Abstract

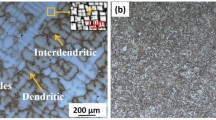

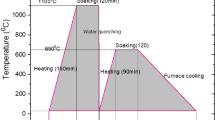

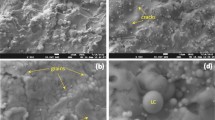

The study investigated the microstructures, residual stress and mechanical properties of double carbides cermet coatings manufactured on AZ31 magnesium alloy substrate by high-velocity oxy-fuel spraying (HVOF). The HVOF spraying was carried out using a JP 5000 TAFA spray system and the commercially available powder WC-20Cr3C2-7Ni was used to manufacture coatings. The variable process parameter was spray distance (320, 360 and 400 mm). The top surfaces of the manufactured coatings are typical for HVOF coatings and is relatively smooth. Nevertheless, some irregularities and voids are observed. All coatings exhibit dense structure with relatively low porosity level (below 3 vol. %) as well as a robust mechanical binding to the substrate which indicates high adhesion. More deep microstructure analysis carried out by TEM microscopy revealed two types of precipitation: WC hexagonal phase in the space group P-6m2 with irregular shape and size as well as Cr7C3 orthorhombic one, in the space group P nma with a rounded shape and regular size. Phase composition after the spraying process indicates the hexagonal WC phase as the main one. Additionally, two chromium carbides phases, Cr3C2 and Cr3C7 have been identified. A small peak of hexagonal W2C carbide was found as well. Analysis of residual stress showed that both components of linear stress for all deposited coatings have a compressive nature. The increasing spray distance caused an increase of the linear stress values, from – 72.7 up to – 131.5 MPa for δ11 and from – 57.2 up to – 112.2 MPa for δ22. Such values could suggest that thermal stress generated during coating deposition was also low. In the case of the shear stress the values are much lower than linear one, but with the same tendency, increasing with longer spray distance: 14.2, 21.0 and 32.2 MPa for 320, 360 and 400 mm, respectively. The obtained results of HIT show a slight influence on the spray distance. With the increasing spraying distance, the value of hardness decreasing: 12.96, 12.53 and 11.76 GPa according to SD equal to 320, 360 and 400 mm, respectively. Similar was in the case of the EIT values: 315, 309 and 304 GPa for 320, 360 and 400 mm, respectively. All values of the fracture toughness were in the range between 3.5 and 4.0 MPa m1/2, with little influece of the spray distance.

Similar content being viewed by others

Data availability

We confirm that all data can be available.

References

Hirsch J. Recent development in aluminium for automotive applications. Trans Nonferrous Metals Soc China. 2014;24:1995–2002. https://doi.org/10.1016/S1003-6326(14)63305-7.

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des (1980-2015). 2014;56:862–71. https://doi.org/10.1016/j.matdes.2013.12.002.

Gupta M, Sharon NML. Magnesium, magnesium alloys, and magnesium composites. 1st ed. Wiley; 2011. https://doi.org/10.1002/9780470905098.

Kim S-H, Kim H, Kim NJ. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature. 2015;518:77–9. https://doi.org/10.1038/nature14144.

Ghali E. Corrosion resistance of aluminum and magnesium alloys: understanding, performance, and testing. Hoboken: John Wiley; 2010.

Dong H. Surface engineering of light alloys aluminium, magnesium and titanium alloys. New Delhi: Woodhead Publishing; 2010.

Shu DW, Ahmad IR. Magnesium alloys: an alternative for aluminium in structural applications. Adv Mater Res. 2010;168–170:1631–5. https://doi.org/10.4028/www.scientific.net/AMR.168-170.1631

Radha R, Sreekanth D. Insight of magnesium alloys and composites for orthopedic implant applications—a review. J Magnesium Alloys. 2017;5:286–312. https://doi.org/10.1016/j.jma.2017.08.003.

Pardo A, Merino MC, Mohedano M, Casajús P, Coy AE, Arrabal R. Corrosion behaviour of Mg/Al alloys with composite coatings. Surf Coat Technol. 2009;203:1252–63. https://doi.org/10.1016/j.surfcoat.2008.10.030.

Zhang L, Yang S, Lv X, Jie X. Wear and Corrosion Resistance of Cold-Sprayed Cu-Based Composite Coatings on Magnesium Substrate. J Therm Spray Tech. 2019;28:1212–24. https://doi.org/10.1007/s11666-019-00887-9.

Guo KW. A review of magnesium/magnesium alloys corrosion and its protection, recent pat. Corros Sci. 2010;2:13–21. https://doi.org/10.2174/1877610801002010013.

Gnanavelbabu A, Prahadeeswaran M, Rai R, Ross NS, Gupta MK. Tribo-corrosive wear behaviour of squeeze-casted Mg/TiN/hBN composite under different ageing temperature. Tribol Int. 2023;187: 108748. https://doi.org/10.1016/j.triboint.2023.108748.

Gnanavelbabu A, Vinothkumar E, Ross NS, Rai R, Kuntoğlu M. Investigating the influence of NaCl concentration on the electrochemical corrosion behavior of metal oxide reinforced magnesium matrix composites. Archiv Civ Mech Eng. 2023;23:113. https://doi.org/10.1007/s43452-023-00658-y.

Hu R-G, Zhang S, Bu J-F, Lin C-J, Song G-L. Recent progress in corrosion protection of magnesium alloys by organic coatings. Prog Org Coat. 2012;73:129–41. https://doi.org/10.1016/j.porgcoat.2011.10.011.

Ghosh R, Thota HK, Rani RU. Corrosion resistance and thermo-optical properties of lithium polysilicate spray coated anodized AZ31B magnesium alloy for space applications. Corros Sci Technol. 2019;18:182–9. https://doi.org/10.14773/CST.2019.18.5.182.

Wang S, Wang Y, Cao G, Chen J, Zou Y, Yang B, Ouyang J, Jia D, Zhou Y. Highly reliable double-layer coatings on magnesium alloy surfaces for robust superhydrophobicity, chemical durability and electrical property. Ceram Int. 2021;47:35037–47. https://doi.org/10.1016/j.ceramint.2021.09.045.

Mondal AK, Kumar S, Blawert C, Dahotre NB. Effect of laser surface treatment on corrosion and wear resistance of ACM720 Mg alloy. Surf Coat Technol. 2008;202:3187–98. https://doi.org/10.1016/j.surfcoat.2007.11.030.

Morelli S, Rombolà G, Bolelli G, Lopresti M, Puddu P, Boccaleri E, Seralessandri L, Palin L, Testa V, Milanesio M, Lusvarghi L. Hard ultralight systems by thermal spray deposition of WC-CoCr onto AZ31 magnesium alloy. Surf Coat Technol. 2022;451: 129056. https://doi.org/10.1016/j.surfcoat.2022.129056.

Pawlowski L. The science and engineering of thermal spray coatings. Chichester: Wiley; 2008.

Mardali M, SalimiJazi HR, Karimzadeh F, Luthringer B, Blawert C, Labbaf S. Comparative study on microstructure and corrosion behavior of nanostructured hydroxyapatite coatings deposited by high velocity oxygen fuel and flame spraying on AZ61 magnesium based substrates. Appl Surf Sci. 2019;465:614–24. https://doi.org/10.1016/j.apsusc.2018.09.127.

Bansal P, Singh G, Sidhu HS. Plasma-sprayed hydroxyapatite-strontium coating for improved corrosion resistance and surface properties of biodegradable AZ31 Mg alloy for biomedical applications. J Mater Eng erform. 2021;30:1768–79. https://doi.org/10.1007/s11665-021-05490-0.

Marzbanrad B, Razmpoosh MH, Toyserkani E, Jahed H. Role of heat balance on the microstructure evolution of cold spray coated AZ31B with AA7075. J Magnesium Alloys. 2021;9:1458–69. https://doi.org/10.1016/j.jma.2021.03.009.

Fauchais PL, Heberlein JVR, Boulos MI. Thermal spray fundamentals. Boston: Springer US; 2014. https://doi.org/10.1007/978-0-387-68991-3.

García-Rodríguez S, López AJ, Torres B, Rams J. 316L stainless steel coatings on ZE41 magnesium alloy using HVOF thermal spray for corrosion protection. Surf Coat Technol. 2016;287:9–19. https://doi.org/10.1016/j.surfcoat.2015.12.075.

Zhang H, Wang S, Yang X, Hao S, Chen Y, Li H, Pan D. Interfacial characteristic and microstructure of Fe-based amorphous coating on magnesium alloy. Surf Coat Technol. 2021;425: 127659. https://doi.org/10.1016/j.surfcoat.2021.127659.

Jonda E, Łatka L, Maciej A, Khozhanov A. Investigations on the microstructure and corrosion performance of different WC-based cermet coatings deposited by high velocity oxy fuel process onto magnesium alloy substrate. Adv Sci Technol Res J. 2023;17:25–35. https://doi.org/10.12913/22998624/160513.

Jonda E, Szala M, Sroka M, Łatka L, Walczak M. Investigations of cavitation erosion and wear resistance of cermet coatings manufactured by HVOF spraying. Appl Surf Sci. 2023;608: 155071. https://doi.org/10.1016/j.apsusc.2022.155071.

Oladijo OP, Venter AM, Cornish LA, Sacks N. X-ray diffraction measurement of residual stress in WC-Co thermally sprayed coatings onto metal substrates. Surf Coat Technol. 2012;206:4725–9. https://doi.org/10.1016/j.surfcoat.2012.01.044.

Oliver WC, Pharr GM. Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res. 2004;19:3–20. https://doi.org/10.1557/jmr.2004.19.1.3.

Chicot D. Hardness length-scale factor to model nano- and micro-indentation size effects. Mater Sci Eng, A. 2009;499:454–61. https://doi.org/10.1016/j.msea.2008.09.040.

Łatka L, Chicot D, Cattini A, Pawłowski L, Ambroziak A. Modeling of elastic modulus and hardness determination by indentation of porous yttria stabilized zirconia coatings. Surf Coat Technol. 2013;220:131–9. https://doi.org/10.1016/j.surfcoat.2012.07.025.

Faisal NH, Ahmed R, Prathuru AK, Spence S, Hossain M, Steel JA. An improved Vickers indentation fracture toughness model to assess the quality of thermally sprayed coatings. Eng Fract Mech. 2014;128:189–204. https://doi.org/10.1016/j.engfracmech.2014.07.015.

Garbiec D, Siwak P. Microstructural evolution and development of mechanical properties of spark plasma sintered WC–Co cemented carbides for machine parts and engineering tools. Arch Civ Mech Eng. 2019;19:215–23. https://doi.org/10.1016/j.acme.2018.10.004.

Evans AG, Wilshaw TR. Quasi-static solid particle damage in brittle solids—I. Observations analysis and implications. Acta Metallur. 1976;24:939–56. https://doi.org/10.1016/0001-6160(76)90042-0.

Myalska H, Szymański K, Moskal G. Microstructure and selected properties of WC-Co-Cr coatings deposited by high velocity thermal spray processes. SSP. 2016;246:117–22. https://doi.org/10.4028/www.scientific.net/SSP.246.117.

Bhosale DG, Rathod WS. Tribo-behaviour of APS and HVOF sprayed WC–Cr 3 C 2 –Ni coatings for gears. Surf Eng. 2021;37:80–90. https://doi.org/10.1080/02670844.2020.1742988.

Ding X, Ke D, Yuan C, Ding Z, Cheng X. Microstructure and cavitation erosion resistance of HVOF deposited WC-Co coatings with different sized WC. Coatings. 2018;8:307. https://doi.org/10.3390/coatings8090307.

Ahmed R, Ali O, Berndt CC, Fardan A. Sliding wear of conventional and suspension sprayed nanocomposite WC-Co coatings: an invited review. J Therm Spray Tech. 2021;30:800–61. https://doi.org/10.1007/s11666-021-01185-z.

Karaoglanli AC, Oge M, Doleker KM, Hotamis M. Comparison of tribological properties of HVOF sprayed coatings with different composition. Surf Coat Technol. 2017;318:299–308. https://doi.org/10.1016/j.surfcoat.2017.02.021.

Cabral-Miramontes JA, Gaona-Tiburcio C, Almeraya-Calderón F, Estupiñan-Lopez FH, Pedraza-Basulto GK, Poblano-Salas CA. Parameter studies on high-velocity oxy-fuel spraying of CoNiCrAlY coatings used in the aeronautical industry. Int J Corros. 2014;2014:1–8. https://doi.org/10.1155/2014/703806.

Niemczewska-Wójcik M, Mańkowska-Snopczyńska A, Piekoszewski W. The investigation of wear tracks with the use of noncontact measurement methods, Archives of Civil and Mechanical. Engineering. 2013;13:158–67. https://doi.org/10.1016/j.acme.2013.01.005.

Mayrhofer E, Janka L, Mayr WP, Norpoth J, Rodriguez Ripoli M, Gröschl M. Cracking resistance of Cr3C2–NiCr and WC–Cr3C2–Ni thermally sprayed coatings under tensile bending stress. Surf Coat Technol. 2015;281:169–75. https://doi.org/10.1016/j.surfcoat.2015.09.002.

Song B, Murray JW, Wellman RG, Pala Z, Hussain T. Dry sliding wear behaviour of HVOF thermal sprayed WC-Co-Cr and WC-CrxCy-Ni coatings. Wear. 2020;442–443: 203114. https://doi.org/10.1016/j.wear.2019.203114.

Raza A, Ahmad F, Badri TM, Raza MR, Malik K. An influence of oxygen flow rate and spray distance on the porosity of HVOF coating and its effects on corrosion—a review. Materials. 2022;15:6329. https://doi.org/10.3390/ma15186329.

Qiao L, Wu Y, Hong S, Long W, Cheng J. Wet abrasive wear behavior of WC-based cermet coatings prepared by HVOF spraying. Ceram Int. 2021;47:1829–36. https://doi.org/10.1016/j.ceramint.2020.09.009.

Litasov KD, Shatskiy A, Fei Y, Suzuki A, Ohtani E, Funakoshi K. Pressure-volume-temperature equation of state of tungsten carbide to 32 GPa and 1673 K. J Appl Phys. 2010;108: 053513. https://doi.org/10.1063/1.3481667.

Mukhopadhyay A, Basu B. Recent developments on WC-based bulk composites. J Mater Sci. 2011;46:571–89. https://doi.org/10.1007/s10853-010-5046-7.

Li Y, Gao Y, Xiao B, Min T, Yang Y, Ma S, Yi D. The electronic, mechanical properties and theoretical hardness of chromium carbides by first-principles calculations. J Alloy Compd. 2011;509:5242–9. https://doi.org/10.1016/j.jallcom.2011.02.009.

Ksiazek M, Boron L, Radecka M, Richert M, Tchorz A. Mechanical and tribological properties of HVOF-sprayed (Cr3C2-NiCr+Ni) composite coating on ductile cast iron. J of Materi Eng and Perform. 2016;25:3185–93. https://doi.org/10.1007/s11665-016-2226-x.

Yao H-L, Yang C, Yi D-L, Zhang M-X, Wang H-T, Chen Q-Y, Bai X-B, Ji G-C. Microstructure and mechanical property of high velocity oxy-fuel sprayed WC-Cr3C2-Ni coatings. Surf Coat Technol. 2020;397: 126010. https://doi.org/10.1016/j.surfcoat.2020.126010.

Bolelli G, Berger L-M, Börner T, Koivuluoto H, Lusvarghi L, Lyphout C, Markocsan N, Matikainen V, Nylén P, Sassatelli P, Trache R, Vuoristo P. Tribology of HVOF- and HVAF-sprayed WC–10Co4Cr hardmetal coatings: a comparative assessment. Surf Coat Technol. 2015;265:125–44. https://doi.org/10.1016/j.surfcoat.2015.01.048.

Jonda E, Łatka L, Tomiczek A, Godzierz M, Pakieła W, Nuckowski P. Microstructure investigation of WC-based coatings prepared by HVOF onto AZ31 substrate. Materials. 2021;15:40. https://doi.org/10.3390/ma15010040.

Jonda E, Łatka L, Godzierz M, Maciej A. Investigations of microstructure and corrosion resistance of WC-Co and WC-Cr3C2-Ni coatings deposited by HVOF on magnesium alloy substrates. Surf Coat Technol. 2023;459: 129355. https://doi.org/10.1016/j.surfcoat.2023.129355.

Santana YY, Renault PO, Sebastiani M, La Barbera JG, Lesage J, Bemporad E, Le Bourhis E, Puchi-Cabrera ES, Staia MH. Characterization and residual stresses of WC–Co thermally sprayed coatings. Surf Coat Technol. 2008;202:4560–5. https://doi.org/10.1016/j.surfcoat.2008.04.042.

Nohava J, Mušálek R, Matějíček J, Vilémová M. A contribution to understanding the results of instrumented indentation on thermal spray coatings—case study on Al2O3 and stainless steel. Surf Coat Technol. 2014;240:243–9. https://doi.org/10.1016/j.surfcoat.2013.12.033.

Łatka L, Pawlowski L, Chicot D, Pierlot C, Petit F. Mechanical properties of suspension plasma sprayed hydroxyapatite coatings submitted to simulated body fluid. Surf Coat Technol. 2010;205:954–60. https://doi.org/10.1016/j.surfcoat.2010.06.025.

Bolelli G, Berger L-M, Bonetti M, Lusvarghi L. Comparative study of the dry sliding wear behaviour of HVOF-sprayed WC–(W, Cr)2C–Ni and WC–CoCr hardmetal coatings. Wear. 2014;309:96–111. https://doi.org/10.1016/j.wear.2013.11.001.

Ji D-H, Zhuang H, Hu Q, Yao H, Zhang Y, Guo H, Zhao H, Shen M. Effect of abrasive particle size on the tribological behavior of thermal sprayed WC-Cr3C2-Ni coatings. J Alloy Compd. 2022;924: 166536. https://doi.org/10.1016/j.jallcom.2022.166536.

Fauchais P, Montavon G, Lima RS, Marple BR. Engineering a new class of thermal spray nano-based microstructures from agglomerated nanostructured particles, suspensions and solutions: an invited review. J Phys D: Appl Phys. 2011;44: 093001. https://doi.org/10.1088/0022-3727/44/9/093001.

Ang ASM, Berndt CC. A review of testing methods for thermal spray coatings. Int Mater Rev. 2014;59:179–223. https://doi.org/10.1179/1743280414Y.0000000029.

Chen Y, Wu Y, Hong S, Long W, Ji X. The effect of impingement angle on erosion wear characteristics of HVOF sprayed WC-Ni and WC-Cr 3 C 2 -Ni cermet composite coatings. Mater Res Express. 2020;7: 026503. https://doi.org/10.1088/2053-1591/ab6d31.

Goyal AK, Sapate SG, Mehar S, Vashishtha N, Bagde P, Rathod A. Tribological properties of HVOF sprayed WC-Cr 3 C 2 -Ni coating. Mater Res Express. 2019;6: 106415. https://doi.org/10.1088/2053-1591/ab3946.

Lima MM, Godoy C, Modenesi PJ, Avelar-Batista JC, Davison A, Matthews A. Coating fracture toughness determined by Vickers indentation: an important parameter in cavitation erosion resistance of WC–Co thermally sprayed coatings. Surf Coat Technol. 2004;177–178:489–96. https://doi.org/10.1016/S0257-8972(03)00917-4.

Acknowledgements

The authors are thankful to Resurs Company, Warszawa, Poland for help in HVOF spraying. Publication supported by the rector's pro-quality grant. Silesian University of Technology, grant no. 10/010/RGJ22/1084.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jonda, E., Łatka, L., Godzierz, M. et al. Microstructure, residual stress and mechanical properties of double carbides cermet coatings manufactured on AZ31 substrate by high velocity oxy-fuel spraying. Archiv.Civ.Mech.Eng 24, 61 (2024). https://doi.org/10.1007/s43452-024-00867-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00867-z