Abstract

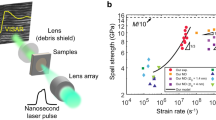

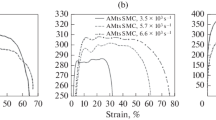

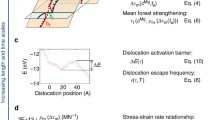

New generation of lightweight structures and technologies enables the development of materials to exhibit superior property combinations. In the present work, cellular automata is used to address the problem of dislocation behaviour and 4 factors: (i) a high density of dislocations, (ii) sub-nanometre intragranular solute clusters, (iii) 2 geometries of nanometre-scale intergranular solute structures and (iv) grain sizes tens of nanometres in diameter featuring in aluminium alloys containing a nanostructural hierarchy and exhibiting record strength with good ductility—an aerospace grade 7075 alloy exhibits a yield strength of 1 GPa and total elongation to failure of 9 %. We show that the clusters and geometries of nanometre-scale intergranular solute structures govern the strength of such material, resulting in their increasing elongation. Our results demonstrate that this simulation explains the phenomena of the super-strong materials of new generation with entirely new regimes of property-performance space.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Valiev RZ (2007) J Mater Sci 42:1483. doi:10.1007/s10853-006-1281-3

Liu M, Roven HJ, Liu X, Murashkin M, Valiev RZ, Ungár T, Balogh L (2010) J Mater Sci 45:4659. doi:10.1007/s10853-010-4604-3

Hassani FZ, Ketabchi M, Hassani MT (2011) J Mater Sci 46:7689. doi:10.1007/s10853-011-5748-5

Murashkin M, Kil’mametov AR, Valiev RZ (2008) Phys Metal Metal 106:90

Liddicoat PV, Liao XZ, Zhao YH, Zhu YT, Murashkin MY, Lavernia EJ, Valiev RZ, Ringer SP (2010) Nature Commun 1:1

Hall EO (1951) Proc Phys Soc Lond B 64:747

Friedel J (1967) Dislocation. Pergamon, Oxford

Hirth J, Lothe J (1992) Theory of dislocations. Krieger, Malabar

Tjong SC, Chen H (2004) Mater Sci Eng R 45:1

Meyers MA, Mishra A, Benson DJ (2006) Prog Mater Sci 51:427

Karch J, Birringer R, Gleiter H (1987) Nature 330:556

McFadden SX, Mishra RS, Valiev RZ, Zhilyaev AP, Mukherjee AK (1999) Nature 398:684

Kim BN, Hiraga K, Morita K, Sakka Y (2001) Nature 413:288

Siegel RW (1997) Mater Sci Forum 235–238:851

Morris DG, Morris MA (1997) Mater Sci Forum 235–238:861

Nesladek P, Veprek S (2000) Phys Status Solidi A 177:53

Valiev RZ, Murashkin MY, Kilmametov A, Straumal B, Chinh NQ, Langdon TG (2010) J Mater Sci 45:4718. doi:10.1007/s10853-010-4588-z

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2002) Nature Mater 1:45

Gerlich AP, Yue L, Mendez PF, Zhang H (2010) Acta Mater 58:2176

Shan Z, Stach EA, Wiezorek JMK, Knapp JA, Follstaedt DM, Mao SX (2004) Science 30:654

Kumar KS, Suresh S, Chisholm MF, Horton JA, Wang P (2003) Acta Mater 51:387

Zhang H, Srolovitz DJ, Douglas JF, Warren JA (2009) PNAS 106:7735

Van Swygenhoven H, Derlet PM, Frøseth AG (2006) Acta Mater 54:1975

Bobylev SV, Mukherjee AK, Ovid’ko IA (2009) Scripta Mater 60:36

Ni S, Wang YB, Liao XZ, Alhajeri SN, Li HQ, Zhao YH, Lavernia EJ, Ringer SP, Langdon TG, Zhu YT (2011) Scripta Mater 64:327

Nabarro FRN (2006) Acta Mater 54:263

Fan GJ, Choo H, Liawa PK, Lavernia EJ (2005) Mater Sci Eng A 409:243

Keblinski P, Phillpot SR, Wolf D, Gleiter H (1997) Acta Mater 45:987

Keblinski P, Wolf D, Phillpot SR, Gleiter H (1999) Scripta Mater 41:631

Nagamanasa KH, Gokhale S, Ganapathy R, Sood AK (2011) Proc Natl Acad Sci USA 108:11323

Cheng JB, Liang XB, Xu BS, Wu YX (2009) J Non-Cryst Solids 355:1673

Zhang JZ, Zhao YS (2004) Nature 430:332

Furuichi H, Ito E, Kanno Y, Watanabe S, Katsura T, Fujii N (2001) J Non-Cryst Solids 279:215

Soler JM, Beltrán MR, Michaelian K, Garzón IL, Ordejón P, Sánchez-Portal D, Artacho E (2000) Phys Rev B 61:5771

de la Fuente OR, Soler JM (1998) Phys Rev Lett 81:3159

Ophus C, Luber EJ, Edelen M, Lee Z, Fischer LM, Evoy S, Lewis D, Dahmen U, Radmilovic V, Mitlin D (2009) Acta Mater 57:4296

Trelewicz JR, Schuh CA (2007) Acta Mater 55:5948

Schuh CA, Nieh TG, Iwasaki H (2003) Acta Mater 51:431

He JH, Sheng HW, Schilling PJ, Chien C-L, Ma E (2001) Phys Rev Lett 86:2826

Van Swygenhoven H, Caro A (1998) Phys Rev B 58:11246

Maxwell JC (1867) Philos Trans R Soc Lon 157:49

Nitta KH, Suzuki K (1999) Macromol Theory Simul 8:254

Casula G, Carcione JM (1992) Boll Geofis Teor Appl 34:235

Fan GJ, Choo H, Liaw PK, Lavernia EJ (2005) Metall Mater Trans A 36:2641

Frøseth A, Van Swygenhoven H, Derlet PM (2004) Acta Mater 52:2259

Li XY, Wei YJ, Lu L, Lu K, Gao HJ (2010) Nature 464:877

Daehn GS (2001) Acta Mater 49:2017

Radmilovic V, Miller MK, Mitlin D, Dahmen U (2006) Script Mater 54:1973

Kumar KS, Van Swygenhoven H, Suresh S (2003) Acta Mater 51:5743

Li H, Ebrahimi F, Choo H, Liaw PK (2006) J Mater Sci 41:7636. doi:10.1007/s10853-006-0856-3

Voyiadjis GZ, Deliktas B (2010) Acta Mech 213:3

Horstemeyer MF, Baskes MI, Plimpton SJ (2004) Acta Mater 49:4363

Acknowledgement

The supports of the Key Project of Natural Science Foundation of China Grant No. 50931003, the Shanghai Committee of Science and Technology Grants No. 09520500100 and 10PJ1403900, the Key Project of Innovation Program of Shanghai Municipal Education Commission Grant No. 10ZZ62, and Shu Guang Project Grant No. 09SG36 are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, LJ., Zhao, SJ. The effect of nanostructural hierarchy on the mechanical properties of aluminium alloys during deformation processes. J Mater Sci 47, 6872–6881 (2012). https://doi.org/10.1007/s10853-012-6630-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6630-9