Abstract

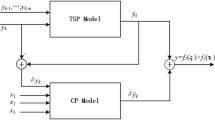

To meet the goals of the national "Dual Carbon" strategy and reduce energy consumption in the steel industry, accurate prediction of steel composition is crucial for precise control over alloy addition in steelmaking. Several models have been created to predict the composition of the converter endpoint with a high level of accuracy. However, the different shortcomings of each have prevented large-scale application in real production environments. CBR prediction model has limited scope to solve the problem. CNN model has complex data processing and no memory. RELM model has randomly given input layer weights and hidden layer deviations. In this study, correlation analysis was used to analyze the factors influencing the carbon content at the endpoint of converter steelmaking. A feasible model was established and applied to predict the carbon content at the endpoint of converter using t-distributed stochastic neighbor embedding (t-SNE), particle swarm optimization (PSO), and backpropagation (BP) neural network. The learning rate, training times, and hidden layer nodes number of the prediction model were optimized. The prediction hit ratios for the carbon content in the error ranges of ± 0.003%, ± 0.01%, and ± 0.02% are 61%, 86%, and 98%, respectively. Meanwhile, apply the established model to actual production, the carbon content of the product can be stably controlled between the lower and median limits, the control effect is significantly better than traditional methods. The results demonstrate that the t-SNE-PSO-BP model performs better than the known models. The accurate prediction of the carbon content at the endpoint of converter can greatly contribute to realizing a “narrow composition control” of the molten steel. Realize accurate prediction of carbon content at the endpoint of converter smelting, and has been effectively applied to industrial production.

Graphical Abstract

Under the traditional method of predicting the endpoint carbon content of the converter, the hit rate of the middle and lower limits of the carbon content in the product is 48%. The t-SNE-PSO-BP model predicts the carbon content at the endpoint of the converter model, and the product carbon content can be controlled stably between 0.21–0.23%. According to the study results and actual application effects, use the t-SNE-PSO-BP model to predict the carbon content at the endpoint of the converter is appropriate, and is conducive to the “narrow composition control” of the steel composition in the converter steelmaking process.

Similar content being viewed by others

References

Zheng RX et al (2021) Intelligent control model of steelmaking using ferroalloy reduction and its application. Chin J Eng 43(12):1689–1697

Zhu R et al (2020) A review of carbon dioxide disposal technology in the converter steelmaking process. Int J Min Met Mater 27(11):1421–1429

Wang Y et al (2021) Non-metallic inclusions in different ferroalloys and their effect on the steel quality: A review. Metall Mater Trans B 52:2892–2925

Liu X et al (2023) Distribution and precipitation mechanism of TiN in industrial pure iron bloom. Steel Res Int 94(1):2200481

Wang DZ et al (2022) Effect of converter scrap ratio on carbon emission in BF-LD process. J Sustain Metall 8(4):1975–1987

Kikuchi N (2020) Development and prospects of refining techniques in steelmaking process. ISIJ Int 60(12):2731–2744

Tanaka M et al (1993) Motions of alloying additions during furnace tapping in steelmaking processing operations. Metall Mater Trans B 24:639–648

Zhang D et al (2017) Application of high efficiency alloy baking in converter steelmaking. China Metallurgy 27(2):70–73

Wang ZL et al (2023) Convolutional neural network-based method for predicting oxygen content at the end point of converter. Steel Res Int 94(1):2200342

Feng LJ et al (2020) Multichannel diffusion graph convolutional network for the prediction of endpoint composition in the converter steelmaking process. IEEE Trans Instrum Meas 70:1–13

Gu MQ et al (2021) An improved CBR model using time-series data for predicting the end-point of a converter. ISIJ Int 61(10):2564–2570

Madhavan N et al (2021) General heat balance for oxygen steelmaking. J Iron Steel Res Int 28:538–551

Liu X et al (2023) Denaturation behavior of inclusions in industrial pure iron by calcium treatment. J Iron Steel Res Int 30(2):249–258

Wu S, Li H (2022) Prediction of PM2.5 concentration in urban agglomeration of China by hybrid network model. J Clean Prod 374:133968

Fei F et al (2023) A new method for evaluating the synergistic effect of urban water body and vegetation in the summer outdoor thermal environment. J Clean Prod 414:137680

Yousefzadeh M et al (2021) Spatiotemporally explicit earthquake prediction using deep neural network. Soil Dyn Earthq Eng 144:106663

Yang G et al (2021) Early warning of water resource carrying status in Nanjing City based on coordinated development index. J Clean Prod 284:124696

Deng Y et al (2019) Prediction model of PSO-BP neural network on coliform amount in special food. Saudi J Bio Sci 26(6):1154–1160

Cuartas M et al (2019) Machine learning algorithms for the prediction of non-metallic inclusions in steel wires for tire reinforcement. J Intell Manuf 32:1739–1751

Lee SY et al (2020) Spatial and sequential deep learning approach for predicting temperature distribution in a steel-making continuous casting process. Ieee Access 8:21953–21965

Wang ZB et al (2023) Crack morphology tailoring and permeability prediction of polyvinyl alcohol-steel hybrid fiber engineered cementitious composites. J Clean Prod 383:135335

Khan A et al (2020) A survey of the recent architectures of deep convolutional neural networks. Artif Intel Rev 53:5455–5516

Acosta SM et al (2021) Relevance vector machine with tuning based on self-adaptive differential evolution approach for predictive modelling of a chemical process. Appl Math Model 95:125–142

Coronado PDU et al (2018) Part data integration in the Shop Floor Digital Twin: Mobile and cloud technologies to enable a manufacturing execution system. J Manuf Syst 48:25–33

Chu JH, Bao YP (2021) Mn evaporation and denitrification behaviors of molten Mn steel in the vacuum refining with slag process. Int J Min Met Mater 28:1288–1297

Rout BK et al (2018) Dynamic model of basic oxygen steelmaking process based on multi-zone reaction kinetics: Model derivation and validation. Metall Mater Trans B 49:537–557

Kwon SH et al (2020) Prediction of hot ductility of steels from elemental composition and thermal history by deep neural networks. Ironmak Steelmak 47(10):1176–1187

Zhang CJ et al (2022) Industrial cyber-physical system driven intelligent prediction model for converter end carbon content in steelmaking plants. J Ind Inf Integr 28:100356

Feng K et al (2022) An integration model for converter molten steel end temperature prediction based on Bayesian formula. Steel Res Int 93:2100433

Park TC et al (2018) Comparative study of estimation methods of the endpoint temperature in basic oxygen furnace steelmaking process with selection of input parameters. Korean J Met Mater 56(11):813–821

Zhang DH, Lou S (2021) The application research of neural network and BP algorithm in stock price pattern classification and prediction. Future Gener Comp Sy 115:872–879

Wang Z et al (2012) Prediction model of end-point manganese content for BOF steelmaking process. ISIJ Int 52(9):1585–1590

Gu MQ et al (2021) Real-time dynamic carbon content prediction model for second blowing stage in BOF based on CBR and LSTM. Processes 9(11):1987–2002

Liu H et al (2021) Using t-distributed Stochastic Neighbor Embedding (t-SNE) for cluster analysis and spatial zone delineation of groundwater geochemistry data. J Hydrol 597:126146

Song SY et al (2022) Intelligent case-based hybrid model for process and endpoint prediction of converter via data mining technique. ISIJ Int 62(8):1639–1648

Xiong Q et al (2022) Soft measurement method of endpoint carbon content and temperature of converter steelmaking based on LNN-DPC weighted ensemble learning. Comput Integr Manuf Syst 28(12):3886–3898

Zhao B et al (2023) Research on prediction model of converter temperature and carbon content based on spectral feature extraction. Sci Rep-UK 13(1):14409

Zhang Z et al (2019) Improved prediction model for BOF end-point manganese content based on IPSO-RELM method. Chin J Eng 41(8):1052–1060

He F et al (2018) Prediction model of end-point phosphorus content in BOF steelmaking process based on PCA and BP neural network. J Process Contr 66:51–58

Wang Z et al (2014) The control and prediction of end-point phosphorus content during BOF steelmaking process. Steel Res Int 85(4):599–606

Wang HB et al (2012) Prediction of endpoint phosphorus content of molten steel in BOF using weighted K-means and GMDH neural network. J Iron Steel Res Int 19(1):11–16

Anowar F et al (2021) Conceptual and empirical comparison of dimensionality reduction algorithms (pca, kpca, lda, mds, svd, lle, isomap, le, ica, t-sne). Comput Sci Rev 40:100378

Kobak D, Linderman GC (2021) Initialization is critical for preserving global data structure in both t-SNE and UMAP. Nat biotechnol 39(2):156–157

Kobak D, Berens P (2019) The art of using t-SNE for single-cell transcriptomics. Nat commun 10(1):5416–5430

Ren XQ et al (2021) A method for state-of-charge estimation of lithium-ion batteries based on PSO-LSTM. Energy 234:121236

Cuong-Le T et al (2021) An efficient approach for damage identification based on improved machine learning using PSO-SVM. Eng Comput-Germany 38:1–16

Moayedi H et al (2020) Optimization of ANFIS with GA and PSO estimating α ratio in driven piles. Eng Comput-Germany 36:227–238

Zhang Y et al (2021) Research on terminal control model of intelligent mining of flame spectral information of converter mouth in late smelting stage. Ironmak Steelmak 48(6):677–684

Duarte ICD et al (2022) Heat-loss cycle prediction in steelmaking plants through artificial neural network. J Oper Res Soc 73(2):326–337

Li JM et al (2020) Multiscale local features learning based on BP neural network for rolling bearing intelligent fault diagnosis. Measurement 153:107419

Xin ZC et al (2023) Predicting the alloying element yield in a ladle furnace using principal component analysis and deep neural network. Int J Min Met Mater 30(2):335–334

Acknowledgements

This work was supported by the Guangdong Basic and Applied Basic Research Foundation (No. 2022A1515110062), and Young Elite Scientists Sponsorship Program by CAST (No. 2022QNRC001). The authors wish to express their gratitude to the foundation for providing financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

The contributing editor for this article was Il Sohn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Bao, Y., Zhao, L. et al. Establishment and Application of Steel Composition Prediction Model Based on t-Distributed Stochastic Neighbor Embedding (t-SNE) Dimensionality Reduction Algorithm. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00798-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40831-024-00798-2