Abstract

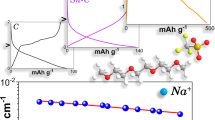

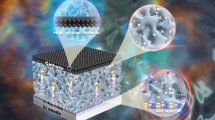

Conventional liquid electrolytes based sodium metal batteries suffer from severe safety hazards owing to electrolyte leakage, inflammability and dendritic sodium deposition. Herein, we report a flame-retardant quasi-solid polymer electrolyte with poly(methyl vinyl ether-alt-maleic anhydride) (P(MVE-alt-MA)) as host, bacterial cellulose (BC) as reinforcement, and triethyl phosphate/vinylene carbonate/sodium perchlorate (TEP/VC/NaClO4) as plasticizer for highly safe sodium metal batteries. The as-obtained quasi-solid polymer electrolyte exhibits superior flame retardancy (self-extinguish within 1 s), complete non-leakage property and wide electrochemical windows (4.4 V). More importantly, Na3V2(PO4)3/Na metal batteries using such polymer electrolyte delivers superior long-term cycling stability (84.4% capacity retention after 1000 cycles) which is significantly better than that (only 2% after 240 cycles) of liquid electrolyte. In addition, this flame-retardant quasi-solid polymer electrolyte provides favorable cycle performance (80.2% capacity retention after 70 cycles at 50 °C and 84.8% capacity retention after 50 cycles at −10 °C) for Na3V2(PO4)3/Na metal batteries. And this battery also displayed a normal charge/discharge property even at −15 °C. These fascinating cycle properties are mainly ascribed to the effective protective layers formed on Na3V2(PO4)3 cathode and sodium metal anode. More thorough investigation elucidates that such flame-retardant quasi-solid polymer electrolyte plays a multifunctional role in the advanced sodium metal batteries: (1) Being involved in the formation of a favorable cathode electrolyte interface (CEI) to inhibit the dissolution of vanadium and maintain the structure integrity of the Na3V2(PO4)3; (2) Participating in building a stable solid electrolyte interface (SEI) to suppress the growth of Na dendrites; (3) Integrating flame-retardance into polymer sodium batteries to enhance flame-resistance, eliminate electrolyte leakage, and thus improve safety of sodium batteries. Based on these results, we further assembled Na3V2(PO4)3/MoS2 pouch cell which can withstand harsh conditions (bended or cut off a corner), confirming the obtained polymer electrolyte with superior non-leakage property. In all, these outstanding characteristics would endow this flame-retardant quasi-solid polymer electrolyte a very promising candidate for highly-safe sodium metal batteries.

Similar content being viewed by others

References

Hueso, K. B.; Palomares, V.; Armand, M.; Rojo, T. Challenges and perspectives on high and intermediate-temperature sodium batteries. Nano Res. 2017, 10, 4082–4114.

Pan, H. L.; Hu, Y. S.; Chen, L. Q. Room-temperature stationary sodiumion batteries for large-scale electric energy storage. Energy Environ. Sci. 2013, 6, 2338–2360.

Li, Y. M.; Lu, Y. X.; Zhao, C. L.; Hu, Y. S.; Titirici, M. M.; Li, H.; Huang, X. J.; Chen, L. Q. Recent advances of electrode materials for low-cost sodium-ion batteries towards practical application for grid energy storage. Energy Storage Mater. 2017, 7, 130–151.

Huang, Y. Y.; Zheng, Y. H.; Li, X.; Adams, F.; Luo, W.; Huang, Y. H.; Hu, L. B. Electrode materials of sodium-ion batteries toward practical application. ACS Energy Lett. 2018, 3, 1604–1612.

Cao, Y. L.; Xiao, L. F.; Wang, W.; Choi, D.; Nie, Z. M.; Yu, J. G.; Saraf, L. V.; Yang, Z. G.; Liu, J. Reversible sodium ion insertion in single crystalline manganese oxide nanowires with long cycle life. Adv. Mater. 2011, 23, 3155–3160.

Qian, J. F.; Wu, C.; Cao, Y. L.; Ma, Z. F.; Huang, Y. H.; Ai, X. P.; Yang, H. X. Prussian blue cathode materials for sodium-ion batteries and other ion batteries. Adv. Energy Mater. 2018, 8, 1702619.

Li, Y. M.; Xu, S. Y.; Wu, X. Y.; Yu, J. Z.; Wang, Y. S.; Hu, Y. S.; Li, H.; Chen, L. Q.; Huang, X. J. Amorphous monodispersed hard carbon microspherules derived from biomass as a high performance negative electrode material for sodium-ion batteries. J. Mater. Chem. A 2015, 3, 71–77.

Li, Q.; Liu, Z. G.; Zheng, F.; Liu, R.; Lee, J.; Xu, G. L.; Zhong, G. M.; Hou, X.; Fu, R. Q.; Chen, Z. H. et al. Identifying the structural evolution of the sodium ion battery Na2FePO4F cathode. Angew. Chem., Int. Ed. 2018, 57, 11918–11923.

Chen, S. Q.; Wu, C.; Shen, L. F.; Zhu, C. B.; Huang, Y. Y.; Xi, K.; Maier, J.; Yu, Y. Challenges and perspectives for NASICON-type electrode materials for advanced sodium-ion batteries. Adv. Mater. 2017, 29, 1700431.

Hwang, J. Y.; Myung, S. T.; Sun, Y. K. Sodium-ion batteries: Present and future. Chem. Soc. Rev. 2017, 46, 3529–3614.

Eshetu, G. G.; Grugeon, S.; Kim, H.; Jeong, S.; Wu, L. M.; Gachot, G.; Laruelle, S.; Armand, M.; Passerini, S. Comprehensive insights into the reactivity of electrolytes based on sodium ions. ChemSusChem. 2016, 9, 462–471.

Xia, X.; Obrovac, M. N.; Dahn, J. R. Comparison of the reactivity of NaxC6 and LixC6 with non-aqueous solvents and electrolytes. Electrochem. Solid-State Lett. 2011, 14, A130–A133.

Xia, X.; Dahn, J. R. Study of the reactivity of Na/hard carbon with different solvents and electrolytes. J. Electrochem. Soc. 2012, 159, A515–A519.

Matsumoto, K.; Hosokawa, T.; Nohira, T.; Hagiwara, R.; Fukunaga, A.; Numata, K.; Itani, E.; Sakai, S.; Nitta, K.; Inazawa, S. The Na[FSA]-[C2C1im][FSA] (C2C1im+: 1-ethyl-3-methylimidazolium and FSA−: Bis(fluorosulfonyl)amide) ionic liquid electrolytes for sodium secondary batteries. J. Power Sources 2014, 265, 36–39.

Wongittharom, N.; Wang, C. H.; Wang, Y. C.; Yang, C. H.; Chang, J. K. Ionic liquid electrolytes with various sodium solutes for rechargeable Na/NaFePO4 batteries operated at elevated temperatures. ACS Appl. Mater. Interfaces 2014, 6, 17564–17570.

Zhang, Z. Z.; Zhang, Q. Q.; Ren, C.; Luo, F.; Ma, Q.; Hu, Y. S.; Zhou, Z. B.; Li, H.; Huang, X. J.; Chen, L. Q. A ceramic/polymer composite solid electrolyte for sodium batteries. J. Mater. Chem. A 2016, 4, 15823–15828.

Goodenough, J. B.; Hong, H. Y. P.; Kafalas, J. A. Fast Na+-ion transport in skeleton structures. Mater. Res. Bull. 1976, 11, 203–220.

Chandrasekaran, R.; Mangani, I. R.; Vasanthi, R.; Selladurai, S. Ionic conductivity and battery characteristic studies on PEO + NaClO3 polymer electrolyte. Ionics 2001, 7, 88–93.

Bhide, A.; Hariharan, K. Composite polymer electrolyte based on (PEO)6: NaPO3 dispersed with BaTiO3. Polym. Int. 2008, 57, 523–529.

Reddy, C. V. S.; Jin, A. P.; Zhu, Q. Y.; Mai, L. Q.; Chen, W. Preparation and characterization of (PVP + NaClO4) electrolytes for battery applications. Eur. Phys. J. E. 2006, 19, 471–476.

Feng, J. K.; An, Y. L.; Ci, L. J.; Xiong, S. L. Nonflammable electrolyte for safer non-aqueous sodium batteries. J. Mater. Chem. A 2015, 3, 14539–14544.

Liu, X. W.; Jiang, X. Y.; Zeng, Z. Q.; Ai, X. P.; Yang. H. X.; Zhong, F. P.; Xia, Y. Y.; Cao, Y. L. High capacity and cycle-stable hard carbon anode for nonflammable sodium-ion batteries. ACS Appl. Mater. Interfaces 2018, 10, 38141–38150.

Zeng, Z. Q.; Jiang, X. Y.; Li, R.; Yuan, D. D.; Ai, X. P.; Yang, H. X.; Cao, Y. L. A safer sodium-ion battery based on nonflammable organic phosphate electrolyte. Adv. Sci. 2016, 3, 1600066.

Wang, J. H.; Yamada, Y.; Sodeyama, K.; Watanabe, E.; Takada, K.; Tateyama, Y.; Yamada, A. Fire-extinguishing organic electrolytes for safe batteries. Nat. Energy 2018, 3, 22–29.

Wei, S. Y.; Choudhury, S.; Xu, J.; Nath, P.; Tu, Z. Y.; Archer, L. A. Highly stable sodium batteries enabled by functional ionic polymer membranes. Adv. Mater. 2017, 29, 1605512.

Monroe, C.; Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 2005, 152, A396–A404.

Tikekar, M. D.; Archer, L. A.; Koch, D. L. Stabilizing electrodeposition in elastic solid electrolytes containing immobilized anions. Sci. Adv. 2016, 2, e1600320.

Tu, Z. Y.; Kambe, Y.; Lu, Y. Y.; Archer, L. A. Nanoporous polymer-ceramic composite electrolytes for lithium metal batteries. Adv. Energy Mater. 2014, 4, 1300654.

Mercan, E.; Sert, D.; Akın, N. Effect of high-pressure homogenisation on viscosity, particle size and microbiological characteristics of skim and whole milk concentrates. Int. Dairy J. 2018, 87, 93–99.

Liu, C. B.; Gao, J. M.; Tang, Y. B.; Chen, X. M. Preparation and characterization of gypsum-based materials used for 3D robocasting. J. Mater. Sci. 2018, 53, 16415–16422.

Fei, G. Q.; Zhang, Y.; Wang, X.; Li, X. R.; Wang, H. H. Effects of continuous phase and crosslinking agent on the rheological behaviors and properties of cationic poly(urethane-acrylate) emulsifier-free microemulsions. J. Nanosci. Nanotechnol. 2018, 18, 8419–8425.

Ponrouch, A.; Marchante, E.; Courty, M.; Tarascon, J. M.; Palacín, M. R. In search of an optimized electrolyte for Na-ion batteries. Energy Environ. Sci. 2012, 5, 8572–8583.

Zimmerman, A. H. Self-discharge losses in lithium-ion cells. IEEE Aerosp. Electron. Syst. Mag. 2004, 19, 19–24.

Seong, W. M.; Park, K. Y.; Lee, M. H.; Moon, S.; Oh, K.; Park, H.; Lee, S.; Kang, K. Abnormal self-discharge in lithium-ion batteries. Energy Environ. Sci. 2018, 11, 970–978.

Shen, W.; Li, H.; Wang, C.; Li, Z. H.; Xu, Q. J.; Liu, H. M.; Wang, Y. G. Improved electrochemical performance of the Na3V2(PO4)3 cathode by B-doping of the carbon coating layer for sodium-ion batteries. J. Mater. Chem. A 2015, 3, 15190–15201.

Ponrouch, A.; Dedryvère, R.; Monti, D.; Demet, A. E.; Mba, J. M. A.; Croguennec, L.; Masquelier, C.; Johansson, P.; Palacín M. R. Towards high energy density sodium ion batteries through electrolyte optimization. Energy Environ. Sci. 2013, 6, 2361–2369.

Dong, T. T.; Zhang, J. J.; Xu, G. J.; Chai, J. C.; Du, H. P.; Wang, L. L.; Wen, H. J.; Zang, X.; Du, A. B.; Jia, Q. M. et al. A multifunctional polymer electrolyte enables ultra-long cycle-life in a high-voltage lithium metal battery. Energy Environ. Sci. 2018, 11, 1197–1203.

Evenson, S. A.; Badya, J. P. S. Solventless attachment of long-chain molecules to poly(ethylene-alt-maleic anhydride) copolymer surfaces. J. Phys. Chem. B 1998, 102, 5500–5502.

Klee, R.; Wiatrowski, M.; Aragón, M. J.; Lavela, P.; Ortiz, G. F.; Alcántara, R.; Tirado, J. L. Improved surface stability of C + MxOy@Na3V2(PO4)3 prepared by ultrasonic method as cathode for sodium-ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 1471–1478.

Nacimiento, F.; Cabello, M.; Alcántara, R.; Lavela, P.; Tirado, J. L. NASICON-type Na3V2(PO4)3 as a new positive electrode material for rechargeable aluminium battery. Electrochim. Acta 2018, 260, 798–804.

Aragón, M. J.; Lavela, P.; Ortiz, G. F.; Alcántara, R.; Tirado, J. L. Induced rate performance enhancement in off-stoichiometric Na3+3xV2−x(PO4)3 with potential applicability as the cathode for sodium-ion batteries. Chem. - Eur. J. 2017, 23, 7345–7352.

Hu, Z. L.; Zhang, S.; Dong, S. M.; Li, Q.; Cui, G. L.; Chen, L. Q. Self-stabilized solid electrolyte interface on a host-free Li-metal anode toward high areal capacity and rate utilization. Chem. Mater. 2018, 30, 4039–4047.

Chai, J. C.; Liu, Z. H.; Ma, J.; Wang, J.; Liu, X. C.; Liu, H. S.; Zhang, J. J.; Cui, G. L.; Chen, L. Q. In situ generation of poly(vinylene carbonate) based solid electrolyte with interfacial stability for LiCoO2 lithium batteries. Adv. Sci. 2017, 4, 1600377.

Zhao, H.; Zhou, X.; Park, S. J.; Shi, F. F.; Fu, Y. B.; Ling, M.; Yuca, N.; Battaglia, V.; Liu, G. A polymerized vinylene carbonate anode binder enhances performance of lithium-ion batteries. J. Power Sources 2014, 263, 288–295.

Zhang, B.; Metzger, M.; Solchenbach, S.; Payne, M.; Meini, S.; Gasteiger, H. A.; Garsuch, A.; Lucht, B. L. Role of 1,3-propane sultone and vinylene carbonate in solid electrolyte interface formation and gas generation. J. Phys. Chem. C 2015, 119, 11337–11348.

Acknowledgements

This original research was financially supported by the National Natural Science Foundation of China (Nos. 51703236 and U1706229), the National Science Fund for Distinguished Young Scholars (No. 51625204), the National Key Research and Development Program of China (No. 2018YFB0104300), Think-Tank Mutual Fund of Qingdao Energy Storage Industry Scientific Research, Key Scientific and Technological Innovation Project of Shandong (No. 2017CXZC0505).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

12274_2019_2369_MOESM1_ESM.pdf

Flame-retardant quasi-solid polymer electrolyte enabling sodium metal batteries with highly safe characteristic and superior cycling stability

Rights and permissions

About this article

Cite this article

Yang, J., Zhang, M., Chen, Z. et al. Flame-retardant quasi-solid polymer electrolyte enabling sodium metal batteries with highly safe characteristic and superior cycling stability. Nano Res. 12, 2230–2237 (2019). https://doi.org/10.1007/s12274-019-2369-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-019-2369-9