Abstract

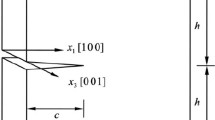

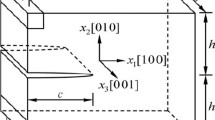

Molecular dynamics simulations are implemented to study the mechanical fracture of CoSb3 with penetrated nanocracks under the mode-I stress. The crack surface and crack front direction are (100) and [001], respectively. It is found that, at a fixed initial crack length, the fracture strength varies with the sample size, but the calculated value of fracture toughness KIC, by employing the classical formula of linear elastic fracture mechanics, maintains constant. When the crack is short in length relative to the sample, the variation of the fracture strength with the initial crack length is well fitted mathematically, and the extrapolation shows rationality even up to the macroscale. More general analyses reveal that, the fracture toughness increases monotonically with increasing the initial crack length until reaching the limit, and the increment is particularly noticeable below 36 nm. Furthermore, different atomic configurations at the crack tip are considered, which show an evident influence on the strength of nano-cracked CoSb3.

Similar content being viewed by others

Data availability

All data generated during this study are publicly available.

References

Yang L, Chen ZG, Dargusch MS, Zou J. High performance thermoelectric materials: progress and their applications. Adv Energy Mater. 2018;8(6):1–28.

Beretta D, Neophytou N, Hodges JM, Kanatzidis MG, Narducci D, Martin-Gonzalez M, Beekman M, Balke B, Cerretti G, Tremel W, Zevalkink A, Hofmann AI, Muller C, Dorling B, Campoy-Quiles M, Caironi M. Thermoelectrics: from history, a window to the future. Mater Sci Eng R Rep. 2019;138:210–55.

Attivissimo F, Di Nisio A, Lanzolla AML, Paul M. Feasibility of a photovoltaic-thermoelectric generator: Performance analysis and simulation results. IEEE Trans Instrum Meas. 2015;64(5):1158–69.

Liu D, Zhao FY, Yang HX, Tang GF. Thermoelectric mini cooler coupled with micro thermosiphon for CPU cooling system. Energy. 2015;83:29–36.

Fan SF, Gao YW. Numerical analysis on the segmented annular thermoelectric generator for waste heat recovery. Energy. 2019;183:35–47.

Agudelo AF, Garcia-Contreras R, Agudelo JR, Armas O. Potential for exhaust gas energy recovery in a diesel passenger car under European driving cycle. Appl Energy. 2016;174:201–12.

Zhang L, Shi XL, Yang YL, Chen ZG. Flexible thermoelectric materials and devices: From materials to applications. Mater Today. 2021;46:62–108.

Hao YN, He XY, Wang LM, Qin XH, Chen GM, Yu JY. Stretchable thermoelectrics: strategies, performances, and applications. Adv Funct Mater. 2022;32(13):2109790.

Rogl G, Rogl P. Skutterudites, a most promising group of thermoelectric materials. Curr Opin Green Sustain Chem. 2017;4:50–7.

Sofo JO, Mahan GD. Electronic structure of CoSb3: a narrow-band-gap semiconductor. Phys Rev B. 1998;58(23):15620–3.

Yadav S, Chaudhary S, Pandya DK. Enhancing thermoelectric properties of p-type CoSb3 skutterudite by Fe doping. Mater Sci Semicon Process. 2021;127:105721.

Qin DD, Cui B, Zhu JB, Shi WJ, Qin HX, Guo FK, Cao J, Cai W, Sui JH. Enhanced thermoelectric and mechanical performance in n-type Yb-filled skutterudites through aluminum alloying. ACS Appl Mater Interfaces. 2020;12(11):12930–7.

Zong PA, Mao ZD, Ou YX, Shi TF, Wang ZW, Zhang QH, Zhang P, Wan CL. Enhanced thermoelectric properties of binary CoSb3 by embedding FeCl3-intercalated graphene nanosheets. J Eur Ceram Soc. 2021;41(13):6523–30.

Rogl G, Rogl P. Mechanical properties of skutterudites. Sci Adv Mater. 2011;3:517–38.

Liu HT, Zhang JW, Zhao MH, Lu CS. Determination of the fracture toughness of glasses via scratch tests with a vickers indenter. Acta Mech Solida Sin. 2022;35(1):129–38.

Tan Y, Yang XQ. Molecular dynamics simulations on the tensile failure of crystalline CoSb3 along different orientations. J Mater Eng Perform. 2020;29(7):4659–68.

Zhang XL, Li GD, Duan B, Chen G, Yang XQ, Zhai PC. Vacancy effect of antimony on shear deformation mechanisms of CoSb3 thermoelectric material. Comput Mater Sci. 2020;182:109761.

Cai LJ, Yang XQ, Zhai PC. Uniaxial tension of crystalline CoSb3 with holes of different sizes: a molecular dynamics study. Appl Phys A-Mater Sci Process. 2022;128:77.

Xu SZ, Xiong LM, Deng Q, McDowell DL. Mesh refinement schemes for the concurrent atomistic-continuum method. Int J Solids Struct. 2016;90:144–52.

Shimada T, Ouchi K, Chihara Y, Kitamura T. Breakdown of continuum fracture mechanics at the nanoscale. Sci Rep. 2015;5:8596.

Yin HQ, Qi HJ, Fan FF, Zhu T, Wang BL, Wei YJ. Griffith criterion for brittle fracture in graphene. Nano Lett. 2015;15(3):1918–24.

Jiang Z, Lin R, Zhao J. Fracture toughnesses and crack growth angles of single-layer graphyne sheets. Acta Mech Solida Sin. 2019;32:339–55.

Hao TY, Zhang ZC, Ahmed T, Xu J, Brown S, Hossain ZM. Line-defect orientation- and length-dependent strength and toughness in hBN. J Appl Phys. 2021;129:014304.

Pan F, Tian H, Zhang B. Nanofracture of stretched hexagonal boron nitride strip with an edge crack. Eng Fract Mech. 2021;242:107485.

Large scale atomic/molecular massively parallel simulator, LAMMPS. http://lammps.sandia.gov.

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mater Sci Eng. 2010;18:015012.

Gross D, Seelig T. Fracture mechanics: with an introduction to micromechanics. Springer; 2006.

Dewapriya MAN, Rajapakse RKND, Phani AS. Atomistic and continuum modeling of temperature-dependent fracture of graphene. Int J Fract. 2014;187:199–212.

Liu N, Hong JW, Pidaparti R, Wang XQ. Fracture patterns and the energy release rate of phosphorene. Nanoscale. 2016;8:5728–36.

Maryam ZD, Amin HM, Azam S, Zohre K, Sajjad H, Mohammad RG, Mohammad RS. Fracture toughness and crack propagation behavior of nanoscale beryllium oxide graphene-like structures: a molecular dynamics simulation analysis. Eng Fract Mech. 2020;235:107194.

Peng YP, Ji R, Phan T, Gao W, Levitas VI, Xiong LM. An atomistic-to-microscale computational analysis of the dislocation pileup-induced local stresses near an interface in plastically deformed two-phase materials. Acta Mater. 2022;226:117663.

Eilertsen J, Subramanian MA, Kruzic JJ. Fracture toughness of Co4Sb12 and In0.1Co4Sb12 thermoelectric skutterudites evaluated by three methods. J Alloy Compd. 2013;552:492–8.

Duan B, Zhai PC, Wen PF, Zhang S, Liu LS, Zhang QJ. Enhanced thermoelectric and mechanical properties of Te-substituted skutterudite via nano-TiN dispersion. Scr Mater. 2012;67(4):372–5.

Funding

The funding was provided by the National Natural Science Foundation of China (No. 51972253).

Author information

Authors and Affiliations

Contributions

XY contributed to methodology, validation, and writing—review and editing. LC contributed to investigation, visualization, and writing—original draft. PZ contributed to conceptualization and supervision.

Corresponding author

Ethics declarations

Competing interests

There are no competing interests.

Ethics approval and consent to participate

The present paper obeys the ethical responsibilities required by Acta Mechanica Solida Sinica.

Consent for publication

The authors of this paper give consent for its publication in Acta Mechanica Solida Sinica.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, X., Cai, L. & Zhai, P. Size Effect on the Fracture Strength and Toughness of Nano-cracked CoSb3: A Molecular Dynamics Study. Acta Mech. Solida Sin. 36, 685–691 (2023). https://doi.org/10.1007/s10338-023-00419-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00419-7