Abstract

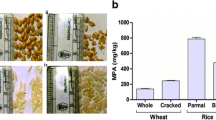

The Kluyveromyces marxianus yeast has been arousing great interest as a biocatalyst for biorefineries due to its ability to assimilate different sugars, in addition to its rapid growth, thermotolerance, and GRAS status. In this research, different sources of nutrients, such as rice bran and extracts of malt, yeast, and peptone, were evaluated for the cultivation of K. marxianus ATCC 36,907 aiming at ethanol production in submerged fermentations conducted in a batch system. Mineral supplementation of the medium was also evaluated. The best results of process performance for production, yield, and productivity in ethanol were obtained in the medium supplemented with rice bran extract, calcium chloride, and ammonium sulfate (25.50 g/L; Y(P/S) 0.49 g/g; QP 2.13 g/Lh), and the medium supplemented only with yeast-malt extract peptone (YMP) (24.88 g/L; Y(P/S) 0.50 g/g; QP 2.06 g/Lh), after 12 h of cultivation. Supplementation of the medium with malt extract without adding mineral salts also contributed to similar values of production and yield in ethanol after 24 h of cultivation (25.59 g/L; Y(P/S) 0.50 g/g; QP 1.16 g/Lh−1). The results revealed no need for mineral supplementation of the media added with YMP or malt extract for ethanol production by the yeast. On the other hand, rice bran extract, mainly associated with calcium chloride and ammonium sulfate, represents an excellent and inexpensive source of nutrients for this yeast and has the potential to replace traditional commercial supplements.

Similar content being viewed by others

Data availability

The datasets generated during the current study are available in the manuscript itself.

References

OECD/FAO (2020) OECD-FAO Agricultural Outlook 2020–2029. In: Table C.1 - World Cereal Proj. OECD-FAO Agric. Outlook 2020–2029. https://www.oecd-ilibrary.org/agriculture-and-food/oecd-fao-agricultural-outlook-2020-2029_1112c23b-en. Accessed 1 Apr 2022

Huang B, Huang C, Lyu Z et al (2018) Available energy and amino acid digestibility of defatted rice bran fed to growing pigs1. J Anim Sci 96:3138–3150. https://doi.org/10.1093/jas/sky191

Bodie AR, Micciche AC, Atungulu GG, et al (2019) Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Front Sustain Food Syst 3:Article 47. https://doi.org/10.3389/fsufs.2019.00047

SpaggiariDall’Asta MC, Galaverna G, del Castillo Bilbao MD (2021) Rice bran by-product: from valorization strategies to nutritional perspectives. Foods 10:85. https://doi.org/10.3390/foods10010085

Moriyama S, Fukumoto K, Taniguchi M et al (2013) Rice bran extract (RBE) as supplement for cell culture. BMC Proc 7:P106. https://doi.org/10.1186/1753-6561-7-S6-P106

Seyoum Y, Humblot C, Baxter BA, et al (2022) Metabolomics of rice bran differentially impacted by fermentation with six probiotics demonstrates key nutrient changes for enhancing gut health. Front Nutr 8:Article 795334. https://doi.org/10.3389/fnut.2021.795334

Narh C, Frimpong C, Mensah A, Wei Q (2018) Rice bran, an alternative nitrogen source for Acetobacter xylinum bacterial cellulose synthesis. BioResources 13:4346–4363. https://doi.org/10.15376/biores.13.2.4346-4363

Moreira VR, Lebron YAR, Freire SJ et al (2019) Evaluation of rice bran as a supplement for production of bioethanol by Saccharomyces cerevisiae. Floresta e Ambient 26:e20180423. https://doi.org/10.1590/2179-8087.042318

Mochidzuki K, Kobayashi S, Wang H et al (2015) Effect of rice bran as a nitrogen and carbohydrate source on fed-batch simultaneous saccharification and fermentation for the production of bioethanol from rice straw. J Japan Inst Energy 94:151–158. https://doi.org/10.3775/jie.94.151

Martiniano SE, Philippini RR, Chandel AK et al (2014) Evaluation of rice bran extract as a nitrogen source for improved hemicellulosic ethanol production from sugarcane bagasse by new xylose-fermenting yeast strains isolated from Brazilian forests. Sugar Tech 16:1–8. https://doi.org/10.1007/s12355-013-0219-8

da Silva DDV, de Cândido EJ, de Arruda PV et al (2014) New cultive medium for bioconversion of C5 fraction from sugarcane bagasse using rice bran extract. Brazilian J Microbiol 45:1469–1475. https://doi.org/10.1590/S1517-83822014000400043

Lane MM, Burke N, Karreman R et al (2011) Physiological and metabolic diversity in the yeast Kluyveromyces marxianus. Antonie Van Leeuwenhoek 100:507–519. https://doi.org/10.1007/s10482-011-9606-x

Ortiz-Merino RA, Varela JA, Coughlan AY, et al (2018) Ploidy variation in Kluyveromyces marxianus separates dairy and non-dairy isolates. Front Genet 9:Article 94. https://doi.org/10.3389/fgene.2018.00094

Arora R, Behera S, Sharma NK, Kumar S (2019) Evaluating the pathway for co-fermentation of glucose and xylose for enhanced bioethanol production using flux balance analysis. Biotechnol Bioprocess Eng 24:924–933. https://doi.org/10.1007/s12257-019-0026-5

Dasgupta D, Ghosh D, Bandhu S, Adhikari DK (2017) Lignocellulosic sugar management for xylitol and ethanol fermentation with multiple cell recycling by Kluyveromyces marxianus IIPE453. Microbiol Res 200:64–72. https://doi.org/10.1016/j.micres.2017.04.002

Lane MM, Morrissey JP (2010) Kluyveromyces marxianus: a yeast emerging from its sister’s shadow. Fungal Biol Rev 24:17–26. https://doi.org/10.1016/j.fbr.2010.01.001

Tseng C-C, Lin Y-J, Liu W et al (2020) Metabolic engineering probiotic yeast produces 3S, 3′S-astaxanthin to inhibit B16F10 metastasis. Food Chem Toxicol 135:110993. https://doi.org/10.1016/j.fct.2019.110993

da Silva FL, de Oliveira CA, dos Santos DA et al (2018) Valorization of an agroextractive residue-Carnauba straw for the production of bioethanol by simultaneous saccharification and fermentation (SSF). Renew Energy 127:661–669. https://doi.org/10.1016/j.renene.2018.05.025

da Costa Correia JA, de Sousa SJ, Gonçalves LRB, Rocha MVP (2020) Different design configurations of simultaneous saccharification and fermentation to enhance ethanol production from cashew apple bagasse pretreated with alkaline hydrogen peroxide applying the biorefinery concept. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00796-w

Lertwattanasakul N, Kosaka T, Hosoyama A et al (2015) Genetic basis of the highly efficient yeast Kluyveromyces marxianus: complete genome sequence and transcriptome analyses. Biotechnol Biofuels 8:47. https://doi.org/10.1186/s13068-015-0227-x

Wang D, Wu D, Yang X, Hong J (2018) Transcriptomic analysis of thermotolerant yeast Kluyveromyces marxianus in multiple inhibitors tolerance. RSC Adv 8:14177–14192. https://doi.org/10.1039/C8RA00335A

Mo W, Wang M, Zhan R et al (2019) Kluyveromyces marxianus developing ethanol tolerance during adaptive evolution with significant improvements of multiple pathways. Biotechnol Biofuels 12:63. https://doi.org/10.1186/s13068-019-1393-z

Li P, Tan X, Fu X et al (2021) Metabolomic analysis reveals Kluyveromyces marxianus’s stress responses during high-temperature ethanol fermentation. Process Biochem 102:386–392. https://doi.org/10.1016/j.procbio.2021.01.024

Tinôco D, da Silveira WB (2021) Kinetic model of ethanol inhibition for Kluyveromyces marxianus CCT 7735 (UFV-3) based on the modified Monod model by Ghose & Tyagi. Biologia (Bratisl) 76:3511–3519. https://doi.org/10.1007/s11756-021-00876-w

Lang X, Besada-Lombana PB, Li M et al (2020) Developing a broad-range promoter set for metabolic engineering in the thermotolerant yeast Kluyveromyces marxianus. Metab Eng Commun 11:e00145. https://doi.org/10.1016/j.mec.2020.e00145

Leonel LV, Arruda PV, Chandel AK et al (2021) Kluyveromyces marxianus: a potential biocatalyst of renewable chemicals and lignocellulosic ethanol production. Crit Rev Biotechnol 41:1131–1152. https://doi.org/10.1080/07388551.2021.1917505

Proust L, Sourabié A, Pedersen M, et al (2019) Insights into the complexity of yeast extract peptides and their utilization by Streptococcus thermophilus. Front Microbiol 10:Article 906. https://doi.org/10.3389/fmicb.2019.00906

Almeida ELM, Moreira e Silva G, Vassalli IA et al (2020) Effects of nitrogen supplementation on Saccharomyces cerevisiae JP14 fermentation for mead production. Food Sci Technol 40:336–343. https://doi.org/10.1590/fst.11219

Busti S, Mapelli V, Tripodi F et al (2016) Respiratory metabolism and calorie restriction relieve persistent endoplasmic reticulum stress induced by calcium shortage in yeast. Sci Rep 6:27942. https://doi.org/10.1038/srep27942

Guneser O, Yuceer YK, Hosoglu MI et al (2022) Production of flavor compounds from rice bran by yeasts metabolisms of Kluyveromyces marxianus and Debaryomyces hansenii. Brazilian J Microbiol. https://doi.org/10.1007/s42770-022-00766-6

Camargo D, Gomes SD, Sene L (2014) Ethanol production from sunflower meal biomass by simultaneous saccharification and fermentation (SSF) with Kluyveromyces marxianus ATCC 36907. Bioprocess Biosyst Eng 37:2235–2242. https://doi.org/10.1007/s00449-014-1201-x

Tavares B, Felipe MGA, dos Santos JC et al (2019) An experimental and modeling approach for ethanol production by Kluyveromyces marxianus in stirred tank bioreactor using vacuum extraction as a strategy to overcome product inhibition. Renew Energy 131:261–267. https://doi.org/10.1016/j.renene.2018.07.030

AOAC International (2016) Official Methods of analysis, 20th ed. AOAC INTERNATIONAL, Rockville, MD

Huang SC, Shiau CY, Liu TE et al (2005) Effects of rice bran on sensory and physico-chemical properties of emulsified pork meatballs. Meat Sci 70:613–619. https://doi.org/10.1016/j.meatsci.2005.02.009

Ademola Za A, Ganiyat Ta O (2008) Comparative utilization of biodegraded rice husk in the diets of Clarias gariepinus. J Fish Aquat Sci 3:312–319. https://doi.org/10.3923/jfas.2008.312.319

Palma M, Madeira SC, Mendes-Ferreira A, Sá-Correia I (2012) Impact of assimilable nitrogen availability in glucose uptake kinetics in Saccharomyces cerevisiae during alcoholic fermentation. Microb Cell Fact 11:99. https://doi.org/10.1186/1475-2859-11-99

Ciesarová Z, Šmogrovičová D, Dömény Z (1996) Enhancement of yeast ethanol tolerance by calcium and magnesium. Folia Microbiol (Praha) 41:485–488. https://doi.org/10.1007/BF02814663

Castillo-Plata AK, Sigala JC, Lappe-Oliveras P, Le Borgne S (2021) KCl/KOH supplementation improves acetic acid tolerance and ethanol production in a thermotolerant strain of Kluyveromyces marxianus isolated from henequen (Agave fourcroydes). Rev Mex Ing Química 21:1–18. https://doi.org/10.24275/rmiq/Bio2567

Santos J, Sousa MJ, Leão C (2012) Ammonium is toxic for aging yeast cells, inducing death and shortening of the chronological lifespan. PLoS One 7:e37090. https://doi.org/10.1371/journal.pone.0037090

de Melo AT, Martho KF, Roberto TN et al (2019) The regulation of the sulfur amino acid biosynthetic pathway in Cryptococcus neoformans: the relationship of Cys3, Calcineurin, and Gpp2 phosphatases. Sci Rep 9:11923. https://doi.org/10.1038/s41598-019-48433-5

Leonel LV, Sene L, da Cunha MAA et al (2020) Valorization of apple pomace using bio-based technology for the production of xylitol and 2G ethanol. Bioprocess Biosyst Eng 43:2153–2163. https://doi.org/10.1007/s00449-020-02401-w

Milessi TSS, Antunes FAF, Chandel AK, Silva SS (2013) Rice bran extract: an inexpensive nitrogen source for the production of 2G ethanol from sugarcane bagasse hydrolysate. 3 Biotech 3:373–379. https://doi.org/10.1007/s13205-012-0098-9

Zarei I, Brown DG, Nealon NJ, Ryan EP (2017) Rice bran metabolome contains amino acids, vitamins & cofactors, and phytochemicals with medicinal and nutritional properties. Rice 10:24. https://doi.org/10.1186/s12284-017-0157-2

Oda Y, Nakamura K, Shinomiya N, Ohba K (2010) Ethanol fermentation of sugar beet thick juice diluted with crude cheese whey by the flex yeast Kluyveromyces marxianus KD-15. Biomass Bioenerg 34:1263–1266. https://doi.org/10.1016/j.biombioe.2010.03.014

Clarke KG (2013) Microbiology. In: Clarke KG (ed) Bioprocess Engineering. Elsevier, pp 7–24

Demiray E, Ertuğrul Karatay S, Dönmez G (2020) Efficient bioethanol production from pomegranate peels by newly isolated Kluyveromyces marxianus. Energy Sources Part A Recover Util Environ Eff 42:709–718. https://doi.org/10.1080/15567036.2019.1600621

Jiang Y, Shi Y, Li R et al (2021) The peptides in oat and malt extracts that are preferentially absorbed by Lactobacillus plantarum and stimulates its proliferation in milk. Int J Food Sci Technol 56:4690–4699. https://doi.org/10.1111/ijfs.15140

Pentjuss A, Stalidzans E, Liepins J et al (2017) Model-based biotechnological potential analysis of Kluyveromyces marxianus central metabolism. J Ind Microbiol Biotechnol 44:1177–1190. https://doi.org/10.1007/s10295-017-1946-8

Sakihama Y, Hidese R, Hasunuma T, Kondo A (2019) Increased flux in acetyl-CoA synthetic pathway and TCA cycle of Kluyveromyces marxianus under respiratory conditions. Sci Rep 9:5319. https://doi.org/10.1038/s41598-019-41863-1

Silva GM, Giordano RLC, Cruz AJG, Ramachandriya KD et al (2015) Ethanol production from sugarcane bagasse using SSF process and thermotolerant yeast. Trans ASABE 58:193–200. https://doi.org/10.13031/trans.58.11024

Van Urk H, Voll WSL, Scheffers WA, Van Dijken JP (1990) Transient-state analysis of metabolic fluxes in crabtree-positive and crabtree-negative yeasts. Appl Environ Microbiol 56:281–287. https://doi.org/10.1128/aem.56.1.281-287.1990

Pessani NK, Atiyeh HK, Wilkins MR et al (2011) Simultaneous saccharification and fermentation of Kanlow switchgrass by thermotolerant Kluyveromyces marxianus IMB3: The effect of enzyme loading, temperature and higher solid loadings. Bioresour Technol 102:10618–10624. https://doi.org/10.1016/j.biortech.2011.09.011

Fu X, Li P, Zhang L, Li S (2019) Understanding the stress responses of Kluyveromyces marxianus after an arrest during high-temperature ethanol fermentation based on integration of RNA-Seq and metabolite data. Appl Microbiol Biotechnol 103:2715–2729. https://doi.org/10.1007/s00253-019-09637-x

Saini P, Beniwal A, Malik RK, Vij S (2017) Comparative physiology of Kluyveromyces marxianus and Saccharomyces cerevisiae during batch cultivation on glucose as a sole carbon source. Indian J Dairy Sci 70:427–433

Rodrussamee N, Lertwattanasakul N, Hirata K et al (2011) Growth and ethanol fermentation ability on hexose and pentose sugars and glucose effect under various conditions in thermotolerant yeast Kluyveromyces marxianus. Appl Microbiol Biotechnol 90:1573–1586. https://doi.org/10.1007/s00253-011-3218-2

Madeira-Jr JV, Gombert AK (2018) Towards high-temperature fuel ethanol production using Kluyveromyces marxianus: on the search for plug-in strains for the Brazilian sugarcane-based biorefinery. Biomass Bioenerg 119:217–228. https://doi.org/10.1016/j.biombioe.2018.09.010

Costa DA, de Souza CJA, Costa PS et al (2014) Physiological characterization of thermotolerant yeast for cellulosic ethanol production. Appl Microbiol Biotechnol 98:3829–3840. https://doi.org/10.1007/s00253-014-5580-3

Arora R, Behera S, Sharma NK, Kumar S (2017) Augmentation of ethanol production through statistically designed growth and fermentation medium using novel thermotolerant yeast isolates. Renew Energy 109:406–421. https://doi.org/10.1016/j.renene.2017.03.059

Funding

The authors are grateful to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for funding the scholarship of T.C. Pintro and L.V. Leonel (Financing Code 001).

Author information

Authors and Affiliations

Contributions

L. Sene and T.C. Pintro: experiment design; T.C. Pintro, L.V. Leonel, and S. Bender: investigation and laboratory analysis. T.C. Pintro: data analysis. L. Sene and T.C. Pintro: writing (original draft). L. Sene and M.A.A. Cunha: writing (review and editing).

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All the authors have read and understood the editorial policies for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sene, L., Pintro, T.C., Leonel, L.V. et al. Rice bran extract as an alternative nutritional supplement for Kluyveromyces marxianus. Biomass Conv. Bioref. 14, 11479–11489 (2024). https://doi.org/10.1007/s13399-022-03252-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03252-z