Abstract

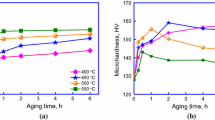

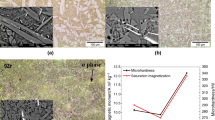

Cu-2Ti-0.3Zr and Cu-2Ti-0.3Zr-0.2La alloys were prepared by vacuum melting, and their mechanical properties and conductivity were measured after aging treatment. Both alloys were aged at 450 °C for 30 min to obtain optimum properties, and the microhardness of the Cu-Ti-Zr-La alloy increased by 8.5% and the strength by 5% compared to the Cu-Ti-Zr alloy. Characterization of the alloys by EBSD revealed that the addition of La inhibits grain growth, refines the grains and enhances the texture. The Cu4Ti phase precipitated during the Cu-Ti-Zr alloy’s aging process, and the Cu5Zr phase precipitated after La was added. It was found by analyzing the strengthening mechanisms of the Cu-Ti-Zr-La alloy that precipitation strengthening significantly contributes to the alloy strength.

Similar content being viewed by others

References

Q. Lei, Z. Xiao, W. Hu, B. Derby, and Z. Li, Phase Transformation Behaviors and Properties of a High Strength Cu-Ni-Si Alloy, Mater. Sci. Eng. A, 2017, 697, p 37–47. https://doi.org/10.1016/j.msea.2017.05.001

K.X. Song, Y.F. Geng, Y.J. Ban, Y. Zhang, Z. Li, X.J. Mi, J. Cao, Y.J. Zhou, and X.B. Zhang, Effect of Strain Rates on Dynamic Deformation Behavior of Cu-20Ag Alloy, J. Mater. Res. Technol., 2021, 79, p 75–87. https://doi.org/10.1016/j.jmst.2020.11.043

Y. Zhang, H.L. Sun, A.A. Volinsky, B.H. Tian, K.X. Song, B.J. Wang, and Y. Liu, Hot Workability and Constitutive Model of the Cu-Zr-Nd Alloy, Vacuum, 2017, 146, p 35–43. https://doi.org/10.1016/j.vacuum.2017.09.017

R. Mishnev, I. Shakhova, A. Belyakov, and R. Kaibyshev, Deformation Microstructures, Strengthening Mechanisms, and Electrical Conductivity in a Cu-Cr-Zr Alloy, Mater. Sci. Eng. A, 2015, 629, p 29–40. https://doi.org/10.1016/j.msea.2015.01.065

S.L. Tang, M. Zhou, X. Li, Y. Zhang, D.Y. Xu, Z.Y. Zhang, B.H. Tian, Y.L. Jia, Y. Liu, A.A. Volinsky, and E.S. Marchenko, Microstructure and Hot Deformation Behavior of the Cu-1Ni-0.9Sn-0.5Ti-0.3Cr Alloy, Mater. Today Commun., 2022, 31, p 103771. https://doi.org/10.1016/j.mtcomm.2022.103771

Y.F. Geng, X. Li, Y. Zhang, Y.L. Jia, H.L. Zhou, B.H. Tian, Y. Liu, A.A. Volinsky, X.H. Zhang, K.X. Song, P. Liu, and X.H. Chen, Microstructure Evolution of Cu-1.0Co-0.65Si-0.1Ti Alloy During Hot Deformation, Vacuum, 2020, 177, p 109376. https://doi.org/10.1016/j.vacuum.2020.109376

A. Meng, J.F. Nie, K. Wei, H.J. Kang, Z.J. Liu, and Y.H. Zhao, Optimization of Strength, Ductility and Electrical Conductivity of a Cu-Cr-Zr Alloy by Cold Rolling and Aging Treatment, Vacuum, 2019, 167, p 329–335. https://doi.org/10.1016/j.vacuum.2019.06.027

W. Wang, H.J. Kang, Z.N. Chen, Z.J. Chen, C.L. Zou, R.G. Li, G.M. Yin, and T.M. Wang, Effects of Cr and Zr Additions on Microstructure and Properties of Cu-Ni-Si Alloys, Mater. Sci. Eng. A, 2016, 673, p 378–390. https://doi.org/10.1016/j.msea.2016.07.021

J. Chalon, J.D. Guérin, L. Dubar, A. Dubois, and E.S. Puchi-Cabrera, Characterization of the Hot-Working Behavior of a Cu-Ni-Si Alloy, Mater. Sci. Eng. A, 2016, 667, p 77–86. https://doi.org/10.1016/j.msea.2016.04.061

Y.C. Tang, Y.L. Kang, L.J. Yue, and X.L. Jiao, Mechanical Properties Optimization of a Cu-Be-Co-Ni Alloy by Precipitation Design, J. Alloys Compd., 2017, 695, p 613–625. https://doi.org/10.1016/j.jallcom.2016.11.014

Y.C. Tang, Y.L. Kang, L.J. Yue, and X.L. Jiao, The Effect of Aging Process on the Microstructure and Mechanical Properties of a Cu-Be-Co-Ni Alloy, Mater. Des., 2015, 85, p 332–341. https://doi.org/10.1016/j.matdes.2015.06.157

Y.C. Tang, G.M. Zhu, Y.L. Kang, L.J. Yue, and X.L. Jiao, Effect of Microstructure on the Fatigue Crack Growth Behavior of Cu-Be-Co-Ni Alloy, J. Alloys Compd., 2016, 663, p 784–795. https://doi.org/10.1016/j.jallcom.2015.12.017

S. Nagarjuna, U.C. Babu, and P. Ghosal, Effect of Cryo-Rolling on Age Hardening of Cu-1.5 Ti Alloy, Mater. Sci. Eng. A, 2008, 491, p 331–337. https://doi.org/10.1016/j.msea.2008.02.014

F.L. Wang, Y.P. Li, K. Wakoh, Y. Koizumi, and A. Chiba, Cu-Ti-C Alloy with High Strength and High Electrical Conductivity Prepared by Two-Step Ball-Milling Processes, Mater. Des., 2014, 61, p 70–74. https://doi.org/10.1016/j.matdes.2014.04.034

C. Li, X.H. Wang, B. Li, J. Shi, Y.F. Liu, and P. Xiao, Effect of Cold Rolling and Aging Treatment on the Microstructure and Properties of Cu-3Ti-2Mg Alloy, J. Alloys Compd., 2020, 818, p 152915. https://doi.org/10.1016/j.jallcom.2019.152915

X. Wang, Z. Xiao, W.T. Qiu, Z. Li, and F. Liu, The Evolution of Microstructure and Properties of a Cu-Ti-Cr-Mg-Si Alloy with High Strength During the Multi-Stage Thermomechanical Treatment, Mater. Sci. Eng. A, 2021, 803, p 140510. https://doi.org/10.1016/j.msea.2020.140510

L. Huang, L.J. Peng, X.J. Mi, G. Zhao, G.J. Huang, H.F. Xie, and W.J. Zhang, Relationship Between Microstructure and Properties of High-Strength Cu-Ti-Cr Alloys During Aging, J. Alloys Compd., 2023, 942, p 168865. https://doi.org/10.1016/j.jallcom.2023.168865

W. Huan, X.Y. Dai, P.J. Han, C.Z. Zhou, Y.H. Wei, and L.F. Hou, Age Hardening Studies of a Cu-4Ti-Cr-Fe Alloy, Mater. Sci. Technol., 2019, 35, p 1848–1855. https://doi.org/10.1080/02670836.2019.1651474

L. Rong, Z. Xiao, Z. Li, X.P. Meng, and X. Wang, Work Hardening Behavior and Microstructure Evolution of a Cu-Ti-Cr-Mg Alloy During Room Temperature and Cryogenic Rolling, Materials, 2023, 16, p 424. https://doi.org/10.3390/ma16010424

X. Wang, Z. Li, Z. Xiao, and W.T. Qiu, Microstructure Evolution and Hot Deformation Behavior of Cu-3Ti-0.1Zr Alloy with Ultra-High Strength, Trans. Nonferrous Met. Soc. China, 2020, 30, p 2737–2748. https://doi.org/10.1016/S1003-6326(20)65416-4

H. Doi, S. Suzuki, K. Mimura, M. Isshiki, and Y. Waseda, Electrical Conductivity and Hardness of Quenched and Aged High-Purity Cu-Ti-Al Alloys, J. Jpn. I. Met., 2004, 68, p 78–81. https://doi.org/10.2320/jinstmet.68.78

W.J. Liu, J. Li, X. Chen, M.H. Ji, X.P. Xiao, H. Wang, and B. Yang, Effect of Vanadium on the Microstructure and Kinetics of Discontinuous Precipitation in Cu-3.2Ti-0.2Fe Alloy, J. Mater. Res. Technol., 2021, 14, p 121–136. https://doi.org/10.1016/j.jmrt.2021.06.045

I.S. Batra, A. Laik, G.B. Kale, G.K. Dey, and U.D. Kulkarni, Microstructure and Properties of a Cu-Ti-Co Alloy, Mater. Sci. Eng. A, 2005, 402, p 118–125. https://doi.org/10.1016/j.msea.2005.04.015

S.F. Fang, Prediction of the Hardness of Cu-Ti-Co Alloy Using Machine Learning Techniques, Key Eng. Mater., 2018, 777, p 372–376. https://doi.org/10.4028/www.scientific.net/KEM.777.372

S. Nagarjuna, K.K. Sharma, I. Sudhakar, and D.S. Sarma, Age Hardening Studies in a Cu-4.5 Ti-0.5 Co Alloy, Mater. Sci. Eng. A, 2001, 313, p 251–260. https://doi.org/10.1016/S0921-5093(00)01834-7

R. Markandeya, S. Nagarjuna, and D.S. Sarma, Effect of Prior Cold Work on Age Hardening of Cu-4Ti-1Cr Alloy, Mater. Sci. Eng. A, 2005, 404(1–2), p 305–313. https://doi.org/10.1016/j.msea.2005.05.072

R. Markandeya, S. Nagarjuna, and D.S. Sarma, Effect of Prior Cold Work on Age Hardening of Cu-3Ti-1Cr Alloy, Mater. Char., 2006, 57(4–5), p 348–357. https://doi.org/10.1016/j.matchar.2006.02.017

R. Markandeya, S. Nagarjuna, and D.S. Sarma, Precipitation Hardening of Cu-Ti-Cr Alloys, Mater. Sci. Eng. A, 2004, 371(1–2), p 291–305. https://doi.org/10.1016/j.msea.2003.12.002

T.J. Konno, R. Nishio, S. Semboshi, T. Ohsuna, and E. Okunishi, Aging Behavior of Cu-Ti-Al Alloy Observed by Transmission Electron Microscopy, J. Mater. Sci., 2008, 43, p 3761–3768. https://doi.org/10.1007/s10853-007-2233-2

X.H. Wang, C.Y. Chen, T.T. Guo, J.T. Zou, and X.H. Yang, Microstructure and Properties of Ternary Cu-Ti-Sn Alloy, J. Mater. Eng. Perform., 2015, 24, p 2738–2743. https://doi.org/10.1007/s11665-015-1483-4

X.M. Cao, H.Q. Li, C.J. Xiang, C.X. Yang, and F.A. Guo, Effect of Zr on heat-resistance of Cu-Ti alloy, Hot Working Technol., 2008, 14, p 16–18. https://doi.org/10.14158/j.cnki.1001-3814.2008.14.005

R. Markandeya, S. Nagarjuna, and D.S. Sarma, Influence of Prior Cold Work on Age Hardening of Cu-Ti-Zr Alloys, Mater. Sci. Technol., 2005, 21(10), p 1171–1180. https://doi.org/10.1179/174328405X58922

S.L. Tang, M. Zhou, Y. Zhang, D.Y. Xu, Z.Y. Zhang, X.H. Zheng, D. Li, X. Li, B.H. Tian, Y.L. Jia, Y. Liu, A.A. Volinsky, and E.S. Marchenko, Improved Microstructure, Mechanical Properties and Electrical Conductivity of the Cu-Ni-Sn-Ti-Cr Alloy Due to Ce Micro-Addition, Mater. Sci. Eng. A, 2023, 871, p 144910. https://doi.org/10.1016/j.msea.2023.144910

Z.Y. Zhang, M. Zhou, Y. Zhang, S.L. Tang, D.Y. Xu, B.H. Tian, X. Li, Y.L. Jia, Y. Liu, and A.A. Volinsky, Ce Effects on Deformation-Induced Microstructure Evolution in Cu-Ti-Ni-Mg Alloys, Adv. Eng. Mater., 2023, 25, p 2201913. https://doi.org/10.1002/adem.202201913

H. Li, P. Chen, Z.X. Wang, F. Zhu, R.G. Song, and Z.Q. Zheng, Tensile Properties, Microstructures and Fracture Behaviors of an Al-Zn-Mg-Cu Alloy During Ageing After Solution Treating and Cold-Rolling, Mater. Sci. Eng. A, 2019, 742, p 798–812. https://doi.org/10.1016/j.msea.2018.03.098

Y.K. Xie, Y.L. Deng, Y. Wang, and X.B. Guo, Effect of Asymmetric Rolling and Subsequent Ageing on the Microstructure, Texture and Mechanical Properties of the Al-Cu-Li Alloy, J. Alloys Compd., 2020, 836, p 155445. https://doi.org/10.1016/j.jallcom.2020.155445

S.L. Fu, P. Liu, X.H. Chen, H.L. Zhou, F.C. Ma, W. Li, and K. Zhang, Effect of Aging Process on the Microstructure and Properties of Cu-Cr-Ti Alloy, Mater. Sci. Eng. A, 2021, 802, p 140598. https://doi.org/10.1016/j.msea.2020.140598

D.R. Curran, L. Seaman, and D.A. Shockey, Dynamic Failure of Solids, Phys. Rep., 1987, 147(5–6), p 253–388. https://doi.org/10.1016/0370-1573(87)90049-4

C. Li, H. Tan, W.M. Wu, S. Zhao, and H.B. Zhang, Effect of Electropulsing Treatment on Microstructure and Tensile Fracture Behavior of Nanocrystalline Ni Foil, Mater. Sci. Eng. A, 2016, 657, p 347–352. https://doi.org/10.1016/j.msea.2016.01.075

J.W. Li, J. Xu, B. Guo, D.B. Shan, and T.G. Langdon, Shear Fracture Mechanism in Micro-Tension of an Ultrafine-Grained Pure Copper Using Synchrotron Radiation X-ray Tomography, Scr. Mater., 2017, 132, p 25–29. https://doi.org/10.1016/j.scriptamat.2017.01.021

D. Jorge-Badiola, A. Iza-Mendia, and I. Gutiérrez, Study by EBSD of the Development of the Substructure in a Hot Deformed 304 Stainless Steel, Mater. Sci. Eng. A, 2005, 394(1–2), p 445–454. https://doi.org/10.1016/j.msea.2004.11.049

C. Haase, and L.A. Barrales-Mora, Influence of Deformation and Annealing Twinning on the Microstructure and Texture Evolution of Face-Centered Cubic High Entropy Alloys, Acta Mater., 2018, 150, p 88–103. https://doi.org/10.1016/j.actamat.2018.02.048

Y.F. Geng, Y.J. Ban, X. Li, Y. Zhang, Y.L. Jia, B.H. Tian, M. Zhou, Y. Liu, A.A. Volinsky, K.X. Song, and S.L. Tang, Excellent Mechanical Properties and High Electrical Conductivity of Cu-Co-Si-Ti Alloy Due to Multiple Strengthening, Mater. Sci. Eng. A, 2021, 821, p 141639. https://doi.org/10.1016/j.msea.2021.141639

H.M. Wen, T.D. Topping, D. Isheim, D.N. Seidman, and E.J. Lavernia, Strengthening Mechanisms in a High-Strength Bulk Nanostructured Cu-Zn-Al Alloy Processed via Cryomilling and Spark Plasma Sintering, Acta Mater., 2013, 61(8), p 2769–2782. https://doi.org/10.1016/j.actamat.2012.09.036

X.W. Zuo, K. Han, C.C. Zhao, R.M. Niu, and E.G. Wang, Microstructure and Properties of Nanostructured Cu-28wt%Ag Microcomposite Deformed After Solidifying Under a High Magnetic Field, Mater. Sci. Eng. A, 2014, 619, p 319–327. https://doi.org/10.1016/j.msea.2014.09.070

J. Freudenberger, J. Lyubimova, A. Gaganov, H. Witte, A.L. Hickman, H. Jones, and M. Nganbe, Non-destructive Pulsed Field Cu Ag-Solenoids, Mater. Sci. Eng. A, 2010, 527(7–8), p 2004–2013. https://doi.org/10.1016/j.msea.2009.11.038

S.C. Wang, Z. Zhu, and M.J. Starink, Estimation of Dislocation Densities in Cold Rolled Al-Mg-Cu-Mn Alloys by Combination of Yield Strength Data, EBSD and Strength Models, J. Microsc., 2005, 217, p 174–178. https://doi.org/10.1111/j.1365-2818.2005.01449.x

Y. Liu, Z. Li, Y.X. Jiang, Y. Zhang, Z.Y. Zhou, and Q. Lei, The Microstructure Evolution and Properties of a Cu-Cr-Ag Alloy During Thermal-Mechanical Treatment, J. Mater. Res., 2017, 32(7), p 1324–1332. https://doi.org/10.1557/jmr.2017.17

Y.K. Wu, Y. Li, J.Y. Lu, S. Tan, F. Jiang, and J. Sun, Correlations Between Microstructures and Properties of Cu-Ni-Si-Cr Alloy, Mater. Sci. Eng., 2018, 731, p 403–412. https://doi.org/10.1016/j.msea.2018.06.075

Acknowledgments

This work was supported by the National Natural Science Foundation of China (52071134), the Joint Foundation for Science and Technology Research and Development Plan of Henan Province (232103810030, 232103810031), the Program for Innovative Research Team at the University of the Henan Province (22IRTSTHN001), the China Postdoctoral Science Foundation (2023TQ0107), Key Research and Development Program of the Jiangxi Province (20224BBE52002).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, N., Zhou, M., Tian, B. et al. Effects of Trace La on the Aging Properties of the Cu-Ti-Zr Alloys. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09352-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09352-3