processing, 2nd edn. Addison Wesley, Reading, MA

Shi JB, Malik J (2000) Normalized cuts and image segmentation. IEEE Trans Pattern Anal Mach Intell 22(8):888–905

Stanley DR (1983) The radon transform and some of its applications. Wiley, New York

Sezgin M, Sankur B (2004) Survey over image thresholding techniques and quantitative performance evaluation. J Electron Imag 13(1):146–165

Wang ZZ, Zhang YM (2011) Robust and automated segmentation of a class of fuzzy edge images. Int J Model Ident Control 12:88–95

Wang ZZ, Zhang YM (2012) Segmentation of fuzzy images: a novel and fast two-step pseudo MAP method. Mach Vis Appl 23(6):1209–1218

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Huang, Y. & Zhang, Y. Unsupervised droplet identification during the pulsed laser enhanced GMAW process. Int J Adv Manuf Technol 67, 1449–1457 (2013). https://doi.org/10.1007/s00170-012-4580-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4580-7