Abstract

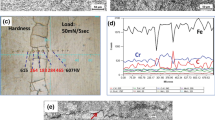

The present study aims to investigate the influence of thermal aging treatments on the intergranular corrosion and cyclic oxidation behavior of low nickel and nickel-free austenitic stainless steels (Cr–Mn and Cr–Mn–N ASSs). From the findings, Microstructural features of Cr–Mn–N and Cr–Mn austenitic stainless steels in As received (AR) condition resulted in an austenite grain matrix along with concurrent twinning, and it is also observed that the nickel free austenitic stainless steels (Cr–Mn–N ASS) with fine grain structure than low nickel austenitic stainless steels (Cr–Mn ASS). In the solution annealing (SA) condition, both alloys were observed to have a coarser austenite grain matrix with a reduced number of twins. Further, austenite grain coarsening with wider twins and chromium-rich inter-metallic phases was revealed in the solution annealing followed by aging (SA + A) conditions. The hardness was higher in AR condition, followed by SA and SA + A treatments in both Cr–Mn–N and Cr–Mn ASSs. This could be due to the grain coarsening effect with thermal aging treatments. In AR and SA conditions there was no evidence of intergranular corrosion (IGC) attack was observed, whereas in SA + A condition with higher durations, i.e., from 180 min onwards, ditch structure was observed in both Cr–Mn–N and Cr–Mn ASS. The Cr–Mn–N ASS shows poor % DOS than Cr–Mn ASS. This could be due to high rate of Cr-rich precipitates development. A higher rate of oxidation kinetics (i.e., weight gain per unit area and spallation rate) was observed in SA + A than in AR and SA conditions in both alloys.

Similar content being viewed by others

References

J.W. Simmons, Overview: high-nitrogen alloying of stainless steels. Mater. Sci. Eng. A 207, 159–169 (1996)

M. Kikuchi and Y. Mishima, "High nitrogen steels," in Proceedings of the Conference on High Nitrogen Steels (HNS' 95), Kioto, Japan, 1996.

R. Mohammed, G.M. Reddy, K.S. Rao, Effect of filler wire composition on microstructure and pitting corrosion of nickel free high nitrogen stainless steel GTA welds. Trans. Indian Inst. Met. 69(10), 1919–1927 (2016)

Li, Huabing & Jiang, Zhou-hua & Zhang, Zu-rui & Cao, Yang & Yang, Yan, Intergranular corrosion behavior of high-nitrogen austenitic stainless steel. International Journal of Minerals, Metallurgy and Materials. 654–660 (2009).

Y.S. Yoon, H.Y. Ha, T.H. Lee, S. Kim, Effect of N and C on stress corrosion cracking susceptibility of austenitic Fe18Cr10Mn-based stainless steels. Corros. Sci.. Sci. 80, 28–36 (2014)

R. Mohammed, G. Madhusudhan Reddy, K. Srinivasa Rao, Welding of nickel-free high-nitrogen stainless steel: microstructure and mechanical properties. Defence Technol. 13(2), 59–71 (2017)

M.G. Pujar, R.K. Dayal, S.N. Malhotra, T.P.S. Gill, Evaluation of microstructure and electro-chemical corrosion behavior of austenitic 316 stainless-steel weld metals with varying chemical compositions. J. Mater. Eng. Perform. 14(3), 327–342 (2005)

L. Chen, H. Tan, Z. Wang, J. Li, Y. Jiang, Influence of cooling rate on microstructure evolution and pitting corrosion resistance in the simulated heat-affected zone of 2304 duplex stainless sheets of steel. Corros. Sci. Sci. 58, 168–174 (2012)

J. Moon, H.-Y. Ha, T.-H. Lee, Corrosion behavior in high heat input welded heat-affected zone of Ni-free high-nitrogen Fe–18Cr–10Mn–N austenitic stainless steel. Mater CharactCharact 82, 113–119 (2013)

H. Li, Z. Jiang, H. Feng, Q. Ma, D. Zhan, Aging precipitation behavior of 18Cr–16Mn–2Mo–l.lN high nitrogen austenitic stainless steel and its influences on mechanical properties. J. Iron. Steel. Inst. 19(8), 43–51 (2012)

B. Kartik, R. Veerababu, M. Sundararaman, D.V.V. Satyanarayana, Effect of high-temperature ageing on microstructure and mechanical properties of a nickel-free high nitrogen austenitic stainless steel. Mater. Sci. Eng. A 642, 288–296 (2015)

T.-H. Lee, C.-S. Oh, C.G. Lee, S.-J. Kim, S. Takaki, Precipitation of r-phase in high-nitrogen austenitic 18Cr–18Mn–2Mo–0.9N stainless steel during isothermal aging. Scr. Mater. 50, 1325–1328 (2004)

W. Xinqiang, F. Yao, J. Huang, E. Han, W. Ke, K. Yang, Z. Jiang, Investigation on pitting corrosion of nickel-free and manganese alloyed high-nitrogen stainless steels. J. Mater. Eng. Perform. 18, 287–298 (2009)

Sahri, M. I., Othman, N. K., Samsu, Z., & Daud, A. R. (2014). Investigation of high-temperature corrosion behavior on 304L austenite stainless steel in corrosive environments.

C.-C. Tsaur, J.C. Rock, C.-J. Wang, Y.-H. Su, The cyclic oxidation of 310 stainless steel with pre-coated NaCl/Na2SO4 mixtures at 750°C. Mater. Chem. Phys. 89(2–3), 445–453 (2005)

Arivazhagan, N., Devendranath Ramkumar, K., Karthikeyan, S., Manikandan, M., Narayanan, S., & Surendra, S. (2012). Cyclic oxidation Studies on Gas Tungsten Arc Welded AISI 304 and AISI 4140 Dissimilar Joints. Trends in Intelligent Robotics, Automation, and Manufacturing, 436–441.

J.G. Gonzalez-Rodriguez, S. Haro, A. Martinez-Villafañe, V.M. Salinas-Bravo, J. Porcayo-Calderon, Corrosion performance of heat resistant alloys in Na2SO4–V2O5 molten salts. Mater. Sci. Eng. A 435–436, 258–265 (2006)

Y. Kawahar, R. Teranishi, C. Takushima, J. Hamada, K. Kaneko, Effect of nitrogen addition on the stacking-fault energies in Si-added austenitic stainless steel. ISIJ Int. 61, 1029 (2021)

I.A. Yakubtsov, A. Ariapour, D.D. Perovic, Effect of nitrogen on stacking fault energy of fcc iron-based alloys. Acta Mater. Mater. 47, 1271 (1999)

A.C. Gonzaga, C. Barbosa, S.S.M. Tavares, A. Zeemann, J.C. Payão, Influence of post-welding heat treatments on sensitization of AISI 347 stainless steel welded joints. J. Market. Res. 9(1), 908–921 (2020)

D.L. Reichert, G.E. Stoner, A modified double loop EPR technique for detection of sensitization in cast stainless steel. J. Electrochem. Soc.Electrochem. Soc. 137, 411–413 (1990)

X. Yu, S. Chen, Y. Liu, F. Ren, A study of intergranular corrosion of austenitic stainless-steel by Electrochemical potentiodynamic re-activation, electron backscattering diffraction, and cellular automaton. Corros. Sci. Sci. 52(6), 1939–1947 (2010)

S.X. Li, Y.N. He, S.R. Yu, P.Y. Zhang, Evaluation of the effect of grain size on chromium carbide precipitation and intergranular corrosion of 316L stainless steel. Corros. Sci. Sci. 66, 211–216 (2013)

Standard Test Method for Electro-chemical Re-activation (EPR) for Detecting 107 Sensitization of AISI Type 304 and 304L Stainless-steels, ASTM G108-94, Annu. B. ASTM Stand., vol. 94, no. Reapproved 2010, pp. 1–9, 2010.

H. Shaikh, Use of eddy current testing method in detection and evaluation of sensitization and intergranular corrosion in austenitic stainless-steels. Corrosion Sci 48(6), 1462–1482 (2006)

S. Pednekar, S. Smialowska, Effect of prior cold work on the degree of sensitization in type 304 stainless-steel. Corrosion 36(10), 565–577 (1980)

A.V. Bansod, A.P. Patil, A.P. Moon, N.N. Khobragade, Intergranular corrosion behavior of low-nickel and 304 austenitic stainless sheets of steel. JMEPEG 25, 3615–3626 (2016)

M. Dománková, P. Marek, R. Moravčík, The effect of cold work on the sensitisation of austenitic stainless steels Mater. Tehnolog. 41(3), 131 (2007)

ASTM A262 Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels (ASM International).

V. Zatkalíková, L. Markovičová, M. Uhríčik, P. Hanusová, Susceptibility to the intergranular attack in austenitic stainless steels. IOP Conf. Ser.: Mater. Sci. Eng. 726, 012017 (2020)

K. Krishna Kumar, J. Anburaj, R. Dhanasekar, T. Satishkumar, J. Abuthakir, P. Manikandan, R. Subramanian, Kinetics of Cr2N precipitation and its effect on pitting corrosion of nickel-free high-nitrogen austenitic stainless steel. J. Mater. Eng. Perform. 29, 6044 (2020)

S. Kamal, R. Jayaganthan, S. Prakash, High-temperature cyclic oxidation and cyclic oxidation behaviors of superalloys at 900°C. Bull. Mater. Sci. 33(3), 299–306 (2010)

M. Arivarasu, M. Venkatesh Kannan, K. Devendranath Ramkumar & N. Arivazhagan (2017): Hot-corrosion resistance of dissimilar AISI 4340 and AISI 304L weldments in the molten salt environment at 600°C, Corrosion Engineering, Science and Technology

Funding

The authors would like to thank the Director of NIT Andhra Pradesh for research funding under the seed grant. The authors sincerely acknowledge the support and facilities extended by DMRL, Hyderabad, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tirumalla, A., Mohammed, R., Sheik, S. et al. Influence of Thermal Aging Treatments on Intergranular Corrosion and Cyclic Oxidation Behavior of Low Nickel and Nickel-Free Austenitic Stainless Steels. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00746-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00746-0