Abstract

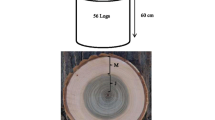

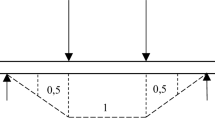

Peeling industry is the most important outlet for poplar resource composed of many cultivars. A comprehensive evaluation of wood quality of these different cultivars is necessary for a better knowledge of their suitability for innovative applications, like LVL for construction, in order to help foresters in their choices. This research participates to this approach, focusing on mechanical properties of LVL boards produced from ten cultivars, having grown in four different soils. Two trees were harvested per soil type and per cultivar; the tests were performed on eighty trees, which were peeled 1.4 mm thick and 3 mm thick. The produced veneers were used to manufacture 160 LVL boards using two adhesives: polyvinyl acetate (PVAc) and melamine–urea–formaldehyde (MUF). Each board was characterized by non-destructive and destructive mechanical tests, measuring their density, modulus of elasticity and modulus of rupture. The results show that the boards’ mechanical performance is neither linked to veneer thickness nor adhesive type. No cultivar or soil effect was clearly identified. The studied cultivars are not suitable for structural applications. Nevertheless, a discussion about an increase in the poplar rotation duration seems relevant in order to be able to use this wood for construction.

Similar content being viewed by others

References

Abdul Khalil HPS, Nurul Fazitaa MR, Bhata AH, Jawaida M, Nik Fuadb NA (2010) Development and material properties of new hybrid plywood from oil palm biomass. Mater Des 31:417–424

Aydin I, Colak S, Colakoglu G, Salih E (2004) A comparative study on some physical and mechanical properties of laminated veneer lumber (LVL) produced from Beech (Fagus orientalis Lipsky) and Eucalyptus camaldulensis Dehn veneers. Holz Roh Werkst 62:218–220

Baar J, Tippner J, Rademacher P (2015) Prediction of mechanical properties—modulus of rupture and modulus of elasticity—of five tropical species by non-destructive methods. Maderas Ciencia y Tecnología 17(2):239–252

Bal BC, Bektas I (2012a) The effects of wood species, load direction, and adhesives on bending properties of laminated veneer lumber. BioResources 7(3):3104–3112

Bal BC, Bektas I (2012b) The effects of some factors on the impact bending strength of laminated veneer lumber. BioResources 7(4):5855–5863

Bao F, Fu F, Choong ET, Hse C (2001) Contribution factor of wood properties of three poplar clones to strength of laminated veneer lumber. Wood Fiber Sci 33(3):345–352

Bekhta P, Marutzky R (2007) Reduction of glue consumption in the plywood production by using previously compressed veneer. Holz Roh Werkst 65:87–88

Berthelot A, Maine P, Bouvet A, Da Silva PD (2010) Caractéristiques générales du bois et des fibres. Dossier Qualités du bois de peuplier (General characteristics of wood and fibers. Poplar wood qualities file). Forêt-Entreprise 191:22–26

Bortoletto G Jr (2008) Quality evaluation of Pinus merkusii wood for veneer production (In Portuguese). Sci For 36:95–103

Brancheriau L, Bailléres H (2002) Natural vibration analysis of clear wooden beams: a theoretical review. Wood Sci Technol 36:347–365

Brancheriau L, Baillères H (2003) Use of the partial least squares method with acoustic vibration spectra as a new grading technique for structural timber. Holzforschung 57(6):644–652

Bucur V (2006) Acoustics of wood. Springer Verlag, Berlin

De Melo RR, Del Menezzi CHS (2014) Influence of veneer thickness on the properties of LVL from Parica (Schizolobium amazonicum) plantation trees. Eur J Wood Prod 72:191–198

De Boever L, Vansteenkiste D, Van Acker J, Stevens M (2007) End-use related physical and mechanical properties of selected fast-growing poplar hybrids (Populus trichocarpa × P. deltoides). Ann Wood Sci 64:621–630

Eckelman CA (1993) Potential uses of laminated veneer lumber in furniture. For Prod J 43(4):19–24

H’ng PS, Paridah MT, Chin KL (2010) Bending properties of LVL produced from Keruing (Dipterocarpus sp) reinforced with low density wood species. Asian J Sci Res 3:118–125

Haines DW, Leban JM, Herbé C (1996) Determination of Young’s modulus for spruce, fir and isotropic materials by the resonance flexure method with comparisons to static flexure and other dynamic methods. Wood Sci Technol 30:253–263

Hein PRG, Brancheriau L, Trugilho PF, Lima JT, Chaix G (2010) Resonance and near infrared spectroscopy for evaluating dynamic wood properties. J Near Infrared Spectrosc 18(6):443–454

Huda AA, Koubaa A, Cloutier A, Hemandez RE, Fortin Y (2014) Variation of the physical and mechanical properties of hybrid poplar clones. BioResources 9(1):1456–1471

Huda AA, Koubaa A, Cloutier A, Hernández RE, Périnet P, Fortin Y (2018) Phenotypic and genotypic correlations for wood properties of hybrid poplar clones of Southern Quebec. Forests 9(3):140

Kilic M (2011) The effects of the force load direction on bending strength and modulus of elasticity in laminated veneer lumber (LVL). BioResources 6(3):2805–2810

Kilic Y, Colak M, Baysal E, Burdurlu E (2006) An investigation of some physical and mechanical properties of laminated veneer lumber manufactured from black alder (Alnus glutinosa) glued with polyvinyl acetate and polyurethane adhesives. For Prod J 56:56–59

Klasnja S, Kopitovic S, Orlovic S (2003) Variability of some wood properties of eastern cottonwood (Populus deltoides Bartr) clones. Wood Sci Technol 37:331–337

Kretschmann DE, Moody RC, Pellerin RF, Bendtsen BA, Cahill JM, McAlister RH, Sharp DW (1993) Effect of various proportion of juvenile wood on laminated veneer lumber. FPL Res. Paper FPLRP-521

Kurt R (2010) Suitability of three hybrid poplar clones for laminated veneer lumber manufacturing using melamine urea formaldehyde adhesive. BioResources 5(3):1868–1878

Kurt R, Meric H, Aslan K, Cil M (2012) Laminated veneer lumber (LVL) manufacturing using three hybrid poplar clones. Turk J Agric For 36:237–245

Lutz JF (1974) Techniques for peeling process, slicing, drying veneer. USDA Forest Service Research Paper FPL 228, p 68

Marchal R, Mothe F, Denaud L, Thibaut B, Bleron L (2009) Cutting forces in wood machining–basics and applications in industrial processes. Holzforschung 63:157–167

Matos JLM (1997) Studies on the manufacture of Pinus taeda LVLs (in Portuguese). Dissertation, PhD in Forest Science, Paraná Federal University

Naudin E (2018) Sécurisation des approvisionnements en Peuplier: étude prospective de la ressource française (Securing poplar supplies: prospective study on the French resource) CODIFAB France. https://www.codifab.fr/sites/default/files/prospectiveressourcepeuplier-synthese-2018.pdf. Accessed 22 June 2019

Naudin E (2019) Ressource Peuplier: gérer puis sortir du prochain déficit (Poplar resource: manage and exit the next deficit). Forêt-entreprise 248:9–13

Nazerian M, Ghalehno MD, Kashkooli AB (2011) Effect of wood species, amount of juvenile wood and heat treatment on mechanical and physical properties of laminated veneer lumber. J Appl Sci 11:980–987

Oja J, Källsner B, Grundberg S (2005) Predicting the strength of sawn wood products: a comparison between x-ray scanning of logs and machine strength grading of lumber. For Prod J 55:55–60

Ouis D (1999) Vibrational and acoustical experiments on logs of spruce. Wood Sci Technol 33:151–184

Paillassa E (2014) Les peupleraies: Quels enjeux pour l’avenir de la populiculture française? (Poplar plantations: What challenges for the future of French poplar growing?). Revue Forrestière Fr. LXVI 3:301–311

Pliura A, Zhang SY, Mackay J, Bousquet J (2007) Genotypic variation in wood density and growth traits of poplar hybrids at four clonal trails. For Ecol Manag 238:92–106

Polge H (1973) Facteurs écologiques et qualité du bois (Ecological factors and wood quality). Annales des sciences forestières, INRA/EDP Sci 30(3):307–328

Qin GH, Jiang YZ, Qiao YL (2013) Selection of poplar hybrid clones (Populus ssp.) from backcrossed progenies of the Aigeiros section for industrial purpose. Silvae Genetica 62(1–2):52–61

Rahayu I, Denaud L, Marchal R, Darmawan W (2015) Ten new poplar cultivars provide laminated veneer lumber for structural application. Ann For Sci 72:705–715

Reuling D, Lanvin JD, Bouvert A, Proust E (2010) Les cultivars de peuplier Caractéristiques mécaniques du bois. Dossier Qualités du bois de peuplier (Poplar cultivars Mechanical characteristics of wood. Poplar wood qualities file). Forêt entreprise 191:39–43

Shukla SR, Kamdem PD (2009) Properties of laboratory made yellow poplar (Liriodendron tulipifera) laminated veneer lumber: effect of the adhesives. Eur J Wood Prod 67:397–405

Yang JL, Ilic Y, Wardlaw T (2003) Relationships between static and dynamic modulus of elasticity for a mixture of clear and decayed eucalyptus wood. Aust For 66:193–196

Zobel BJ, Jett JJ (1995) Genetics of wood production. Springer series in wood science. Springer, New York

Acknowledgements

This research was carried out at the Laboratoire Bourgogne des Matériaux et des Procédés (LaBoMaP), Ecole National Superieure d’Arts et Metiérs (ENSAM), Cluny, Bourgogne, France. Our thanks are addressed to our partners FCBA and IDF for their active collaboration. We also wish to thank KLEIBERIT and ICABOIS companies for providing the glues used in the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El Haouzali, H., Marchal, R., Bléron, L. et al. Mechanical properties of laminated veneer lumber produced from ten cultivars of poplar. Eur. J. Wood Prod. 78, 715–722 (2020). https://doi.org/10.1007/s00107-020-01546-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01546-5