Abstract

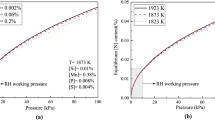

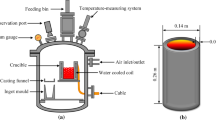

Considering the precise composition control on the vacuum refining of high-Mn steel, the behaviors of both Mn evaporation and nitrogen removal from molten Mn steel were investigated via vacuum slag refining in a vacuum induction furnace. It was found that the reaction interfaces of denitrification and Mn evaporation tend to migrate from the surface of slag layer to the surface of molten steel with the gradual exposure of molten steel during the vacuum slag refining process. Significantly, compared with the experimental group without slag addition, the addition of slag into steel can result in a lower Mn evaporation rate constant of 0.0192 cm·min−1 at 370 Pa, while the denitrification rate is almost not affected. Besides, the slag has a stronger inhibitory effect on Mn evaporation than the reduced vacuum pressure. Moreover, the inhibitory effect of the slag layer on Mn evaporation can be weakened with the increase of the initial Mn content in molten steel. The slag layer can work as an inhibitory layer to reduce the Mn evaporation from molten steel, the evaporation reaction of Mn mainly proceeds on the surface of the molten steel. This may be attributed to the Mn mass transfer coefficient for one of reaction at steel/slag interface, mass transfer in molten slag, and evaporation reaction at slag/gas interface is lower than that of evaporation reaction at steel/gas interface. The introduction of slag is proposed for both denitrification and manganese control during the vacuum refining process of Mn steels.

Similar content being viewed by others

References

Y.H. Wen, H.B. Peng, H.T. Si, R.L. Xiong, and D. Raabe, A novel high manganese austenitic steel with higher work hardening capacity and much lower impact deformation than Hadfield manganese steel, Mater. Des., 55(2014), p. 798.

T. Allam, X.F. Guo, M. Lipińska-Chwałek, A.S. Hamada, E. Ahmed, and W. Bleck, Impact of precipitates on the hydrogen embrittlement behavior of a V-alloyed medium-manganese austenitic stainless steel, J. Mater. Res. Technol., 9(2020), No. 6, p. 13524.

Y.J. Wang, S. Zhao, R.B. Song, and B. Hu, Hot ductility behavior of a Fe-0.3C-9Mn-2Al medium Mn steel, Int. J. Miner. Metall. Mater., 28(2021), No. 3, p. 422.

S. Sevsek, F. Brasche, D.A. Molodov, and W. Bleck, On the influence of grain size on the TWIP/TRIP-effect and texture development in high-manganese steels, Mater. Sci. Eng. A, 754(2019), p. 152.

M. Daamen, B. Wietbrock, S. Richter, and G. Hirt, Strip casting of a high-manganese steel (FeMn22C0.6) compared with a process chain consisting of ingot casting and hot forming, Steel Res. Int., 82(2011), No. 1, p. 70.

M. Alba, M. Nabeel, and N. Dogan, Effect of aluminium content on the formation of inclusions in Fe-5Mn-xAl steels, Ironmaking Steelmaking, 48(2021), No. 4, p. 379.

Z.Y. Liu, Y.P. Bao, M. Wang, X. Li, and F.Z. Zeng, Austenite grain growth of medium-carbon alloy steel with aluminum additions during heating process, Int. J. Miner. Metall. Mater., 26(2019), No. 3, p. 282.

L.Z. Kong, Z.Y. Deng, L. Cheng, and M.Y. Zhu, Reaction behaviors of Al-killed medium-manganese steel with glazed MgO refractory, Metall. Mater. Trans. B, 49(2018), No. 6, p. 3522.

C.F. Redeker, D. Rohrberg, J. Schöttler, J. Kroos, and K.H. Spitzer, Metallurgical methods for the production of steels with high manganese contents in the range of 12 to 25%wt, [in] The 2nd CSM-VDEh-Seminar on Metallurgical Fundamentals, Düsseldorf, Germany, 2007.

R. Elliott, K. Coley, S. Mostaghel, and M. Barati, Review of manganese processing for production of TRIP/TWIP steels, part 1: Current practice and processing fundamentals, JOM, 70(2018), No. 5, p. 680.

V. Hernandez, S. Mostaghel, S. Ge, C. Harris, and M. Cramer, Innovative and economical approach for the production of mid- and high-manganese steel, [in] AIS Technology Conference Proceedings, Pittsburgh, 2016.

J.L. Guo, L.H. Zhao, Y.P. Bao, S. Gao, and M. Wang, Carbon and oxygen behavior in the RH degasser with carbon powder addition, Int. J. Miner. Metall. Mater., 26(2019), No. 6, p. 681.

J.H. Chu, Y.P. Bao, X. Li, M. Wang, and F. Gao, Kinetic study of Mn vacuum evaporation from Mn steel melts, Sep. Purif. Technol., 255(2021), art. No. 117698.

A. Rafiei, G.A. Irons, and K.S. Coley, Argon-oxygen decarburization of high-manganese steels: Effect of temperature, Alloy composition, and submergence depth, Steel Res. Int., 92(2021), No. 1, art. No. 2000480.

H.B. Liu, J.H. Liu, S. Johannes, F.M. Penz, L. Sun, R.Z. Zhang, and Z.G. An, Effect of CO2 and O2 mixed injection on the decarburization and manganese retention in high-Mn twinning-induced plasticity steels, Metall. Mater. Trans. B, 51(2020), No. 2, p. 756.

S. Hoile, Processing and properties of mild interstitial free steels, Mater. Sci. Technol., 16(2000), No. 10, p. 1079.

M. Takahashi, Development of high strength steels for automobiles, Nippon Steel Tech. Rep., 2003, No. 88, p. 2.

L.F. Zhang, State of the art in the control of inclusions in tire cord steels—A review, Steel Res. Int., 77(2006), No. 3, p. 158.

I. Karaman, H. Sehitoglu, H.J. Maier, and Y.I. Chumlyakov, Competing mechanisms and modeling of deformation in austenitic stainless steel single crystals with and without nitrogen, Acta Mater., 49(2001), No. 19, p. 3919.

V. Vats, T. Baskaran, and S.B. Arya, Tribo-corrosion study of nickel-free, high nitrogen and high manganese austenitic stainless steel, Tribol. Int., 119(2018), p. 659.

J.H. Shin, J. Lee, D.J. Min, and J.H. Park, Solubility of nitrogen in high manganese steel (HMnS) melts: Interaction parameter between Mn and N, Metall. Mater. Trans. B, 42(2011), No. 6, p. 1081.

H.J. Wu, Q.Q. Li, Z. Wang, and F.J. Jiang, Vacuum denitrification and nitrogen absorption of molten steel under ultra-low nitrogen conditions, Mater. Sci. Technol., 35(2019), No. 2, p. 240.

K. Qian, B. Chen, L. Zhang, Z.H. Du, and K. Liu, Kinetics study of nitrogen removal from liquid IN718 alloy during vacuum induction melting, Vacuum, 179(2020), art. No. 109521.

B. Chen, Z.H. Du, K. Liu, X.J. Zhang, and Z.H. Wang, Study on the denitrogenization kinetics of uranium during electron beam cold hearth refining, Vacuum, 172(2020), art. No. 109014.

Y.T. Xu, Z.P. Chen, and G. Zhang, Kinetic model of decarburization and denitrogenation in vacuum oxygen decarburization process for ferritic stainless steel, Metall. Mater. Trans. B, 40(2009), No. 3, p. 345.

G.G. Cheng, P. Zhao, L.S. Liu, and X.H. Ma, Mechanism of nitrogen absorption affected by surface active elements in molten steel, Res. Iron Steel, 25(1997), No. 2, p. 3.

Q.G. Zhang, Theoretical research on effect of oxygen content in liquid steel on nitrogen absorption, Steelmaking, 2003, No. 6, p. 25.

K. Ito, K. Amano, and H. Sakao, Kinetic study on nitrogen absorption and desorption of molten iron, Trans. Iron Steel Inst. Jpn., 28(1988), No. 1, p. 41.

J. Li, J. Fu, L. Di, D.G. Zhou, B.P. Chen, B.W. Feng, C.J. Tu, and Z.M. Zhang, Study on effect of soluble oxygen on nitrogen absorption of liquid steel, Iron Steel, 2002, No. 4, p. 19.

R. Yamanaka, K. Ogawa, H. Iritani, and S. Koyama, Denitrogenization mechanism from molten steel by flux treatment, ISIJ Int., 32(1992), No. 1, p. 136.

Y.X. Dai, J. Li, C.B. Shi, and W. Yan, Dephosphorization of high silicon hot metal based on double slag converter steelmaking technology, Ironmaking Steelmaking, 48(2021), No. 4, p. 447.

S.H. Chen, M. Jiang, X.F. He, and X.H. Wang, Top slag refining for inclusion composition transform control in tire cord steel, Int. J. Miner. Metall. Mater., 19(2012), No. 6, p. 490.

L.H. Zhao, L. Lin, and Q.F. Wu, Experimental study on sulfur removal from ladle furnace refining slag in hot state by blowing air, Int. J. Miner. Metall. Mater., 23(2016), No. 1, p. 33.

H.X. Yu, D.X. Yang, M.M. Li, and N. Zhang, Effects of Al addition on the reaction between high-manganese steel and CaO-SiO2-Al2O3-MgO slag, Steel Res. Int., 91(2020), No. 10, art. No. 2000143.

Z.Y. Deng, L.Z. Kong, D. Liang, and M.Y. Zhu, Reaction of Al-killed manganese steel with ladle slag, Steel Res. Int., 90(2019), No. 5, art. No. 1800480.

J.H. Chu, Y.P. Bao, X. Li, F. Gao, and M. Wang, Characterization of oxidation behavior of Mn fumes generated in the vacuum treatment of melting Mn steels, Steel Res. Int., 92(2021), No. 1, art. No. 2000333.

J.Y. Zhao, H.W. Yang, C.B. Nan, B. Yang, D.C. Liu, and B.Q. Xu, Kinetics of Pb evaporation from Pb-Sn liquid alloy in vacuum distillation, Vacuum, 141(2017), p. 10.

Z.M. Chen, J.X. Liu, and R. Li, Simulation and property prediction of MgO-FeO-MnO solid solution in steel slag, Mater. Lett., 273(2020), art. No. 127930.

L.Z. Kong, Z.Y. Deng, and M.Y. Zhu, Reaction behaviors of Al-killed medium-manganese steel with different refractories, Metall. Mater. Trans. B, 49(2018), No. 3, p. 1444.

Y.G. Yu, B.P. Chen, Y.G. Wang, B.H. Tu, and J. Fu, Evaporation of trace bismuth during vacuum melting of steel, J. Univ. Sci. Technol. Beijing, 16(1994), No. 6, p. 522.

Acknowledgement

This work was financially supported by the National Natural Science Foundation of China (No. 51874021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chu, Jh., Bao, Yp. Mn evaporation and denitrification behaviors of molten Mn steel in the vacuum refining with slag process. Int J Miner Metall Mater 28, 1288–1297 (2021). https://doi.org/10.1007/s12613-021-2311-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2311-5