Abstract

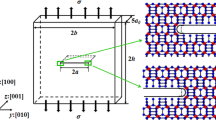

The fracture behavior of a single-crystal Al-nanoplate with an edge crack under tensile loading was simulated using a molecular statics technique to evaluate crack growth resistance in Al. The crack length was determined using a stiffness method. A parabolic function fitted from simulation results was used to predict the crack length from the stiffness value extracted from unloading curves. Based on energy considerations, crack growth resistance was calculated. Crack growth resistance rose sharply in the initial stages of crack growth, and with an additional crack extension, it increased gradually to converge to a constant far exceeding the fracture toughness predicted by the Griffith criterion. This trend in the crack growth resistance curve was closely related to the amorphous zone formed at the crack tip after the onset of crack propagation.

Similar content being viewed by others

References

A. Stranz, A. Waag, and E. Peiner: Thermal characterization of vertical silicon nanowires. J. Mater. Res. 26, 1958 (2011).

L. Lu, Y. Shen, X. Chen, L. Qian, and K. Lu: Ultrahigh strength and high electrical conductivity in copper. Science 304, 422 (2004).

A.S. Alexandrov and V.V. Kabanov: Magnetic quantum oscillations in nanowires. Phys. Rev. Lett. 95, 76601 (2005).

X.R. Zhuo and H.G. Beom: Molecular statics simulations of the size-dependent mechanical properties of copper nanofilms under shear loading. Comput. Mater. Sci. 99, 390 (2015).

D.J. Maxwell, S.R. Emory, and S. Nie: Nanostructured thin-film materials with surface-enhanced optical properties. Chem. Mater. 13, 1082 (2001).

Y. Cui, Q. Wei, H. Park, and C.M. Lieber: Nanowire nanosensors for highly sensitive and selective detection of biological and chemical species. Science 293, 1289 (2001).

K. Jensen, C. Girit, W. Mickelson, and A. Zettl: Tunable nanoresonators constructed from telescoping nanotubes. Phys. Rev. Lett. 96, 215503 (2006).

O. Sul and E. Yang: A multi-walled carbon nanotube–aluminum bimorph nanoactuator. Nanotechnology 20, 95502 (2009).

S.B. Legoas, V.R. Coluci, S.F. Braga, P.Z. Coura, S.O. Dantas, and D.S. Galvao: Molecular-dynamics simulations of carbon nanotubes as gigahertz oscillators. Phys. Rev. Lett. 90, 55504 (2003).

Z.L. Wang and J. Song: Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312, 242 (2006).

M.J. Buehler, F.F. Abraham, and H. Gao: Hyperelasticity governs dynamic fracture at a critical length scale. Nature 426, 141 (2003).

J. Diao, K. Gall, and M.L. Dunn: Surface-stress-induced phase transformation in metal nanowires. Nat. Mater. 2, 656 (2003).

C.B. Cui and H.G. Beom: Molecular dynamics simulations of edge cracks in copper and aluminum single crystals. Mater. Sci. Eng., A 609, 102 (2014).

X.R. Zhuo and H.G. Beom: Size-dependent fracture properties of cracked silicon nanofilms. Mater. Sci. Eng., A 636, 470 (2015).

D. Farkas: Fracture resistance of nanocrystalline Ni. Metall. Mater. Trans. A 38, 2168 (2007).

D. Farkas, H. Van Swygenhoven, and P.M. Derlet: Intergranular fracture in nanocrystalline metals. Phys. Rev. B: Condens. Matter Mater. Phys. 66, 60101 (2002).

R.K. Kalia, A. Nakano, A. Omeltchenko, K. Tsuruta, and P. Vashishta: Role of ultrafine microstructures in dynamic fracture in nanophase silicon nitride. Phys. Rev. Lett. 78, 2144 (1997).

K.L. Baker and D.H. Warner: Extended timescale atomistic modeling of crack tip behavior in aluminum. Modell. Simul. Mater. Sci. Eng. 20, 65005 (2012).

H. Krull and H. Yuan: Suggestions to the cohesive traction–separation law from atomistic simulations. Eng. Fract. Mech. 78, 525 (2011).

M. Ippolito, A. Mattoni, N. Pugno, and L. Colombo: Failure strength of brittle materials containing nanovoids. Phys. Rev. B: Condens. Matter Mater. Phys. 75, 224110 (2007).

Y. Mishin, D. Farkas, M.J. Mehl, and D.A. Papaconstantopoulos: Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys. Rev. B: Condens. Matter Mater. Phys. 59, 3393 (1999).

D.H. Tsai: The virial theorem and stress calculation in molecular dynamics. J. Chem. Phys. 70, 1375 (1979).

A.K. Subramaniyan and C.T. Sun: Continuum interpretation of virial stress in molecular simulations. Int. J. Solids Struct. 45, 4340 (2008).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

J. Li: AtomEye: An efficient atomistic configuration viewer. Modell. Simul. Mater. Sci. Eng. 11, 173 (2003).

D. Farkas, M. Duranduru, W.A. Curtin, and C. Ribbens: Multiple-dislocation emission from the crack tip in the ductile fracture of Al. Philos. Mag. A 81, 1241 (2001).

R.G. Hoagland, M.S. Daw, S.M. Foiles, and M.I. Baskes: An atomic model of crack tip deformation in aluminum using an embedded atom potential. J. Mater. Res. 5, 313 (1990).

H. Kimizuka, H. Kaburaki, F. Shimizu, and J. Li: Crack-tip dislocation nanostructures in dynamical fracture of fcc metals: A molecular dynamics study. J. Comput.-Aided Mol. Des. 10, 143 (2003).

A. Stukowski and K. Albe: Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Modell. Simul. Mater. Sci. Eng. 18, 85001 (2010).

T.L. Anderson: Fracture Mechanics: Fundamentals and Applications, 3rd ed. (CRC Press, Boca Raton, 2005).

J. Eftis and H. Liebowitz: On fracture toughness evaluation for semi-brittle fracture. Eng. Fract. Mech. 7, 101 (1975).

A.A. Griffith: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A. 221, 163 (1921).

L. Hung and E.A. Carter: Ductile processes at aluminium crack tips: Comparison of orbital-free density functional theory with classical potential predictions. Modell. Simul. Mater. Sci. Eng. 19, 45002 (2011).

P. White: Molecular dynamic modelling of fatigue crack growth in aluminium using LEFM boundary conditions. Int. J. Fatigue. 44, 141 (2012).

R.G. Hoagland, M.S. Daw, and J.P. Hirth: Some aspects of forces and fields in atomic models of crack tips. J. Mater. Res. 6, 2565 (1991).

A.K. Nair, D.H. Warner, and R.G. Hennig: Coupled quantum–continuum analysis of crack tip processes in aluminum. J. Mech. Phys. Solids 59, 2476 (2011).

G.E. Beltz, D.M. Lipkin, and L.L. Fischer: Role of crack blunting in ductile versus brittle response of crystalline materials. Phys. Rev. Lett. 82, 4468 (1999).

F.J. Gómez and M. Elices: Fracture loads for ceramic samples with rounded notches. Eng. Fract. Mech. 73, 880 (2006).

R.G. Hoagland: Crystallographic aspects of dislocation emission from a crack tip in an fcc metal. Philos. Mag. A 76, 543 (1997).

W.W. Gerberich, H. Huang, W. Zielinski, and P.G. Marsh: A dislocation shielding prediction of the toughness transition during cleavage of semibrittle crystals. Metall. Mater. Trans. A 24, 535 (1993).

V. Tvergaard and J.W. Hutchinson: Effect of strain-dependent cohesive zone model on predictions of crack growth resistance. Int. J. Solids Struct. 33, 3297 (1996).

ACKNOWLEDGMENTS

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of Education, Republic of Korea (NRF-2013R1A1A2A10008799).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhuo, X.R., Kim, J.H. & Beom, H.G. Atomistic investigation of crack growth resistance in a single-crystal Al-nanoplate. Journal of Materials Research 31, 1185–1192 (2016). https://doi.org/10.1557/jmr.2016.155

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.155