Abstract

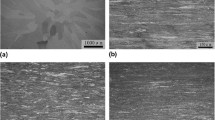

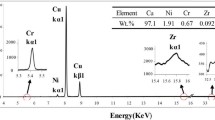

By studying the effect of preparation technology and plastic deformation on the microstructure and property evolution of Cu–Ti alloys with a larger composition range, its application scope can be further expanded. In present paper, Cu–Ti alloys with Ti content of 1.0, 4.5 and 10.0 wt % were prepared by aluminothermic reaction and their microstructures and properties were regulated by rolling deformation. The results show that Cu–1.0 wt % Ti alloy is in the solid solution state, Cu–4.5 wt % Ti alloy has a small number of punctate precipitates, and Cu–10.0 wt % Ti alloy has a large number of Cu4Ti precipitate distributed in a network at grain boundaries. For the as-cast Cu–Ti alloys, they consist of a large number of equiaxed micron crystals and a few nanocrystals. With the increase of Ti content, the relative density and grain size of the alloys decrease, the strength and hardness increase, but the elongation and electrical conductivity decrease. Compared with the as-cast alloys, the phase composition of the rolled alloy does not change, but the relative density increases, the grains are elongated along the deformation direction and some grains are crushed into nanocrystals. The precipitated phases are broken and the distribution in the matrix is more uniform and dispersed. For the rolled alloys with the same composition, with the increase of rolling deformation, the strength and hardness increase sharply, but the plasticity decreases significantly, and the electrical conductivity increases slightly at first and then decreases.

Similar content being viewed by others

REFERENCES

X. Huang, G. Xie, X. Liu, H. Fu, L. Shao, and Z. Hao, “The influence of precipitation transformation on Young’s modulus and strengthening mechanism of a Cu–Be binary alloy,” Mater. Sci. Eng., A 772, 138592 (2020). https://doi.org/10.1016/j.msea.2019.138592

H. Zhang, Ya. Jiang, J. Xie, Yo. Li, and L. Yue, “Precipitation behavior, microstructure and properties of aged Cu–1.7 wt % Be alloy,” J. Alloys Compd. 773, 1121–1130 (2019). https://doi.org/10.1016/j.jallcom.2018.09.296

S. Nagarjuna and M. Srinivas, “Grain refinement during high temperature tensile testing of prior cold worked and peak aged Cu–Ti alloys: Evidence of superplasticity,” Mater. Sci. Eng., A 498, 468–474 (2008). https://doi.org/10.1016/j.msea.2008.08.029

M. Tanahashi, J. Miura, T. Iwadachi, K. Nojiri, T. Fujisawa, and C. Yamauchi, “Oxidation behavior of molten Cu–Be binary and Cu–Be–X (X = Ca or Zr) ternary alloys at 1423 K (1150°C) under controlled oxygen partial pressure,” Metall. Mater. Trans. B 48, 554–563 (2017). https://doi.org/10.1007/s11663-016-0849-9

L. Huang, Z. Cui, X. Meng, X. Zhang, X. Zhang, X. Song, N. Tang, Z. Xiao, Q. Lei, and Z. Li, “Effects of microelements on the microstructure evolution and properties of ultrahigh strength Cu–Ti alloys,” Mater. Sci. Eng., A 823, 141581 (2021). https://doi.org/10.1016/j.msea.2021.141581

C. Li, X. Wang, B. Li, J. Shi, Ya. Liu, and P. Xiao, “Effect of cold rolling and aging treatment on the microstructure and properties of Cu–3Ti–2Mg alloy,” J. Alloys Compd. 818, 152915 (2020). https://doi.org/10.1016/j.jallcom.2019.152915

L. Shen, Z. Li, Q. Dong, Z. Xiao, S. Li, and Q. Lei, “Microstructure evolution and quench sensitivity of Cu–10Ni–3Al–0.8Si alloy during isothermal treatment,” J. Mater. Res. 30, 736–744 (2015). https://doi.org/10.1557/jmr.2015.12

K. Christofidou, K. Robinson, P. Mignanelli, E. Pickering, N. Jones, and H. Stone, “The effect of heat treatment on precipitation in the Cu–Ni–Al alloy Hiduron® 130,” Mater. Sci. Eng., A 692, 192–198 (2017). https://doi.org/10.1016/j.msea.2017.03.069

B. Luo, D. Li, C. Zhao, Z. Wang, Z. Luo, and W. Zhang, “A low Sn content Cu–Ni–Sn alloy with high strength and good ductility,” Mater. Sci. Eng., A 746, 154–161 (2019). https://doi.org/10.1016/j.msea.2018.12.120

Ye. Jiang, Z. Li, Z. Xiao, Ya. Xing, Ya. Zhang, and M. Fang, “Microstructure and properties of a Cu–Ni–Sn alloy treated by two-stage thermomechanical processing,” JOM 71, 2734–2741 (2019). https://doi.org/10.1007/s11837-019-03606-5

W. A. Soffa and D. E. Laughlin, “High-strength age hardening copper–titanium alloys: Redivivus,” Prog. Mater. Sci. 49, 347–366 (2004). https://doi.org/10.1016/s0079-6425(03)00029-x

I. S. Batra, A. Laik, G. B. Kale, G. K. Dey, and U. D. Kulkarni, “Microstructure and properties of a Cu–Ti–Co alloy,” Mater. Sci. Eng., A 402, 118–125 (2005). https://doi.org/10.1016/j.msea.2005.04.015

S. Nagarjuna, “Thermal conductivity of Cu–4.5 Ti alloy,” Bull. Mater. Sci. 27, 69–71 (2004). https://doi.org/10.1007/bf02708488

S. Semboshi, T. Nishida, H. Numakura, T. Al-Kassab, and R. Kirchheim, “Effects of aging temperature on electrical conductivity and hardness of Cu–3 at pct Ti alloy aged in a hydrogen atmosphere,” Metall. Mater. Trans. A 42, 2136–2143 (2011). https://doi.org/10.1007/s11661-011-0637-8

S. Nagarjuna and M. Srinivas, “High temperature tensile behaviour of a Cu–1.5 wt % Ti alloy,” Mater. Sci. Eng., A 335, 89–93 (2002). https://doi.org/10.1016/s0921-5093(01)01945-1

S. Semboshi, H. Numakura, W. L. Gao, H. Suda, and A. Sugawara, “Effect of prior cold-working on strength and electrical conductivity of Cu–Ti dilute alloy aged in a hydrogen atmosphere,” Mater. Sci. Forum 654–656, 1315–1318 (2010). https://doi.org/10.4028/www.scientific.net/msf.654-656.1315

J. Liu, X. Wang, Q. Ran, G. Zhao, and X. Zhu, “Microstructure and properties of Cu–3Ti–1Ni alloy with aging process,” Trans. Nonferrous Met. Soc. China 26, 3183–3188 (2016). https://doi.org/10.1016/s1003-6326(16)64450-3

A. Datta and W. A. Soffa, “The structure and properties of age hardened Cu–Ti alloys,” Acta Metall. 24, 987–1001 (1976). https://doi.org/10.1016/0001-6160(76)90129-2

X. Wang, C. Chen, T. Guo, J. Zou, and X. Yang, “Microstructure and properties of ternary Cu–Ti–Sn alloy,” J. Mater. Eng. Perform. 24, 2738–2743 (2015). https://doi.org/10.1007/s11665-015-1483-4

K. Koike, K. D. Clarke, and A. J. Clarke, “Microstructural evolution and mechanical properties of heavily cold-rolled and subsequently annealed Cu–3 wt % Ti alloys with nano-lamellar structure,” JOM 71, 4789–4798 (2019). https://doi.org/10.1007/s11837-019-03838-5

I. S. Golovin, “Grain-boundary relaxation in copper before and after equal-channel angular pressing and recrystallization,” Phys. Met. Metallogr. 110, 405–413 (2010). https://doi.org/10.1134/s0031918x10100121

C. J. Barr and K. Xia, “Grain refinement in low SFE and particle-containing nickel aluminium bronze during severe plastic deformation at elevated temperatures,” J. Mater. Sci. Technol. 82, 57–68 (2021). https://doi.org/10.1016/j.jmst.2020.12.016

N. Hansen, X. Huang, and D. A. Hughes, “Microstructural evolution and hardening parameters,” Mater. Sci. Eng., A 317, 3–11 (2001). https://doi.org/10.1016/s0921-5093(01)01191-1

Q. Liu, X. Huang, D. J. Lloyd, and N. Hansen, “Microstructure and strength of commercial purity aluminium (AA 1200) cold-rolled to large strains,” Acta Mater. 50, 3789–3802 (2002). https://doi.org/10.1016/s1359-6454(02)00174-x

J. Mei, R. D. Halldearn, and P. Xiao, “Mechanisms of the aluminium-iron oxide thermite reaction,” Scr. Mater. 41, 541–548 (1999). https://doi.org/10.1016/s1359-6462(99)00148-7

Yu. Zheng, H. Zhao, S. Zhu, P. La, F. Zhan, M. Zhu, J. Sheng, and H. Liu, “Effect of rolling deformation on microstructure and properties of Cu–Ni–Mo alloy prepared by aluminothermic reaction,” Mod. Phys. Lett. B 35, 2150510 (2021). https://doi.org/10.1142/s0217984921505102

J. L. Murray, “The Cu−Ti (copper–titanium) system,” Bull. Alloy Phase Diagrams 4, 81–95 (1983). https://doi.org/10.1007/bf02880329

F. Ochoa, J. J. Williams, and N. Chawla, “Effects of cooling rate on the microstructure and tensile behavior of a Sn–3.5 wt % Ag solder,” J. Electron. Mater. 32, 1414–1420 (2003). https://doi.org/10.1007/s11664-003-0109-z

E. Nes, B. Holmedal, E. Evangelista, and K. Marthinsen, “Modelling grain boundary strengthening in ultra-fine grained aluminum alloys,” Mater. Sci. Eng., A 410–411, 178–182 (2005). https://doi.org/10.1016/j.msea.2005.08.121

L.-J. Hu and Sh.-J. Zhao, “The effect of nanostructural hierarchy on the mechanical properties of aluminium alloys during deformation processes,” J. Mater. Sci. 47, 6872–6881 (2012). https://doi.org/10.1007/s10853-012-6630-9

F. O. Sonmez and A. Demir, “Analytical relations between hardness and strain for cold formed parts,” J. Mater. Process. Technol. 186, 163–173 (2007). https://doi.org/10.1016/j.jmatprotec.2006.12.031

A. Yoshie, T. Fujita, M. Fujioka, K. Okamoto, and H. Morikawa, “Formulation of flow stress of Nb added steels by considering work-hardening and dynamic recovery,” ISIJ Int. 36, 467–473 (1996). https://doi.org/10.2355/isijinternational.36.467

L. Qu, E. Wang, K. Han, X. Zuo, L. Zhang, P. Jia, and J. He, “Studies of electrical resistivity of an annealed Cu–Fe composite,” J. Appl. Phys. 113, 173708 (2013). https://doi.org/10.1063/1.4803716

M. A. Morris, M. Leboeuf, and D. G. Morris, “Recrystallization mechanisms in a Cu–Cr–Zr alloy with a bimodal distribution of particles,” Mater. Sci. Eng., A 188, 255–265 (1994). https://doi.org/10.1016/0921-5093(94)90380-8

Funding

We gratefully acknowledge the supports by the Science and Technology Plan of Gansu Province (grant nos. 18YF1WA069, 21ZD4GA029 and 20JR10RA201), the Key Research Program of Education Department of Gansu Province (grant no. GSSYLXM-03) and the fund of the State Key Laboratory of Advanced Processing and Recycling of Non-Ferrous Metals (grant no. SKLAB02019010).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuehong Zheng, Zhu, S., Gao, H. et al. Microstructure and Properties of Cu–Ti Alloys Prepared by Aluminothermic Reaction and Subsequent Rolling. Phys. Metals Metallogr. 124, 1555–1566 (2023). https://doi.org/10.1134/S0031918X2260155X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2260155X