Abstract

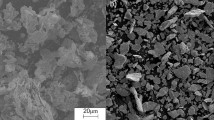

In this study, aluminum hybrid composites were developed by the powder metallurgy in which Si3N4 and ZrO2 were used as reinforcements. The synthesized composite powder as per weight percentage of the reinforcements milled in a centrifugal ball mill at 600 rpm for 0.5 and 2.5 h and then compacted at 420 MPa. The compacted composites were kept in a tube furnace for sintering at 550°C under controlled environment conditions for 30 min. The influence of the milling time and wt % of the reinforcements was investigated in relation of the effect on the microstructure, density, and hardness of the composites. The SEM images indicated that the Si3N4/ZrO2 particles were homogeneously mixed with the matrix and the reduction of clusters also observed with increasing the milling time. It was also observed that high milling time and wt % of high-density reinforcements increase the density of the composites, and the porosity decreases. Finally, it was found that the micro-hardness also improved with fine homogeneous and high-strength ceramic reinforcements embedded in the matrix.

Similar content being viewed by others

REFERENCES

M. T. Khorshid, S. A. J. Jahromi, and M. M. Moshksar, “Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion,” Mater. Des. 31, 3880–3884 (2010). https://doi.org/10.1016/j.matdes.2010.02.047

J. Singh and A. Chauhan, “Characterization of hybrid aluminum matrix composites for advanced applications—A review,” J. Mater. Res. Technol. 5, 159–169 (2016). https://doi.org/10.1016/j.jmrt.2015.05.004

V. V. Vani and S. K. Chak, “The effect of process parameters in aluminum metal matrix composites with powder metallurgy,” Manuf. Rev. 5, 7 (2018). https://doi.org/10.1051/mfreview/2018001

M. K. Surappa, “Aluminum matrix composites: challenges and opportunities,” Sadhana 28, 319–334 (2003). https://doi.org/10.1007/BF02717141

S. Sivakumar, S. K. Thimmappa, and B. R. Golla, “Corrosion behavior of extremely hard Al–Cu/Mg–SiC light metal alloy composites,” J. Alloys Compd. 767, 703–711 (2018). https://doi.org/10.1016/j.jallcom.2018.07.117

N. Panwar and A. Chauhan, “Fabrication methods of particulate reinforced Aluminum metal matrix composite—A review,” Mater. Today Proc. 5, 5933–5939 (2018). https://doi.org/10.1016/j.matpr.2017.12.194

S. M. Zebarjad and S. A. Sajjadi, “Dependency of physical and mechanical properties of mechanical alloyed Al–Al2O3 composite on milling time,” Mater. Des. 28, 2113–2120 (2007). https://doi.org/10.1016/j.matdes.2006.05.020

A. Parveen, N. R. Chauhan, and M. Suhaib, “Study of Si3N4 reinforcement on the morphological and tribo-mechanical behaviour of aluminum matrix composites,” Mater. Res. Express 6, 42001 (2019). https://doi.org/10.1088/2053-1591/aaf8d8

C. V. V. V. Mahesh Kumar, “A comprehensive review on material selection, processing, characterization and applications of aluminum metal matrix composites, Mater. Res. Express 6, (2019). https://doi.org/10.1088/2053-1591/ab0ee3

G. P. Zhang, Q. S. Mei, C. L. Li, F. Chen, X. M. Mei, J. Y. Li, and X. F. Ruan, “Fabrication and properties of Al–TiAl3–Al2O3 composites with high content of reinforcing particles by accumulative roll-bonding and spark plasma sintering,” Mater. Today Commun. 24, (2020). https://doi.org/10.1016/j.mtcomm.2020.101060

P. S. Bains, S. S. Sidhu, and H. S. Payal, “Fabrication and machining of metal matrix composites: A review,” Mater. Manuf. Process. 31, 553–573 (2016). https://doi.org/10.1080/10426914.2015.1025976

M. O. Bodunrin, K. K. Alaneme, and L. H. Chown, “Aluminium matrix hybrid composites: A review of reinforcement philosophies; Mechanical, corrosion and tribological characteristics,” J. Mater. Res. Technol. 4, 434–445 (2015). https://doi.org/10.1016/j.jmrt.2015.05.003

J. M. Torralba, C. E. Da Costa, and F. Velasco, “P/M aluminum matrix composites: An overview,” J. Mater. Process. Technol. 133, 203–206 (2003). https://doi.org/10.1016/S0924-0136(02)00234-0

P. Samal, P. R. Vundavilli, A. Meher, and M. M. Mahapatra, “Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties,” J. Manuf. Process. 59, 131–152 (2020). https://doi.org/10.1016/j.jmapro.2020.09.010

P. Sharma, D. Khanduja, and S. Sharma, “Tribological and mechanical behavior of particulate aluminum matrix composites,” J. Reinf. Plast. Compos. 33, 2192–2202 (2014). https://doi.org/10.1177/0731684414556012

V. Umasankar, “Experimental evaluation of the influence of processing parameters on the mechanical properties of SiC particle reinforced AA6061 aluminum alloy matrix composite by powder processing,” J. Alloys Compd. 582, 380–386 (2014). https://doi.org/10.1016/j.jallcom.2013.07.129

Y. Afkham, R. A. Khosroshahi, R. Kheirifard, R. T. Mousavian, and D. Brabazon, Microstructure and morphological study of ball-milled metal matrix nanocomposites, Phys. Met. Metallogr. 118 (2017) 749–758. https://doi.org/10.1134/S0031918X17080026

M. A. Eremina, S. F. Lomaeva, S. N. Paranin, S. L. Demakov, and E. P. Elsukov, “Effect of compaction method on the structure and properties of bulk Cu + Cr3C2 composites,” Phys. Met. Metallogr. 117, 510–517 (2016). https://doi.org/10.1134/S0031918X16050057

J. S. Benjamin and T. E. Volin, “The mechanism of mechanical alloying,” Met. Trans. 5, 1929–1934 (1974). https://doi.org/10.1007/BF02644161

C. Suryanarayana, “Mechanical alloying and milling,” Prog. Mater. Sci. 46, 1–184 (2001). https://doi.org/10.1016/S0079-6425(99)00010-9

J. W. Kaczmar, K. Pietrzak, and W. Wlosinski, “The production and application of metal matrix composite materials,” J. Mater. Process. Technol. 106, 58–67 (2000). https://doi.org/10.1016/S0924-0136(00)00639-7

J. Fogagnolo, F. Velasco, M. Robert, and J. Torralba, “Effect of mechanical alloying on the morphology, microstructure and properties of aluminum matrix composite powders,” Mater. Sci. Eng., A 342, 131–143 (2003). https://doi.org/10.1016/S0921-5093(02)00246-0

H. Arik, “Effect of mechanical alloying process on mechanical properties of a-Si3N4 reinforced aluminum-based composite materials,” Mater. Des. 29, 1856–1861 (2008). https://doi.org/10.1016/j.matdes.2008.03.010

A. Fathy, A. Wagih, M. Abd El-Hamid, and A. A. Hassan, “Effect of mechanical milling on the morphology and structural evaluation of Al–Al2O3 nanocomposite powders,” Int. J. Eng. Trans. A 27, 625–632 (2014). https://doi.org/10.5829/idosi.ije.2014.27.04a.14

E. Dagasan, E. Gercekcioglu, and S. Unalan, “Characterization of ball milled Al–Al2O3 sub-micron composites,” in IOP Conf. Ser. Mater. Sci. Eng. 295, (2018). https://doi.org/10.1088/1757-899X/295/1/012045.

K. Goyal and K. Marwaha, “Processing and Properties of aluminum matrix composites : A short review,” Eur. J. Adv. Eng. Technol. 3, 54–59 (2016).

D. Nayak and M. Debata, “Effect of composition and milling time on mechanical and wear performance of copper-graphite composites processed by powder metallurgy route,” Powder Metall. 57, 265–273 (2014). https://doi.org/10.1179/1743290113Y.0000000080

S. Karthkeyan, R. Karunanithi, and A. Ghosh, “Investigation on microstructures, mechanical and wear properties of Al 390/ZrO2 composite materials fabricated by P/M method,” Multidiscip. Model. Mater. Struct. 17, (2020). https://doi.org/10.1108/MMMS-10-2019-0180

Udaya and P. Fernandes, “Effect of fly ash and ball milling time on CNT-FA reinforced aluminum matrix hybrid composites,” Mater. Res. Express. 6, 085027 (2019). https://doi.org/10.1088/2053-1591/ab1e20

V. S. Ekinci, C. Baǧci, and H. Arik, “Effect of Al2O3 content and milling time on microstructure and mechanical properties of aluminum metal matrix composites,” Exp. Technol. 38, 66–73 (2014). https://doi.org/10.1111/j.1747-1567.2011.00790.x

J. B. Fogagnolo, E. M. Ruiz-Navas, M. H. Robert, and J. M. Torralba, “6061 Al reinforced with silicon nitride particles processed by mechanical milling,” Scr. Mater. 47, 243–248 (2002). https://doi.org/10.1016/S1359-6462(02)00133-1

J. B. Fogagnolo; M. H. Robert, and J. M. Torralba, “The effects of mechanical alloying on the extrusion process of AA 6061 alloy reinforced with Si3N4,” J. Braz. Soc. Mech. Sci. Eng., 1–11 (2003).

A. Fathy, O. Elkady, and A. Abu-Oqail, “Production and properties of Cu–ZrO2 nanocomposites,” J. Compos. Mater. 52, 1519–1529 (2018). https://doi.org/10.1177/0021998317726148

M. Toozandehjani, K. A. Matori, F. Ostovan, S. A. Aziz, and M. S. Mamat, “Effect of milling time on the microstructure, physical and mechanical properties of Al–Al2O3 nanocomposite synthesized by ball milling and powder metallurgy,” Materials (Basel) 10, (2017). https://doi.org/10.3390/ma10111232

D. R. Amador and J. M. Torralba, “Morphological and microstructural characterisation of low-alloying Fe powder obtained by mechanical attrition,” J. Mater. Process. Technol. 143–144, 776–780 (2003). https://doi.org/10.1016/S0924-0136(03)00372-8

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parveen, A., Chauhan, N.R. & Suhaib, M. Influence of Process Parameters and Reinforcements on Aluminum Hybrid Composites Developed by Powder Metallurgy Process. Phys. Metals Metallogr. 122, 1007–1013 (2021). https://doi.org/10.1134/S0031918X21100094

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21100094