Abstract

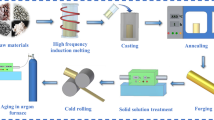

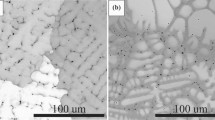

Grain refinement studies were attempted on the Mg–4Zn–2Sr alloy by varying the Zr content (0.5, 1.0, 1.5, 2.0 wt%). Metallurgical and mechanical characterisations were done on the casted samples, and the findings were analysed. In the Mg–4Zn–2Sr alloy, α-Mg and a new ternary compound Mg11Zn2Zr were formed in the triple point junctions of the grain boundary. With the addition of Zr, drastic grain refinement was observed from 110 to 25 µm. The optimum grain refinement was obtained with 1.5%Zr addition; beyond that, it decreased. Tiny α-Zr agglomerates between the α-Mg and ternary phases as a cluster pattern when Zr addition increased. The maximum hardness of 72 Hv was recorded for Mg–4Zn–2Sr–2Zr alloy due to the hard particle strengthening and grain refinement. Due to the high grain refinement, the maximum tensile properties were observed for the Mg–4Zn–2Sr–1.5Zr alloy.

Similar content being viewed by others

Availability of Data and Materials

All the original data are available with the corresponding author.

Code Availability

Not applicable.

References

D. Eliezer, E. Aghion, F.H. Froes, Magnesium science technology and applications. Adv. Perform. Mater. 5(201–212), 201 (1998)

B.L. Mordike, T. Ebert, Magnesium properties-applications-potential. Mater. Sci. Eng. A 302, 37–45 (2001)

Y.X. Chen, D.X. Li, Microstructure and orientation relationships of Mg alloy matrix composite reinforced with SiC whiskers and B4C particles. Mater. Lett. 61, 4884–4886 (2007)

K. Cho, T. Sano, K. Doherty, C. Yen, G. Gazonas, J. Montgomery, P. Moy, Magnesium Technology and manufacturing for ultra lightweight armored ground vehicles. Proceedings Army Science Conference, Accession Number: ADA499411

M. Niinomi, Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 33, 477–486 (2002). https://doi.org/10.1007/s11661-002-0109-2

R. Radha, D. Sreekanth, Insight of magnesium alloys and composites for orthopedic implant applications-a review. J. Magnes. Alloy 5, 286–312 (2017)

S. Budruk Abhijeet, R. Balasubramaniam, M. Gupta, Corrosion behaviour of Mg–Cu and Mg–Mo composites in 3.5% NaCl. Corros. Sci. 50, 2423–2428 (2008)

D. Li, Qi. Yuan, Yu. Kun, T. Xiao, L. Liu, Y. Dai, L. Xiong, B. Zhang, A. Li, Mg-Zn-Mn alloy extract induces the angiogenesis of human umbilical vein endothelial cells via FGF/FGFR signaling pathway. Biochem. Biophys. Res. Commun. 514, 618–624 (2019)

T. Bhattacharjee, C.L. Mendis, T.T. Sasaki, T. Ohkubo, K. Hono, Effect of Zr addition on the precipitation in Mg-Zn-based alloy. Scripta Mater. 67, 967–970 (2012)

J. Buha, Reduced temperature (22–100 °C) ageing of an Mg–Zn alloy. Mater. Sci. Eng. A 491, 70–79 (2008)

X. Gao, J.F. Nie, Characterization of strengthening precipitate phases in a Mg-Zn alloy. Scripta Mater. 56, 645–648 (2007)

F. Czerwinski, Magnesium and its alloys, in Magnesium injection molding. ed. by F. Czerwinski (Springer, Boston, 2008). https://doi.org/10.1007/978-0-387-72528-4_1

S.F. Hassan, M. Gupta, Development of a novel magnesium/nickel composite with improved mechanical properties. J. Alloys Compd. 335, 10–15 (2002)

S.F. Hassan, M. Gupta, Development of a novel magnesium-copper based composite with improved mechanical properties. Mater. Res. Bull. 37, 377–389 (2002)

D.H. Kang, S.S. Park, Y.S. Oh, N.J. Kim, Effect of nano-particles on the creep resistance of Mg–Sn based alloys. Mater. Sci. Eng. A 449–451, 318 (2007)

S. Parsana, N. Radadia, M. Sheth, N. Sheth, N. Vimal Savsani, E. Prasad, T. Ramprabhu, Machining parameter optimization for EDM machining of Mg–RE–Zn–Zr alloy using multi-objective Passing Vehicle Search algorithm. Arch. Civ. Mech. Eng. 18, 799–817 (2018)

J.M. Tainio, D.A. Avila Salazar, A. Nommeots-Nomm, C. Roiland, B. Bureau, D.R. Neuville, D.S. Brauer, J. Massera, Structure and in vitro dissolution of Mg and Sr containing borosilicate bioactive glasses for bone tissue engineering. J. Non-Cryst. Solids 533, 119893 (2020)

A. Pola, M. Tocci, F.E. Goodwin, Review of microstructures and properties of zinc alloys. Metals 10, 253 (2020). https://doi.org/10.3390/met10020253

Y. Mingbo, P. Fusheng, C. Renju, S. Jia, Comparison about effects of Sb, Sn and Sr on as-cast microstructure and mechanical properties of AZ61–0.7Si magnesium alloy. Mater. Sci. Eng. A 489, 413–418 (2009)

X. Song, P. Bayati, M. Gupta, M. Elahinia, M. Haghshenas, Fracture of magnesium matrix nanocomposites: a review. Int. J. Lightweight Mater. Manuf. 4, 67–98 (2021)

Y. Mingbo, S. Jia, Modification and refinement mechanism of Mg2Si phase in Sr containing AZ61-0.7Si magnesium alloy. China Foundry 6, 37–42 (2009)

C.J. Boehlert, K. Knittel, The microstructure, tensile properties, and creep behavior of Mg–Zn alloys containing 0–4.4 wt% Zn. Mater. Sci. Eng. A 417, 315–321 (2006)

H.S. Brar, J. Wong, M.V. Manuel, Investigation of the mechanical and degradation properties of Mg–Sr and Mg–Zn–Sr alloys for use as potential biodegradable implant materials. J. Mech. Behav. Biomed. Mater. 7, 87–95 (2012)

E. Koç, M. Bobby Kannan, M. Ünal, E. Candan, Influence of zinc on the microstructure, mechanical properties and in vitro corrosion behavior of magnesium-zinc binary alloys. J. Alloys Compd. 648, 291–296 (2015)

F. Meng, J.M. Rosalie, A. Singh, H. Somekawa, K. Tsuchiya, Ultrafine grain formation in Mg–Zn alloy by in situ precipitation during high-pressure torsion. Scr. Mater. 78–79, 57–60 (2014)

J. Yuan, K. Zhang, X. Zhang, X. Li, T. Li, Y. Li, M. Ma, G. Shi, Thermal characteristics of Mg–Zn–Mn alloys with high specific strength and high thermal conductivity. J. Alloys Compd. 578, 32 (2013)

D. Zhang, D. Zhang, Bu. Fanqiang, X. Li, B. Li, T. Yan, K. Guan, Q. Yang, X. Liu, J. Meng, Excellent ductility and strong work hardening effect of as-cast Mg-Zn-Zr-Yb alloy at room temperature. J. Alloys Compd. 728, 404 (2017)

S.K. Ghosh, P. Saha, Crack and wear behavior of SiC particulate reinforced aluminium based metal matrix composite fabricated by direct metal laser sintering process. Mater. Design 32, 139–145 (2011)

R. Cerny, G. Renaudin, The intermetallic compound Mg21Zn25. Acta Cryst. C C58, I154–I155 (2002)

S. Cai, T. Lei, N. Li, F. Feng, Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg–Zn alloys. Mater. Sci. Eng. C 32, 2570–2577 (2012)

X. Ye, M. Chen, M. Yang, J. Wei, D. Liu, In vitro corrosion resistance and cytocompatibility of nano-hydroxyapatite reinforced Mg–Zn–Zr composites. J. Mater. Sci. Mater. Med. 21, 1321–1328 (2010)

H. Li, Q. Peng, X. Li, K. Li, Z. Han, D. Fang, Microstructures, mechanical and cytocompatibility of degradable Mg–Zn based orthopedic biomaterials. Mater. Des. 58, 43–51 (2014)

D.H. St. John, M.A. Easton, M. Qian, J.A. Taylor, Grain refinement of magnesium alloys: a review of recent research theoretical developments, and their application. Metall. Mater. Trans. A 44, 2935–2949 (2013)

F. Pan, M. Yang, Y. Ma, Development of new types of magnesium alloys containing Sr or RE elements. Mater. Sci. Forum 561–565, 191–197 (2007)

T. Ding, H.-g Yan, J.-H. Chen, W.-J. Xia, Bin SU and Zong-lin YU, Dynamic recrystallization and mechanical properties of high-strain-rate hot rolled Mg−5Zn alloys with addition of Ca and Sr. Trans. Nonferrous Met. Soc. China 29, 1631–1640 (2019)

E. Baril, P. Labelle, M.O. Pekguleryuz, Elevated temperature Mg-Al-Sr: creep resistance mechanical properties, and microstructure. J. Miner. Met. Mater. Soc. 55, 34–39 (2003)

X. He, J. Chen, H. Yan, S. Bin, G. Zhang, C. Miao, Effects of minor Sr addition on microstructure and mechanical properties of the as-cast Mg–4.5Zn–4.5Sn–2Al-based alloy system. J. Alloys Compd. 579, 39–44 (2013)

M. Cheng, J. Chen, H. Yan, S. Bin, Y. Zhaohui, W. Xia, X. Gong, Effects of minor Sr addition on microstructure, mechanical and bio-corrosion properties of the Mg-5Zn based alloy system. J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.08.164

A.F. Cipriano, A. Sallee, M. Tayoba, M.C. Cortez, A.L. Alcaraz, R.G. Guan, Z.Y. Zhao, H. Liu, Cytocompatibility and early inflammatory response of human endothelial cells in direct culture with Mg–Zn–Sr alloys. Acta Biomater. 48, 499–520 (2017)

Y. Li, C. Wen, D. Mushahary, R. Sravanthi, N. Harishankar, G. Pande, P. Hodgson, Mg–Zr–Sr alloys as biodegradable implant materials. Acta Biomater. 8, 3177–3188 (2012)

F. Witte, J. Fischer, J. Nellesen, H.-A. Crostack, V. Kaese, A. Pisch, F. Beckmann, H. Windhagen, In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials 27, 1013–1018 (2006)

G.K. Sigworth, T.A. Kuhn, Grain refinement of aluminum casting alloys. Int. J. Metalcast. 1, 31–40 (2007)

Y.C. Lee, A.K. Dahle, D.H. StJohn, The role of solute in grain refinement of magnesium. Metall. Mater. Trans. A 31, 2895–2906 (2000)

H. Westngen, T.K. Aune, Magnes. Technol. (2006). https://doi.org/10.1007/3-540-30812-1_5

K.P. Rao, Y.V.R.K. Prasad, C. Dharmendra, K. Suresh, N. Hort, H. Dieringa, Review on hot working behavior and strength of calcium-containing magnesium alloys. Adv. Eng. Mater. 20, 1701102 (2018)

H. Zhou, R. Hou, J. Yang, Y. Sheng, Z. Li, L. Chen, W. Li, X. Wang, Influence of Zirconium (Zr) on the microstructure, mechanical properties and corrosion behavior of biodegradable zinc-magnesium alloys. J. Alloy. Compd. 840, 155792 (2020)

Li. Jin, G. Li, J. Dong, W. Ding, Microstructure and mechanical properties of extruded Mg-Zn-Ce-Zr alloy rods. Mater. Sci. Forum 706–709, 1199–1204 (2012)

H. Okamoto, Supplemental literature review of binary phase diagrams: Cs-In, Cs-K, Cs-Rb, Eu-In, Ho-Mn, K-Rb, Li-Mg, Mg-Nd, Mg-Zn, Mn-Sm, O-Sb, and Si-Sr. J. Phase Equilib. Diffus. 34, 251–263 (2013)

S. Bai, F. Wang, Z. Wang et al., Effect of Ca Content on hot tearing susceptibility of Mg-4Zn-xCa-03Zr (x = 0.5, 1, 1.5, 2) Alloys. Inter. Metalcast. 15, 1298–1308 (2021). https://doi.org/10.1007/s40962-020-00553-9

M. Nemec, V. Gärtnerova, M. Klementova, A. Jager, Analysis of intermetallic particles in Mg–12 wt% Zn binary alloy using transmission electron microscopy. Mater. Charact. 106, 428–436 (2015)

Z. Li, M. Chen, W. Li, H. Zheng, Y. Chen, D. Liu, F. Jin, J Alloys Compd 702, 290 (2017)

G. Zhu, Z. Wang, W. Qiu et al., Effect of yttrium on hot tearing susceptibility of Mg-6Zn-1Cu-0.6Zr alloys. Int. J. Metalcast. 14(1), 179–190 (2020). https://doi.org/10.1007/s40962-019-00352-x

M. Celikin, M. Pekguleryuz, Creep resistant Mg–Mn based alloys for automotive powertrain applications. Miner Met. Mater. Ser. (2018). https://doi.org/10.1007/978-3-319-72332-7_51

C. Wang, M. Sun, F. Zheng, L. Peng, W. Ding, The synergistic effect of trace Sr and Zr on the microstructure and properties of a biodegradable Mg-Zn-Zr-Sr alloy. J Magnes Alloy. 702, 290–302 (2014)

J. Wang, Y.-N. Zhang, P. Hudon, I.-H. Jung, P. Chartrand, M. Medraj, Experimental study of the crystal structure of the Mg15–xZnxSr3 ternary solid solution in the Mg–Zn–Sr system at 300 °C. Mater. Des. 86, 305 (2015)

J. Bian, B. Yu, L. Jiang et al., Research on the effect of Sr and Zr on microstructure and properties of Mg–4Zn Alloy. Int. J. Metalcast. 15, 1483–1498 (2021). https://doi.org/10.1007/s40962-021-00576-w

T.V. Atamanenko, D.G. Eskin, L. Zhang, L. Katgerman, Criteria of grain refinement induced by ultrasonic melt treatment of aluminum alloys containing Zr and Ti. Metall. Mater. Trans. A 41, 2056 (2010)

H. Okamoto, Magnesium–zirconium (Mg-Zr). J. Phase Equilib. Diffus. 28, 305–306 (2007). https://doi.org/10.1007/s11669-007-9060-7

D.H. Stohn, M. Qian, M.A. Easton, P. Cao, Z. Hildebrand, Grain refinement of magnesium alloys. Metall. Mater. Trans. A 36, 1669 (2005)

D.B. Prabhu, C. Muthuraja, J. Nampoothiri, P. Gopalakrishnan, K.R. Ravi, Solidification analysis of Mg–4Zn–xSr system to study phase transformations in Mg-rich corner. Trans. Indian Inst. Met. 71, 2801–2806 (2018)

P. Cao, M. Qian, D.H. St. John, M.T. Frost, Uptake of iron and its effect on grain refinement of pure magnesium by zirconium. Mater. Sci. Technol. 20, 585 (2004)

Y. Ding, Y. Li, J. Lin, C. Wen, Effects of zirconium and strontium on the biocorrosion of Mg–Zr–Sr alloys for biodegradable implant applications. J. Mater. Chem. B 3, 3714 (2015)

J. Yan, Y. Sun, F. Xue, S. Xue, W. Tao, Microstructure and mechanical properties in cast magnesium–neodymium binary alloys. Mater. Sci. Eng. A 476, 366–371 (2008)

W. Li, S. Guan, J. Chen, Hu. Junhua, S. Chen, L. Wang, S. Zhu, Preparation and in vitro degradation of the composite coating with high adhesion strength on biodegradable Mg–Zn–Ca alloy. Mater. Charact. 62, 1158–1165 (2011)

Yu. Fu, W. Han, L. Xiaoteng, H. Hai, Effect of calcium addition on microstructure, casting fluidity and mechanical properties of Mg-Zn-Ce-Zr magnesium alloy. J. Rare Earths 35, 503–509 (2017)

Acknowledgement

The authors wish to thank for the casting and characterisation facilities provided by MatRICS—Materials Research and Innovation Centric Solutions, Vellimalai, Kanyakumari District, India, Tel: +91 91766 06699; web: www.matricstech.com.

Funding

No funds, grants or other support were received.

Author information

Authors and Affiliations

Contributions

JG, KKAK contributed to the design and implementation of the research and writing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Publishers can publish images and results there are no restrictions.

Human or Animals Rights

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Godwin, J., Ajith Kumar, K.K. & Muthukumar, S. Microstructure and Mechanical Behaviour of Mg–4Zn–2Sr Alloy with Varying Zirconium Addition. Inter Metalcast 17, 3143–3154 (2023). https://doi.org/10.1007/s40962-023-00964-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-00964-4