Abstract

The impact of recombinant protein production (RPP) on host cells and the metabolic burden associated with it undermine the efficiency of the production system. This study utilized proteomics to investigate the dynamics of parent and recombinant cells induced at different time points for RPP. The results revealed significant changes in both transcriptional and translational machinery that may have impacted the metabolic burden, growth rate of the culture and the RPP. The timing of protein synthesis induction also played a critical role in the fate of the recombinant protein within the host cell, affecting protein and product yield. The study identified significant differences in the expression of proteins involved in fatty acid and lipid biosynthesis pathways between two E. coli host strains (M15 and DH5⍺), with the E. coli M15 strain demonstrating superior expression characteristics for the recombinant protein. Overall, these findings contribute to the knowledge base for rational strain engineering for optimized recombinant protein production.

Similar content being viewed by others

Introduction

The recombinant proteins have a wide range of uses in various industries, such as pharmaceutical, chemical and biotechnological, for producing diverse molecules via biocatalysis. Various hosts are being exploited for producing recombinant proteins heterologously1. Nevertheless, the selection of an appropriate host for RPP remains a challenging task due to changes in the paradigm and dynamics of cellular processes of the host system. In this context, one of the most used microbial species for producing recombinant proteins is Escherichia coli due to its well-understood genetics and physiology, ease of manipulation, low cost of culture, and rapid growth2. Its further advantages include attaining high cell density, scalability, and well-established engineering tools to alter and optimize various parameters to regulate the cellular processes of the host and, in turn, RPP.

There are several cellular and environmental factors that affect the RPP in the host system. The type of media used for bacterial growth and choice of protein expression system are among the major parameters that influence the RPP in a very significant manner3. The promoter used for facilitating the expression of RPP is another factor that makes a large difference. There are two bacteriophage-derived promoters that have extensively been used for this purpose in E. coli—T5 and T7 bacteriophage promoters. The T5 bacteriophage utilizes the host RNA polymerase to transcribe its genes4. In contrast, T7 bacteriophage encodes its own T7 RNA polymerase for transcribing its genes. Therefore, RPP, under the control of the T7 bacteriophage promoter, needs co-expression of T7 RNA polymerase in the host5. While this strategy has the advantage of having a dedicated RNA polymerase enabling exclusive expression of genes under T7 RNA polymerase promoters6, its expression is limited to the host that co-expresses the T7 RNA polymerase gene. Therefore the utility of E. coli as a host for T5 promoter-controlled gene expression is much wider.

Higher quantities of expressed recombinant protein in an E. coli host leads to a notable impact on host cell metabolism detectable through growth retardation, which is generally known as “metabolic burden”7,8. The factors contributing to the metabolic burden are multifaceted, depending on the host/vector combination and on the properties of the encoded gene with its transcription and translation products, as well as on the environmental conditions encountered during the production process9,10,11. The prime reasons for the protein production-related metabolic burden have been attributed to plasmid amplification and maintenance, transcription, translation, and protein folding-related processes12. However, the production of the same protein under identical conditions in the same vector combination but in different hosts can change the metabolic perturbations considerably, suggesting that the phenomenon is even more complex than anticipated13. Insights of the metabolic potential of exponentially growing and stationary phase cells are critical not only for understanding and improving production processes but also for gaining knowledge and a better comprehension of bacterial physiology14. Considering E. coli as the host of choice for the production of numerous recombinant proteins, biopharmaceuticals, small molecules and homologous metabolites15, it becomes imperative to gain insights into the effect of RPP on the host system metabolism.

Often, the recombinant proteins expressed inside the heterologous host have certain catalytic functions, and the substrate (especially if it is synthesized inside the host) or the product of the catalytically active proteins may interfere with the host physiology. This is true for all metabolic engineering-related strategies. Our laboratory is involved in microbial hydrocarbon production in E. coli where cyanobacterial Acyl-ACP (acyl carrier protein) reductase (AAR) plays an important role16. We thus selected AAR as a reference recombinant protein in the present study. AAR expression impacts the host cell in a significant manner, and it is extremely difficult to express in active form because of the marginal stability exhibited by the protein when expressed in E. coli 17. Therefore, studying the impact of producing such tough protein on cellular metabolism will help to gain cellular insights because of the complexity involved with its expression and folding in the heterologous host.

In the current study, we used a pQE30-based expression platform that uses a T5 promoter for expressing recombinant protein, and through employing a label-free quantification (LFQ) proteomics approach, we have analysed the whole cell proteome of the cells expressing recombinant protein when subjected to different conditions and compared it with the control. Our results on proteomics investigation of the two commonly used E. coli hosts, i.e., M15 and DH5⍺, under different culture media (LB & M9) conditions, show significant differences in gene expression and cellular dynamics during the growth and protein production phase. Significant changes in DNA metabolism, RNA metabolism, transcription, translation, protein folding/secretion, sigma factors, cell division, and transporters were observed, which have significance in designing the host for high-level recombinant protein production.

Results

Identification of process parameters for optimal recombinant protein production

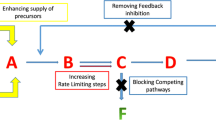

Several crucial cellular and environmental process parameters exist that play a key role in determining the fate of recombinant protein production in a host system18,19. A systematic study was designed to understand these phenomena as represented schematically in Fig. 1. The study includes investigating the effect of basic yet crucial parameters like host cellular environment (different host strains), protein-induction time point, post protein-induction duration, cell growth, growth medium, and end-product (the catalytic product of recombinant enzyme) on the expression of recombinant protein acyl-ACP reductase (AAR) in E. coli host. The induction time point for the proteomics study was chosen based on the optimal expression of the key protein (AAR).

Schematic representation of study design. (a) culturing cells with two different hosts (E. coli M15 and E. coli DH5⍺), (b) growth profile with induction and proteomics sampling time point, (c) bottom-up proteomics experiment, (d) data analysis, (e) data shortlisted based on statistical approach, (f) metabolic mapping, and g. interpretation.

The growth and end-product (hexadecanol) formation profile of two different E. coli host strains (M15 and DH5⍺) expressing recombinant AAR were compared with that of the control. The strains were cultured in two different growth media (defined M9 and complex LB), and recombinant protein was induced at two different growth points (early-log phase at OD600 of 0.1 (at the time of inoculation) and mid-log phase at OD600 of 0.6). This resulted in 8 different sets of test conditions with their respective controls (Table 1). The parameters obtained for these test conditions, e.g., growth profile, maximum specific growth rate (µmax) and cell concentration, were compared with parental control cells (Fig. 2 and Table 1). The recombinant protein expression profile and end-product formation, when hosts were subjected to different media and induction conditions, were also obtained (Fig. 2) to comprehend the dynamics of the protein expression profile, which can then be correlated with the above-mentioned parameters.

Comparative growth and protein and product profile of E. coli hosts grown in different media. (a1) E. coli M15 with M9 medium growth curve. (a2) E. coli M15 with LB medium growth curve. (a3) E. coli DH5⍺ with M9 medium growth curve. (a4) E. coli DH5⍺ with LB medium growth curve. (b1) SDS PAGE for E. coli M15 at post induction mid-log growth phase, (b2) SDS PAGE for E. coli M15 at late-log phase, (b3) SDS PAGE for E. coli DH5⍺ at post induction mid-log growth phase, (b4) SDS PAGE for E. coli DH5⍺ at late-log phase (Note-Full length gel available as Fig. S7). (c1) Hexadecanol Profile for E. coli M15 with M9 Test at early and mid-log induction. (c2) Hexadecanol Profile for E. coli M15 LB Test at early and mid-log induction. (c3) Hexadecanol Profile for E. coli DH5⍺ M9 Test at early and mid-log induction. (c4) Hexadecanol Profile for E. coli DH5⍺ LB Test at early and mid-log induction; LB = Luria Bertani medium; M9 = Minimal modified medium; C = Control; T = Test (Recombinant strain). (*) mark indicates recombinant protein Acyl-(acyl carrier protein (ACP)) reductase (AAR). Growth curve has been constructed using cell growth parameters measured via optical density at 600 nm (OD600). Blue and green arrow marks indicate the sampling time points for the mid-log phase and late-log phase, respectively.

We have observed from the growth profiles of all the cells (Fig. 2a1–a4) that the µmax of host cells cultured in the M9 medium was lower as compared to the LB medium (Table 1), irrespective of the host strain used. The µmax was ~ 3- and 1.5-fold lower for E. coli M15 and DH5α strains, respectively, when grown in the defined medium as compared to the complex medium (Table 1). In both types of strains, the cell titer (dry cell weight per liter) obtained was relatively higher in the defined medium as compared to the complex medium (Table 1). An exception to this observation was one condition for the test sample where the early growth phase titer of E. coli M15 was slightly higher in complex medium. Moreover, a noticeable lag phase was observed in the growth profile of cells grown in the defined medium (Fig. 2a1,a3), which was absent when cells were cultivated using the complex medium (Fig. 2a2,a4). A delay in the attainment of stationary phase, whether grown in defined or complex media, has also been observed in the case of E. coli M15 cells expressing recombinant protein (Fig. 2a1) as compared to the control (Fig. 2a2). The effect of protein induction at different phases of cell growth (early at OD600 ~ 0.1 and mid-log at OD600 ~ 0.6) was also observed on cell growth. Induction at the mid-log phase resulted in a higher growth rate, irrespective of the strains and the media used (Table 1). It was observed earlier that substrate and nutrient utilisation by the host plays an important role in determining the growth and, consequently, the death rate of cells20, with slower growth leading to an exponentially slower death.

We further analysed the recombinant protein expression profile of different cultures on SDS-PAGE gel by loading equal quantities of protein extract (i.e., 50 µg) (Fig. 2b). The samples were taken at two time points: mid-log phase of growth, i.e., OD600 of ~ 0.8, and late log phase of growth, i.e., 12 h of post-inoculation. The expected molecular mass of AAR is 37.65 kDa, and thus a protein band near to this size in the test samples that is absent in the control samples would be an indication of induction of the recombinant AAR in the host. As expected, induction at the early phase of growth led to an early expression of recombinant protein in both the host strains cultured in different media (Fig. 2b1,b3); however, this expression eventually diminished in the late growth phase of 12 h, especially when cultured in M9 medium (Fig. 2b2,b4). Induction at the mid-log phase retained the expression level of the protein even during the late growth phase (Fig. 2b1–b4). Protein expression comparison uncovers dynamic patterns influenced by both induction timing and variations in culture media. Inducing expression during the early growth phase indeed triggers rapid protein production across all cultures, reflecting the heightened metabolic activity characteristic of this stage. However, the subsequent decline in expression during the late growth phase, particularly evident in the M9 medium, suggests underlying complexities. This reduction may stem from resource depletion or metabolic changes as cells approach the stationary phase. In contrast, induction during the mid-log phase presents an intriguing alternative, maintaining steady protein expression levels throughout the growth phases. This sustained expression underscores the favorable physiological conditions during the mid-log phase, likely optimized cellular resources for protein synthesis. Moreover, the differential impact of culture media on protein expression dynamics reveals subtle nuances. While both media initially support expression, the more pronounced decline in the M9 medium hints at its limited capacity for sustained protein production, possibly due to a lack of essential nutrients or metabolic intermediates crucial for synthesis. Overall, this comprehensive analysis highlights the intricate interplay between induction timing, growth phase dynamics, and culture media composition, offering valuable insights for optimizing recombinant protein expression strategies.

We also tested the functional integrity of the expressed recombinant protein by analysing the product of an AAR-catalyzed reaction, i.e., hexadecanal, which is eventually converted into hexadecanol with the help of endogenously expressed aldehyde reductase enzyme21. The product formation was monitored by GC–MS analysis22, and in all the conditions, the respective maximum yield was obtained in the late log or stationary phase of the growth curve (Fig. 2c). Strain E. coli M15 yielded a higher titer of hexadecanol as compared to E. coli DH5α independent of the media used (Fig. 2c1–c4). Moreover, induction at the mid-log phase (OD600 of 0.6) has yielded higher product titer in both the strains and the media as compared to early phase induction (Fig. 2c1–c4). Between the two media tested, interestingly, the defined M9 medium yielded a higher product (Fig. 2c1–c4). In this medium, the protein expression in E. coli DH5α was significantly less than E. coli M15 for mid-log induction (Fig. 2b), which could be the reason for lesser hexadecanol production. However, low-level production of hexadecanol in E. coli DH5α in LB medium despite reasonable AAR expression during mid-log induction pointed out host-specific factors assisting in catalysis and export of hexadecanol.

Insights into differentially expressed host cell proteins upon recombinant protein production

After elucidating the parameters to obtain optimum expression levels of functional recombinant protein in a host, we attempted to gain insights into the dynamics of the host’s proteome profile by using HRMS (high-resolution mass spectrometry) 23,24. We only considered the mid-log (OD600 of ~ 0.6) induction condition for our proteomic study as it yielded the highest recombinant enzyme and its catalytic product (Fig. 2b,c). A combinatorial proteomic study of post-induction cultures of E. coli M15 and E. coli DH5⍺ strains expressing rAAR cultivated in LB or M9 medium was conducted and compared with the control condition. Usage of both complex and defined media helped to comprehend carbon substrate usage and cellular dynamics in its metabolic network. M9 medium was supplemented with a known concentration of carbon substrate (2% glucose) as well as growth nutrients that aid metabolism, while LB medium was utilized as a rich source of the carbon substrate. We focused on two stages of growth, the post-induction mid-log and late-log phases of growth, to better understand the mechanism and cellular alterations upon recombinant protein production.

The bottom-up proteomics approach was used to compare the host cell (control) and recombinant strain (test) (data available on ProteomeXchange, online database). These samples were analysed in duplicates according to the technique outlined in the methods section and validated at a 1% false discovery rate (FDR). The number of proteins detected in E. coli M15 (862 to 1192) (Fig. S1a1–a4) was less than E. coli DH5α (1206 to 1635) (Fig. S1b1–b4, Supplementary Sheet 3). In addition, as expected, the number of proteins detected in the cells cultivated in the M9 medium was greater than those cultivated in the LB medium, as cells have to synthesise many additional sets of cellular machinery to grow in the defined medium. Moreover, both strains synthesized a distinct set of proteins during the mid-log growth phase compared to the late-log growth phase, as illustrated in Fig. S1.

The resulting proteomic data was further analysed, and the proteins with a P-value of less than 0.05 and a fold change (log2) of more than ± 2 of recombinant samples with respect to control were statistically shortlisted using R programming (Materials and Methods section), as shown in Fig. 3 and the Supplementary Sheet 1. Hierarchical clustering by differentially expressed genes is shown by heat map (Fig. 3) with substantial independent clusters (Fig. 3a1–a4), which indicated a noticeable difference between the control and test (recombinant) samples. The mid-log (the samples labelled as ‘− 6.1 and − 6.2 in Fig. 3a) and late-log phase (the sample labelled as ‘− 12.1 and − 12.2 in Fig. 3a) samples of all the control strains clustered together while the test samples either formed a separate cluster (Fig. 3a2,a4 or the same cluster (Fig. 3a3). However, a deviation was observed for the E. coli M15 strain cultured in M9 medium (Fig. 3a1), where control and test data clustered together for the mid- and late-log extracted samples, respectively. This indicates that the E. coli M15 cells resist the change in cellular protein expression dynamics upon recombinant protein expression throughout the growth phase. Volcano plots, as shown in Fig. 3b1–b4,c1–c4, were generated to observe differentially expressed proteins (DEPs). Significant differences in the host-cell-protein dynamics could be clearly observed in the host cells producing rAAR in different media as compared to the control. The range of fold change in the expression of host proteins due to recombinant protein production was similar in LB for both E. coli M15 and E. coli DH5⍺ cells (+ 20.5 to -19.0 and + 23.5 to -17.8 for mid- and late-log phase of growth, respectively, for M15; + 23.2 to -20.6 and + 25.8 to -22.8 for mid- and late-log phase of growth, respectively, for DH5⍺). However, E. coli M15 showed less drastic change in M9 as compared to E. coli DH5⍺ (+ 15.2 to − 18.7 and + 17.9 to − 16.7, respectively, for mid- and late-log phase of growth, respectively, for E. coli M15; + 20.5 to − 23.1 and + 22.2 to − 18.3, respectively, for E. coli DH5⍺ (Supplementary Sheet 1). An overall trend in number of differentially expressed host cell proteins (HCP) was analysed in all conditions, and it was found that the numbers were higher in the mid-log phase of growth as compared to the late-log phase of growth (Fig. 3b1–b4. Interestingly, in all the conditions except E. coli DH5α in LB, more cellular proteins got downregulated than upregulated when AAR was recombinantly expressed (Fig. S2). Scatter plots (Fig. 3d1–d4) were generated to identify unique groups of differentially expressed proteins (Supplementary Sheet 1). The data generated were further applied to look for pathway enrichment analysis using PANTHER version 1425, KEGG26 and Biocyc27 online modules.

Differential gene expression analysis of recombinant protein-expressing cells with that of control. Row ‘First’ (i.e., a1, b1, c1 and d1) represents E. coli M15 grown in M9, Row ‘Second’ (i.e., a2, b2, c2 and d2) represents E. coli M15 grown in LB, Row ‘Third’ (i.e., a3, b3, c3 and d3) represents E. coli DH5⍺ grown in M9, and Row ‘Fourth’ (i.e., a4, b4, c4 and d4) represents E. coli DH5⍺ grown in LB. Heat maps, denoted as a1, a2, a3, and a4, illustrate the growth of two strains of E. coli (M15 and DH5⍺) in M9 and LB media during mid-log and late-log phases. Volcano plots, labelled b1, b2, b3, and b4 for mid-log phase, and c1, c2, c3, and c4 for late-log phase, demonstrate the differential expression of genes post-induction in E. coli M15 and DH5⍺ strains grown in LB and M9 media. The Scattered plots, represented by d1, d2, d3, and d4, depict the correlation matrix of differentially expressed proteins in mid-log and late-log growth phases of E. coli M15 and DH5⍺ strains in LB and M9 media.

Metabolic mapping: growth and recombinant protein expression is enhanced through metabolism

The simple identification and quantification of proteins from a cell proteome is insufficient for a complete comprehension of complicated biological mechanisms. The differences in the growth profiles (Fig. 2) are indicative of the variable-activated metabolic pathways when host cells expressing rAAR were subjected to different growth conditions (A-H in Table 1). When cells were grown in an LB medium, the growth rate was very fast without lag phase (Fig. 2a2,a4, Table 1), which suggested that there would be more active metabolism involved in biomass formation. On the other hand, growth in the M9 medium (Fig. 2a1,a3, Table 1) was slower as compared with the LB medium with proper metabolism to form higher products at the stationary phase. Intriguingly, the results show that an early-stage (OD600 ~ 0.1 induction) formation of recombinant protein doesn’t help to produce an optimum product, but slower growth and mid-log induction (OD600 ~ 0.6 induction) of recombinant protein helps to make maximum product yield (Fig. 2c1–c4).

Therefore, optimized growth conditions and nutrient environment aid in achieving a high yield of recombinant protein and, in turn, product. The highest recombinant protein and product yield was obtained when E. coli M15 cells in the M9 medium were induced during the mid-phase of growth (Table 1, Fig. 2b2,c1). Thus, understanding the metabolism during both mid-log and late-log growth phases of all the conditions, especially the highest yielding condition (i.e., E. coli M15 cells induced during the mid-phase of growth in the M9 medium) and its comparison with other sets, will infer a deeper understanding of the phenotypic and genotypic differences among different hosts in use. To integrate protein expression data into metabolic data, we have used the online bioinformatic tool BioCyc with a host-specific database (E. coli M15 and E. coli DH1 (the parental strain of E. coli DH5α)). It shows the overlapping of genetic differences with respect to the metabolic system (metabolic mapping). The term cell map or structural proteomics refers to proteomics research whose purpose is to map out the structure of protein complexes or proteins present in a specific cellular organelle 28. Cellular metabolism was obtained using a KEGG Mapper under high-confidence statistical conditions, and the obtained gene information was used to conduct metabolomic mapping on the BioCyc platform, leading to information on synthesis, degradation, energy, cellular process, central dogma, stimulus–response, and cell exterior metabolism (Figs. 4, S3). After observing a significant set of impacted cellular protein expression upon heterologous protein production (Fig. 4), their annotation was carried out using PANTHER version 14 (Fig. S5 and supplementary Sheet 2), and KEGG mapper as represented in Fig. 5. Functional analysis revealed enrichment for genetic information processing, nucleotide-, amino acid-, and carbohydrate metabolism, environmental information processing, metabolism of co-factors and vitamins, signaling and cellular processes, and energy and lipid metabolism-related activities.

Cellular metabolic mapping in E. coli M15 and E. coli DH5⍺ strain. Colour coding—LB: mid-log phase—Blue & late-log phase—Red; M9: mid-log phase—Yellow & late-log phase—Green. The data indicates upregulation or downregulations of proteins involved in the biosynthetic or degradation pathways of cellular metabolism. Abbreviations: AA Syn—Amino acid synthesis; Nucleo Syn—Nucleotide synthesis; FA/Lip Syn—Fatty acid and lipid synthesis; Amine Syn—Amine synthesis; Carbo Syn—Carbohydrate synthesis; Sec Metab—Secondary metabolite synthesis; cell-struct-cell structure; Metab Reg—Metabolic regulation.

KEGG mapper of different conditions in E. coli M15 and E. coli DH5α hosts during mid-log and late-log growth phases. The Y-axis represents the percentage coverage of KEGG pathways for the proteins expressed under different growth conditions. The X-axis represents various KEGG pathways detected in the analyzed cellular proteins.

Amino acid metabolism had significantly changed in the condition that yielded the highest recombinant protein expression (Fig. S3). Interestingly, the dynamics in the expression profile of proteins involved in amino acid metabolism may be directly related to the composition of the amino acids in the AAR protein (non-polar amino acids (55.1%), polar amino acids (21.8%), and basic amino acids (11.1%)), especially in condition that yielded the highest recombinant protein. Enzymes involved in biosynthesis and degradation of amino acids were detected, and the levels were found to be significantly upregulated and downregulated, respectively, in the recombinant host for the prevalent amino acids (Ala, Gly, Ile, Glu, Thr, Arg) in rAAR protein. gcvT encoding aminomethyltransferase GcvT (Gly); astB and astD encoding N-succinylarginine dihydrolase AstB and aldehyde dehydrogenase AstD involved in synthesis of glutamate from arginine (Glu); thrC encoding threonine synthase (ThrC) (Thr); argD, argE, argB (Arg), pheA (Phe), dapF (Lys), proA (Pro), metC (Met), trpC (Trp), tnaA (Trp) involved in biosynthetic pathways of the respective amino acids (shown in bracket) were found to be significantly upregulated in the highest yielding condition. Moreover, levels of enzymes involved in degradation pathways of predominant amino acids were detected to be present in lower levels in condition (i.e., E. coli M15 cells induced during the mid-phase of growth in the M9 medium). D-amino acid dehydrogenase (DadA) enzyme encoded by dadA (Ala); Acetolactate synthase and threonine deaminase encoded by ilvA and ilvI (Thr) were also detected in lower levels in the recombinants as compared to the control. Another enzyme involved in the racemization of alanine encoded by the dadX gene was found to be upregulated (~ 16 fold) in the highest yielding condition (Supplementary Sheet 1).

Intriguingly, the less prevalent amino acids in rAAR followed the opposite trend. It was observed that the biosynthetic pathways of non-abundant amino acids in a recombinant protein, which in the present case includes Cys, His, Trp, and Tyr were upregulated in conditions other than the highest yielding strain (Fig. S3). Whereas diminished or no change for the enzyme dynamics profile of scarcely present amino acids was observed for the highest yielding condition except for that of Trp biosynthetic pathway. For instance, the enzymes involved in biosynthetic pathways of Cys (cysE), His (hisH, hisF), and Tyr (tyrB) were remarkably upregulated in the recombinant DH5⍺ strains with no change in the highest yielding M15 strain.

The lipid metabolism is typically regulated via its precursor fatty acyl CoA. This precursor is also one of the substrates for AAR, and enzymes synthesizing/utilizing this precursor were upregulated/downregulated, respectively, in the highest yielding condition out of all the conditions. dhaL gene encoding dihydroxyacetone kinase subunit L is downregulated by ~ 13-fold in condition (i.e., E. coli M15 cells induced during the mid-phase of growth in the M9 medium) as compared to the control (Fig. 4, Supplementary Sheet 1). The suppression of the gene results in diminished glycerol degradation resulting in driving glycerol-driven fatty acyl CoA synthesis pathway in the highest yielding condition. yciA gene encoding acyl-CoA thioesterase protein was found to be significantly downregulated (~ 16.5 fold) in case of the highest yielding condition. The protein is responsible for hydrolysing coenzyme A moiety from fatty acyl-CoA. The downregulation of the yciA gene product thereby results in increased availability of the substrate (fatty acyl CoA) for the produced AAR protein and, in turn, results in increased product formation. Recombinant protein production manipulates cellular metabolism (Figs. 6a,b, S6) to be driven towards substrate accumulation, which in the present case is fatty acyl-ACP/CoA 29,30.

Insights of metabolic pathways that are modulated during recombinant protein production in E. coli M15 (a) and E. coli DH5⍺ (b). Colour coding are as follows—Blue: Glycolysis, Purple: Pentose phosphate pathway, Brown: Citric acid cycle, and Yellow: Fatty acid biosynthesis pathway. Numbers indicate fold change values of recombinant strain with respect to control. Raw data has been provided in Supplementary Sheet 3.

The genetic information processing proteins, including dysregulation of transcriptional and translational proteins (Supplementary Sheet 1), can compromise protein yield, quality, and cell viability. We observed two prominent changes in the list of transcriptional regulatory proteins within the highest yielding condition, i.e., E. coli M15 grown in M9 medium and induced at mid-log phase, which were absent in other conditions. The expression of yafC was upregulated by 15-fold, while rcsB was downregulated by ~ 15-fold (Fig. S4). The YafC is predicted to be a transcription factor that regulates genes related to metabolism and chlorine resistance31, and RcsB is a response regulator involved in biofilm and exopolysaccharide formation32. The changes in these two transcriptional regulatory proteins, i.e., upregulation of yafC and downregulation of rcsB, certainly seem to have a favourable impact on rAAR expression. The peptide deformylase (Pdf) enzyme encoded by the def gene was found to be significantly upregulated in the highest yielding condition and all the other conditions E. coli M15 cells were subjected to, which was not the case for E. coli DH5⍺ cells (Fig. S4). Intriguingly, Pdf is responsible for assuring kinetic control of nascent protein biogenesis by acting as an early chaperone. This helps in enhancing polypeptide formation and, in turn, recombinant protein expression33,34. It can be claimed that cellular conditions offered by M15 cells are translationally conducive, resulting in heightened functional recombinant protein production as compared to E. coli DH5⍺ cells, which is reflected in terms of product (hexadecanol) formation as well. A very fascinating observation had been made out of the given data in the highest yielding condition. A significant downregulation of the tRNA ligases (TyrS, TrpS, HisS, CysS) of the respective bottom-most abundant amino acids (Tyr, Trp, His, Cys) present in the AAR protein was observed (Fig. S4). However, for amino acids of intermediate abundance (Arg, Glu, Thr (Supplementary Sheet 1)), an increased expression in the respective tRNA ligases (ArgS, GltX, Thr) were detected. An unexpected slight downregulation of the tRNA ligases (AlaS, LeuS) for the topmost abundant amino acids (Ala, Leu) of AAR was also noticed as a result of auto-repression35. Such a comprehensive balance in terms of various tRNA ligase expression levels on the basis of amino acid composition had been observed only in the highest yielding condition out of all the conditions cells were subjected to recombinant AAR production.

Changes in regulators of carbohydrate metabolic pathway genes were also observed. In another condition, proteins such as SspA and YciH are upregulated and have been shown to regulate genes involved in carbon metabolism, specifically in the tricarboxylic acid cycle (TCA cycle) and the glyoxylate shunt36. The glyoxylate shunt is an alternative pathway that allows bacteria to use fatty acids as a source of carbon and energy (Figs. 6a, S6). These proteins, SspA and YciH, help bacteria adapt to different nutrient conditions and optimize their energy metabolism.

The regulators of stress responses might play an important role in cell growth and recombinant protein production of transformed cells. We observed down-regulation of several genes in the highest-yielding strain that may impact cell growth and recombinant production. The downregulation of rcsB gene, which is a part of the Rcs phosphorelay system associated with cellular stress responses and biofilm formation whose expression negatively impacts growth in response to environmental challenges32,37, may be favourable to the cells. Further, reduced stress response and antibiotic resistance may occur due to the observed downregulation of rmf and dinJ 38,39; whereas downregulated yciT, glnS, prfC, suhB, rluB, yfhL can lead to inhibition of enzyme activity, accumulation of incomplete or abnormal proteins, and impact on biosynthetic pathways, potentially resulting in a decline in the growth rate of the M15 host cells40,41. The overexpression of specific genes, such as zntR, yegP, hrpA, rlmN, evgA, treR, mraZ, and rpoS, can potentially enhance the production of recombinant proteins in both host cells. These gene products play various roles in improving protein production and stability. For example, ZntR helps maintain zinc homeostasis, leading to improved protein folding and stability. YegP maintains membrane integrity, aiding in the secretion of recombinant proteins. HrpA acts as a chaperone for proper protein folding and prevents protein aggregation. RlmN and MraZ contribute to ribosome biogenesis, which improves protein synthesis. EvgA and TreR, which are involved in stress response, enhance cellular resources for protein production, and RpoS acts as a stress response regulator, improving protein folding and stability.

Upregulated stress response genes, like sspA, rsmB, iscR (for the E. coli M15 induced at mid-log phase), phoQ, ypdF, and lolB, are enhancing the ability of bacteria to adapt to changing environmental conditions. Functionally, sspA and rsmB stabilize mRNA and regulate gene expression post-transcriptionally, while iscR and phoQ regulate iron homeostasis, oxidative stress response, and membrane remodeling42,43. ypdF and lolB contribute to oxidative stress response, DNA replication, and outer membrane integrity44,45,46.

The expression levels of various genes in E. coli DH5⍺ host cells (Figs. 6b, S6b) also significantly impact recombinant protein production, including yield, quality, and efficiency.

Discussion

This study presents a pioneering approach by leveraging proteomics to meticulously trace the intricate cellular dynamics exhibited by parental and recombinant cells under distinct growth conditions, notably in M9 defined and LB complex media, induced at strategically optimized time points. We have considered two common laboratory E. coli strains for this study, both being derivatives of K12 strains. One strain, i.e., E. coli M15(pREP4), is known to keep strict transcriptional control over the recombinant gene expression by providing extra copies of the lacI gene via pREP4 low-copy plasmid, thus ensuring no leaking expression. Another strain, i.e., E. coli DH5α, is known to have mutations in the recombinase and endonuclease genes for better plasmid stability47,48. When grown without heterologous protein expression (control), the parental cells showed uninterrupted growth, while recombinant cells grew at a slower rate during the growth phase in the M9 minimal medium compared to the LB medium (Fig. 2a1–a4). The optimization efforts coupled with proteomics data underscored the significance of transcription and translational machinery in contributing to the metabolic burden (Fig S4, Supplementary Sheet 1). It was evident that the metabolic burden escalated only when recombinant protein synthesis correlated with protein folding challenges during production, culminating in proteolytic degradation and ensuing cellular responses, especially heat shock reactions (Fig. S3). Notably, our findings underscore the pivotal role of the timing of recombinant protein induction within the host cell, dictating its fate (Fig. 2b1–b4). The study unveiled substantial disparities in both protein yield and product outcomes contingent upon the induction timing of recombinant protein production during different growth phases, even amidst diverse nutrient environments. Specifically investigating Acyl-(acyl carrier protein) reductase (AAR) protein synthesis in LB and M9 minimal media, our findings highlighted a significant enhancement in protein titer and product yield when inducing protein synthesis during the mid-growth phase compared to induction at the time of inoculation (Fig. 2). While the production of recombinant protein contributed to the metabolic burden, transcription or the transcript itself emerged as the primary factor (Figs. 4, 5). Furthermore, an excess of transcription or elevated levels of recombinant mRNA, in general, elicited growth retardation, albeit not necessarily severe growth inhibition, profoundly influencing metabolic product outcomes49,50.

The study identified a significant difference in the expression levels of proteins involved in the fatty acid and lipid biosynthesis pathway between the two host strains. Lipid metabolism, which is a pivotal cellular process responsible for the synthesis, storage, and utilization of fatty acids, appears to be strategically regulated under high recombinant protein-yielding conditions to favour the production of fatty acyl CoA (Fig. 6). In addition to fatty acyl ACP, fatty acyl CoA is also a precursor for AAR, and thus, any enhancement in its production can directly contribute to higher AAR product yield. The observed downregulation of the dhaL gene, which encodes the dihydroxyacetone kinase subunit L that is intrinsically linked to glycerol metabolism, in high recombinant protein-yielding E. coli M15 strain is significant. The downregulation of dhaL can lead to reduced glycerol degradation51. This reduction, in turn, directs the pathway towards an increase in glycerol-driven fatty acyl CoA synthesis, thereby creating a surplus of the necessary substrate for AAR production.

Furthermore, the observed downregulation of the yciA gene, which encodes the acyl-CoA thioesterase protein, by about 16.5-fold in recombinant E. coli M15 strain (Supplementary Sheet 1), is also of substantial relevance. Acyl-CoA thioesterase plays a pivotal role in lipid metabolism by hydrolyzing the coenzyme A moiety from fatty acyl-CoA52. The reduced expression of this protein would mean that there is a decreased hydrolysis of fatty acyl-CoA. Consequently, this leads to an accumulation of the substrate, fatty acyl CoA, creating a favourable environment for the AAR protein to function optimally, thus leading to increased product formation. The insights gathered from Fig. 6a,b, and Fig. S6 further underline the complexity of cellular metabolism and its dynamic response to recombinant protein production. Such manipulations can divert metabolic pathways to favour specific reactions and accumulate desired products. In the current scenario, the metabolic adjustments appear to favour the accumulation of fatty acyl-ACP/CoA, which serves as a crucial substrate for AAR. Overall, the observed modulation of lipid metabolism under high rAAR yielding condition, through gene regulatory mechanisms, optimally positions the cell for enhanced AAR production.

In conclusion, we examined in this study the cellular responses of E. coli M15 and E. coli DH5⍺ host cells grown under different nutrient conditions upon expression of recombinant protein. The comprehensive investigation, delving into the intricate interplay of cellular dynamics, gene regulation, and metabolic pathways, uncovers pivotal factors governing recombinant protein production. Particularly, the strategic modulation of lipid metabolism showcases a pronounced impact on AAR protein yield, elucidating the significance of pathway manipulation for enhanced product outcomes. These insights not only highlight the complexity of cellular responses to protein synthesis but also pave the way for targeted metabolic engineering strategies in microbial systems. The findings underscore the potential for optimizing bioprocessing strategies and yield enhancement by leveraging the regulatory mechanisms governing cellular metabolism, presenting a promising framework for further advancements in recombinant protein expression and desired product yield.

Methods

Strain use and maintenance

Escherichia coli strains that are derivative of K12, i.e., M15 (strain DZ291—StrR F– φ80lacZΔM15 thi lac- mtl- recA+) (Qiagen) and DH5⍺ (F– φ80lacZΔM15 Δ(lacZYA-argF) U169 recA1 endA1 hsdR17 (rK–, mK+) phoA supE44 λ–thi-1 gyrA96 relA1) (Invitrogen), were used as host systems for the expression of a 37.5 kDa recombinant Acyl-(acyl carrier protein (ACP)) reductase (rAAR) protein. The rAAR gene was cloned in E. coli expression vector pQE30 with T5 promotor (Qiagen) and transformed in E. coli strains using the chemical transformation method. The transformed recombinant E. coli M15 strain is kanamycin resistant due to the presence of pREP4 plasmid (to avoid leaky expression) as well as ampicillin resistant due to the presence of pQE30 plasmid, while recombinant E. coli DH5⍺ is only ampicillin resistant due to the presence of pQE30-based plasmid. The strains were stored on a M9 medium containing glycerol (20%) at -80 °C.

Medium composition and inoculum preparation

M9 modified and LB medium as described by Tabinda Shakeel et al53 and Sezonov, G. et al54 was used in this study at a glucose concentration of 2%. The pH of the medium was adjusted to 7.5 using 6N HCl and 10N NaOH solutions. For preparing inoculum, a − 80 °C glycerol stock of strain was thawed and inoculated to 50 mL medium in a 250 mL Erlenmeyer flask. The culture was incubated at 30 °C for 12 h at 150 rpm in an orbital shaker. The inoculum volume for the shake flask experiment was decided based on the initial optical density (OD) of the primary culture at 600 nm. For each run, the initial OD600 was kept at 0.1 for shake flask experiments.

Shake flask experiments

All shake flask experiments were performed in 2000 mL baffled Erlenmeyer flasks containing 100 mL of M9 minimal Medium and LB medium. For the primary culture, 50 mL medium was inoculated with glycerol stock of strain and incubated at 30 °C for 12 h at 150 rpm in an orbital shaker After 12 h, OD of the primary culture was calculated by taking absorbance at 600 nm using a spectrophotometer (SpectraMax, M1, Molecular Devices, USA). About 50 mL of M9 minimal medium and LB medium was inoculated with the primary culture where initial OD600 of all culture flasks were kept at 0.1. For offline measurements of cell density and metabolites (Fig. S8), 2 mL of culture broth was harvested every 2 h. At OD600 of 0.6, culture was induced with 1 mM final concentration of IPTG and harvested at the mid-log and late-log phase of growth.

Cell density estimation

For cell density estimation, 2 mL of culture broth was harvested aseptically every two hours of cultivation. Cell density was calculated using dry cell weight measurement in duplicates. For dry cell weight measurement, 1 mL of cell broth was pipetted on dry 0.2 µm filter paper (Whatman, mdi) in pre-weight dry filter paper, and Filter paper was dried at room temperature and measured the post-drying weight. The mass difference was used to calculate the dry cell weight.

Metabolite measurements

Glucose and other metabolite concentrations in the culture supernatant were determined by ion exclusion chromatography (Fig. S8). BioRad, Aminex HPX-87H column (7.8 × 300 mm, 10 μm, Cat.No: 125-0140) and HPX-87H guard column (4.6 × 300 mm, Cat No: 125-0129) were used for glucose estimation. The mobile phase consisted of 4 mM H2SO4, and a flow rate of 0.3 mL/min was used for analysis. Column temperature was kept at 40 °C. Analysis was performed using the Agilent HPLC 1200 system (Agilent Tech. Inc., USA) with a refractive index detector. For fatty alcohol analysis, an equal volume of ethyl acetate containing 10 mg/L of 1-octadecene as internal standards was added to the culture and mixed, centrifuged, and the upper organic layer was used for analysis. A gas chromatography system (GC, 7890 A from Agilent) equipped with an HP-5 column of 30 m length, 0.32 mm internal diameter and 0.25 µm film thickness and an FID detector was used for analysis. The oven programme was set as follows: initial 100 °C for 3 min, then temperature ramped up to 250 °C with rate of 10 °C/min and was then held at 250 °C for additional 10 min. The total running time of the programme was 28 min. The inlet and detector temperatures were maintained at 150 °C and 280 °C, respectively.

Cell disruption and total protein estimation

The cells were dissolved in lysate buffer (50 mM Tris, 100 mM NaCl and 1 mM DTT at pH 7.4) and lysed using an Ultrasonicator system (VCX-150, Nugen Scientific) for 20 min at 1000 Hz for 15 s ON–OFF. After lysis, the total protein was measured in lysed supernatant using the BCA (Pierce Protein assay Kit, Thermo Scientific, USA) method and transformed AAR protein expression was identified by SDS-PAGE.

Proteomics analysis

To prepare the samples for proteomic studies, total protein was identified by the BCA Method and 50 µg of total protein was used. 50 µg of total protein was reconstituted in 20 μL of resuspension buffer containing 7 M urea and 2 M thiourea, added 2 µl of 100 mM DTT to the solution to make the final DTT concentration 10 mM and gently vortexed and incubated at 37 °C for 30 min. This was followed by the addition of 6 μL of 100 mM iodoacetamide prepared in 30 mM and incubated at 25 °C (room temperature) in the dark for 30 min. Adjusted the pH 7–8 of the solution by addition of 25 mM ammonium bicarbonate, samples were then digested using sequencing grade trypsin (1 μg per 50 μg of total protein; Pierce Biotechnology, USA) overnight at 37 °C. The enzymatic digestion was terminated by the addition of formic acid to pH 3.0 to 4.0. The tryptic peptides were desalted using a C18 Spin column (Thermo Scientific, USA). Eluted samples were vacuum-dried and reconstituted in 0.1% (v/v) formic acid before being subjected to LC–MS/MS55.

Data acquisition, processing and analysis

LC–MS/MS analysis was performed using Orbitrap Fusion Lumos Tribrid Mass Spectrometer equipped with nano-LC Easy nLC 1200 (Thermo Fischer Scientific, Singapore). Liquid chromatography separation was performed at a flow rate of 300 nl/ml on a C18 pre-column (Acclaim PepMapTM 100, 75 um X 2 cm, nanoViper, P/N 164946, Thermofisher Scientific Incorporation) followed by analytical column (Acclaim PepMapTM RSLC C18, 75um X 50 cm, 2um, 100 Å, P/N ES803). The peptides were separated using a gradient of 2% solvent B to 10% in 5 min followed by gradient increase to 45% and sharp increase to 95%, then retention of 95% for 10 min. Solvent A was aqueous solution in 0.1% formic acid, and solvent B was 95% acetonitrile in 0.1% formic acid. The eluted peptides were injected into the mass spectrometer and the MS1 data were acquired in full scan mode at 120,000 orbitrap resolution with mass range from 375 to 2000 Da. Data were acquired using the Thermo Xcalibur software setup version 4.3.73.11 (Thermo Fischer Scientific, Inc 2019). Precursors were allowed to fragment using Higher-energy C-trap dissociation (HCD) in ion trap (IT) detector with collision energy of 28 in a data dependent MSn Scan acquisition. Charge state screening of precursor ions and monoisotopic precursor selection was enabled. The parent ions once fragmented were excluded for 40 s with exclusion mass width of + /− 10 ppm. The lock mass option (polydimethylcyclosiloxane; m/z 445.120025) enabled accurate mass measurement in the MS Mode. For analysis, raw LC–MS/MS data files obtained from the mass spectrometer were processed with Proteome Discoverer™ (Version 2.4.1.15, Thermo Fisher™ Scientific Inc). The Proteome Discoverer processing workflow was employed in the label free quantitation (LFQ) of relative protein abundance across the samples and controls. For the search process, Sequest HT tools were used. Peak lists obtained from MS/MS spectra were identified using the MSF files. Protein identification was conducted against a concatenated target/decoy version of the uniport database (E coli + DH5⍺ + K12) and AAR peptide sequence along with Proteome Discoverer contaminant database.

The identification settings were as follows: trypsin digestion with maximum of 2 missed cleavages; minimum peptide length 6; precursor mass tolerance 10 ppm; fragment mass tolerance 0.6 Da; fixed modifications; carbamidomethyl c (+ 57.021464 Da), variable modifications; oxidation of m (+ 15.994915 Da), acetylation of protein n-term (+ 42.010565 Da). Peptides and proteins inferred from the spectrum results using Uniprot database (Escherichia + coli + DH5⍺ + K12) and AAR peptide sequence). Peptide Spectrum Matches (PSM’s), peptides and proteins were validated at a target False Discovery Rate (FDR) strict to 0.01 and relaxed to 0.05.

Statistical analysis

The statistically significant differences between recombinant and wildtype samples were calculated using the R programme (R version 4.1.0 (2021-05-18). P (−log10) < 0.05 was considered as statistically significant and log2 fold of above + /− 2. All data were calculated in replicates. The code is available in the repository.

Functional gene annotation

To find out functional gene annotation from significant proteins that have fold change greater than 2 & lesser than -2, we have used an online bioinformatics tool that is KEGG mapper assign KEGG Ortholog (KO) (https://www.kegg.jp/kegg/mapper/assign_ko.html) and PANTHER gene ontology with Escherichia coli (562) database 56, and the input sequence was sorted out using Python programming.

Cellular metabolic mapping

Metabolic mapping was employed for significant confident proteomics data using online tool Bio Cyc, Omics viewer module (https://biocyc.org/overviewsWeb/celOv.shtml?orgid=ECOLI) with uploading mid-log and late-log phase data (Supplementary Sheet 1) with default parameters and specific host database57. As a result, we obtained complete metabolic pathway information, which is discussed in the result part.

Data availability

The mass spectrometry proteomics data have been deposited to the ProteomeXchange Consortium via the PRIDE58 partner repository with the dataset identifier PXD050495 and https://doi.org/10.6019/PXD050495. Statistical analysis R programming and Python code was deposited in github, reference details is https://github.com/Rish014/Proteomics.git.

References

Rosano, G. L. & Ceccarelli, E. A. Recombinant protein expression in Escherichia coli: advances and challenges. Front. Microbiol. https://doi.org/10.3389/fmicb.2014.00172 (2014).

Jia, B. & Jeon, C. O. High-throughput recombinant protein expression in Escherichia coli: Current status and future perspectives. Open Biol. 6, 160196 (2016).

Akmayan, İ. Investigation of the effect of different culture conditions on recombinant protein production. Bull. Biotechnol. 4, 42–48 (2023).

Klimuk, E. et al. Novel Escherichia coli RNA polymerase binding protein encoded by bacteriophage T5. Viruses 12, 807 (2020).

Hinton, D. M. Transcriptional control in the prereplicative phase of T4 development. Virol. J. 7, 289 (2010).

Durbin, R. Gene expression systems based on bacteriophage T7 RNA polymerase. In Gene Expression Systems 9–44 (Elsevier, 1999). https://doi.org/10.1016/B978-012253840-7/50002-X.

Bentley, W. E., Mirjalili, N., Andersen, D. C., Davis, R. H. & Kompala, D. S. Plasmid-encoded protein: The principal factor in the “metabolic burden” associated with recombinant bacteria. Biotechnol. Bioeng. 35, 668–681 (1990).

Bhattacharya, S. K. & Dubey, A. K. Metabolic burden as reflected by maintenance coefficient of recombinant Escherichia coli overexpressing target gene. Biotechnol. Lett. 17, 1155–1160 (1995).

Lecina, M., Sarró, E., Casablancas, A., Gòdia, F. & Cairó, J. J. IPTG limitation avoids metabolic burden and acetic acid accumulation in induced fed-batch cultures of Escherichia coli M15 under glucose limiting conditions. Biochem. Eng. J. 70, 78–83 (2013).

Gubellini, F. et al. Physiological response to membrane protein overexpression in E. coli. Mol. Cell. Proteom. 10, M111.007930 (2011).

Hoffmann, F. & Rinas, U. Stress induced by recombinant protein production in Escherichia coli. 73–92 (2004). https://doi.org/10.1007/b93994.

Mairhofer, J., Scharl, T., Marisch, K., Cserjan-Puschmann, M. & Striedner, G. Comparative transcription profiling and in-depth characterization of plasmid-based and plasmid-free Escherichia coli expression systems under production conditions. Appl. Environ. Microbiol. 79, 3802–3812 (2013).

Mittal, P., Brindle, J., Stephen, J., Plotkin, J. B. & Kudla, G. Codon usage influences fitness through RNA toxicity. Proc. Natl. Acad. Sci. 115, 8639–8644 (2018).

Liu, C.-L., Bi, H.-R., Bai, Z., Fan, L.-H. & Tan, T.-W. Engineering and manipulation of a mevalonate pathway in Escherichia coli for isoprene production. Appl. Microbiol. Biotechnol. 103, 239–250 (2019).

Tsuruta, H. et al. High-level production of amorpha-4,11-diene, a precursor of the antimalarial agent artemisinin, in Escherichia coli. PLoS ONE 4, e4489 (2009).

Fatma, Z. et al. Model-assisted metabolic engineering of Escherichia coli for long chain alkane and alcohol production. Metab. Eng. 46, 1–12 (2018).

Sharma, A., Shakeel, T., Gupta, M., Rajacharya, G. H. & Yazdani, S. S. Biophysical and structural studies reveal marginal stability of a crucial hydrocarbon biosynthetic enzyme acyl ACP reductase. Sci. Rep. 11, 12045 (2021).

Ou, J. et al. Stationary phase protein overproduction is a fundamental capability of Escherichia coli. Biochem. Biophys. Res. Commun. 314, 174–180 (2004).

Palomares, L. A., Estrada-Mondaca, S. & Ramírez, O. T. Production of recombinant proteins: Challenges and solutions. In Recombinant Gene Expression 015–052 (Humana Press). https://doi.org/10.1385/1-59259-774-2:015.

Biselli, E., Schink, S. J. & Gerland, U. Slower growth of Escherichia coli leads to longer survival in carbon starvation due to a decrease in the maintenance rate. Mol. Syst. Biol. https://doi.org/10.15252/msb.20209478 (2020).

Fatma, Z., Jawed, K., Mattam, A. J. & Yazdani, S. S. Identification of long chain specific aldehyde reductase and its use in enhanced fatty alcohol production in E. coli. Metab. Eng. 37, 35–45 (2016).

Shakeel, T. et al. A consensus-guided approach yields a heat-stable alkane-producing enzyme and identifies residues promoting thermostability. J. Biol. Chem. 293, 9148–9161 (2018).

Novák, P. & Havlíček, V. Protein extraction and precipitation. In Proteomic Profiling and Analytical Chemistry 51–62 (Elsevier, 2016). https://doi.org/10.1016/B978-0-444-63688-1.00004-5.

Abdelmegid, S. et al. Identification of host defense-related proteins using label-free quantitative proteomic analysis of milk whey from cows with Staphylococcus aureus subclinical mastitis. Int. J. Mol. Sci. 19, 78 (2017).

Mi, H., Muruganujan, A., Ebert, D., Huang, X. & Thomas, P. D. PANTHER version 14: More genomes, a new PANTHER GO-slim and improvements in enrichment analysis tools. Nucl. Acids Res. 47, D419–D426 (2019).

Kanehisa, M. & Sato, Y. KEGG Mapper for inferring cellular functions from protein sequences. Protein Sci. 29, 28–35 (2020).

Karp, P. D. et al. The BioCyc collection of microbial genomes and metabolic pathways. Brief. Bioinformat. 20, 1085–1093 (2019).

Paley, S., Krummenacker, M. & Karp, P. D. Representation and inference of cellular architecture for metabolic reconstruction and modeling. Bioinformatics 32, 1074–1079 (2016).

Zhang, F. et al. Enhancing fatty acid production by the expression of the regulatory transcription factor FadR. Metab. Eng. 14, 653–660 (2012).

Song, H.-S. et al. Dynamic modeling of aerobic growth of Shewanella oneidensis. Predicting triauxic growth, flux distributions, and energy requirement for growth. Metab. Eng. 15, 25–33 (2013).

Duarte-Velázquez, I. et al. Escherichia coli transcription factors of unknown function: Sequence features and possible evolutionary relationships. PeerJ 10, e13772 (2022).

Majdalani, N. & Gottesman, S. THE RCS PHOSPHORELAY: A complex signal transduction system. Ann. Rev. Microbiol. 59, 379–405 (2005).

Bienvenut, W. V., Giglione, C. & Meinnel, T. Proteome-wide analysis of the amino terminal status of Escherichia coli proteins at the steady-state and upon deformylation inhibition. Proteomics 15, 2503–2518 (2015).

Bögeholz, L. A. K., Mercier, E., Wintermeyer, W. & Rodnina, M. V. Kinetic control of nascent protein biogenesis by peptide deformylase. Sci. Rep. 11, 24457 (2021).

Jakubowski, H. Amino acid selectivity in the aminoacylation of coenzyme A and RNA minihelices by aminoacyl-tRNA synthetases. J. Biol. Chem. 275, 34845–34848 (2000).

Dolan, S. K. & Welch, M. The glyoxylate shunt, 60 years on. Ann. Rev. Microbiol. 72, 309–330 (2018).

Olsson, J., Dasgupta, S., Berg, O. G. & Nordström, K. Eclipse period without sequestration in Escherichia coli. Mol. Microbiol. 44, 1429–1440 (2002).

del Castillo, I., Gómez, J. M. & Moreno, F. mprA, an Escherichia coli gene that reduces growth-phase-dependent synthesis of microcins B17 and C7 and blocks osmoinduction of proU when cloned on a high-copy-number plasmid. J. Bacteriol. 172, 437–445 (1990).

Lewis, K. Persister cells and the riddle of biofilm survival. Biochemistry (Moscow) 70, 267–274 (2005).

Imlay, J. A. The molecular mechanisms and physiological consequences of oxidative stress: Lessons from a model bacterium. Nat. Rev. Microbiol. 11, 443–454 (2013).

Görke, B. & Stülke, J. Carbon catabolite repression in bacteria: Many ways to make the most out of nutrients. Nat. Rev. Microbiol. 6, 613–624 (2008).

Bury-Moné, S. et al. Global analysis of extracytoplasmic stress signaling in Escherichia coli. PLoS Genet. 5, e1000651 (2009).

Chatterjee, A., Cui, Y. & Chatterjee, A. K. RsmA and the quorum-sensing signal, N-[3-Oxohexanoyl]-l-Homoserine Lactone, Control the Levels of rsmB RNA in Erwinia carotovora subsp. carotovora by Affecting Its Stability. J. Bacteriol. 184, 4089–4095 (2002).

Giel, J. L. et al. Regulation of iron–sulphur cluster homeostasis through transcriptional control of the Isc pathway by [2 Fe–2 S]–IscR in E scherichia coli. Mol. Microbiol. 87, 478–492 (2013).

Bijlsma, J. J. E. & Groisman, E. A. The PhoP/PhoQ system controls the intramacrophage type three secretion system of Salmonella enterica. Mol. Microbiol. 57, 85–96 (2005).

Aguilera, L. et al. Proteomic analysis of outer membrane vesicles from the probiotic strain Escherichia coli Nissle 1917. Proteomics 14, 222–229 (2014).

Pasini, M. et al. Using promoter libraries to reduce metabolic burden due to plasmid-encoded proteins in recombinant Escherichia coli. New Biotechnol. 33, 78–90 (2016).

Hanahan, D., Jessee, J. & Bloom, F. R. [4] Plasmid transformation of Escherichia coli and other bacteria. 63–113 (1991). https://doi.org/10.1016/0076-6879(91)04006-A.

Li, Z. & Rinas, U. Recombinant protein production associated growth inhibition results mainly from transcription and not from translation. Microb. Cell Fact. 19, 83 (2020).

Zeng, H. & Yang, A. Quantification of proteomic and metabolic burdens predicts growth retardation and overflow metabolism in recombinant Escherichia coli. Biotechnol. Bioeng. 116, 1484–1495 (2019).

Zhang, L., Tang, Y., Guo, Z. & Shi, G. Engineering of the glycerol decomposition pathway and cofactor regulation in an industrial yeast improves ethanol production. J. Ind. Microbiol. Biotechnol. 40, 1153–1160 (2013).

Hunt, M. C. & Alexson, S. E. The role Acyl-CoA thioesterases play in mediating intracellular lipid metabolism. Progress Lipid Res. 41, 99–130 (2002).

Shakeel, T., Fatma, Z. & Yazdani, S. S. In vivo quantification of alkanes in Escherichia coli. Bio-Protocol https://doi.org/10.21769/BioProtoc.3593 (2020).

Sezonov, G., Joseleau-Petit, D. & D’Ari, R. Escherichia coli physiology in Luria-Bertani broth. J. Bacteriol. 189, 8746–8749 (2007).

Ogunyewo, O. A. et al. Accessory enzymes of hypercellulolytic Penicillium funiculosum facilitate complete saccharification of sugarcane bagasse. Biotechnol. Biofuels 14, 171 (2021).

Kanehisa, M., Sato, Y. & Kawashima, M. KEGG mapping tools for uncovering hidden features in biological data. Protein Sci. 31, 47–53 (2022).

Paley, S. & Karp, P. D. The BioCyc metabolic network explorer. BMC Bioinform. 22, 208 (2021).

Perez-Riverol, Y. et al. The PRIDE database and related tools and resources in 2019: Improving support for quantification data. Nucl. Acids Res. 47, D442–D450 (2019).

Acknowledgements

Authors acknowledge funding support from the Department of Biotechnology, Govt of India, via Bioenergy Centre grant no. BT/PR/Centre/03/2011-Phase II.

Author information

Authors and Affiliations

Contributions

GHR and SSY designed the study, GHR and AS conducted all the experiments, GH and AS drafted the manuscript, SSY edited the manuscript and generated resources for the study.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rajacharya, G.H., Sharma, A. & Yazdani, S.S. Proteomics and metabolic burden analysis to understand the impact of recombinant protein production in E. coli. Sci Rep 14, 12271 (2024). https://doi.org/10.1038/s41598-024-63148-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-63148-y

- Springer Nature Limited