Abstract

Cell culture media is a significant contributor to the high cost of bioprocesses. This study explored the potential of algae to re-condition spent cell culture medium, which may reduce the costs of pharmaceutical and lab-grown-meat manufacturing. Chlorella sorokiniana, a thermally resistant microalgal species, exhibited heterotrophic and mixotrophic growth in mammalian cell culture growth media (GM). Spent animal cell media, generated by culturing quail myoblast cells (QM7s) for 4 or 8d (4D-SGM and 8D-SGM, respectively), was harvested for algal culture. Increased algal growth was observed in 4D-SGM, when compared to fresh media after 3d (optical density of 1.39 ± 0.22, 0.47 ± 0.17, p ≤ 0.05). Within 72 h, ammonia and glucose were eliminated from 4D-SGM with algal treatment. After treating 4D-SGM with algae, the treated media was reintroduced into QM7 cell cultures. No cytotoxic effects were observed on QM7 cells grown in algal-treated growth media and QM7 cells exhibited better metabolic activity in algal-treated spent medium than in untreated spent medium (80.85 ± 12.02% and 44.57 ± 10.82% activity of fresh media group, respectively, p ≤ 0.05). These results suggest that C. sorokiniana can be grown in spent media at 37 °C, sequester ammonia, and potentially extend the lifespan of media, thereby enabling more affordable bioprocesses.

Highlights

C. sorokiniana is a microalgal species that can grow in animal cell culture media at 37 °C.

C. sorokiniana can rapidly eliminate all ammonia from spent animal cell culture media.

C. sorokiniana does not depend on light to grow in animal cell culture media.

Animal cells exhibit better metabolic activity when cultured in algal-treated spent media.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The products of modern animal cell bioprocesses, such as monoclonal antibodies, therapeutic proteins, cell therapies, tissue engineered grafts, and cultured meat have the potential to radically contribute to satisfying global pharmaceutical and food challenges [1,2,3,4]. The realization of cultured meat systems alone may contribute to meeting all 17 of the Sustainable Development Goals [5]. While some of these technologies are currently regulated, marketed, and employed, their costs and availability limit their access for large populations. For example, as of 2018, the upfront drug cost of chimeric antigen receptor T-cell (CAR-T) therapy, a next generation cancer treatment, excluding costs associated with clinical support, was estimated at $373,000 [6]. Similarly, cellular agriculture, or the in vitro manufacturing of agricultural products, primarily meat, may aid in reducing the environmental strain of traditional livestock systems while providing a reliable source of affordable animal protein to large populations. As of 2023, some cultured meat manufacturing processes have been proposed and received regulatory approval, yet there currently exists no widely available cultured meat product marketed in the US that is economically competitive with traditional meat [7, 8]. The development of innovative, cost-effective strategies for scaled animal cell bioproduction is necessary to minimize the costs of current and future therapies, and to realize the potential for cellular agriculture to diminish the environmental risk of our food production systems.

Cell culture media is vital for supporting animal cell growth and metabolism in such bioprocesses [9]. Medium typically contains sugars, vitamins, minerals, hormones, amino acids, proteins, and growth factors, among many other potentially vital components that are unique to meeting the demands of a particular cell type. As animal cells divide and metabolize in large scale expansion bioprocesses, low concentrations of cellular waste, such as ammonia, accumulate in the cell culture media [10]. Eventually, a concentration threshold is reached, at which point cells exhibit characteristics that are detrimental to further cell growth. During controlled manufacturing processes, cultures are commonly maintained under this concentration threshold by continually adding fresh media to the culture, thus increasing the working reactor volume in fed-batch processes [11]. While modern approaches to on-line analysis of nutrients in media, such as raman spectroscopy, allow for design of more efficient and productive feeding strategies, upon reaching the concentration threshold at maximum volume capacity, the costly media is disposed of as waste [12].

Current analyses conclude that cell culture media is the most expensive input in a cultured meat production process. One such analysis suggested that, at current commercial prices, the serum free media formulation, Essential-8, would cost about 7,535,958 per 20,000 L [13]. At such costs, a batch production strategy employing a 20,000 L tank would yield meat at a cost of >9.60-$34.00/kg. While recent developments in media technology, such as demonstrated use of recombinant albumin, continue to reduce the projected costs of bulk media for cellular agriculture processes, the development of new strategies for extending the lifespan of cell culture media may also further decrease production costs [14].

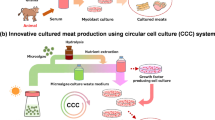

The metabolic plasticity of microalgae is well documented by extensive study of their potential applications in biofuel production and wastewater treatment [15, 16]. Their capacity for biomass growth is conserved when subjected to a wide range of both media constituents and general culture environments. Experiments confirm their ability to sequester nitrogen originating from ammonia, suggesting their potential capacity to eliminate it from animal cell culture media [17]. Haraguchi et al. [18] hypothesized that algae can eliminate ammonia that has accumulated in cell culture media after murine myoblast cell (C2C12) expansion. Within their proposed process Chlorococcum littorale, a marine unicellular green alga, sequestered nearly all ammonia from the spent animal cell culture media. Within this bioprocess, the spent cell culture media was treated by C. littorale at room temperature, within a light controlled, room-temperature environment, as constrained by the environmental requirements of the alga. It is important to note that satellite cells, a commonly proposed cell type for cultured meat products, are traditionally cultured at 37 °C in Dulbecco’s Modified Eagle Medium (DMEM)containing 10% Fetal Bovine Serum (FBS) and buffered at a pH of 7.4; thus, it would be advantageous to identify a species of algae better suitable for growth in the cell culture environment [19]. The identification of a species capable of growth and ammonia removal in this cell culture environment may enable transition from batch treatment of spent media to a continuous approach. Within an integrated bioreactor supporting algae growth and mammalian cell growth kinetics can be modeled and monitored in concert.

While most photosynthetic algae, such as C. littorale, are typically cultured at much lower temperature and in more alkaline conditions than animal cell cultures, other algae species have adapted to more extreme environments [20]. The freshwater alga, Chlorella sorokiniana has been observed growing in a wide variety of, sometimes extreme, environmental conditions in nature, suggesting that it may maintain the ability to be conditioned to grow in more saline and complex solutions such as DMEM at 37 °C [21,22,23]. In laboratory environments, this strain has been studied for its potential in wastewater treatment, fermentation, and biofuel production applications. Previous literature demonstrates its growth at temperatures up to 40 °C, at pH ranges between 5.8 and 9, suggesting a unique opportunity to grow C. sorokiniana within the same environmental conditions as animal cells [24]. Additionally, C. sorokiniana has metabolic plasticity to grow both photoautotrophically, in the presence of light, and heterotrophically, in the absence of light when carbon sources, such as glucose or acetate, are locally available in the growth medium [25]. If the provision of light can be eliminated within a theoretical waste-media management system, this evolutionary advantage may enable light independent culture media systems driven by continuously supplemented glucose.

Previously, we sought to improve the affordability of tissue engineering and bioprocessing for cellular agriculture by incorporating materials inspired by nature, crossing-kingdoms between plant tissues and animal tissues; notably, via use of decellularized plant tissue such as spinach to support of human pluripotent stem cell-derived cardiomyocytes, and broccoli and agricultural waste such as corn husk and jackfruit rind as cell carriers in suspension cultures [26,27,28]. Continuing this theme, we propose the incorporation of C. sorokiniana, as an organism in parallel culture with animal cells, into mass-bioproduction systems to enhance production capacity aimed at reducing the cost of the most expensive input, cell culture media.

In this study, we hypothesized that C. sorokiniana would grow in media designed to support animal cells at 37 °C and could eliminate ammonia from spent cell culture media to enable retention of animal cell metabolic activity. Growth rates of algal cultures in algal media and animal cell growth media were compared under variable light conditions. The cytotoxicity of algal-treated animal cell culture media was measured. The rate at which ammonia and glucose were removed from the media was observed and the metabolic activity of animal cells grown in fresh, spent, and algal treated spent animal cell growth media was compared.

Materials and methods

Algal cultivation

Chlorella sorokiniana UTEX1230 was acquired from the Culture Collection of Algae at The University of Texas at Austin. The culture was subcultured and maintained in Tris-Acetate-Phosphate medium (TAP) (PhytoTech Labs) at pH 7.4, in 125 mL Erlenmeyer flasks, on an orbital shaker at 100 RPM, at ~ 60+/-5 µmol/m− 2/s on a 12-hour day/night cycle using an USHIO– UFL, F32 T8/850, CRI85 linear fluorescent light bulbs, for a minimum of 5 days at 37 °C before inoculating into fresh TAP media at a density of 500,000 cells/mL. Microalgae were subcultured into fresh TAP media approximately every 7 days to maintain actively growing cultures. Algae were grown for at least 5 days prior to initiation of each experiment. For comparison of stock algae cultivation, BG-11 media, an algal media containing no ammonia was also assessed, visually, for C. Sorokiniana growth.

Cell culture

QM7 Cells (CRL-1962 ATCC), transformed quail myoblasts, were acquired and cultured at 37 °C and 5% CO2, using a temperature and gas controlled incubator, in growth media (GM) consisting of 89% Dulbecco’s Modified Eagle Medium/Ham’s F-12 Medium (DMEM-F-12) (Thermo Fisher Scientific), 10% heat-inactivated fetal bovine serum - FBS (Thermo Fisher Scientific), and 1% Penicillin and Streptomycin (Thermo Fisher Scientific)). Cell culture medium was replaced every 48–72 h during maintenance culture and cells were subcultured upon reaching approximately 80% confluence. Confluence was determined via visual estimation using light microscopy. QM7 cells were cultured in the dark. Fresh DMEM-F12 is buffered with sodium bicarbonate to pH of 7.4 in a 5% CO2 environment.

Imaging microalgae

Microscopic images of C. sorokiniana were taken after 7 days of growth in GM using an Axioimager Z2 microscope (Zeiss, Oberkochen, Germany). Brightfield images were taken and overlaid with fluorescent images taken at 649 nm/667 nm excitation/emission to observe the conservation of chlorophyll within the chloroplasts after extended culture in GM. ZEN 3.4 Blue Edition© imaging software (Carl Zeiss Microscopy) was used for image processing.

Spent animal cell culture media preparation

To prepare stock quantities of spent animal cell culture media, 500,000 QM7 cells were inoculated into T-75 tissue culture flasks containing 10mL of GM. Cultures were maintained without media change or subculturing for 2, 4, 6 or 8 days for analysis of the accumulation of ammonia and the consumption of glucose. Additional flasks of QM7 cells were prepared for generating spent cell culture media for use in subsequent growth experiments. Following 4 and 8 days of culture, the media was collected and frozen at -80 °C and considered spent growth media (4D-SGM and 8D-SGM, respectively). The pH of 4D-SGM and 8-SGM was not monitored as pH fluctuations were expected due to the presence of sodium bicarbonate buffer reacting with potential fluctuations in dissolved O2 and CO2 consequent of algal photosynthesis.

Algal growth under variable light intensities

Algae were inoculated at 500,000 cells/mL into 125 ml Erlenmeyer flasks containing 10mL of fresh GM. Flasks were placed in the incubator at 37 °C under light intensities of approximately 13, 28, 64, and 165 µmol/m2/s, measured by a LI-COR light meter (LI 250 A), ) equipped with a quantum sensor. An additional group of flasks were wrapped in aluminum foil for measurement of heterotrophic dark growth. Algal growth was monitored daily for 4 d using 3 averaged absorbance readings at 670 nm using a Victor Nivo Multimode Plate Reader (Revity).

Cytotoxicity of algal-treated media

Algae in stationary phase, 5–7 days post subculture, were inoculated into 10 mL of fresh GM to establish an initial density of 500,000 cells/mL for 4 days before being removed from the media via vacuum filtration. Approximately 100,000 QM7 cells were inoculated into each well of 6 well tissue culture treated plastic (Corning, ref. 353,046) plates in fresh growth media. After 24 h the GM was gently aspirated out of each well and replaced with the algal-treated media. Control groups were given fresh growth media. Cells were incubated at 37 °C and 5% CO2 for 72 h. Experimental cells were stained with Hoechst, Calcein-AM and Propidium Iodide (Thermo Fisher Scientific) before being fixed in 4% paraformaldehyde. A positive control for dead cells was prepared by exposing additional groups to 70% ethanol for 20 min prior to staining. A minimum of three images were taken per group using a Cytation-1 microscope (Agilent). The percentage of Hoechst-stained cell nuclei expressing positive signals for propidium iodide was calculated using ImageJ.

Algal growth in spent animal cell culture media

To identify if C. sorokiniana could grow in spent animal cell growth media, algal cells were inoculated and growth quantified daily for 7 d in 125 mL Erlenmeyer flasks containing GM, 4D-SGM, 8D-SGM, and TAP media in the environmental conditions previously described. Growth rates were calculated with Eq. 1, where r is the growth rate (1/day), Ot refers to the optical density at a given timepoint post inoculation, OD0 refers to the optical density immediately following initial inoculation, and t is equal to the elapsed time since initial inoculation.

Eq. 1: growth rate of C. sorokiniana.

Quantification of ammonia, and glucose in algal-treated media

Algae were inoculated into 4D-SGM at densities of 107 and 108 algal cells/mL, after counting with a hemocytometer. One mL media samples were taken daily from each group and filtered to remove cells using a 0.22 μm pore sized polyvinylidene syringe filter (Merck). Additional ammonia and glucose measurements were taken at 3 and 7 h post inoculation for the 108 group. Total ammonia and glucose were measured using a CEDEX Bioanalyzer (Roche) using an automated enzymatic photometric assay using glutamate dehydrogenase (Roche) and an automated enzymatic photometric assay using hexokinase (Roche).

Metabolic analysis of animal cells cultured in algal-treated media

A 108 aliquot of algal cells/mL was inoculated into 8 to 10 ml of 8D-SGM and maintained at 37 °C, at 60 ± 5 µM/m2/s light with a 12 h photoperiod for 24 h to generate algal-treated 8 day spent media. 10,000 QM7 cells were inoculated into 96 well plates in 100 µl of fresh GM. After 24 h, the GM was replaced with 100 µl of fresh GM, 8D-SGM, or algal-treated 8D-SGM. Cultures were maintained for 24 h before analysis via MTT assay (Thermo Fisher Scientific). Briefly, 10 µl of 12mM solution of 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide was added to each well and maintained for 4 h at 37 °C. From each well, all but 25 µl of media were removed and mixed with 50 µl of dimethyl sulfoxide (DMSO). After 10 min incubation at 37 °C wells were mixed again and absorbance was read at 540 nm using a PerkinElmer Victor3 spectrophotometer (PerkinElmer). The absorbance of three wells were averaged per group to yield a data point.

Statistical analysis

Graphpad Prism (Version 9.3.1) was used for all statistical analyses. Mixed effects analysis with post-hoc Tukey’s multiple comparisons test was used for analysis of C. sorokiniana growth between variable light intensities, between light and dark conditions, and for growth in spent animal media. A Brown-Forsythe and Welch ANOVA with post-hoc unpaired t-tests with Welch’s correction was used for analysis of glucose and ammonia consumption by QM7 cells and analysis of MTT assays. Unpaired two-tailed t-tests were used to compare cell viability and percent ammonia and glucose consumption between algal inoculation densities at each day. One, two, three, and four asterisks denote a p ≤ 0.05, 0.01, 0.001 and 0.0001, respectively. The term, ns, indicates no significance. Absorbance values were recorded three times per algal culture at each timepoint to represent the growth of that culture. All algal growth experiments were twice repeated with 2–3 flasks per experiment for a minimum of 5 total flasks observed per condition. Absorbance readings were measured three times per flask at each time point and averaged together to yield a single data point. Each live/dead and metabolic assay was performed on three separate occasions. On growth curves, standard error (SE) is represented by dotted lines colored to match its corresponding mean growth curve, represented by solid lines.

Results

Light intensity and C. Sorokiniana growth

Prior to determining the effect of algal metabolism on the growth of QM7 cells, baseline growth kinetics of C. sorokiniana were identified. Algae inoculated into fresh GM were submitted to different light intensities and growth was measured over four days (Fig. 1a). By day four, growth slowed or ceased. Significant differences in final algal density were observed between 165 and 13 µmol/m2/s (0.23 ± 0.08 and 0.46 ± 0.10, respectively), and 28 and 13 µmol/m2/s (0.41 ± 0.10 and 0.46 ± 0.10, respectively) (Fig. 1b).

Growth of C. sorokiniana at different light intensities. (A) algal growth curves when exposed to light intensities of 13, 26, 64, and 165 µmol/m2/s of light. (B) C. sorokiniana absorbance readings when exposed to light intensities of 13, 26, 64, and 165 µmol/m2/s of light, represented by day represented as bar charts for visualization of statistical analysis. Each group experiencing variable light intensity is compared to all other groups at that time point. (C) C. sorokiniana growth curves in GM when grown in the light (60 ± 5 µmol/m2/s) and in the dark. (D) Algal growth in the light (60 ± 5 µmol/m2/s) vs. in the dark for 3 and 7 d, represented as bar charts for visualization of statistical analysis. One, two, and three asterisks denote a p ≤ 0.05, 0.01, and 0.001, respectively. n ≥ 5

Because many algae can grow heterotrophically, algae were inoculated into GM and maintained in either the light (60 ± 5 µmol/m2/s) or the dark and grown for 7 days. After 3 days, the average culture density reached the stationary phase for both conditions. Dark-grown culture cell density was more than double that of the light-grown cultures (Fig. 1c-d). The growth rate of the dark-grown cultures was about twice that of the light-grown cultures (Fig. 1c). After 7 days, the average culture densities did not change. Statistically significant differences in culture density were observed between groups at days 3 and 7.

Spent media analysis

Total glucose and ammonia concentrations were measured over 8 days of QM7 cell growth. After 4 days the total concentration of glucose in the media decreased from 3 to 0.95 ± 0.08 g/L, and by day 8 it was 0.12 g/L (Fig. 2a). Simultaneously, the total concentration of ammonia in the media increased from 0.5 at day 0 to 1.90 ± 0.10 mmol/L by day 8 (Fig. 2b).

C. sorokiniana Growth in Spent Media

C. sorokiniana was inoculated into TAP media, GM, 4D-SGM, 8D-SGM, and BG-11 media and grown for 7 days at 37 °C at 60 ± 5 µmol/m2/s. Brightfield images showed that the algae appeared normal with intact cell walls and characteristic green chloroplasts, and, with fluorescent overlay, exhibited chlorophyll autofluorescence after 7 days of growth in animal cell GM (Fig. 3a-b). After 3 days, growth was observed in all groups (Fig. 3c). Compared to GM at day 3 there was about 3-fold more growth in the TAP and 4D-SGM grown cells. Growth in TAP and 4D-SGM continued to day 6. After day 6, cell growth in 4D-SGM began to decline while in TAP it continued to increase. Although algal growth in 8D-SGM reached the same yield at day 7 as cells growing in 4D-SGM, the growth kinetics were substantially different. Algal growth rates and yields were significantly greater for cells in TAP, 4D-SGM and 8D-SGM than in GM (Fig. 3d) over 7 days.

Algal growth in different media. (A) Microscopic brightfield image of C. sorokiniana after 7 days growth in GM. (B) Autofluorescence of algal chlorophyll after 7 days growth in GM 649 nm/667nm excitation/emission represented as bar charts for visualization of statistical analysis. (C) Algal growth kinetics in different media formulations and conditions. (D)C. sorokiniana absorbance readings at days 3 and 7 when grown in fresh GM, TAP, 4D-SGM, 8D-SGM, and BG-11. Each group is compared to fresh GM at that time point. One, two, three, and four asterisks denote a p ≤ 0.05, 0.01, 0.001 and 0.0001, respectively. n ≥ 5

C. Sorokiniana consumption of ammonia and glucose

Glucose and ammonia consumption by algae in 4D-SGM media at 2 inoculation densities. (A) C. sorokiniana growth when inoculated into 4D-SGM at densities of 108 and 107 algal cells/mL. (B) Percent ammonia removed from 4D-SGM over time at inoculation densities of 108 and 107 cells/mL. (C) Percent glucose removed from 4D-SGM over time at inoculation densities of 108 and 107 cells/mL. One, two, and three, asterisks denote a p ≤ 0.05, 0.01, and 0.001 respectively. n ≥ 5

Algae were inoculated into 4D-SGM at two cell densities and grown for 3 days (Fig. 4a). A lag period spanning ~ 1 day was observed for cultures inoculated at the lower density, 107 cells/mL. After one day, ammonia and glucose decreased in each inoculation group, with a significantly greater percentage being removed by the 108 cells/mL group (79.17 ± 32.31% ammonia and 94.13 ± 6.96% glucose) compared to the 107 group (11.84 ± 13.09% ammonia and 10.26 ± 5.1% glucose) (Fig. 4b-c). The rate of consumption for both media components was greater in the 108 group, but by day 3 both groups had metabolized all of the glucose and ammonia in the media.

C. sorokiniana was inoculated into each media group and, over time, notable differences in growth rate were observed (Table 1). In GM, which contained the highest concentration of glucose but the lowest concentration of ammonia, growth was observed to day 3. This growth was comparable to 8D-SGM, which contained little glucose, but had the most ammonia. Beyond day 3, growth continued in 8D-SGM while growth declined in GM. These results suggest that higher concentrations of glucose, upon C. sorokiniana inoculation, do not necessarily ensure longer term (> 3 days) growth. The presence of ammonia and light may enable longer-term growth in animal cell media than in GM, despite less initial glucose. C. sorokiniana that was inoculated into 4D-SGM contained significantly more glucose and less ammonia than 8D-SGM and significantly less glucose and more ammonia than GM, yet after 3 days, growth was comparable to that in TAP media, and there was twice the growth in each other group. Those results suggested that the combination of both ammonia and glucose may have driven greater immediate growth in animal cell culture media than the presence of ammonia or glucose alone. While the density of C. sorokiniana in 4D-SGM remained higher, its density declined after day 3 in contrast to the 8D-SGM, which showed continued growth throughout the extent of the experiment.

Early phase refers to the growth rate calculated during the first three days following inoculation where ODt and OD0 refer to OD recorded at days 3 and 0, respectively, and t is equal to 3 days. Late phase refers to the growth rate between days 3 and 7 where ODt and OD0 refer to OD recorded at days 3 and 7, respectively, and t is equal to 4 days. Comprehensive growth refers to the growth rate calculated for the length of the experiment where ODt and OD0 refer to OD recorded at days 0 and 7, respectively, and t is equal to 7 days.

We explored how the inoculation density of the algae affects the speed at which ammonia and, due to mixotrophic growth, glucose, can be removed from spent media. Within 24 h, nearly 100% of ammonia was removed from the media in the high-density group and reductions in total ammonia and glucose were observed as early as 3 h post inoculation for the high-density group (Fig. 4). By day 3, nearly all ammonia and glucose, with little variation, was removed from spent media in both inoculation density groups. These results suggest that bioprocesses can be designed to facilitate rapid removal of ammonia from spent animal cell growth media.

Response of QM7 cells to algal treated media

For qualitative observation, C. sorokiniana was grown in phenol red containing GM. After algae were filtered from media, the algal conditioned media appeared pink, as expected of fresh GM media containing phenol red, indicating no substantial change in pH. For quantifying the cytotoxicity of algal-treated GM, C. sorokiniana was grown in phenol-red-free GM, and QM7 cells were cultured in the algal treated fresh GM. Live/dead analyses were performed, and there was no statistically significant difference between the fresh GM and the algal treated-GM group (Fig. 5a, b.

When the metabolic activity of QM7 cells was compared after 1 day of culture in GM, 8D-SGM, and Algal-treated-8D-SGM media, MTT assay showed there was no significant difference between GM and Algal-treated-8D-SGM grown cells. In contrast, QM7 cells grown in 8D-SGM media exhibited significantly less metabolic activity (Fig. 5C).

QM7 cell response to algal-treated media. (A) QM7 cells stained using Live (green cytoplasm)/ dead (red nuclei) stain. All nuclei are also stained with Hoecsht 33,342 (Blue). (B) Cell viability, determined via colocalization of dead signal with nuclear stain, is compared between QM7 cells cultured in GM and 8D-SGM after four days. (C) MTT Analysis of QM7 cells that were exposed to GM, 8D-SGM, and Alg-Treated-8D-SGM. Absorbance data for each condition is represented as the percentage of the average absorbance recorded for the fresh media group for its corresponding MTT test

Discussion

Advances in bioprocessing have enabled the affordable production of many commercial products in the food and pharmaceutical industries [29]. Recognizable food products such as yeast, vinegar, and yogurt, as well as thickeners and preservatives such as xanthan gum and lactic acid, respectively, have been mass produced in well controlled processes in compliance with regulatory safety requirements for decades [30,31,32,33,34]. Adjacently, many complex molecules and modern medicines including antibiotics, enzymes, and vaccines, have been affordably mass produced and globally distributed; however, affordable mass production of next generation foods and medicines, including the products of cellular agriculture, and cell therapies is possible but is still technically and economically limited [29, 35]. If such next generation technologies are to become available and affordable to large populations, novel strategies for affordable production must be developed. In this study we explored the ability of a small green alga, C. sorokiniana, to grow mutualistically with animal cells for improved bioprocessing of lab-grown meat.

The accumulation of ammonia in cell culture media is primarily driven by the metabolism of glutamine and other amino acids by animal cells [10, 36, 37]. Glutamine is both a nitrogen source for protein synthesis and an alternative to glucose as a carbon energy source. It is supplied as the most concentrated amino acid of many cell culture media formulations including Essential-8, a commonly proposed formulation for rapid growth of cells such as those for cellular agriculture applications, due to its ability to rapidly enter cells and contribute to total protein biomass [9, 14, 38]. Ammonia is released when glutamine is converted to glutamate for contribution to ATP production in the Krebs cycle during cell growth. Deamidation of glutamine, yielding ammonia, also spontaneously occurs during its lifespan in a bioreactor, independent of living cells, at rates dependent on its temperature and pH [39, 40]. Previous studies report that deamidation occurs faster at pH values above or below 6, and as temperatures increase beyond 37 °C [40]. Ultimately, ammonia’s rapid accumulation is expected in rapid expansion bioprocesses which use high concentrations of glutamine.

Previous studies explore, with mixed results, the effects of the reduction or replacement of glutamine with other compounds for animal cell cultures on cell productivity. For example, complete elimination of glutamine in batch culture of HEK293-D9 resulted in approximately 50% reduction of the integral of viable cell density [41]. Another glutamine replacement, L-alanyl-l-glutamine (commercially marketed as Glutamax), has repeatedly demonstrated support of animal cell growth with reduced accumulation of media; however, in one study, the growth rate of the target Chinese hamster ovarian cell line was reduced during the first seven days of culture [42]. After day 7, in glutamine containing cultures, concentrations of ammonia that had previously been observed to be detrimental to the strain’s growth were recorded alongside a greater apoptotic ratio. Together, these results suggest that cultures that include glutamine, alongside a strategy to eliminate the ammonia before it accumulates beyond a detrimental threshold, may exhibit faster growth without the deleterious effects of the ammonia.

Several strategies to eliminate ammonia waste from animal cell culture media for pharmaceutical applications have been established; however, they have not yet been widely adapted for the context of cultured meat. Materials like zeolite, zirconium phosphate, activated carbon and anionic resins, can be packed into columns and introduced into bioreactors to selectively adsorb ammonia from the aqueous solutions [43,44,45,46]. The columns are subsequently removed from the media and then stripped of the adsorbed ammonia before reuse. Gas-permeable membranes made from materials such as polyvinylidene fluoride have also been used to encourage passive diffusion of ammonia from aqueous solutions, such as spent cell culture media, to a permeate side containing an acid which would then be disposed of as waste [47, 48]. Another method, electrodialysis, or the application of a DC electric field to the culture media has been incorporated into systems for selectively removing ammonia [49]. These technologies all have successfully demonstrated the removal of ammonia for the preservation of media integrity; however, a recent analysis suggests that without a strategy for reclamation and reuse of waste nitrogen from growth media, cultured meat produced at scale would still have nearly as much nitrogen waste generated as a percentage of nitrogen input into the system (76%) as conventional beef systems (84%), and even more nitrogen waste than swine (47%) or poultry (55%) systems [50].

Several variables define the growth capabilities and metabolism of microalgae and, depending on the geographical environment and habitats within which the species have adapted. Adaptive laboratory evolution, or the intentional induction of stress in a controlled environment, can also modify the behavior of algae under unique growth conditions [51]. For example, light intensity can affect species that may be shaded by canopy or caves, or exposed to direct sunlight in tropical deserts [52]. We explored the effect of light intensity on the growth of C. sorokiniana in animal cell culture medium to identify lighting conditions that would be satisfactory for algal growth in an animal cell bioreactor. We observed that C. sorokiniana grown under the highest light intensity exhibited the least amount of growth. Due to the complex relationship between light intensity and quality, CO2 consumption, exogenous carbon, and photosynthesis it is difficult to identify the root cause of the reduction in growth [53]. It is possible that high light intensities led to rapid CO2 consumption and CO2 sooner becoming a limiting component to photosynthesis. We suggest future studies exploring the relationship between light intensity and CO2 consumption rates. Additionally, while the maximum intensity used in this study, 164 µmol/m2/sec, did not approach that found in some outdoor cultivation plants (~ 2000 µmol/m2/sec at noon), it is possible that the high intensity of the light caused photoinhibition in the culture and thus limited its growth [54]. Photoinhibition, or the reduction in photosynthetic capability in the presence of too much light, is marked with a reduction in CO2 assimilation by the organism and is believed to primarily be the result of damage to Photosystem II ultimately limiting growth [55].

C. sorokiniana also exhibit the metabolic plasticity for not just photoautotrophic growth (light dependent), but also heterotrophic growth where growth occurs in the absence of light [25]. Instead carbon sources, such as glucose or acetate, are assimilated from the media for metabolism. Additionally, previous studies demonstrate the capacity for C. sorokiniana and other species to exhibit mixotrophic growth, which refers to the simultaneous use of photoautotrophic and heterotrophic metabolic strategies [17, 25, 56]. Because of the presence of glucose in GM, it is important to note that the addition of light to C. sorokiniana cultures in GM may modify the metabolic strategy of the algae from heterotrophic to mixotrophic. The advantages of heterotrophic and mixotrophic cultivation over photoautotrophic cultivation for improved growth rates, biomass yield, and enhanced material quality and are well documented within the context of biofuel manufacturing [57, 58]. We explored the growth of C. sorokiniana in GM when exposed to light and found that, after three days, C. sorokiniana maintained in the dark exhibited significantly more growth than when grown in light. Previous studies describe, for photoautotrophic species, a phenomenon referred to as self-shading, which is characterized as the reduction in algal specific growth rate due to light obfuscation by the algal biomass itself, can limit further algal growth [59, 60]. Additionally, photoautotrophic species are dependent on the presence of CO2 for photosynthesis; thus, to prevent growth limitations, CO2 is typically sparged into photobioreactors at additional production cost [61]. Our results suggest that the design and implementation of a heterotrophic C. sorokiniana driven cell culture media recycling system may not depend on balancing the complex kinetics of the algal demand for both light and CO2 [62].

To define metrics that assess the productivity of animal cell bioprocesses, one must consider the desired output of the culture [29, 63]. For pharmaceutical applications this could be, for example, the maximum amount of cells grown per unit volume of media, referred to as cell yield, or, e.g., the mass of antibody produced per liter per day [64]. For cellular agriculture, this could be either the cell density or the percentage of successfully differentiated myocytes [65]. It is the goal of bioprocess engineers to ensure that their subject cells exist in their most metabolically efficient state that maximizes a predefined productivity metric. Thus, it is important to assess the consumption rates of metabolic fuel, such as glucose, and the production rates of metabolic waste, such as ammonia, for each unique cell type and the cells’ respective metabolic goals. Understanding that C. sorokiniana has the capacity to grow mixotrophically, and that algal growth rate is accelerated in media containing ammonia [21], it is important to monitor, for the sake of algal growth management, the rates at which animal cells consume and produce these critical components. We found that glucose consumption and ammonia generation by QM7 cells was continuous across 8 days of culture. After 8 days, the concentration of ammonia had accumulated beyond 1.8 mmol, a common threshold at which point ammonia inhibits cell growth, and glucose was nearly exhausted [66]. The greatest increase in ammonia occurred between days 6 and 8 of culture. This may be due to the cells increasing their dependence on glutamine metabolism for ATP generation due to the lower concentrations of glucose.

Glucose is an essential component of cell culture media and its rapid consumption by C. Sorokiniana would demand, as a consequence of this strategy, increased quantities of glucose delivered at an increased rate for replenishment. While glucose is not predicted to be as much of a significant cost driver of cultured meat bioprocess inputs as complex biomolecules such as growth factors, it still must be affordably sourced. Previous researchers have demonstrated the production of glucose from microalgae, including C. Sorokiniana [66]. While we propose heterotrophic growth of C. Sorokiniana for this bioprocess, an opportunity still lies in using photoautotrophic growth of C. Sorokiniana to enable photosynthetic fixation of carbon into algal biomass, which could be subsequently enzymatically hydrolyzed into glucose for replenishing the system. Another potential source of sustainable glucose may come from the biomass of higher plants. Cellulose scaffolds derived from higher plant tissues are already being proposed as potential substrates for cultured meat [67]. Enzymatic digestion of such scaffolds may strategically reduce the ratio of decellularized plant tissue, to cultured meat tissue to enable the fabrication of more meat-like products. This process may enable simultaneous release of glucose for feeding the cells.

Having demonstrated the capacity for C. sorokiniana to eliminate ammonia from spent animal cell culture media, it was of importance to ensure that there was limited cytotoxic consequences on animal cells for having grown algae in its growth media. Based on our limited analyses, our results suggest that little to no metabolites were released into the animal cell culture media because of C. sorokiniana growth that imposes short term cytotoxic effects on QM7 cells. Similarly, the metabolic activity of QM7 cells cultured in algal-treated media was examined and after 24 h of culture, the cumulative metabolic activity of the QM7 cell cultures in algae treated 8D-SGM was greater than that of untreated 8D-SGM, and comparable to that in GM, per MTT assay. Additional studies are needed to determine how algal-treated media affects other key cell behaviors such as animal cell growth rates, cell adhesion, cell motility, and cell differentiation. Such studies can inform bioprocess operations, such as residence time, length of time of algal treatment, and potentially timing of replenishment of key nutrients, such as glucose [29].

Other media constituents include serum or serum replacements, growth factors such as FGF or TGF-β inorganic salts such as magnesium chloride, potassium chloride, and sodium phosphate., amino acids such as L-glutamine, L-lysine, L-arginine, etc., and vitamins [68,69,70,71]. All play important roles in supporting key processes in cell growth, metabolism, and differentiation, so future research should explore the potential reduction additional animal cell media components following microalgal growth. The study of the consumption kinetics of L-glutamine must be prioritized due to its inherent instability and critical role in cellular metabolism. Having demonstrated C. sorokiniana’s ability to grow under the same environmental conditions as animal cells, we suggest the investigation of novel semipermeable membrane technology for separation of animal and algal cells within the same bioproduction unit, so that continuous operation could be maintained in a mutualistically symbiotic ecosystem inspired bioreactor [72].

A proposed bioprocess (Fig. 6) could involve preparation of affordable decellularized scaffolds from plants or agricultural waste for inoculation, with animal cells, into a proliferation reactor [27, 73, 74]. Within this proliferation reactor, cell culture media designed specifically to support proliferation would be provided and continuously monitored. As the media is metabolized by the animal cells, it would be continuously pumped through a mass exchange system designed to enable media to enter a secondary microalgal reactor without any cross transfer of animal or algal cells. Within this microalgal reactor, C. sorokiniana should continuously eliminate ammonia before the animal culture medium is reintroduced into the proliferation reactor via the mass exchange system. As animal cells continue to grow in the proliferation reactor, confluent cell carriers are passed into a differentiation reactor which would be similarly supported by its own microalgal reactor.

QM7 cell response to algal-treated media. (A) C. sorokiniana grown in GM containing phenol red passing through a vacuum filter. As the media passes through the filter a color change from dark red to pink is observed and a bright green cake of algae biomass is retained at the filter. (B) QM7 cells stained using Live (green cytoplasm)/ dead (red nuclei) stain. All nuclei are also stained with Hoecsht 33,342 (Blue). (C) Cell viability, determined via colocalization of dead signal with nuclear stain, is compared between QM7 cells cultured in GM and 8D-SGM after four days. (D) MTT Analysis of QM7 cells that were exposed to GM, 8D-SGM, and Alg-Treated-8D-SGM. Absorbance data for each condition is represented as the percentage of the average absorbance recorded for the fresh media group for its corresponding MTT test

Conclusions

The availability and affordability of next generation medicines, such as cell therapies, and cellular agriculture products, such as cultured meat, will depend on the implementation of affordable bioproduction strategies. We demonstrate the ability for C. sorokiniana, a freshwater alga, to grow in spent animal cell culture media at 37 °C, and rapidly sequester ammonia. We observed microalgal growth behavior is dependent on the presence and intensity of light, and the presence of ammonia and glucose. We also found no cytotoxic effects of C. sorokiniana growth in cell culture media and the potential to extend the lifespan of spent media, as indicated by QM7 metabolic activity. These results justify further investigation into the capacity of C. sorokiniana to reduce cell culture media waste and the efficiency of such a process. We posit that the integration of algal bioreactors into animal cell production lines may enable development of new resource-efficient, cost-effective, semicontinuous manufacturing systems that enable affordable mass production of animal cell populations.

Data availability

Data supporting the findings of this study are available from the corresponding authors, upon reasonable request.

References

Liu JKH. The history of monoclonal antibody development– progress, remaining challenges and future innovations. Ann Med Surg. Sep. 2014;3(4):113–6. https://doi.org/10.1016/j.amsu.2014.09.001.

Zhu MM, Mollet M, Hubert RS, Kyung YS, Zhang GG. Industrial Production of therapeutic proteins: cell lines, Cell Culture, and purification. Handb Ind Chem Biotechnol. May 2017;1639–69. https://doi.org/10.1007/978-3-319-52287-6_29.

Han F, et al. Tissue Engineering and Regenerative Medicine: achievements, Future, and sustainability in Asia. Front Bioeng Biotechnol. Mar. 2020;8:83. https://doi.org/10.3389/fbioe.2020.00083.

Treich N. Cultured meat: promises and challenges. Environ Resour Econ. 2021;79(1):33–61. https://doi.org/10.1007/s10640-021-00551-3.

Nobre FS. Cultured meat and the sustainable development goals. Trends Food Sci Technol. Jun. 2022;124:140–53. https://doi.org/10.1016/j.tifs.2022.04.011.

Potnis KC et al. Nov., Cost-effectiveness of chimeric antigen receptor T-cell therapy in adults with relapsed or refractory follicular lymphoma, Blood Adv., vol. 7, no. 5, pp. 801–810, 2022, https://doi.org/10.1182/bloodadvances.2022008097.

Failla M, Hopfer H, Wee J. Evaluation of public submissions to the USDA for labeling of cell-cultured meat in the United States. Front Nutr. Sep. 2023;10:1197111. https://doi.org/10.3389/fnut.2023.1197111.

Hong TK, Shin D-M, Choi J, Do JT, Han SG. Current issues and technical advances in cultured meat production: a review. Food Sci Anim Resour. May 2021;41(3):355–72. https://doi.org/10.5851/kosfa.2021.e14.

Yao T, Asayama Y. Animal-cell culture media: History, characteristics, and current issues, Reprod. Med. Biol., vol. 16, no. 2, pp. 99–117, Mar. 2017, https://doi.org/10.1002/rmb2.12024.

Schneider M, Marison IW, von Stockar U. The importance of ammonia in mammalian cell culture. J Biotechnol. May 1996;46(3):161–85. https://doi.org/10.1016/0168-1656(95)00196-4.

Xu W-J, Lin Y, Mi C-L, Pang J-Y, Wang T-Y. Progress in fed-batch culture for recombinant protein production in CHO cells. Appl Microbiol Biotechnol. 2023;107(4):1063–75. https://doi.org/10.1007/s00253-022-12342-x.

Domján J, et al. Real-time amino acid and glucose monitoring system for the automatic control of nutrient feeding in CHO cell culture using Raman spectroscopy. Biotechnol J. 2022;17(5):2100395. https://doi.org/10.1002/biot.202100395.

Specht L. An analysis of culture medium costs and production volumes for cultivated meat.

Stout AJ et al. Jun., Simple and effective serum-free medium for sustained expansion of bovine satellite cells for cell cultured meat, Commun. Biol., vol. 5, no. 1, Art. no. 1, 2022, https://doi.org/10.1038/s42003-022-03423-8.

Abdelfattah A, et al. Microalgal-based wastewater treatment: mechanisms, challenges, recent advances, and future prospects. Environ Sci Ecotechnology. Sep. 2022;13:100205. https://doi.org/10.1016/j.ese.2022.100205.

Ganesan R et al. Jul., A review on prospective production of biofuel from microalgae, Biotechnol. Rep., vol. 27, p. e00509, 2020, https://doi.org/10.1016/j.btre.2020.e00509.

Li X, Li W, Zhai J, Wei H, Wang Q. Effect of ammonium nitrogen on microalgal growth, biochemical composition and photosynthetic performance in mixotrophic cultivation. Bioresour Technol. Feb. 2019;273:368–76. https://doi.org/10.1016/j.biortech.2018.11.042.

Haraguchi Y, Okamoto Y, Shimizu T. A circular cell culture system using microalgae and mammalian myoblasts for the production of sustainable cultured meat. Arch Microbiol. Sep. 2022;204(10):615. https://doi.org/10.1007/s00203-022-03234-9.

Motohashi N, Asakura Y, Asakura A. Isolation, Culture, and Transplantation of Muscle Satellite Cells, J. Vis. Exp. JoVE, no. 86, p. 50846, Apr. 2014, https://doi.org/10.3791/50846.

Ota M, Takenaka M, Sato Y, R. L. S.and, Inomata H Jr. Effects of light intensity and temperature on photoautotrophic growth of a green microalga, Chlorococcum Littorale. Biotechnol Rep. May 2015;7:24–9. https://doi.org/10.1016/j.btre.2015.05.001.

Ziganshina EE, Bulynina SS, Ziganshin AM. Growth characteristics of Chlorella sorokiniana in a Photobioreactor during the utilization of different forms of Nitrogen at various temperatures. Plants. Apr. 2022;11(8):1086. https://doi.org/10.3390/plants11081086.

Bulynina SS, Ziganshina EE, Ziganshin AM. Growth Efficiency of Chlorella sorokiniana in Synthetic Media and Unsterilized Domestic Wastewater, BioTech, vol. 12, no. 3, p. 53, Aug. 2023, https://doi.org/10.3390/biotech12030053.

Ziganshina EE, Bulynina SS, Ziganshin AM. Assessment of Chlorella sorokiniana Growth in Anaerobic Digester Effluent, Plants, vol. 10, no. 3, p. 478, Mar. 2021, https://doi.org/10.3390/plants10030478.

Qiu R, Gao S, Lopez PA, Ogden KL. Effects of pH on cell growth, lipid production and CO2 addition of microalgae Chlorella sorokiniana, Algal Res., vol. 28, pp. 192–199, Dec. 2017, https://doi.org/10.1016/j.algal.2017.11.004.

Park J-E, Zhang S, Han TH, Hwang S-J. The contribution ratio of Autotrophic and Heterotrophic metabolism during a Mixotrophic Culture of Chlorella sorokiniana. Int J Environ Res Public Health. Feb. 2021;18(3):1353. https://doi.org/10.3390/ijerph18031353.

Gershlak JR, et al. Crossing kingdoms: using decellularized plants as perfusable tissue engineering scaffolds. Biomaterials. May 2017;125:13–22. https://doi.org/10.1016/j.biomaterials.2017.02.011.

Perreault LR et al. Repurposing agricultural waste as low-cost cultured meat scaffolds, Front. Food Sci. Technol., vol. 3, 2023, Accessed: Nov. 10, 2023. [Online]. Available: https://www.frontiersin.org/articles/10.3389/frfst.2023.1208298.

Applied Sciences.| Free Full-Text| An Edible, Decellularized Plant Derived Cell Carrier for Lab Grown Meat. Accessed: Nov. 10, 2023. [Online]. Available: https://www.mdpi.com/2076-3417/12/10/5155.

Rathore AS, Mishra S, Nikita S, Priyanka P. Bioprocess Control: current progress and future perspectives. Life. Jun. 2021;11(6):557. https://doi.org/10.3390/life11060557.

Lahue C, Madden AA, Dunn RR, Smukowski Heil C. History and domestication of Saccharomyces cerevisiae in Bread Baking. Front Genet. Nov. 2020;11:584718. https://doi.org/10.3389/fgene.2020.584718.

Ho CW, Lazim AM, Fazry S, Zaki UKHH, Lim SJ. Varieties, production, composition and health benefits of vinegars: a review. Food Chem. Apr. 2017;221:1621–30. https://doi.org/10.1016/j.foodchem.2016.10.128.

Savaiano DA, Hutkins RW. Yogurt, cultured fermented milk, and health: a systematic review. Nutr Rev. May 2021;79(5):599. https://doi.org/10.1093/nutrit/nuaa013.

Mortensen A et al. Jul., Re-evaluation of xanthan gum (E 415) as a food additive, EFSA J., vol. 15, no. 7, p. e04909, 2017, https://doi.org/10.2903/j.efsa.2017.4909.

Abedi E, Hashemi SMB. Lactic acid production– producing microorganisms and substrates sources-state of art, Heliyon, vol. 6, no. 10, p. e04974, Oct. 2020, https://doi.org/10.1016/j.heliyon.2020.e04974.

Humbird D. Scale-up economics for cultured meat. Biotechnol Bioeng. 2021;118(8):3239–50. https://doi.org/10.1002/bit.27848.

Slivac I, Blajić V, Radošević K, Kniewald Z, Gaurina Srček V. Influence of different ammonium, lactate and glutamine concentrations on CCO cell growth, Cytotechnology, vol. 62, no. 6, pp. 585–594, Dec. 2010, https://doi.org/10.1007/s10616-010-9312-y.

Capiaumont J, Legrand C, Carbonell D, Dousset B, Belleville F, Nabet P. Methods for reducing the ammonia in hybridoma cell cultures. J Biotechnol. Feb. 1995;39(1):49–58. https://doi.org/10.1016/0168-1656(94)00142-y.

Rj D, T C. Q’s next: the diverse functions of glutamine in metabolism, cell biology and cancer. Oncogene. Jan. 2010;29(3). https://doi.org/10.1038/onc.2009.358.

Chen P, Harcum SW. Effects of elevated ammonium on glycosylation gene expression in CHO cells, Metab. Eng. 2006 Mar 1;8(2):123–32.https://doi.org/10.1016/j.ymben.2005.10.002.

Scotchler J, Robinson A. Deamidation of glutaminyl residues: dependence on pH, temperature, and ionic strength. Anal BiochemistryI. 1974;59(1). https://doi.org/10.1016/0003-2697(74)90040-2.

Karengera E, Robotham A, Kelly J, Durocher Y, De Crescenzo G, Henry O. Concomitant reduction of lactate and ammonia accumulation in fed-batch cultures: impact on glycoprotein production and quality. Biotechnol Prog. 2018;34(2):494–504. https://doi.org/10.1002/btpr.2607.

Imamoto Y, Tanaka H, Takahashi K, Konno Y, Suzawa T. Advantages of AlaGln as an additive to cell culture medium: use with anti-CD20 chimeric antibody-producing POTELLIGENT™ CHO cell lines, Cytotechnology, vol. 65, no. 1, pp. 135–143, Jan. 2013, https://doi.org/10.1007/s10616-012-9468-8.

Oslan SNH, et al. Integrated stirred-Tank Bioreactor with Internal Adsorption for the removal of ammonium to enhance the cultivation performance of gdhA Derivative Pasteurella multocida B:2. Microorganisms. Oct. 2020;8(11):1654. https://doi.org/10.3390/microorganisms8111654.

Osborne MG, Geiger CJ, Corzett CH, Kram KE, Finkel SE. Removal of toxic volatile compounds in batch culture prolongs stationary phase and delays death of Escherichia coli. Appl Environ Microbiol, 87, 24, pp. e01860–21, https://doi.org/10.1128/AEM.01860-21.

Yamaguchi M, Ichikawa T, Miyaoka H, Zhang T, Miyaoka H, Kojima Y. Proton-based solid acids for ammonia absorption in ammonia water, Int. J. Hydrog. Energy, vol. 45, no. 41, pp. 22189–22194, Aug. 2020, https://doi.org/10.1016/j.ijhydene.2020.05.255.

Nayve FR, Motoki M, Matsumura M, Kataoka H. Selective removal of ammonia from animal cell culture broth, Cytotechnology, vol. 6, no. 2, pp. 121–130, Jun. 1991, https://doi.org/10.1007/BF00373029.

Brose DJ, van Eikeren P. A membrane-based method for removal of toxic ammonia from mammalian-cell culture. Appl Biochem Biotechnol. 1990;24–5. https://doi.org/10.1007/BF02920270.

Soto-Herranz M, Sánchez-Báscones M, García-González MC, Martín-Ramos P. Comparison of the Ammonia Trapping performance of different gas-permeable tubular membrane system configurations. Membranes. Nov. 2022;12(11):1104. https://doi.org/10.3390/membranes12111104.

Chang Y-HD, Grodzinsky AJ, Wang DIC. In-situ removal of ammonium and lactate through electrical means for hybridoma cultures. Biotechnol Bioeng. 1995;47(3):308–18. https://doi.org/10.1002/bit.260470305.

Myers GM, Jaros KA, Andersen DS, Raman DR. Nutrient recovery in cultured meat systems: Impacts on cost and sustainability metrics, Front. Nutr., vol. 10, p. 1151801, Apr. 2023, https://doi.org/10.3389/fnut.2023.1151801.

Sandberg TE, Salazar MJ, Weng LL, Palsson BO, Feist AM. The emergence of adaptive laboratory evolution as an efficient tool for biological discovery and industrial biotechnology, Metab. Eng., vol. 56, pp. 1–16, Dec. 2019, https://doi.org/10.1016/j.ymben.2019.08.004.

Hopes A, Mock T. Evolution of Microalgae and their adaptations in different Marine ecosystems. in Encyclopedia of Life sciences. John Wiley & Sons, Ltd; 2015. pp. 1–9. https://doi.org/10.1002/9780470015902.a0023744.

Metsoviti MN, Papapolymerou G, Karapanagiotidis IT, Katsoulas N. Effect of light intensity and quality on growth rate and composition of Chlorella vulgaris. Plants. Dec. 2019;9(1):31. https://doi.org/10.3390/plants9010031.

Holdmann C, Schmid-Staiger U, Hornstein H, Hirth T. Keeping the light energy constant — cultivation of Chlorella sorokiniana at different specific light availabilities and different photoperiods. Algal Res. Jan. 2018;29:61–70. https://doi.org/10.1016/j.algal.2017.11.005.

Nawrocki WJ et al. Molecular origins of induction and loss of photoinhibition-related energy dissipation qI. Sci Adv, 7, 52, p. eabj0055, https://doi.org/10.1126/sciadv.abj0055.

Lacroux J, Seira J, Trably E, Bernet N, Steyer J-P, van Lis R. Mixotrophic Growth of Chlorella sorokiniana on acetate and butyrate: interplay between substrate, C:N ratio and pH. Front Microbiol. 2021;12:703614. https://doi.org/10.3389/fmicb.2021.703614.

Cecchin M et al. Apr., Molecular basis of autotrophic vs mixotrophic growth in Chlorella sorokiniana, Sci. Rep., vol. 8, no. 1, Art. no. 1, 2018, https://doi.org/10.1038/s41598-018-24979-8.

Piasecka A, Baier A. Metabolic and Proteomic Analysis of Chlorella sorokiniana, Chloroidium Saccharofilum, and Chlorella vulgaris cells cultured in Autotrophic, Photoheterotrophic, and Mixotrophic Cultivation modes. Molecules. Jul. 2022;27(15):4817. https://doi.org/10.3390/molecules27154817.

Straka L, Rittmann BE. Effect of culture density on biomass production and light utilization efficiency of Synechocystis sp. PCC 6803. Biotechnol Bioeng. 2018;115(2):507–11. https://doi.org/10.1002/bit.26479.

Saccardo A, Bezzo F, Sforza E. Microalgae growth in ultra-thin steady-state continuous photobioreactors: assessing self-shading effects, Front. Bioeng. Biotechnol., vol. 10, 2022, Accessed: Jan. 11, 2024. [Online]. Available: https://www.frontiersin.org/articles/https://doi.org/10.3389/fbioe.2022.977429.

Chisti Y. Constraints to commercialization of algal fuels. J Biotechnol. Sep. 2013;167(3):201–14. https://doi.org/10.1016/j.jbiotec.2013.07.020.

Chisti Y. Biodiesel from microalgae. Biotechnol Adv. May 2007;25(3):294–306. https://doi.org/10.1016/j.biotechadv.2007.02.001.

Salvador WOS, Ribeiro IAB, Nogueira DES, Ferreira FC, Cabral JMS, Rodrigues CAV. Bioprocess Economic Modeling: Decision Support Tools for the Development of Stem Cell Therapy Products, Bioengineering, vol. 9, no. 12, Dec. 2022, https://doi.org/10.3390/bioengineering9120791.

Mitra S, Murthy GS. Bioreactor control systems in the biopharmaceutical industry: a critical perspective. Syst Microbiol Biomanufacturing. 2022;2(1):91–112. https://doi.org/10.1007/s43393-021-00048-6.

Allan SJ, De Bank PA, Ellis MJ. Bioprocess Design Considerations for Cultured Meat Production With a Focus on the Expansion Bioreactor, Front. Sustain. Food Syst., vol. 3, 2019, Accessed: Apr. 07, 2022. [Online]. Available: https://www.frontiersin.org/article/https://doi.org/10.3389/fsufs.2019.00044.

Pereira S, Kildegaard HF, Andersen MR. Impact of CHO metabolism on cell growth and protein production: an overview of toxic and inhibiting metabolites and nutrients. Biotechnol J. 2018;13(3):1700499. https://doi.org/10.1002/biot.201700499.

Fernandes de, Souza, et al. Effect of milling and enzymatic hydrolysis in the production of glucose from starch-rich Chlorella sorokiniana biomass. Algal Res. 2020;50. https://doi.org/10.1016/j.algal.2020.101961.

Thyden R et al. Jan., An Edible, Decellularized Plant Derived Cell Carrier for Lab Grown Meat, Appl. Sci., vol. 12, no. 10, Art. no. 10, 2022, https://doi.org/10.3390/app12105155.

Schnellbaecher A, Binder D, Bellmaine S, Zimmer A. Vitamins in cell culture media: Stability and stabilization strategies, Biotechnol. Bioeng., vol. 116, no. 6, pp. 1537–1555, Jun. 2019, https://doi.org/10.1002/bit.26942.

Ghasemi N, Bandehpour M, Ranjbari J. Optimization of key factors in serum free medium for production of human recombinant GM-CSF using response surface methodology. Iran J Pharm Res IJPR. 2019;18(Suppl1):146–56. https://doi.org/10.22037/ijpr.2020.112322.13681.

Baltz JM. Media composition: salts and osmolality. Methods Mol Biol Clifton NJ. 2012;912:61–80. https://doi.org/10.1007/978-1-61779-971-6_5.

Rawat J, Bhambri A, Pandey U, Banerjee S, Pillai B, Gadgil M. Amino acid abundance and composition in cell culture medium affects trace metal tolerance and cholesterol synthesis. Biotechnol Prog. Jan. 2023;39(1):e3298. https://doi.org/10.1002/btpr.3298.

Pinto NDS, Brower M. Wide-surface pore microfiltration membrane drastically improves sieving decay in TFF‐based perfusion cell culture and streamline chromatography integration for continuous bioprocessing, Biotechnol. Bioeng., vol. 117, no. 11, pp. 3336–3344, Nov. 2020, https://doi.org/10.1002/bit.27504.

Lu H, Ying K, Shi Y, Liu D, Chen Q. Bioprocessing by Decellularized Scaffold Biomaterials in Cultured Meat: A Review, Bioengineering, vol. 9, no. 12, p. 787, Dec. 2022, https://doi.org/10.3390/bioengineering9120787.

Acknowledgements

We would like to acknowledge Dr. Melissa Towler for her algal cultivation advice, Christopher Bellerive for assistance with media analysis, and Bret Judson and the Boston College Imaging Core for their infrastructure and support.

Funding

This research was funded via laboratory startup funds to Glenn Gaudette from Boston College and a New Harvest fellowship awarded to Richard Thyden.

Author information

Authors and Affiliations

Contributions

Richard Thyden: Conceptualization, Investigation, Data curation, Formal analysis, Methodology, Writing– original draft, Validation, Project administration. Tanja Dominko: Conceptualization, Methodology, Writing– review & editing, Supervision. Pamela Weathers: Conceptualization, Methodology, Writing– review & editing, Supervision, Resources. Antonio Carlos Freitas dos Santos: Conceptualization, Writing– review & editing. Luke Perreault: Methodology, Writing– review & editing. David Reddig: Data Curation, Writing– review & editing. Jack Kloster: Data Curation, Writing– review & editing. Glenn Gaudette: Conceptualization, Formal Analysis, Funding acquisition, Writing– review & editing, Supervision, Resources, Project administration.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors present consent for publication. There were no additional participants in this study.

Institutional review board statement

Not applicable.

Competing interests

The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thyden, R., Dominko, T., Weathers, P. et al. Recycling spent animal cell culture media using the thermally resistant microalga Chlorella sorokiniana. Syst Microbiol and Biomanuf (2024). https://doi.org/10.1007/s43393-024-00280-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43393-024-00280-w