Abstract

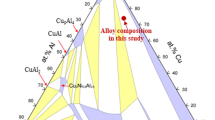

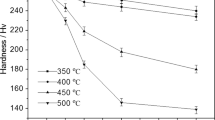

The effects of two-stage thermomechanical processing on the microstructure and properties of Cu-15Ni-8Sn-1.0Zn-0.5Al-0.2Si alloy have been investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy, and mechanical and electrical property testing. Spinodal decomposition and β-Ni3Sn precipitates with L12 ordering structure appeared in the preaged alloy. The crystal orientation relationships between the copper matrix and β-Ni3Sn precipitates were (200)Cu||(100)β, [001]Cu||[001]β and (\( \bar{2}20 \))Cu||(\( \bar{1}10 \))β, [112]Cu||[112]β. The high strength of the studied alloy can mainly be attributed to the combined effects of precipitation strengthening and substructure strengthening. The interaction between the nascent nanoparticles that form during pre-aging and the dislocation configurations that form during cold rolling promotes precipitation in the matrix and suppresses formation of cellular precipitates and coarse precipitates at grain boundaries, improving the comprehensive properties of the alloy. The peak-aged alloy treated with two-stage thermomechanical processing showed hardness of 387 HV, electrical conductivity of 8.5%IACS, tensile strength of 1176 MPa, yield strength of 1106 MPa, elongation of 3.86%, and strength–ductility product of 4539 MPa%.

Similar content being viewed by others

References

C.R. Scorey, S. Chin, M.J. White, and R.J. Livak, JOM 36, 52 (1984).

S. Zhang, B. Jiang, and W. Ding, Tribol. Int. 43, 64 (2010).

Y. Zhang, Z. Xiao, Y. Zhao, Z. Li, Y. Xing, and K. Zhou, Mater. Chem. Phys. 199, 54 (2017).

Z. Li, Q. Lei, S. Li, L. Shen, and S. Li, Mater. Rev. 29, 1 (2015).

B. Luo, D. Li, C. Zhao, Z. Wang, Z. Luo, and W. Zhang, Mater. Sci. Eng. A 746, 154 (2019).

C. Wang, X. Liu, Y. Ma, I. Ohnuma, R. Kainuma, and K. Ishida, Chin. J. Nonferrous Met. 15, 1148 (2005).

L. Deyong, R. Tremblay, and R. Angers, Mater. Sci. Eng. A 124, 223 (1990).

J. Caris, R. Varadarajan, J.J. Stephens, and J.J. Lewandowski, Mater. Sci. Eng. A 491, 137 (2008).

J. Caris, D. Li, J.J. Stephens, and J.J. Lewandowski, Mater. Sci. Eng. A 527, 769 (2010).

G. Zeng, S.D. McDonald, Q. Gu, Y. Terada, K. Uesugi, H. Yasuda, and K. Nogita, Acta Mater. 83, 357 (2015).

J.C. Rhu, S.S. Kim, S.Z. Han, Y.C. Jung, and C.J. Kim, Scr. Mater. 42, 83 (1999).

S. Han, K. Sohn, C. Kim, and S. Kim, Metall. Mater. Trans. A 35, 465 (2004).

M. Miki and Y. Ogino, Mater. Trans. 31, 968 (1990).

R.K. Ray and S.C. Narayanan, Metall. Trans. A 13, 565 (1982).

R.J. Moffat, Exp. Therm. Fluid Sci. 1, 3 (1981).

Z. Guo, J. Jie, S. Liu, Y. Zhang, B. Qin, T. Wang, and T. Li, Mater. Sci. Eng. A 748, 85 (2019).

S. Liu, M. Wang, Z. Li, M. Guo, and Y. Wang, Min. Metall. Eng. 25, 73 (2005).

J.C. Zhao and M.R. Notis, Scr. Mater. 39, 1509 (1998).

J.C. Zhao and M.R. Notis, Acta Mater. 46, 4203 (1998).

P. Hermann and D.G. Morris, Metall. Mater. Trans. A 25, 1402 (1994).

Y. Ouyang, X. Gan, Z. Li, K. Zhou, S. Zhang, Y. Jiang, and X. Zhang, Mater. Sci. Eng. A 704, 128 (2017).

W.S. Jeon, C.C. Shur, J.G. Kim, S.Z. Han, and Y.S. Kim, J. Alloys Compd. 455, 358 (2008).

M. Miki and Y. Ogino, Mater. Trans. JIM 35, 313 (1994).

C. Zhao, W. Zhang, Z. Wang, D. Li, Z. Luo, C. Yang, and D. Zhang, Materials 10, 1038 (2017).

J.T. Plewes, Metall. Mater. Trans. A 6A, 537 (1975).

Y.H. Wang, M.P. Wang, and B. Hong, Trans. Mater. Heat Treat. 25, 97 (2004).

C. Begau, A. Hartmaier, E.P. George, and G.M. Pharr, Acta Mater. 59, 934 (2011).

D.W. Zhang, D.M. Zhao, and Q.M. Dong, J. Funct. Mater. 35, 2160 (2004).

S.M. Hao, X.J. Hao, G. Zhao, and H.X. Li, Acta Metall. Sin. 12, 322 (1999).

Z.T. Wang and R.Z. Tian, The Process Handbook of Copper Alloys, 1st ed. (Changsha: Central South University Press, 2002), p. 323.

L. Shen, Z. Li, Q. Dong, Z. Xiao, and C. Chen, J. Mater. Res. 31, 1113 (2016).

J. Huang, Z. Xiao, J. Dai, Z. Li, H. Jiang, W. Wang, and X. Zhang, Mater. Sci. Eng. A 744, 754 (2019).

Q. Lei, Z. Xiao, W. Hu, B. Derby, and Z. Li, Mater. Sci. Eng. A 697, 37 (2017).

S. Li, Z. Li, Z. Xiao, S. Li, L. Shen, and Q. Dong, Mater. Sci. Eng. A 650, 345 (2016).

Acknowledgements

The authors acknowledge financial support from the National Key Research and Development Program of China (2017YFB0306100), National Natural Science Foundation of China (Grant Nos. U1637210 and 51601227), and Grants from the Project of State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Li, Z., Xiao, Z. et al. Microstructure and Properties of a Cu-Ni-Sn Alloy Treated by Two-Stage Thermomechanical Processing. JOM 71, 2734–2741 (2019). https://doi.org/10.1007/s11837-019-03606-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03606-5