Abstract

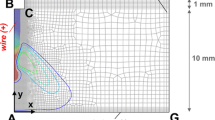

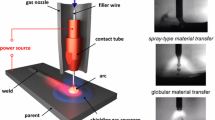

Physical phenomena such as arc interference, deflection in droplet transfer, and bulging in weld pool are observed in the tandem gas metal arc welding (GMAW) process. A hot-wire with opposite polarities to the leading and trailing electrodes was introduced to counter these phenomena. The effects of the hot-wire were assessed experimentally. A 3D steady-state numerical analysis model was used to calculate the temperatures and the shapes of the leading and trailing arcs, respectively, as well as the arc flows and the electromagnetic forces. The results of our experiments and our numerical analyses clarify the effects of a decrease in the electromagnetic force around tandem electrodes due to the hot-wire. This decrease mitigates arc interference and the deflection in droplet transfer. Furthermore, it plays a role in reducing the height of the bulge generated on the surface of the weld pool. These effects can prevent defects in tandem GMAW processes.

Similar content being viewed by others

References

Y. G. Kim, D. C. Kim and S. M. Joo, Evaluation of tensile shear strength for dissimilar spot welds of Al-Si-Mg aluminum alloy and galvanized steel by delta-spot welding process, Journal of Mechanical Science and Technology, 33(11) (2019) 5399–5405.

W. Guo, N. Ding, N. Xu, L. Liu, N. Li, J. Shi and C. M. L. Wu, Fracture analysis of a welded front axle tube structure from a mini-truck, Journal of Mechanical Science and Technology, 34(1) (2020) 109–116.

D. Y. Lee, L. Leifsson, J. Y. Kim and S. H. Lee, Optimisation of hybrid tandem metal active gas welding using Gaussian process regression, Science and Technology of Welding and Joining, 25(3) (2020) 208–217.

J. Lee, I. Kim, J. Lee, M. Park, Y. Kim and C. Park, An experimental study on optimizing for tandem gas metal arc welding process, Journal of the Korean Welding and Joining Society, 32(2) (2014) 22–28.

C. F. Fang, X. H. Meng, Q. X. Hu, F. J. Wang, H. Ren, H. S. Wang, Y. Guo and M. Mao, Tandem and GMAW twin wire welding of Q690 steel used in hydraulic support, Journal of Iron and Steel Research International, 19(5) (2012) 79–85.

D. Chen, M. Chen and C. Wu, Effects of phase difference on the behavior of arc and weld pool in tandem P-GMAW, Journal of Materials Processing Technology, 225 (2015) 45–55.

T. Ueyama, T. Uezono, T. Era, M. Tanaka and K. Nakata, Solution to problems of arc interruption and arc length control in tandem pulsed gas metal arc welding, Science and Technology of Welding and Joining, 14(4) (2013) 305–314.

M. Häßler, S. Rose and U. Füssel, The influence of arc interactions and a central filler wire on shielding gas flow in tandem GMAW, Welding in the World, 60(4) (2016) 713–718.

D. Ye, X. Hua, C. Xu, F. Li and Y. Wu, Research on arc interference and welding operating point change of twin wire MIG welding, The International Journal of Advanced Manufacturing Technology, 89(1–4) (2016) 493–502.

J. Cho and S. J. Na, Three-dimensional analysis of molten pool in GMA-laser hybrid welding, Welding Journal, 88(2) (2009) 35–43.

D. W. Cho, S. J. Na, M. H. Cho and J. S. Lee, Simulations of weld pool dynamics in V-groove GTA and GMA welding, Welding in the World, 57(2) (2013) 223–233.

W. Zhang, C. Kim and T. Debroy, Heat and fluid flow in complex joints during gas metal arc welding—part I: numerical model of fillet welding, Journal of Applied Physics, 95 (2004) 5210–5219.

W. Zhang, C. H. Kim and T. Debroy, Heat and fluid flow in complex joints during gas metal arc welding—part II: application to fillet welding of mild steel, Journal of Applied Physics, 95(9) (2004) 5220–5229.

M. Hertel, A. Spille-Kohoff, U. Füssel and M. Schnick, Numerical simulation of droplet detachment in pulsed gas-metal arc welding including the influence of metal vapour, Journal of Physics D: Applied Physics, 46 (22) (2013).

Y. Zhao and H. Chung, Numerical simulation of the transition of metal transfer from globular to spray mode in gas metal arc welding using phase field method, Journal of Materials Processing Technology, 251 (2018) 251–261.

A. B. Murphy, A self-consistent three-dimensional model of the arc, electrode and weld pool in gas-metal arc welding, Journal of Physics D: Applied Physics, 44 (19) (2011).

X. Ding, H. Li, L. Yang and Y. Gao, Numerical simulation of metal transfer process in tandem GMAW, The International Journal of Advanced Manufacturing Technology, 69(1–4) (2013) 107–112.

M. Schnick, G. Wilhelm, M. Lohse, U. Füssel and A. B. Murphy, Three-dimensional modelling of arc behaviour and gas shield quality in tandem gas-metal arc welding using antiphase pulse synchronization, Journal of Physics D: Applied Physics, 44 (18) (2011).

M. Schnick, U. Fuessel, M. Hertel, M. Haessler, A. Spille-Kohoff and A. B. Murphy, Modelling of gas-metal arc welding taking into account metal vapour, Journal of Physics D: Applied Physics, 43 (43) (2010).

Y. Kim, J. Lee, X. Liu, B. Lee and Y. Chang, Heat transfer enhancement in gas tungsten arc welding using azimuthal magnetic fields generated by external current, Coupled Systems Mechanics, 6(2) (2017) 113–125.

Acknowledgments

This work was supported by Korea Evaluation Institute of Industrial Technology (KEIT) grant funded by the Korea government (MOTIE) (No. 10062648).

Author information

Authors and Affiliations

Corresponding author

Additional information

Jin-young Kim is currently a Ph.D. candidate of Department of Mechanical Convergence Engineering, Hanyang University, Seoul, Korea. His research interests include welding, additive manufacturing, metallurgy, and multiphysics simulation.

Donghyun Van is a manager of Engineering Solution Team, Daewoo Engineering & Construction Co., Seoul, Korea. His research interests include welding, metallurgy, and multiphysics simulation.

Jaeyoung Lee is a graduate student of Department of Mechanical Convergence Engineering, Hanyang University, Seoul, Korea. His research interests include welding and multiphysics simulation.

Jonghyun Yim is a graduate student of Department of Mechanical Convergence Engineering, Hanyang University, Seoul, Korea. His research interests include welding, and additive manufacturing, metallurgy.

Seung Hwan Lee is a Professor of School of Mechanical Engineering, Hanyang University, Seoul, Korea. He received his Ph.D. in Mechanical Engineering from University of Michigan. His research interests include additive manufacturing, laser process, metallurgy, and artificial Intelligent.

Rights and permissions

About this article

Cite this article

Kim, Jy., Van, D., Lee, J. et al. The effect of a hot-wire in the tandem GMAW process ascertained by developing a multiphysics simulation model. J Mech Sci Technol 35, 267–273 (2021). https://doi.org/10.1007/s12206-020-1226-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-1226-9