Abstract

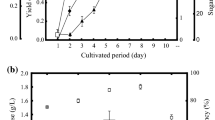

Durian is one important tropical fruit with high nutritional value, but its shell is usually useless and considered as waste. To explore the efficient and high-value utilization of this agricultural and food waste, in this study, durian shell was simply hydrolyzed by dilute sulfuric acid, and the durian shell hydrolysate after detoxification was used for bacterial cellulose (BC) production by Gluconacetobacter xylinus for the first time. BC was synthesized in static culture for 10 days and the highest BC yield (2.67 g/L) was obtained at the 8th day. The typical carbon sources in the substrate including glucose, xylose, formic acid, acetic acid, etc. can be utilized by G. xylinus. The highest chemical oxygen demand (COD) removal (16.40%) was obtained at the 8th day. The highest BC yield on COD consumption and the highest BC yield on sugar consumption were 93.51% and 22.98% (w/w), respectively, suggesting this is one efficient bioconversion for BC production. Durian shell hydrolysate showed small influence on the BC structure by comparison with the structure of BC generated in traditional Hestrin–Schramm medium detected by FE-SEM, FTIR, and XRD. Overall, this technology can both solve the issue of waste durian shell and produce valuable bio-polymer (BC).

Similar content being viewed by others

References

Chandra TC, Mirna M, Sudaryanto Y, Ismadji S (2007) Adsorption of basic dye onto activated carbon prepared from durian shell: studies of adsorption equilibrium and kinetics. Chem Eng J 127:121–129. doi:10.1016/j.cej.2006.09.011

Manshor MR, Anuar H, Nur Aimi MN, Ahmad Fitrie MI, Wan Nazri WB, Sapuan SM, EI-shekeil YA, Wahit MU (2014) Mechanical, thermal and morphological properties of durian skin fibre reinforced PLA biocomposites. Mater Des 59:279–286. doi:10.1016/j.matdes.2014.02.062

Zhao C, Cui XY, Liu Y, Zhang RH, He YF, Wang W, Chen C, Liu GQ (2017) Maximization of the methane production from durian shell during anaerobic digestion. Bioresour Technol 238:433–438. doi:10.1016/j.biortech.2017.03.184

Aimi NN, Anuar H, Manshor M, Nazri WW, Sapuan S (2014) Optimizing the parameters in durian skin fiber reinforced polypropylene composites by response surface methodology. Ind Crop Prod 54:291–295. doi:10.1016/j.indcrop.2014.01.016

Lazim ZM, Hadibarata T, Puteh MH, Yusop Z (2015) Adsorption characteristics of bisphenol a onto low-cost modified phyto-waste material in aqueous solution. Water Air Soil Pollut 226:1–11. doi:10.1007/s11270-015-2318-5

Tham Y, Latif PA, Abdullah AM, Shamala-Devi A, Taufiq-Yap Y (2011) Performances of toluene removal by activated carbon derived from durian shell. Bioresour Technol 102:724–728. doi:10.1016/j.biortech.2010.08.068

Amin AM, Ahmad AS, Yin YY, Yahya N, Ibrahim N (2007) Extraction, purification and characterization of durian (Durio zibethinus) seed gum. Food Hydrocoll 21:273–279. doi:10.1016/j.foodhyd.2006.04.004

Hameed B, Hakimi H (2008) Utilization of durian (Durio zibethinus Murray) peel as low cost sorbent for the removal of acid dye from aqueous solutions. Biochem Eng J 39:338–343. doi:10.1016/j.bej.2007.10.005

Hokputsa S, Gerddit W, Pongsamart S, Inngjerdingen K, Heinze T, Koschella A, Harding SE, Paulsen BS (2004) Water-soluble polysaccharides with pharmaceutical importance from Durian rinds (Durio zibethinus Murr.): isolation, fractionation, characterisation and bioactivity. Carbohydr Polym 56:471–481. doi:10.1016/j.carbpol.2004.03.018

Leontowicz H, Leontowicz M, Haruenkit R, Poovarodom S, Jastrzebski Z, Drzewiecki J, Ayala ALM, Jesion I, Trakhtenberg S, Gorinstein S (2008) Durian (Durio zibethinus Murr.) cultivars as nutritional supplementation to rat’s diets. Food Chem Toxicol 46:581–589. doi:10.1016/j.fct.2007.08.042

Chandra TC, Mirna MM, Sunarso J, Sudaryanto Y, Ismadji S (2009) Activated carbon from durian shell: preparation and characterization. J Taiwan Inst Chem Eng 40:457–462. doi:10.1016/j.jtice.2008.10.002

Chansiripornchai N, Chansiripornchai P, Pongsamart S (2007) A preliminary study of polysaccharide gel extracted from the fruit hulls of durian (Durio zibethinus) on immune responses and cholesterol reduction in chicken. In: International workshop on medicinal and aromatic plants, pp 57–61. doi:10.17660/ActaHortic.2008.786.4

Ho LH, Bhat R (2015) Exploring the potential nutraceutical values of durian (Durio zibethinus L.)—an exotic tropical fruit. Food Chem 168:80–89. doi:10.1016/j.foodchem.2014.07.020

Kurniawan A, Sisnandy VOA, Trilestari K, Sunarso J, Indraswati N, Ismadji S (2011) Performance of durian shell waste as high capacity biosorbent for Cr(VI) removal from synthetic wastewater. Ecol Eng 37:940–947. doi:10.1016/j.ecoleng.2011.01.019

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173. doi:10.1016/j.jrras.2014.02.003

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729. doi:10.1021/ie801542g

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37:19–27. doi:10.1016/j.renene.2011.06.045

Czaja W, Krystynowicz A, Bielecki S, Brownjr R (2006) Microbial cellulose—the natural power to heal wounds. Biomaterials 27:145–151. doi:10.1016/j.biomaterials.2005.07.035

Hu W, Chen S, Yang J, Li Z, Wang H (2014) Functionalized bacterial cellulose derivatives and nanocomposites. Carbohydr Polym 101:1043–1060. doi:10.1016/j.carbpol.2013.09.102

Mikkelsen D, Flanagan B, Dykes G, Gidley M (2009) Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524. J Appl Microbiol 107:576–583. doi:10.1111/j.1365-2672.2009.04226.x

Keshk S (2014) Vitamin C enhances bacterial cellulose production in Gluconacetobacter xylinus. Carbohydr Polym 99:98–100. doi:10.1016/j.carbpol.2013.08.060

Bae S, Shoda M (2004) Bacterial cellulose production by fed-batch fermentation in molasses medium. Biotechnol Prog 20:1366–1371. doi:10.1021/bp0498490

Kongruang S (2008) Bacterial cellulose production by Acetobacter xylinum strains from agricultural waste products. Appl Biochem Biotechnol 148:245–256. doi:10.1007/s12010-007-8119-6

Kuo C-H, Lin P-J, Lee C-K (2010) Enzymatic saccharification of dissolution pretreated waste cellulosic fabrics for bacterial cellulose production by Gluconacetobacter xylinus. J Chem Technol Biotehnol 85:1346–1352. doi:10.1002/jctb.2439

Moon S-H, Park J-M, Chun H-Y, Kim S-J (2006) Comparisons of physical properties of bacterial celluloses produced in different culture conditions using saccharified food wastes. Biotechnol Bioprocess Eng 11:26. doi:10.1007/BF02931864

Wang B, Qi G-X, Huang C, Yang X-Y, Zhang H-R, Luo J, Chen X-F, Xiong L, Chen X-D (2015) Preparation of bacterial cellulose/inorganic gel of bentonite composite by in situ modification. Indian J Microbiol 56:72–79. doi:10.1007/s12088-015-0550-8

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352. doi:10.1042/bj0580345

Wang B, Yang D, Zhang H-R, Huang C, Xiong L, Luo J, Chen X-D (2016) Preparation of esterified bacterial cellulose for improved mechanical properties and the microstructure of isotactic polypropylene/bacterial cellulose composites. Polymers 8:129. doi:10.3390/polym8040129

Yang XY, Huang C, Guo HJ, Xiong L, Li YY, Zhang HR, Chen XD (2013) Bioconversion of elephant grass (Pennisetum purpureum) acid hydrolysate to bacterial cellulose by Gluconacetobacter xylinus. J Appl Microbiol 115:995–1002. doi:10.1111/jam.12255

Frazer F, McCaskey T (1989) Wood hydrolyzate treatments for improved fermentation of wood sugars to 2, 3-butanediol. Biomass 18:31–42. doi:10.1016/0144-4565(89)90079-6

Martinez A, Rodriguez ME, Wells ML, York SW, Preston JF, Ingram LO (2001) Detoxification of dilute acid hydrolysates of lignocellulose with lime. Biotechnol Prog 17:287–293. doi:10.1021/bp0001720

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10. doi:10.1016/j.biortech.2003.10.005

Parajó J, Domínguez H, Domínguez J (1996) Charcoal adsorption of wood hydrolysates for improving their fermentability: influence of the operational conditions. Bioresour Technol 57:179–185. doi:10.1016/0960-8524(96)00066-1

Zhang W, Liu Z, Liu Z, Li F (2012) Butanol production from corncob residue using Clostridium beijerinckii NCIMB 8052. Lett Appl Microbiol 55:240–246. doi:10.1111/j.1472-765X.2012.03283.x

Huang C, Guo H-J, Xiong L, Wang B, Shi S-L, Chen X-F, Lin X-Q, Wang C, Luo J, Chen X-D (2016) Using wastewater after lipid fermentation as substrate for bacterial cellulose production by Gluconacetobacter xylinus. Carbohydr Polym 136:198–202. doi:10.1016/j.carbpol.2015.09.043

Zhang S, Winestrand S, Guo X, Chen L, Hong F, Jönsson LJ (2014) Effects of aromatic compounds on the production of bacterial nanocellulose by Gluconacetobacter xylinus. Microb Cell Fact 13:1–11. doi:10.1186/1475-2859-13-62

Huang H-J, Ramaswamy S, Tschirner U, Ramarao B (2008) A review of separation technologies in current and future biorefineries. Sep Purif Technol 62:1–21. doi:10.1016/j.seppur.2007.12.011

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24. doi:10.1016/S0960-8524(99)00160-1

Rubin EM (2008) Genomics of cellulosic biofuels. Nature 454:841–845. doi:10.1038/nature07190

Mamman AS, Lee JM, Kim YC, Hwang IT, Park NJ, Hwang YK, Chang JS, Hwang JS (2008) Furfural: hemicellulose/xylosederived biochemical. Biofuel Bioprod Bioresour 2:438–454. doi:10.1002/bbb.95

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16. doi:10.1186/1754-6834-6-16

Van Dyk JS, Pletschke BI (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes—factors affecting enzymes, conversion and synergy. Biotechnol Adv 30:1458–1480. doi:10.1016/j.biotechadv.2012.03.002

Liu YT, Wang YP, Liu HJ, Zhang JA (2015) Enhanced lipid production with undetoxified corncob hydrolysate by Rhodotorula glutinis using a high cell density culture strategy. Bioresour Technol 180:32–39. doi:10.1016/j.biortech.2014.12.093

Nakayama A, Kakugo A, Gong JP, Osada Y, Takai M, Erata T, Kawano S (2004) High mechanical strength double-network hydrogel with bacterial cellulose. Adv Funct Mater 14:1124–1128. doi:10.1002/adfm.200305197

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5:187–200. doi:10.1023/A:1009272904582

Hioki N, Hori Y, Watanabe K, Morinaga Y, Yoshinaga F, Hibino Y, Ogura T (1995) Bacterial cellulose; as a new material for papermaking. Jpn TAPPI J 49:718–723. doi:10.2524/jtappij.49.718

Acknowledgements

The authors acknowledge the financial support of the Science and Technology Project of Guangdong Province (2016A010105016), National Natural Science Foundation of China (21606229, 51378486, 31600475), project of Guangzhou Science and Technology (201610010014), Project of Huai-An Science and Technology (HAS2015035), Youth Innovation Promotion Association CAS (2015290), and Foundation of Director of Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences (y407r41001), Key Laboratory of Renewable Energy, Chinese Academy of Sciences (Y707j41001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, MT., Zhao, C., Huang, C. et al. Efficient Using Durian Shell Hydrolysate as Low-Cost Substrate for Bacterial Cellulose Production by Gluconacetobacter xylinus . Indian J Microbiol 57, 393–399 (2017). https://doi.org/10.1007/s12088-017-0681-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-017-0681-1