Abstract

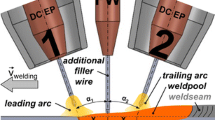

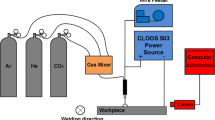

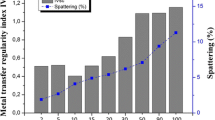

In narrow gap gas metal arc welding (GMAW), it is useful to understand the arc behaviors to ensure the weld quality. Arc behaviors are strongly affected by the shielding gas composition. In this study, a three-component shielding gas mixture was used in tandem narrow gap pulsed GMAW, and the effect of its composition on arc behaviors and weld formation were investigated. The shielding gas included argon, carbon dioxide, and helium. The arc behaviors and electrical characteristics were recorded by a high-speed camera and an electrical signal acquisition system. The results show that the arc behaviors in different shielding gas are different. The arc expands and the arc length decreases with the increase of CO2 content or helium content. The arc is the widest when the shielding gas is 80%Ar10%CO210%He. The weld shape was observed, and it was found that the weld width increases first and then decreases with increasing of the CO2 content. When the helium content is below 15%, the weld width increases as the helium content increases, but when the helium is 15%, the weld width drops due to the decrease of arc length. When the helium content is above 15%, the weld width continues to increase as the helium content increases. The largest weld width can be obtained in 80%Ar10%CO210%He.

Similar content being viewed by others

References

Cai XY, Lin SB, Fan CL, Yang CL, Zhang W, Wang YW (2016) Molten pool behaviour and weld forming mechanism of tandem narrow gap vertical GMAW. Sci Technol Weld Join 21(2):124–130

Cai XY, Fan CL, Lin SB, Yang CL, Bai JY (2016) Molten pool behaviors and forming characteristics of all-position tandem narrow gap GMAW. Int J Adv Manuf Technol 87:2437–2444

Christensen K, Sorensen T, Kristensen J (2005) Gas metal arc welding of butt joint with varying gap width based on neural networks. Sci Technol Weld Join 10(1):32–43

Wang JY, Ren YS, Yang F, Yang HB (2007) Novel rotation arc system for narrow gap MAG welding. Sci Technol Weld Join 12(6):505–507

Ding M, Tang XH, Lu FG, Yao S (2011) Welding of quenched and tempered steels with high-spin arc narrow gap MAG system. Int J Adv Manuf Technol 55:527–533

Guo N, Wang MR, Guo W, Yu JB, Feng JC (2014) Study on forming mechanism of appearance defects in rotating arc narrow gap horizontal GMAW. Int J Adv Technol 75:15–20

Cui HC, Jiang ZD, Tang XH, Lu FG (2014) Research on narrow-gap GMAW with swing arc system in horizontal position. Int J Adv Technol 74:297–305

Xu WH, Lin SB, Fan CL, Yang CL (2015) Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 79:183–196

Xu WH, Lin SB, Fan CL, Yang CL (2014) Evaluation on microstructure and mechanical properties of high-strength low-alloy steel joints with oscillating arc narrow gap GMA welding. Int J Adv Technol 75:1439–1446

Urmston SA (1985) Effect of shielding gas composition on transfer and fusion characteristics in P-GMAW of carbon steels. Cranfield University, Cranfield

Theocharis L (2007) Tandem gas metal arc pipeline welding. Cranfield University, Cranfield

Hunt C, Bols I, Ortege P (1997) Helium—a lightweight gas but a heavyweight performer. Weld Met Fabr 65:10–14

Jones LA, Eagar TW, Lang JH (1998) A dynamic model of drops detaching from a gas metal arc welding electrode. J Phys D Appl Phys 31D:107–123

Yamauchi N, Agusa K (1981) A state of the art report of minor element effects on the gas shielded arc welding phenomena in Japan. J Jpn Weld 50:1059–1065

Lesnewich A (1943) Control of melting rate and metal transfer in gas shielded metal arc welding. Weld J 22:2–42

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, X., Fan, C., Lin, S. et al. Effects of shielding gas composition on arc behaviors and weld formation in narrow gap tandem GMAW. Int J Adv Manuf Technol 91, 3449–3456 (2017). https://doi.org/10.1007/s00170-017-9990-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-9990-0