Abstract

This paper presents a review of various interlayers employed to enhance the properties of similar and dissimilar materials welded by resistance spot welding (RSW). The commonly used base materials are steel, Al alloys/steel, Al/Al alloys, Al/Ti alloys, Al/Mg alloys, etc., and the interlayers proposed by various researchers include Zn, Ni, Sn, galvanised steel, SS304, Al–Mg, AlSi12, graphene, carbon nanotube, etc. Microstructural changes due to the incorporation of various interlayers were observed, and the enhancement of different mechanical and surface properties was studied focusing on the weld joint. It also includes weld bonding, the role of different process parameters on the properties of the weldment, failure modes observed in tension or lap shear tests. Studies have shown that increasing the welding parameters and incorporating suitably selected materials in between the mating surfaces of the lap joint can significantly enhance the quality of the joint. For the dissimilar RSW of Al/steel, the usage of optimised morphology of the electrodes, RSW with the incorporation of cover plates, and the usage of various interlayers were observed to subdue the brittle intermetallic compounds formation and enhance the quality of joint in case of Al/Mg alloys.

Similar content being viewed by others

References

P.S. Wei, T.H. Wu, P.S. Wei, T.H. Wu, Electrical contact resistance effect on resistance spot welding. Int. J. Heat Mass Transf. 55, 3316 (2012)

P. Zhang, J. Xie, Y.X. Wang, J.Q. Chen, P. Zhang, J. Xie, Y.X. Wang, J.Q. Chen, Effects of welding parameters on mechanical properties and microstructure of resistance spot welded DP600 joints. Sci. Technol. Weld. Join. 16, 567 (2011)

S.M. Manladan, F. Yusof, S. Ramesh, M. Fadzil, Z. Luo, S. Ao, S.M. Manladan, F. Yusof, S. Ramesh, M. Fadzil, Z. Luo, S. Ao, A review on resistance spot welding of aluminum alloys. Int. J. Adv. Manuf. Technol. 90, 605 (2017)

S.M. Manladan, F. Yusof, S. Ramesh, M. Fadzil, S.M. Manladan, F. Yusof, S. Ramesh, M. Fadzil, A review on resistance spot welding of magnesium alloys. Int. J. Adv. Manuf. Technol. 86, 1805 (2016)

I.A. Soomro, S.R. Pedapati, I.A. Soomro, S.R. Pedapati, Application of in situ post weld heat treatment using double pulse technology and its effect on microstructure and mechanical performance of resistance spot welded HSLA350 steel. Int. J. Adv. Manuf. Technol. 105, 3249 (2019)

Y. Zhang, Z. Luo, Y. Li, Z.M. Liu, Z.Y. Huang, Y. Zhang, Z. Luo, Y. Li, Z.M. Liu, Z.Y. Huang, Microstructure characterization and tensile properties of Mg/Al dissimilar joints manufactured by thermo-compensated resistance spot welding with Zn interlayer. Mater. Des. 75, 166 (2015)

A. Jahandideh, M. Hamedi, S.A. Mansourzadeh, A. Rahi, A. Jahandideh, M. Hamedi, S.A. Mansourzadeh, A. Rahi, An experimental study on effects of post-heating parameters on resistance spot welding of SAPH440 steel. Sci. Technol. Weld. Join. 16, 669 (2011)

S. Fukumoto, T. Inuki, H. Tsubakino, K. Okita, M. Aritoshi, T. Tomita, S. Fukumoto, T. Inuki, H. Tsubakino, K. Okita, M. Aritoshi, T. Tomita, Evaluation of friction weld interface of aluminium to austenitic stainless steel joint. Mater. Sci. Technol. 13, 679 (1997)

N. Yurioka, N. Yurioka, Advances in physical metallurgy and processing of steels, physical metallurgy of steel weldability. ISIJ Int. 41, 566 (2001)

M. Pouranvari, M. Pouranvari, Critical assessment: dissimilar resistance spot welding of aluminium/steel: challenges and opportunities. Mater. Sci. Technol. U.K. 33, 1705 (2017)

R. Rafiei, A. Ostovari Moghaddam, M.R. Hatami, F. Khodabakhshi, A. Abdolahzadeh, A. Shokuhfar, R. Rafiei, A. Ostovari Moghaddam, M.R. Hatami, F. Khodabakhshi, A. Abdolahzadeh, A. Shokuhfar, Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int. J. Adv. Manuf. Technol. 90, 2785 (2017)

M. Kutsuna, R. Ichioka, M. Kutsuna, R. Ichioka, Dissimilar metal joining of steel and titanium by laser roll welding. Weld. World. 51, 5 (2007)

M.J. Rathod, M. Kutsuna, M.J. Rathod, M. Kutsuna, Joining of aluminum alloy 5052 and low-carbon steel by laser roll welding. Weld. Res. 1, 16S (2004)

A. Das, M. Shome, S.F. Goecke, A. De, A. Das, M. Shome, S.F. Goecke, A. De, Numerical modelling of gas metal arc joining of aluminium alloy and galvanised steels in lap joint configuration. Sci. Technol. Weld. Join. 21, 303 (2016)

L. Han, M. Thornton, D. Li, M. Shergold, L. Han, M. Thornton, D. Li, M. Shergold, Effect of governing metal thickness and stack orientation on weld quality and mechanical behaviour of resistance spot welding of AA5754 aluminium. Mater. Des. 32, 2107 (2011)

S. Heights, M. Rashid, S. Fukumoto, J. B. Medley, and Y. Zhou, Effect of lubrication on electrode life in resistance spot welding of aluminum alloys. 1 (2004).

I.K. Al Naimi, M.H. Al Saadi, K.M. Daws, N. Bay, I.K. Al Naimi, M.H. Al Saadi, K.M. Daws, N. Bay, Influence of surface pretreatment in resistance spot welding of aluminum AA1050. Prod. Manuf. Res. 3, 185 (2015)

R.S. Florea, C.R. Hubbard, K.N. Solanki, D.J. Bammann, W.R. Whittington, E.B. Marin, R.S. Florea, C.R. Hubbard, K.N. Solanki, D.J. Bammann, W.R. Whittington, E.B. Marin, Quantifying residual stresses in resistance spot welding of 6061–T6 aluminum alloy sheets via neutron diffraction measurements. J. Mater. Process. Technol. 212, 2358 (2012)

M. Rashid, M. Rashid, Some tribological influences on the electrode-worksheet interface during resistance spot welding of aluminum alloys. J. Mater. Eng. Perform. 20, 456 (2011)

A. Kanekawa, T. Tsuji, Y. Mimura, T. Murakami, X.W. Li, S. Wen, F. Shinozaki, A. Kanekawa, T. Tsuji, Y. Mimura, T. Murakami, X.W. Li, S. Wen, F. Shinozaki, The estimation of proliferative activity by PCNA and AgNORs in leukoplakia and squamous cell carcinoma of the oral cavity. Oncol. Rep. 2, 711 (1995)

Y. Cho, S.J. Hu, W. Li, Y. Cho, S.J. Hu, W. Li, Resistance spot welding of aluminium and steel: a comparative experimental study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 217, 1355 (2003)

Y. Cho, W. Li, S.J. Hu, Y. Cho, W. Li, S.J. Hu, Design of experiment analysis and weld lobe estimation for aluminum resistance spot welding. Weld. J. 85, 45s (2006)

S. Satonaka, C. Iwamoto, G.I. Murakami, Y. Matsumoto, S. Satonaka, C. Iwamoto, G.I. Murakami, Y. Matsumoto, Resistance spot welding of magnesium alloy sheets with cover plates. Weld. World. 56, 44 (2012)

V.A. Klimenov, K.A. Kurgan, A.V. Chumaevskii, A.A. Klopotov, S.F. Gnyusov, V.A. Klimenov, K.A. Kurgan, A.V. Chumaevskii, A.A. Klopotov, S.F. Gnyusov, Structure of Ti–6Al–4V nanostructured titanium alloy joint obtained by resistance spot welding. AIP Conf. Proc. 1698, 209 (2016)

H.C.C. Lin, C.A.A. Hsu, C.S.S. Lee, T.Y.Y. Kuo, S.L.L. Jeng, H.C.C. Lin, C.A.A. Hsu, C.S.S. Lee, T.Y.Y. Kuo, S.L.L. Jeng, Effects of zinc layer thickness on resistance spot welding of galvanized mild steel. J. Mater. Process. Technol. 251, 205 (2018)

M.R.R. Arghavani, M. Movahedi, A.H.H. Kokabi, M.R.R. Arghavani, M. Movahedi, A.H.H. Kokabi, Role of zinc layer in resistance spot welding of aluminium to steel. Mater. Des. 102, 106 (2016)

M. Sun, S.T. Niknejad, G. Zhang, M.K. Lee, L. Wu, Y. Zhou, M. Sun, S.T. Niknejad, G. Zhang, M.K. Lee, L. Wu, Y. Zhou, Microstructure and mechanical properties of resistance spot welded AZ31/AA5754 using a nickel interlayer. Mater. Des. 87, 905 (2015)

M. Sun, S.B. Behravesh, L. Wu, Y. Zhou, H. Jahed, M. Sun, S.B. Behravesh, L. Wu, Y. Zhou, H. Jahed, Fatigue behaviour of dissimilar Al 5052 and Mg AZ31 resistance spot welds with Sn-coated steel interlayer. Fatigue Fract. Eng. Mater. Struct. 40, 1048 (2017)

W. Zhang, D. Sun, L. Han, D. Liu, W. Zhang, D. Sun, L. Han, D. Liu, Interfacial microstructure and mechanical property of resistance spot welded joint of high strength steel and aluminium alloy with 4047 AlSi12 interlayer. Mater. Des. 57, 186 (2014)

M. Winnicki, A. Małachowska, M. Korzeniowski, M. Jasiorski, A. Baszczuk, M. Winnicki, A. Małachowska, M. Korzeniowski, M. Jasiorski, A. Baszczuk, Aluminium to steel resistance spot welding with cold sprayed interlayer. Surf. Eng. 34, 235 (2018)

P. Penner, L. Liu, A. Gerlich, Y. Zhou, P. Penner, L. Liu, A. Gerlich, Y. Zhou, Dissimilar resistance spot welding of aluminum to magnesium with Zn-coated steel interlayers. Weld. J. 93, 225 (2014)

A.M. Lakhani, P.H. Darji, A.M. Lakhani, P.H. Darji, Experimental investigation on resistance spot welding of aluminium alloy 6082T651 using interlayer of SS304. Int. J. Mech. Eng. Technol. 9, 313 (2018)

K.O. Cooke, T.I. Khan, K.O. Cooke, T.I. Khan, Resistance spot welding aluminium to magnesium using nanoparticle reinforced eutectic forming interlayers. Sci. Technol. Weld. Join. 23, 271 (2018)

I. Ibrahim, R. Ito, T. Kakiuchi, Y. Uematsu, K. Yun, C. Matsuda, I. Ibrahim, R. Ito, T. Kakiuchi, Y. Uematsu, K. Yun, C. Matsuda, Fatigue behaviour of Al/steel dissimilar resistance spot welds fabricated using Al–Mg interlayer. Sci. Technol. Weld. Join. 21, 223 (2016)

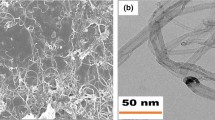

T. Das, R. Das, J. Paul, T. Das, R. Das, J. Paul, Resistance spot welding of dissimilar AISI-1008 steel/Al-1100 alloy lap joints with a graphene interlayer. J. Manuf. Process. 53, 260 (2020)

T. Das, S. Rawal, S. K. Panda, and J. Paul, Resistance spot-welding of AISI-1008 steel joints with MWCNT coating interlayer. Mater. Manuf. Process. 1 (2020).

C. Xu, C. Peng, C. Xu, C. Peng, Effect of Al interlayer on resistance spot welding of MB3/Ti6Al4V. Mater. Res. Express. 6, 1165a4 (2019)

R. Qiu, C. Iwamoto, S. Satonaka, R. Qiu, C. Iwamoto, S. Satonaka, Interfacial microstructure and strength of steel/aluminum alloy joints welded by resistance spot welding with cover plate. J. Mater. Process. Technol. 209, 4186 (2009)

L. Shao, Y. Shi, J.K. Huang, S.J. Wu, L. Shao, Y. Shi, J.K. Huang, S.J. Wu, Effect of joining parameters on microstructure of dissimilar metal joints between aluminum and galvanized steel. Mater. Des. 66, 453 (2015)

F. Hayat, B. Demir, M. Acarer, S. Aslanar, F. Hayat, B. Demir, M. Acarer, S. Aslanar, Effect of weld time and weld current on the mechanical properties of resistance spot welded IF (DIN EN 10130–1999) steel. Kov. Mater. 47, 11 (2009)

V. Firouzdor, S. Kou, V. Firouzdor, S. Kou, Al-to-Mg friction stir welding: Effect of material position, travel speed, and rotation speed. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 41, 2914 (2010)

X. Dai, H. Zhang, J. Liu, J. Feng, X. Dai, H. Zhang, J. Liu, J. Feng, Microstructure and properties of Mg/Al joint welded by gas tungsten arc welding-assisted hybrid ultrasonic seam welding. Mater. Des. 77, 65 (2015)

L. Liu, D. Ren, L. Liu, D. Ren, A novel weld-bonding hybrid process for joining Mg alloy and Al alloy. Mater. Des. 32, 3730 (2011)

L. Liu, L. Xiao, J.C. Feng, Y.H. Tian, S.Q. Zhou, Y. Zhou, L. Liu, L. Xiao, J.C. Feng, Y.H. Tian, S.Q. Zhou, Y. Zhou, Resistance spot welded AZ31 magnesium alloys, part II: effects of welding current on microstructure and mechanical properties. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 41, 2642 (2010)

M. Sun, S.T. Niknejad, H. Gao, L. Wu, Y. Zhou, M. Sun, S.T. Niknejad, H. Gao, L. Wu, Y. Zhou, Mechanical properties of dissimilar resistance spot welds of aluminum to magnesium with Sn-coated steel interlayer. Mater. Des. 91, 331 (2016)

P. Penner, L. Liu, A. Gerlich, Y. Zhou, P. Penner, L. Liu, A. Gerlich, Y. Zhou, Feasibility study of resistance spot welding of dissimilar Al/Mg combinations with Ni based interlayers. Sci. Technol. Weld. Join. 18, 541 (2013)

D. Sun, B. Lang, J. Li, D. Sun, B. Lang, J. Li, Microstructures and mechanical properties of resistance spot welded magnesium alloy joints. Mater. Sci. Eng. A. 460–461, 494 (2007)

L. Liu, S.Q. Zhou, Y.H. Tian, J.C. Feng, J.P. Jung, Y.N. Zhou, L. Liu, S.Q. Zhou, Y.H. Tian, J.C. Feng, J.P. Jung, Y.N. Zhou, Effects of surface conditions on resistance spot welding of Mg alloy AZ31. Sci. Technol. Weld. Join. 14, 356 (2009)

C. Composition and M. Properties, Aluminium 5754 Properties , Fabrication and Applications Chemical Composition of Aluminium 5754 Properties of Aluminium 5754 Mechanical Properties of Aluminium 5754 1 (2005).

M.R. Karimi, M. Sedighi, D. Afshari, M.R. Karimi, M. Sedighi, D. Afshari, Thermal contact conductance effect in modeling of resistance spot welding process of aluminum alloy 6061–T6. Int. J. Adv. Manuf. Technol. 77, 885 (2015)

Y. Feng, Z. Luo, Y. Li, Z. Ling, Y. Feng, Z. Luo, Y. Li, Z. Ling, A novel method for resistance plug welding of 7075 aluminum alloy. Mater. Manuf. Process. 31, 2077 (2016)

A.M. Pereira, J.M. Ferreira, A. Loureiro, J.D.M. Costa, P.J. Bártolo, A.M. Pereira, J.M. Ferreira, A. Loureiro, J.D.M. Costa, P.J. Bártolo, Effect of process parameters on the strength of resistance spot welds in 6082–T6 aluminium alloy. Mater. Des. 31, 2454 (2010)

W. Gaasior, Z. Moser, J. Pstruś, W. Gaasior, Z. Moser, J. Pstruś, Densities of solid aluminum-magnesium (Al–Mg) alloys. J. Phase Equilibria. 21, 167 (2000)

W.H. Zhang, X.M. Qiu, D.Q. Sun, L.J. Han, W.H. Zhang, X.M. Qiu, D.Q. Sun, L.J. Han, Effects of resistance spot welding parameters on microstructures and mechanical properties of dissimilar material joints of galvanised high strength steel and aluminium alloy. Sci. Technol. Weld. Join. 16, 153 (2011)

R. Qiu, H. Shi, K. Zhang, Y. Tu, C. Iwamoto, S. Satonaka, R. Qiu, H. Shi, K. Zhang, Y. Tu, C. Iwamoto, S. Satonaka, Interfacial characterization of joint between mild steel and aluminum alloy welded by resistance spot welding. Mater. Charact. 61, 684 (2010)

T. Das, B. Sahoo, P. Kumar, J. Paul, T. Das, B. Sahoo, P. Kumar, J. Paul, Effect of graphene interlayer on resistance spot welded AISI-1008 steel joints. Mater. Res. Express. 6, 0865c3 (2019)

T. Das, J. Paul, T. Das, J. Paul, Resistance spot welding of similar and dissimilar metals: the effect of graphene interlayer. JOM. 72, 2863 (2020)

C. Li, X. Yuan, K. Wu, H. Wang, Z. Hu, X. Pan, C. Li, X. Yuan, K. Wu, H. Wang, Z. Hu, X. Pan, Nugget formation and its mechanism of resistance spot welded joints in DP600 dual-phase and DC54D ultralow carbon steel. Met. Mater. Int. 23, 1 (2017)

V.H.L. Cortéz, F.A.R. Valdés, L.T. Treviño, V.H.L. Cortéz, F.A.R. Valdés, L.T. Treviño, Weldability of martensitic steel by resistance spot welding a neural network optimization in the automotive industry. Mater. Manuf. Process. 24, 1412 (2009)

U.R. Kattner, J.C. Lin, Y.A. Chang, U.R. Kattner, J.C. Lin, Y.A. Chang, Thermodynamic assessment and calculation of the Ti–Al system. Metall. Trans. A Phys. Metall. Mater. Sci. 23 A, 2081 (1992)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, T., Paul, J. Interlayers in Resistance Spot-Welded Lap Joints: A Critical Review. Metallogr. Microstruct. Anal. 10, 3–24 (2021). https://doi.org/10.1007/s13632-021-00714-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00714-0