Abstract

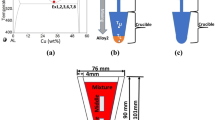

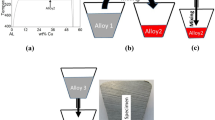

A non-dendritic microstructure normally forming the products made by the controlled diffusion solidification process (CDS) has been studied. Samples from Al-4.7 wt%Cu, Al-8 wt%Cu, and Al-4.7 wt%Zn were made via the CDS process by mixing pure aluminum into Al-Cu and Al-Zn binary alloys at a different mass ratio. ANSYS software was employed to predict the distribution of the mixed alloys during the mixing step. The simulation results show that the mixed alloys breakdown to different size pockets. The higher mass pockets fall into the bottom sample after the mixing step resulting in effect the microstructure forming in the entire sample. The experimental results indicate that globular mixed with rosette and dendritic morphologies form the entire microstructure, although all the morphologies were exposed to the same thermal environment during growth. The results show that the globular morphologies form in the undercooled alloy that have a higher liquidus temperature, while the dendritic morphologies form from the alloy that has a lower liquidus temperature, which is heated during the mixing.

Similar content being viewed by others

Notes

National Instruments, SCX 1100, USA.

Ansys 15, Ansys Inc.

Factsage (TM) 6.1, thermfact and gtt, technologist-1976-2009.

References

A.A. Khalaf, Acta Mater. 103, 301 (2016)

A.A. Khalaf, S. Shankar, JOM 72, 3733–3743 (2020)

M. Pourgharibshahi, H. Saghafian, M. Divandari, G. Timelli, Metall. Mater. Trans. A 50, 326 (2019)

R. Ghiaasiaan, X. Zeng, S. Shankar, Mater. Sci. Eng. A 594, 260 (2014)

M. Pourgharibshahi, M. Divandari, H. Saghafian Larijani, P. Ashtari, J. Mater. Process. Technol. 250, 203 (2017)

D. Saha, S. Shankar, D. Apelian, M.M. Makhlouf, Metall. Mater. Trans. A 35, 2174 (2004)

D. Apelian, M. M. Makhlouf, D. Saha, in Mater. Sci. Forum (2006), pp. 1771–1776.

K. Symeonidis, The controlled diffusion solidification process: fundamentals and principles. Ph.D Thesis, Worcester Polytechnic Institute (WPI), 2009.

A.A. Khalaf, P. Ashtari, S. Shankar, Metall. Mater. Trans. B 40, 843 (2009)

A. A. Khalaf, Controlled diffusion solidification: Process Mechanism and Parameter Study. Ph.D Thesis, McMaster University, 2010.

A.A. Khalaf, S. Shankar, Metall. Mater. Trans. A 42, 2456 (2011)

A.A. Khalaf, S. Shankar, J. Mater. Sci. 47, 8153 (2012)

Y. Li, X. Zhang, Y. Ma, D. Apelian, H. Zhou, X. Liu, China Foundry Res. Dev. 12, 173 (2015)

A.A. Khalaf, K.J. Takrouri, S.N. Appl, Sci. 2, 1337 (2020)

M. Wu, A. Ludwig, Acta Mater. 57, 5632 (2009)

W. Kurz, D.J. Fisher, Fundamentals of Solidification, 2nd edn. (Trans Tech Publications, Aedermannsdorf, 1984).

I. Egry, M.S. Ju, B. Hallstedt, J. Mater. Sci. 47, 8145 (2012)

R. Ghiaasiaan, S. Shankar, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 51, 4711 (2020)

W. Kurz, D.J.J. Fisher, Acta Metall. 29, 11 (1981)

E. Cini, B. Vinet, P.J. Desre, Philos. Mag. A 80, 955 (2000)

G. Müller, J. Metois, P. Rudolph, Crystal Growth -from Fundamentals to Technology (Elsevier, New York, NY, 2004).

R. Trivedi, J. Cryst. Growth 48, 93 (1980)

Acknowledgements

The authors are grateful to Mr. Doug Culley, Mr. Xiaogang Li, and Xiaochun Zheng for helping to use the Factsage software and optical microscope.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khalaf, A.A. Studying of Non-Dendritic Microstructure Forming in Controlled Diffusion Solidification. Inter Metalcast 16, 223–233 (2022). https://doi.org/10.1007/s40962-021-00590-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00590-y