Abstract

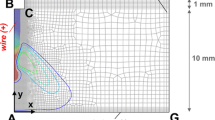

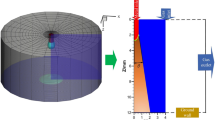

The three-dimensional coupled arc-droplet models for traditional single-wire gas metal arc welding (SW-GMAW) and double-wire gas metal arc welding (DW-GMAW) were established. The mutual attraction of two arcs and the inclination of the droplets in DW-GMAW were analyzed numerically. The temperature, fluid flow velocity, and electromagnetic force distributions were compared between DW-GMAW and SW-GMAW. Compared with SW-GMAW, the temperature distribution on the workpiece surface was bimodal along x-axis and the peak temperature reduced in DW-GMAW. The high-temperature region in the filler metal was decreased dramatically. The fluid flow mode of the arc plasma in DW-GMAW was changed, and the peak velocity of the arc plasma decreased. Besides, the forces acted on the arc plasma were compared and the reason for the arc inclination was analyzed. Experimental data was used to validate the model’s predictions.

Similar content being viewed by others

References

Martina F, Ding J, Williams S et al (2019) Tandem metal inert gas process for high productivity wire arc additive manufacturing in stainless steel. Addit Manuf 25:545–550. https://doi.org/10.1016/j.addma.2018.11.022

Chaturvedi M, Scutelnicu E, Rusu CC et al (2021) Wire arc additive manufacturing: review on recent findings and challenges in industrial applications and materials characterization. Metals (Basel) 11:939

Jin W, Zhang C, Jin S et al (2020) Wire arc additive manufacturing of stainless steels: A review. Appl Sci 10:1563

Devasia BTAJ, Krishna T, Kuruvila MT (2020) Manufacturing of a bimetallic structure of stainless steel and mild steel through wire arc additive manufacturing — a critical review. Int J Innov Sci Res Technol 5:679–685. https://doi.org/10.38124/ijisrt20jun583

Kanemaru S, Sasaki T, Sato T et al (2014) Study for TIG-MIG hybrid welding process. Weld World 58:11–18. https://doi.org/10.1007/s40194-013-0090-y

Kanemaru S, Sasaki T, Sato T et al (2015) Study for the mechanism of TIG-MIG hybrid welding process. Weld World 59:261–268. https://doi.org/10.1007/s40194-014-0205-0

Cho JH, Na SJ (2009) Three-dimensional analysis of molten pool in GMA-laser hybrid welding. Weld J 88:35s–43s

Shi C, Zou Y, Zou Z, Wu D (2014) Twin-wire indirect arc welding by modeling and experiment. J Mater Process Technol 214:2292–2299. https://doi.org/10.1016/j.jmatprotec.2014.04.027

Gu Y, Hua X, Ye D et al (2017) Numerical simulation of hump suppression in high-speed triple-wire GMAW. Int J Adv Manuf Technol 89:727–734. https://doi.org/10.1007/s00170-016-9119-x

Lu Y, Chen S, Shi Y et al (2014) Double-electrode arc welding process: Principle, variants, control and developments. J Manuf Process 16:93–108. https://doi.org/10.1016/j.jmapro.2013.08.003

Assunção PDC, Ribeiro RA, Moreira PMGP et al (2020) A preliminary study on the double cold wire gas metal arc welding process. Int J Adv Manuf Technol 106:5393–5405. https://doi.org/10.1007/s00170-020-05005-6

Wang L, Wu CS, Gao JQ (2016) Suppression of humping bead in high speed GMAW with external magnetic field. Sci Technol Weld Join 21:131–139. https://doi.org/10.1179/1362171815Y.0000000074

Chen J, Zhang Y, Wu C, Padhy GK (2019) Suppression of undercut defects in high-speed GMAW through a compound magnetic field. J Mater Process Technol 274:116288. https://doi.org/10.1016/J.JMATPROTEC.2019.116288

Michie K, Blackman S, Ogunbiyi TEB (1999) Twin-wire GMAW: process characteristics and applications. Weld J 78:31–34

Sathishkumar M, Bhakat YJ, Kumar KG et al (2021) Investigation of double-pulsed gas metal arc welding technique to preclude carbide precipitates in aerospace grade hastelloy X. J Mater Eng Perform 30:661–684. https://doi.org/10.1007/s11665-020-05360-1

Rosli NA, Alkahari MR, bin Abdollah MF et al (2021) Review on effect of heat input for wire arc additive manufacturing process. J Mater Res Technol 11:2127–2145

Ren L, Gu H, Wang W, et al (2021) Microstructure and properties of Al-6.0Mg-0.3Sc alloy deposited by double-wire arc additive manufacturing. 3D Print Addit Manuf 9:301–310. https://doi.org/10.1089/3dp.2020.0039

Chen D, Chen M, Wu C (2015) Effects of phase difference on the behavior of arc and weld pool in tandem P-GMAW. J Mater Process Technol 225:45–55. https://doi.org/10.1016/j.jmatprotec.2015.05.022

Liu G, Tang X, Han S, Cui H (2021) Influence of interwire distance and arc length on welding process and defect formation mechanism in double-wire pulsed narrow-gap gas metal arc welding. J Mater Eng Perform 30:7622–7635. https://doi.org/10.1007/s11665-021-05888-w

Wu K, Cao X, Yin T et al (2019) Metal transfer process and properties of double-wire double pulsed gas metal arc welding. J Manuf Process 44:367–375. https://doi.org/10.1016/j.jmapro.2019.06.019

Ueyama T, Ohnawa T, Tanaka M, Nakata K (2007) Occurrence of arc interaction in tandem pulsed gas metal arc welding. Sci Technol Weld Join 12:523–529. https://doi.org/10.1179/174329307X173715

Moinuddin SQ, Sharma A (2015) Arc stability and its impact on weld properties and microstructure in anti-phase synchronised synergic-pulsed twin-wire gas metal arc welding. Mater Des 67:293–302. https://doi.org/10.1016/j.matdes.2014.11.052

Groetelaars PJ, de Morais CO, Scotti A (2009) Influence of the arc length on metal transfer in the single potential double-wire MIG/MAG process. Weld Int 23:112–119. https://doi.org/10.1080/09507110802349643

Cai X, Fan C, Lin S et al (2017) Effects of shielding gas composition on arc behaviors and weld formation in narrow gap tandem GMAW. Int J Adv Manuf Technol 91:3449–3456. https://doi.org/10.1007/s00170-017-9990-0

Wu K, Xie P, Liu Z et al (2020) Investigation of double arc interaction mechanism and quantitative analysis of double arc offset in high-power double-wire DP-GMAW. J Manuf Process 49:423–437. https://doi.org/10.1016/j.jmapro.2019.10.022

Pu J, Wu S, Hu Q, Wang Y (2019) Effect of welding current on arc behavior in tandem GMAW. Int J Mod Phys B 33:1–6. https://doi.org/10.1142/S0217979219400368

Schnick M, Wilhelm G, Lohse M et al (2011) Three-dimensional modelling of arc behaviour and gas shield quality in tandem gas-metal arc welding using anti-phase pulse synchronization. J Phys D Appl Phys 44:185205. https://doi.org/10.1088/0022-3727/44/18/185205

Ding X, Li H, Yang L, Gao Y (2013) Numerical simulation of metal transfer process in tandem GMAW. Int J Adv Manuf Technol 69:107–112. https://doi.org/10.1007/s00170-013-4999-5

Ding X, Li H, Wei H, Liu J (2016) Numerical analysis of arc plasma behavior in double-wire GMAW. Vacuum 124:46–54. https://doi.org/10.1016/j.vacuum.2015.11.006

Murphy AB (2011) A self-consistent three-dimensional model of the arc, electrode and weld pool in gas-metal arc welding. J Phys D Appl Phys 44:194009. https://doi.org/10.1088/0022-3727/44/19/194009

Lowke JJ, Tanaka M (2006) “LTE-diffusion approximation” for arc calculations. J Phys D Appl Phys 39:3634–3643. https://doi.org/10.1088/0022-3727/39/16/017

Xu G, Hu J, Tsai HL (2008) Three-dimensional modeling of the plasma arc in arc welding. J Appl Phys 104:103301. https://doi.org/10.1063/1.2998907

Xu G, Hu J, Tsai HL (2009) Three-dimensional modeling of arc plasma and metal transfer in gas metal arc welding. Int J Heat Mass Transf 52:1709–1724. https://doi.org/10.1016/j.ijheatmasstransfer.2008.09.018

Zhao Y, Chung H (2017) Numerical simulation of droplet transfer behavior in variable polarity gas metal arc welding. Int J Heat Mass Transf 111:1129–1141. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.090

Zhao Y, Chung H (2018) Influence of power source dynamics on metal and heat transfer behaviors in pulsed gas metal arc welding. Int J Heat Mass Transf 121:887–899. https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.058

Murphy AB (2010) The effects of metal vapour in arc welding. J Phys D Appl Phys 43:434001. https://doi.org/10.1088/0022-3727/43/43/434001

Zielińska S, Musioł K, Dzierga K et al (2007) Investigations of GMAW plasma by optical emission spectroscopy. Plasma Sources Sci Technol 16:832–838. https://doi.org/10.1088/0963-0252/16/4/019

Ogino Y, Hirata Y, Asai S (2017) Numerical simulation of metal transfer in pulsed-MIG welding. Weld World 61:1289–1296. https://doi.org/10.1007/s40194-017-0492-3

Ogino Y, Hirata Y, Asai S (2020) Discussion of the effect of shielding gas and conductivity of vapor core on metal transfer phenomena in gas metal arc welding by numerical simulation. Plasma Chem Plasma Process 40:1109–1126. https://doi.org/10.1007/s11090-020-10102-1

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100:335–354. https://doi.org/10.1016/0021-9991(92)90240-Y

Tanaka M, Lowke JJ (2007) Predictions of weld pool profiles using plasma physics. J Phys D Appl Phys 40:R1–R23. https://doi.org/10.1088/0022-3727/40/1/R01

Lowke JJ (1974) Predictions of arc temperature profiles using approximate emission coefficients for radiation losses. J Quant Spectrosc Radiat Transf 14:111–122. https://doi.org/10.1016/0022-4073(74)90004-1

Tashiro S, Tanaka M, Ushio M et al (2006) Prediction of energy source properties of free-burning arcs. Vacuum 80:1190–1194. https://doi.org/10.1016/j.vacuum.2006.01.058

Lu F, Wang HP, Murphy AB, Carlson BE (2014) Analysis of energy flow in gas metal arc welding processes through self-consistent three-dimensional process simulation. Int J Heat Mass Transf 68:215–223. https://doi.org/10.1016/j.ijheatmasstransfer.2013.09.021

Hu J, Tsai HL (2006) Effects of current on droplet generation and arc plasma in gas metal arc welding. J Appl Phys 100:053304. https://doi.org/10.1063/1.2337261

Drazin P (1987) Fluid mechanics. Physics education. CBS College, New York, pp 350–354

Wang L, Chen J, Wu CS, Luan SC (2020) Numerical analysis of arc and droplet behaviors in gas metal arc welding with external compound magnetic field. J Mater Process Technol 282:116638. https://doi.org/10.1016/j.jmatprotec.2020.116638

Hirata Y (1995) Physics of welding (III) —- melting rate and temperature distribution of electrode wire. Weld Int 9:348–351. https://doi.org/10.1080/09507119509548811

MI Boulos, P Fauchais EP (2013) Thermal plasmas: fundamentals and applications. Springer Science & Business Media, New York

Murphy AB, Arundelli CJ (1994) Transport coefficients of argon, nitrogen, oxygen, argon-nitrogen, and argon-oxygen plasmas. Plasma Chem Plasma Process 14:451–490. https://doi.org/10.1007/BF01570207

Funding

This work is sponsored by the National Natural Science Foundation of China (Grant number 52005296), the Postgraduate Research and Practice Innovation Program of Jiangsu Province (Grant number SJCX22_1143), and the Graduate Innovation Program of China University of Mining and Technology (Grant number 2022WLJCRCZL280).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, J., Ma, Y., Wang, L. et al. Numerical simulation of arc and metal transfer behaviors in double-wire gas metal arc welding. Weld World 66, 2521–2531 (2022). https://doi.org/10.1007/s40194-022-01381-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01381-7