Abstract

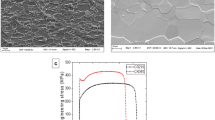

Lightweight materials such as high-strength steels and aluminum alloys are widely used in automotive components for the purposes of weight reduction and consequent higher fuel efficiency. As new alloys have been developed, magnesium alloys have become attractive for the production of automotive components due to their unique properties, such as high specific strength, damping capacity, and recyclability. In the assembly process of these materials, resistance spot welding (RSW) is used to construct thin sheet structures. Although RSW of steel sheets with high weld quality has already been established, the following problems remain with regard to RSW of magnesium alloys: high welding current, degeneration of electrodes, and blowholes and expulsion in or around the nugget. In this study, RSW with cover plates was applied to magnesium alloy sheets to investigate the performance of spot-welded joints. The weld quality was evaluated based on the tensile shear strength of the joints, the shape and the size of the nugget, and the appearance of blowholes and expulsion. Since RSW with cover plates is similar to conductive heat resistance seam welding (CHRSMW), the results showed that RSW with cover plates enabled the spot welding of a magnesium alloy with a large nugget and high tensile shear strength in the joint. It was also shown that blowhole-free spot welds with a large nugget and high tensile shear strength were obtained for welding currents above 8 000 A with a long down-slope time of welding current and a high electrode force.

Similar content being viewed by others

References

Kong X., Li B., Yang Q., Rothwell G., English R. and Ren X.J.: Numerical study of the effect of welding parameters on the strength of spot-welded joints, Applied Mechanics and Materials, 2008, vol. 10-12, pp. 322–326.

Oikawa H., Murayama G., Hiwatashi S. and Matsuyama K.: Resistance spot weldability of high strength steel sheets for automobiles and the quality assurance of joints, Doc. IIW-1783, Welding in the World, 2007, vol. 51, no. 3/4, pp. 7–18.

Cai H.N., Wang Y.S., Zhang Z.W. and Yang H.W.: Optimal spot welding parameters selection for automobile steel plate, Cailiao Gongcheng, Journal of Materials Engineering, July 2006, pp. 304-306.

Aslanlar S.: The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry, Materials and Design, 2006, vol. 27, no. 2, pp. 25–131.

Kim T., Park H. and Rhee S.: Optimization of welding parameters for resistance spot welding of TRIP steel with response surface methodology, International Journal of Production Research, 2005, vol. 43, no. 21, pp. 4643–4657.

Williams N.T. and Parker J.D.: Review of resistance spot welding of steel sheets: Part 1 — Modelling and control of weld nugget formation, International Materials Reviews, 2004, vol. 49, no. 2, pp. 45–75.

Harlin N., Jones T.B. and Parker J.D.: Weld growth mechanism of resistance spot welds in zinc coated steel, Journal of Materials Processing Technology, Dec. 2003, vol. 143-144, pp. 448–453.

Vural M. and Akkus A.: On the resistance spot weldability of galvanized interstitial free steel sheets with austenitic stainless steel sheets, Journal of Materials Processing Technology, Nov. 2004, vol. 153-154, pp. 1–6.

Fukumoto S., Lum I., Biro E., Boomer D.R. and Zhou Y.: Effects of electrode degradation on electrode life in resistance spot welding of aluminum alloy 5182, Welding Journal, 2003, vol. 82, no. 11, pp. 307s–312s

Hao M., Osman K.A., Moomer D.R. and Newton C.J.: Developments in characterization of resistance spot welding of aluminum, 1996, Welding Journal, vol. 75, no. 1, pp. 1–s–8–s.

Ji C.T. and Zhou Y.: Dynamic electrode force and dis- placement in resistance spot welding of aluminum, Journal of Manufacturing Science and Engineering, 2004, vol. 126, no. 3, pp. 605–610.

Hou Z.G., Wang Y.X., Li C.Z. and Chen C.Y.: An analysis of resistance spot welding, Welding Journal, 2006, vol. 85, no. 3, pp. 36–40.

Kawamura Y.: New magnesium alloys with long period stacking ordered structure, Keikinzoku/Journal of Japan Institute of Light Metals, 2004, vol. 54, pp. 503–504 (in Japanese).

Gould J.E. and Chokou W.: Investigating resistance and friction stir welding processes for joining magnesium, Welding Journal, 2006, vol. 85, no. 3, pp. 46–53.

Shi H.X., Qiu R.F., Zhu J.H., Zhang K., Yu H. and Ding G.J.: Effects of welding parameter on the characteristics of magnesium alloy joint welded by resistance spot welding with cover plates, Materials and Design, 2010, vol. 31, no. 10, pp. 4853–4857.

Sun D.Q., Lang B., Sun D.X. and Li J.B.: Microstructures and mechanical properties of resistance spot welded magnesium alloy joints, Materials Science and Engineering: A., 2007, vol. 460-461, pp. 494–498.

Wang Y.R., Mo Z.H., Feng J.C. and Zhang Z.D.: Effect of welding time on microstructure and tensile shear load in resistance spot welded joints of AZ31 Mg alloy, Science and Technology of Welding & Joining, 2007, vol. 12, no. 8, pp. 671–676.

Lang B., Sun D., Wu Q. and Xuan Z.: Optimization design of resistance spot welding parameters of magnesium alloy, China Welding, 2008, vol. 17, no. 1, pp. 49–56.

Lehman L.R. and Gould J.E.: Conductive heat resistance seam welding of aluminum, International Conference on Advances in Welding Technology: High-Productivity Joining Processes (ICAWT ’97), 1997, pp. 73-80.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Satonaka, S., Iwamoto, C., Murakami, Gi. et al. Resistance Spot Welding Of Magnesium Alloy Sheets with Cover Plates. Weld World 56, 44–50 (2012). https://doi.org/10.1007/BF03321364

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321364