Abstract

Penetrating trauma by energised fragments is the most common injury from an explosive event. Fragment penetrations to the truncal region can result in lethal haemorrhage. Personal armour is used to mitigate ballistic threats; it comprises hard armour to protect from high-velocity bullets and soft armour to protect against energised fragments and other ballistic threats (such as from a hand gun) with low impact velocities. Current testing standards for soft armour do not focus on realistic boundary conditions, and a backing material is not always recommended. This study provides a comprehensive set of evidence to support the inclusion of a backing used in testing of soft body armour. Experiments were performed with a gas-gun system using fragment-simulating projectiles (FSPs) of different shapes and sizes to impact on a woven aramid and a knitted high-performance polyethylene ballistic fabric, with and without the ballistic gelatine soft tissue simulant as the backing material. The results showed statistically significant differences in the impact velocities at 50% risk (V50) of fabric perforation across all test configurations when the gelatine backing was used. Furthermore, the backing material enabled the collection of injury-related metrics such as V50 of tissue-simulant penetrations as well as depth of penetration against impact velocity. The normalised energy absorbed by the fabric could also be calculated when the backing material was present. This study confirms that a backing material is essential, particularly when assessing the performance of single layer fabrics against FSPs of low mass. It also demonstrates the additional benefits provided by the backing for predicting injury outcomes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Personal armour has become increasingly important in mitigating injuries sustained from ballistic threats both in combat and civilian law enforcement. Modern personal armour is generally categorised as comprising hard armour and soft armour [1]. Hard armour is generally comprised of rigid ceramic plates or, less commonly, laminated composite panels. Soft armour typically consists of multiple layers of high-performance ballistic fibres sewn into a fabric or bonded together [2]. Hard armour provides high levels of ballistic protection such as from high energy projectiles, but is heavy and inflexible [3]; thus, it is mainly used for providing essential medical coverage to anatomical structures within the thorax [1]. Soft armour on the other hand is flexible and is aimed at protecting from energised fragments and ballistic threats with low impacting energies.

Fragment penetrating injury is the most common wounding mechanism in conflict [4,5,6,7,8]. This includes both primary fragments from the explosive device itself (such as shrapnel, nuts, bolts, and ball bearings) and secondary fragments from the vicinity (such as glass shards and building debris). The soft armour component can cover a greater body surface area, but there are still gaps in soft armour coverage where no protection is worn; this is particularly found in the extremities and junctional regions. In fact, it was reported that the head and the extremities are the two most commonly wounded regions for the UK and US soldiers in Iraq and Afghanistan [9,10,11]. Soft body armour with recently developed ballistic fabrics can help increase protection for coverage gaps while minimising the added burden to the wearers [1, 12,13,14]. Fabrics comprised of woven aramids (synthetic aromatic polyamides) are commonly used ballistic protective materials, with one or two layers having been shown to provide meaningful protection against low-energy fragments [13]. One component of the pelvic protection system used by the United Kingdom Armed Forces is made from two layers of knitted elastic silk material; this has been demonstrated to reduce superficial injuries to the pelvis, upper thigh, and perineal area [10, 14, 15].

Ballistic protective materials are subjected to standardised testing to evaluate their performance. A ballistic testing standard specifies requirements for a sample material, testing procedures, and protection levels provided by the tested armour. Various testing standards are published (Table 1) [16,17,18,19,20,21,22,23,24]. Of these, the NATO standard AEP 2920 [18] appears to be the most commonly used for testing personal armour; it specifies a range of fragment-simulating projectiles (FSPs) for use when evaluating the ballistic protection against fragment threats. Published standards use the V50, the velocity of the projectile at which the probability of armour perforation is less than 50% [18], to provide a practical quantification of the ballistic resistance of personal protection [25]. The value of V50 can be determined accurately from a probabilistic risk curve, but this can require a large number of tests. Alternatively, as recommended by many of the standards, the V50 can be estimated as the arithmetic mean of the FSP-impact velocity for an equal number of shots with and without armour perforation. For example, AEP 2920 calculates the V50 by averaging the three, five, or seven highest projectile velocities resulting in no armour perforation and the three, five, or seven lowest projectile velocities resulting in material perforation, with the spread of these impact velocities respectively less than 40, 50, or 60 m/s, where the smaller spread is preferrable [18]. The arithmetic mean method is a practical approach and was shown to have good agreement with the probability risk curve for a small number of impact tests [26]. AEP 2920 also recommends the use of probit analysis method which provides a ‘standard deviation’ accompanying the V50 value.

Another important aspect of ballistic assessment is the experimental boundary conditions of the tested armour. Two methods of support of soft armour are suggested in the standards: one whereby the armour is secured onto a backing material and one whereby the armour is clamped without a backing material. In the first case, the commonly specified backing material is plastilina clay, whose deformation after impact provides the back-face signature (BFS), generally measured as the depth of the indentation on the clay. This method has been used widely in many applications of both hard and soft body armours to ascertain the risk of blunt impact, but not without limitations: it was developed based on only two specific impact scenarios without further validations and direct correlation to injury [27]. In addition, the suggested plastilina clay is not comparable in material behaviour to most tissues of the human body [28]. In the second case, the armour material is clamped at its four sides, often under a specified clamping force and tension but with no backing material. The specified levels of clamping force and tension provide a rather arbitrary boundary condition; while clamping can retain securely the samples and ensure repeatability of the test results, the mounting condition deviates from the realistic usage conditions. None of the suggested support methods, however, are able to ascertain the risk of penetrating injuries such as open soft tissue injuries and bone fractures. Such information is especially important when testing soft armour, particularly light-weight panels with few layers of fabric for improving coverage gaps, and can better inform the design, selection, and optimisation of armour systems.

Our previous study [26] examined the necessity of a backing material when assessing the performance of various ballistic fabrics against a 0.78-g right-circular cylindrical FSP. We used the 20% by weight ballistic gelatine as the backing material against a single layer of fabric clamped taut with no specific tension so that it was close to conditions during usage. The experimental set-up was then repeated without the use of the gelatine backing, and the two sets of results were compared. Our study showed that not using a soft tissue simulant as backing material resulted in “inaccurate and unpredictable changes in the behaviour of the ballistic materials” due to the lack of a biofidelic interaction between fabric and soft tissue. Furthermore, the usage of ballistic gelatine enabled measurements such as the depth of penetration (DoP), V50 of any soft tissue penetration, and V50 of at least 15 mm soft tissue penetration to reflect quantitatively the extent of penetrating injury to tissue behind the armour as well as the energy absorbed by the fabric, which is a useful parameter for comparing different fabrics.

The aim of this paper is to expand on our previous work [26] to provide a more comprehensive set of evidence on the effect on outcome measures of using a backing material in ballistic testing of soft body armour. Various STANAG 2920-recommended FSPs were used of different shapes and sizes to perform ballistic testing on a woven and a knitted ballistic fabric, with and without the ballistic gelatine soft tissue simulant as the backing material.

Materials and Methods

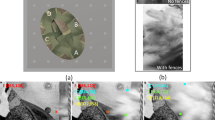

Ballistic tests were performed using a gas-gun system [29]. The device comprises a 32-mm-bore, 3-m-long stainless-steel smooth barrel with one end connected to a firing reservoir and the other end connected to a target chamber (Fig. 1). The reservoir, charged with either compressed air or helium, together with Mylar® diaphragms were used as the firing mechanism to accelerate the projectile to a desired velocity between 20 m/s and 600 m/s. The fragment simulating projectile (FSP) was housed in front of a sabot unit which allowed for various shapes and sizes of the FSP to be used in the system. The sabot and FSP were separated at the end of the barrel by the sabot stripper construction installed at the entrance of the target chamber so that only the FSP could continue its course to impact the sample mounted inside the target chamber. High-speed photography (Phantom VEO710L, AMETEK, USA) at a rate of 170,000 frames per second was used to record the impact event, identify FSPs with yaw angles greater than 10 degrees that were subsequently rejected, observe the response of the sample, and estimate the impact velocity of the FSP.

The experimental protocol described in the previous work by Nguyen et al. [26] was implemented in this study for two different ballistic fabrics and five different FSPs (Fig. 1). The five FSPs (Table 2) were chosen from the recommendations by the STANAG 2920 NATO standard to cover various shapes (sphere, right circular cylinder, and chisel-nosed cylinder), sizes (2.64 mm to 10 mm cross-sectional diameter), and masses (0.16 g to 4.15 g). 190-g/m2 Twaron® woven aramid and 610-g/m2 Dyneema® knitted HPPE (high-performance polyethylene) were chosen as the fabric targets since these materials and constructions are typically used for soft body armour, whose one or more layers had been shown to provide some protection against fragments [10, 13, 26, 30]. The ballistic fabric samples were mounted as described by Nguyen et al. [26] ; they were mounted taut to a frame with no specific tension to ensure the boundary conditions during usage are replicated as well as possible while still keeping the experiments well-controlled. Specifically, the 400 × 400 mm woven aramid panels were rolled up in four sides into a 100 × 100 mm test area, and the 400 × 400 mm knitted HPPE panels were carefully clamped at all sides to a 100 × 100 mm test area so that they were not stretched out or folded. The ballistic impacts were spread evenly over the tested samples and any permanent damage to the fabric (tearing or thinning of material) was at least 30 mm away from the others.

To investigate the effect of the soft tissue simulant backing, two sets of experiments were carried out for all fabrics and FSPs: one set had a 250 × 150 × 50 mm block of 20% by weight ballistic gelatine [29] placed behind and in light contact with the tested fabric; the other set was of exactly the same conditions, but without any backing material behind the sample (i.e. just air). 300-bloom type A ballistic gelatine of 20% by weight was chosen as it had been commonly used as soft tissue simulant in ballistic tests [26, 29, 31] and shown to have ballistic responses similar to that of human tissue [31,32,33,34,35]. All gelatine blocks used in this study were calibrated with the 0.34-g 4.4-mm ball bearing and showed the expected response in agreement with literature [29, 31, 34]. They were stored at 10 ± 1°C before and after each shot and were never left at room temperature for more than 10 minutes during a test.

After each impact test, the tested sample was inspected for any material perforation where the FSP tore the fabric and completely escaped from its back face. The V50 for material perforation, which portrayed the ballistic performance of the fabric, was obtained using two methods: (i) the Weibull survivability analysis (NCSS statistical software, Utah, USA) as described by Nguyen et al. [26] and (ii) the arithmetic mean evaluation described by the AEP-2920 NATO standard [18]. The range of uncertainty for these methods was respectively given by the 95% confidence interval and the standard deviation. To compare the values of V50 between the two boundary conditions, unpaired t-tests (α = 0.05) were performed on data from method (ii) and the z-test (α = 0.05) on data from method (i). For the z-test, it was assumed that the V50 value estimated by the survival analysis was equivalent to that as if obtained as a mean, with corresponding standard deviation, from a large number of tests following a normal distribution.

For tests with gelatine backing, the tissue simulant was also visually checked for any penetration, i.e. permanent track left by the FSP in the backing material regardless of whether the FSP remained inside. In tests where gelatine penetration occurred, the gelatine was cut along the FSP travel track to measure the DoP using a ruler. Values of V50 were obtained, also using the Weilbull regression model [26], for any gelatine penetration regardless of DoP and for greater-than-15-mm gelatine penetration. The value of 15 mm of penetration was chosen here because the shortest distance from the surface of the skin to an essential structure in the human body is 14.6 ± 5.1 mm; that is the distance to the femoral artery [35, 36]. Furthermore, the DoP from tests with gelatine backing material was compared with that from tests with gelatine only, i.e. no protective fabric, using the same FSPs. From this, the normalised percentage energy absorption of the material against a specific FSP was calculated as:

where v1 and v0 are, respectively, the impact velocity of the FSP with and without the protective material that result in the same DoP in gelatine, and ρA is the areal density of the ballistic fabric [26].

Results

Three-hundred-and-five ballistic tests were analysed — 166/305 tests with the set-up using ballistic gelatine and 139/305 tests with the set-up not using the backing. On average, 15 tests were carried out per fabric per FSP, with at least 13 tests for each category. For both boundary conditions, 123/305 tests (40%) resulted in material perforation (Fig. 2A). For tests with ballistic gelatine backing, 121/166 tests (73%) resulted in gelatine penetration in which 73/121 (60%) penetrations were 15 mm or deeper; all but one impacts (59/60 tests, 98%) perforating the fabric also penetrated the gelatine (Fig. 2B, 83% of which were 15 mm or deeper). Approximately half of the gelatine penetration cases occurred even though the fabric was not perforated (41% for Twaron® weave and 62% for Dyneema® knit) (Fig. 2C); 39% of these penetrations were deeper than 15 mm.

Effect of ballistic gelatine backing

The values of V50 for material perforation by the five FSPs, obtained from the two evaluation methods, are shown in Figure 3. The figure also shows the values for the same fabrics impacted by a 0.78-g cylindrical FSP, obtained from the previous study by Nguyen et al. [26]. The percentage difference between the two V50 (with and without backing) is displayed, calculated as the difference between the two V50 values divided by the V50 value from the test with gelatine backing. The obtained percentage differences are similar across all FSPs for the same impacted material (approximately 50-60% for Twaron® weave and 5-15% for Dyneema® knit). The V50 values are higher with gelatine backing for the Twaron® woven fabric whereas they are similar or lower with gelatine backing for the Dyneema® knitted fabric. The two boundary conditions yield statistically different V50 (p < 0.05) for all FSPs impacting the Twaron® woven fabric, and half of the FSP cases impacting the Dyneema® knitted fabric.

Comparison of V50 for perforation of (A) Twaron® weave and (B) Dyneema® knit ballistic fabric in single-layer format with and without gelatine backing. The values of V50 were obtained using the STANAG 2920 method and the Weibull survivability analysis. The percentage difference (relative to results with gelatine) is labelled for each projectile. * The two V50 values are statistically different (p < 0.05). ** data obtained in a previous study [26]. RC: right circle; CN: chisel nosed

Additional metrics of protection offered by fabrics for tests with gelatine backing

Figure 4 shows additional V50 values (± 95% confidence interval), obtained from the Weibull survival analysis, representing the 50% risks of material perforation, any soft tissue penetration, and soft tissue penetration of 15 mm or greater for all tested fabrics and FSPs. The overall trend indicates that the V50 values are lowest for any gelatine penetration. The V50 values are similar between material perforation and at-least-15-mm gelatine penetration, with the two exceptions where the latter is higher for Twaron® weave impacted by smallest FSPs (5-mm sphere and 0.16-g cylinder) and two exceptions where the latter is lower for Dyneema® knit impacted by the largest FSPs (10-mm sphere and 4.15-g cylinder). Between the two fabrics, Dyneema® knit has higher V50 values. Among tests of the same fabric, the V50 values are generally similar for all FSPs.

Figure 5 shows the DoP in the gelatine backing against impact velocity of the FSP for all tested fabrics and FSPs. Linear data fits were applied on the obtained data sets, whose slope and x-intercept depict the resistance of the fabric against the specific FSP. For both fabrics, the resistance is lowest against the 4.15-g RC cylinder, followed by the 10-mm sphere, 1.1-g CN cylinder, 5-mm sphere, and 0.16-g RC cylinder (Fig. A, Supplementary Materials). With or without material perforation, impacts against the Twaron® woven fabric result in a linear correlation between the DoP and the tested range of impact velocities of each FSP. This, however, is not the case for the Dyneema® knitted fabric, except for impacts with the 0.16-g RC cylindrical FSP. For the other impacts with Dyneema® knit, the slope of the linear data fit becomes much steeper for impact velocities where material perforation occurs. Both fabrics are shown to reduce the DoP into the gelatine backing when compared to no protection present. This reduction, however, decreases drastically for the perforated Dyneema® knit fabric.

The depth of penetration in gelatine backing against the FSP impact velocity of different FSPs for tests with Twaron® weave (solid lines) and Dyneema® knit (dashed lines). Filled markers denote impacts without perforation of fabric; unfilled markers denote impacts with fabric perforation. Dotted lines show the trends from the same FSPs with no ballistic fabric, i.e. gelatine only.

The normalised percentage energy absorption values of all test configurations are shown in Figure 6 for three outcome scenarios: penetration in the gelatine with perforation of the material, penetration in the gelatine without perforation of the material, and no penetration in the gelatine all except for one of which was also with no perforation of the material. The overall values are the average of those calculated for these three scenarios. Generally, Twaron® woven fabric has higher energy absorption power per unit of mass, especially for cylindrical FSPs. Apart from the 10-mm spherical FSP against Twaron® weave, the common trend is that the energy absorption is highest for cases with no penetration in gelatine, which is also the same across all FSPs, followed by those with gelatine penetration but no material perforation, and then those with material perforation and gelatine penetration. The absorption values are closer between the two latter cases for Twaron® weave and between the two former cases for Dyneema® knit. The normalised percentage energy absorption is especially low for the configuration of 10-mm spherical FSP against Dyneema® knit.

Discussion

The reported results reconfirm the protection benefits provided by a thin layer of the 190-gsm Twaron® woven and 610-gsm Dyneema® knitted fabrics. Similar to the conclusions shown by Nguyen et al., the Dyneema® knit had better overall performance in terms of V50 values and DoP likely due to its high areal density, but lower energy absorption per unit mass compared to the Twaron® weave. The high elasticity of the knitted fabric allowed it to stretch and be resistant to perforation; this, however, led to the FSPs penetrating the soft tissue simulant even without perforating the fabric, similar to pencilling behind armour blunt traumas [3, 36]. This behaviour was more apparent in heavier FSPs; hence the V50 values of gelatine penetration were lower compared to those of material perforation for heavier FSPs. It was especially noticeable for the 10-mm sphere and the 4.15-g RC cylinder whose V50 for greater-than-15-mm gelatine penetration was much lower than material perforation. Interacting with the woven fabric, the rounder spherical FSPs had more tendency to slip between the displaced yarns, resulting in low V50 values; the chisel-nosed cylinder had smaller edged contact surface so it wedged and sheared through the yarns, giving lower V50 values compared to the similar sized 0.78-g RC cylinder with larger and flatter contact surface [26]. The higher friction between the cylindrical FSPs and the primary yarns of the woven fabric also resulted in no perforation to the fabric but still penetration in gelatine. These pencilling injuries can only be quantified with the presence of a backing material. Once the FSP penetrated the backing material, the damage, in terms of DoP, was shown to be mainly related to the momentum of the FSP. The protection efficiency (the energy absorption per unit of mass) of the fabrics was generally dependent on the range of impact velocity of FSP. Each fabric gave the highest normalised energy absorption for the lower impact velocity range where no penetration and perforation occurred; this was followed by the velocity range resulting in gelatine penetration, but not material perforation; in the range where material perforation occurred, the protection dropped to lowest, especially for the knitted fabric.

Fragment simulating projectiles of different geometries and sizes, recommended by STANAG-2920, were chosen to provide a comprehensive set of evidence for the role of the tissue-simulant backing material in the ballistic assessment of thin protective fabrics. In particular, the right-circular cylindrical and spherical shapes were identified as the most common geometries for small metal fragments recovered from secondary blast penetrating injuries [37,38,39]. The 10-mm sphere and the 4.15-g cylinder are the two largest and heaviest FSPs listed [18]. The 0.16-g cylinder was the smallest and lighter FSP listed. The 5-mm ball bearing was also found as one of the main injury threats in victims of the Boston marathon bombing [40, 41]. The 1.1-g chisel-nosed cylinder was designed to represent natural fragments and has been used widely for ballistic testing of body armour [42]. Other types of penetrating threat that can be mitigated by thin ballistic fabrics [14], which should be employed for further investigation, is soil ejecta and handgun bullets [16, 24, 43].

The ballistic fabrics chosen for this investigation are of different architecture—woven and knitted—and different areal density—190 gsm and 610 gsm—to represent different test specimens. These types of material are commonly used in soft body armours, although often consist of as many as 10 to 50 layers [13]. The single-layer construction used here has been shown to provide meaningful protective benefits [10, 13, 26, 30], but its specific testing methodology has not been thoroughly advised by current testing standards.

The backing material chosen here was 20% by weight ballistic gelatine as it is a popular choice of soft tissue simulant [14, 25, 28], whose responses are representative of human tissue in general [14, 30,31,32,33]. It is, however, only appropriate for body areas with large amounts of muscle, particularly the neck and leg, but not for areas with air-containing organs such as the thorax and abdomen [31]. For the thoracic and abdominal regions, using a different backing structure would be more appropriate [44, 45]. In addition, for impacts by light FSPs at low velocities, the skin is more resistance to perforation than gelatine [31, 46] and so the results for the 0.16-g cylindrical FSP are likely overestimated. Including a layer of skin simulant to the relevant backing material should be considered in future works with light FSPs. Overall, even though there is no evidence that the backing material has to be biofidelic, in order to obtain a meaningful risk assessment that can translate to real-world performance, one should consider using a backing material whose ballistic response is similar to that of the body region that the tested armour intends to protect.

The difference in V50 values for material perforation is similar between various FSPs for the same protective fabric, but different between different fabrics. This agrees with the previous study by Nguyen et al. [26], which used a 0.78-g cylindrical FSP; it produced a similar percentage difference for the same Twaron® weave and Dyneema® knit (63% and 16% respectively, Fig. 3) and varying percentage differences between the five ballistic fabrics tested. Furthermore, the trends in the discrepancy are not consistent between the fabrics: with the backing material present, the V50 values increased for Twaron® weave by 48% to 66% and generally decreased for Dyneema® knit by 3% to 10% compared to when the backing material is not present. This was also observed for other fabrics in the previous study [26]. These observations suggest that the ballistic assessment of a soft body armour should not be simplified to exclude a backing since the missing interaction between the armour and the backing likely gives rise to an inaccurate ballistic threshold of the armour that cannot be predicted or scaled.

An additional benefit of using a backing material in the assessment of soft armour is the ability to estimate the amount of soft tissue damage caused by FSP penetration. We proposed here the V50 for any gelatine penetration as a metric associated with the risk of wounding and ingress of a foreign object into human tissue which in turn is associated with risk of infection. Our results showed that there could be cases of gelatine penetration without perforation of the armour; use of the well-established V50 for armour perforation does not capture this penetration and therefore could overestimate the protective ability of the fabric.

We also proposed here the V50 for deep penetration into the gelatine as a metric associated with the risk of injury to organs; the distance to the femoral artery (approximately 15 mm) [47, 48] was used here. Depending on the intended location of the armour, one could consider using a different value to represent deep penetration; 17 mm is the distance to the liver, 19 mm to the heart, 15 mm to the common carotid artery in the neck, and 41 and 85 mm respectively to the lateral and posterior surface of the tibia [47, 49, 50].

Furthermore, the use of a backing material and therefore the ability to measure a DoP allows one to predict the amount of kinetic energy carried by the projectile when striking an essential structure inside the human body; this, combined with injury-risk curves of the essential structure of interest allows the calculation of the ability of a fabric to protect specifically that essential structure [50]. Finally, the presence of a backing material enables the calculation of the energy absorbed by the fabric, which is useful for comparisons between fabrics, as well as the examination of the effects of different types of clothing on the wound pattern 51.

Conclusions

This study focused on the ballistic assessment of thin protective fabrics. It showed that the inclusion of a backing soft tissue simulant makes a statistically significant difference to the performance of both woven and knitted fabrics impacted by various FSPs of different shape, size, and mass. Use of a backing material was also shown to allow for the utility of additional metrics that relate to injury risk. Consequently, it is recommended that a backing material is included when assessing the performance of soft ballistic protection, at least for armour with few layers of fabrics and against small metal fragments.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Breeze J et al (2016) Defining the essential anatomical coverage provided by military body armour against high energy projectiles. J R Army Med Corps 162:284–290

Mawkhlieng U, Majumdar A (2019) Soft body armour. Text Prog 51:139–224

Tilsley L, Carr DJ, Lankester C, Malbon C (2018) Do air-gaps behind soft body armour affect protection? J R Army Med Corps 164:15–18

Bowyer GW (1996) Management of small fragment wounds: experience from the Afghan border. J Trauma 40:S170–S172

Hill PF, Edwards DP, Bowyer GW (2001) Small fragment wounds: biophysics, pathophysiology and principles of management. J R Army Med Corps 147:41–51

Covey DC (2002) Blast and fragment injuries of the musculoskeletal system. J Bone Joint Surg 84-A:1221–1234

Champion HR, Holcomb JB, Young LA (2009) Injuries from explosions: Physics, biophysics, pathology, and required research focus. J Trauma - Inj Infect Crit Care 66:1468–1477

Eastridge BJ et al (2012) Death on the battlefield (2001-2011): Implications for the future of combat casualty care. J Trauma Acute Care Surg 73:431–437

Owens BD et al (2008) Combat wounds in Operation Iraqi Freedom and Operation Enduring Freedom. J Trauma Inj Infect Crit Care 64:295–299

Breeze J, Allanson-Bailey LS, Hepper AE, Midwinter MJ (2015) Demonstrating the effectiveness of body armour: A pilot prospective computerised surface wound mapping trial performed at the role 3 hospital in Afghanistan. J R Army Med Corps 161:36–41

Penn-Barwell JG, Roberts SAG, Midwinter MJ, Bishop JRB (2015) Improved survival in UK combat casualties from Iraq and Afghanistan: 2003-2012. J Trauma Acute Care Surg 78:1014–1020

Carr DJ (1999) Failure mechanisms of yarns subjected to ballistic impact. J Mater Sci Lett 18:585–588

Sakaguchi S, Carr D, Horsfall I, Girvan L (2012) Protecting the extremities of military personnel: Fragment protective performance of one- and two-layer ensembles. Text Res J 82:1295–1303

Lewis EA, Pigott MA, Randall A, Hepper AE (2013) The development and introduction of ballistic protection of the external genitalia and perineum. J R Army Med Corps 159:i15–i17

Rankin IA et al (2022) Protective clothing reduces lower limb injury severity against propelled sand debris in a laboratory setting. Hum Factors Mech Eng Def Saf 6(12)

Ballistic resistance of body armor NIJ Standard-0101.06. (2008)

Mil-STD-662F test method standard: V50 ballistic test for armor. (1997)

NATO Standard AEP-2920 procedures for the evaluation and classification of personal armour. (2016).

Payne, T., Malbon, C. & O’Rourke, S. Body armour standard (2017). (2017).

Teijin. International body armor standards.

VPAM 2006 General basis for ballistic material, construction and product testing. (2006).

VPAM BSW 2006 Test guideline for ballistic protective vests. (2009).

CEN prEN ISO 14876-2 International Standard. (2002).

IS 17051 Indian standard: Textiles - bullet resistant jackets - performance requirements. (2008).

Ojoc GG, Pirvu C, Sandu S, Deleanu L (2020) Standardization in testing ballistic protection systems. in: IOP Conference Series: Materials Science and Engineering vol. 724 012049

Nguyen T-TN, Meek G, Breeze J, Masouros SD (2020) Gelatine backing affects the performance of single-layer ballistic-resistant materials against blast fragments. Front Bioeng Biotechnol 8:744

Hanlon E, Gillich P (2012) Origin of the 44-mm behind-armor blunt trauma standard. Mil Med 177:333

Genov BG (2012) Why ballistic testing methods of body armor do not give us accurate information. in: 15th International Conference on Applied Mechanics and Mechanical Engineering

Nguyen T-TN et al (2018) Fragment penetrating injury to long bones. In: Proceedings of Personal Armour Systems Symposium 2018 vol. 1979, pp 312–321

Breeze J et al (2013) Experimental penetration of fragment simulating projectiles into porcine tissues compared with simulants. J Forensic Legal Med 20:296–299

Shepherd CJ, Appleby-Thomas GJ, Hazell PJ, Allsop DF (2009) The dynamic behaviour of ballistic gelatin. AIP Conf Proc 1195:1399–1402

Appleby-Thomas GJ et al (2011) On the dynamic behavior of three readily available soft tissue simulants. J Appl Phys 109

Breeze J, James GR, Hepper AE (2013) Perforation of fragment simulating projectiles into goat skin and muscle. J R Army Med Corps 159:84–89

Kieser DC, Riddell R, Kieser JA, Theis J-C, Swain MV (2014) Bone micro-fracture observations from direct impact of slow velocity projectiles. J Arch Mil Med 2:1–6

Jennings RM, Malbon C, Brock F, Harrisson S, Carr DJ (2018) A preliminary study into injuries due to non-perforating ballistic impacts into soft body armour over the spine. Injury 49:1251–1257

Breeze J et al (2013) Characterisation of explosive fragments injuring the neck. Br J Oral Maxillofac Surg 51:e263–e266

Singh AK et al (2014) Radiologic features of injuries from the Boston marathon bombing at three hospitals. Am J Roentgenol 203:235–239

Yazgan C, Aksu NM (2016) Imaging features of blast injuries: experience from 2015 Ankara bombing in Turkey. Br Inst Radiol 89

Singh AK, Sodickson A, Abujudeh H (2016) Imaging of abdominal and pelvic injuries from the Boston Marathon bombing. Emerg Radiol 23:35–39

Eikermann M et al (2014) Case 11-2014: A man with traumatic injuries after a bomb explosion at the Boston marathon. N Engl J Med 370:1441–1451

Gotts PL, Helliker M (2020) The development of the chisel nosed fragment simulating projectiles for personal armour testing. in The Personal Armour Systems Symposium 2020 97–105

Breeze J, Steel CJ, Streit A, Sarber KM (2021) Characterisation of retained energised fragments from explosive devices in military personnel. BMJ Mil Health 0:1–4

Nguyen T-TN, Breeze J, Masouros SD (2021) Penetration of energised metal fragments to thoracic tissues. J Biomech Eng 144:071002

Tsukada H, Nguyen T-TN, Breeze J, Masouros SD (2021) Fragment penetration into the heart: initial findings. in International Research Council on the Biomechanics of Injury Conference, IRCOBI 2021

Breeze J, Clasper JC (2013) Determining the velocity required for skin perforation by fragment simulating projectiles: a systematic review. J R Army Med Corps 159:265–270

Breeze J, Lewis EA, Mahoney PF (2020) Minimum depths to essential structures in a UK military population using computed tomography: application to stab-resistant body armour. Int J Legal Med 2256. https://doi.org/10.1007/s00414-020-02256-6

Seyahi N, Kahveci A, Altiparmak MR, Serdengecti K, Erek E (2005) Ultrasound imaging findings of femoral veins in patients with renal failure and its impact on vascular access. Nephrol Dial Transplant 20:1864–1867

Breeze J, Helliker M, Carr DJ (2013) An integrated approach towards future ballistic neck protection materials selection. Proc Inst Mech Eng Part H J Eng Med 227:581–587

Nguyen T-TN et al (2020) Mapping the risk of fracture of the tibia from penetrating fragments. Front Bioeng Biotechnol 8:1086

Stevenson T, Carr DJ, Stapley SA (2019) The effect of military clothing on gunshot wounding patterns in gelatine. Int J Legal Med 133:1121–1131

Acknowledgements

This work was conducted in the Royal British Legion Centre for Blast Injury Studies at Imperial College London. We would like to acknowledge the financial support of the Defence Medical Services and the Royal British Legion. We wish to thank DSM and Tejin for the provision of Dyneema® and Twaron® samples, respectively.

Author information

Authors and Affiliations

Contributions

SM and JB conceived the project idea which was developed into an experimental model by T-TNN. All the tests, including preparation of samples and data acquisition, were carried out by T-TNN and HT. The data analysis was conducted by T-TNN. T-TNN drafted the manuscript and all authors reviewed, edited, and approved of the final version.

Corresponding author

Ethics declarations

Competing Interests

The investigators do not have any conflict of interest related to this project.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Fig. A

The depth of penetration in gelatine backing against the FSP impact velocity of different FSPs for tests with Twaron® weave (left, solid lines) and Dyneema® knit (right, solid lines). Filled markers denote impacts without perforation of fabric; unfilled markers denote impacts with fabric perforation. Dotted lines show the trends from the same FSPs with no ballistic fabric, i.e. gelatine only. Black lines show the depth from the skin surface of various human tissues and organs [47,48,49,50]. (PNG 430 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nguyen, TT.N., Tsukada, H., Breeze, J. et al. The Critical Role of a Backing Material in Assessing the Performance of Soft Ballistic Protection. Hum Factors Mech Eng Def Saf 6, 13 (2022). https://doi.org/10.1007/s41314-022-00052-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41314-022-00052-1