Abstract

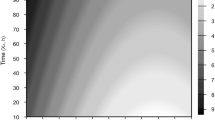

Bio-valorization approach of frying oil waste (FOW) to exploit it in different ways to produce added-value compounds is attractive from an economic and ecological standpoint. The aim of the current study was to investigate the incorporation of FOW in the fungal culture medium in order to develop feasible products such as single cell oils (SCOs), lipase, and citric acid (CA). According to response surface methodology (RSM), three independent variables have a significant effect on lipase and lipid accumulation by Lichtheimia corymbifera, namely, FOW amount (15 mL/L), ammonium sulfate concentration (5 g/L), and pH (6.0). The contour plots and 3D surface responses show the significant interaction of FOW amount and pH with ammonium sulfate concentration during lipase production. At these conditions, SCOs, lipase, and CA were produced with percentages 1.55 g/L, 54.3 U/mL, and 4.93 g/L, respectively. Fatty acid profile of the produced SCOs includes unsaturated fatty acids (USFAs) higher than saturated fatty acids (SFAs), which were 56.27 and 43.17% respectively. Furthermore, the dominant SFA is palmitic acid (29.22%), while the dominant USFA is oleic acid (30.78%). In conclusion, this study succeeded in valorization of FOW for SCOs, lipase, and CA in a one batch.

Graphical abstract

Similar content being viewed by others

References

Liu W, Yuan H (2020) Simultaneous production of hydrogen and carbon nanotubes from cracking of a waste cooking oil model compound over Ni-Co/SBA-15 catalysts. Int J Energy Res 44:11564–11582

Mannu A, Ferro M, Pietro MED, Mele A (2019) Innovative applications of waste cooking oil as raw material. Sci Prog 102:153–160

AbdElkodous M, El-Husseiny HM, El-Sayyad GS, Hashem AH, Doghish AS, Elfadil D, Radwan Y, El-Zeiny HM, Bedair H, Ikhdair OA (2021) Recent advances in waste-recycled nanomaterials for biomedical applications: waste-to-wealth. Nanotechnol Rev 10:1662–1739

Sanli H, Canakci M, Alptekin E (2011) Characterization of waste frying oils obtained from different facilities, World Renewable Energy Congress-Sweden; 8-13 May; 2011; Linköping; Sweden, Linköping University Electronic Press. pp. 479-485

Bhatia SK, Gurav R, Choi T-R, Kim HJ, Yang S-Y, Song H-S, Park JY, Park Y-L, Han Y-H, Choi Y-K, Kim S-H, Yoon J-J, Yang Y-H (2020) Conversion of waste cooking oil into biodiesel using heterogenous catalyst derived from cork biochar. Bioresour Technol 302:122872

Gui MM, Lee K, Bhatia S (2008) Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 33:1646–1653

Lin CSK, Pfaltzgraff LA, Herrero-Davila L, Mubofu EB, Abderrahim S, Clark JH, Koutinas AA, Kopsahelis N, Stamatelatou K, Dickson F (2013) Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ Sci 6:426–464

Papanikolaou S, Dimou A, Fakas S, Diamantopoulou P, Philippoussis A, Galiotou-Panayotou M, Aggelis G (2011) Biotechnological conversion of waste cooking olive oil into lipid-rich biomass using Aspergillus and Penicillium strains. J Appl Microbiol 110:1138–1150

Vastano M, Corrado I, Sannia G, Solaiman DK, Pezzella C (2019) Conversion of no/low value waste frying oils into biodiesel and polyhydroxyalkanoates. Sci Rep 9:1–8

Bhatia SK, Gurav R, Choi Y-K, Lee H-J, Kim SH, Suh MJ, Cho JY, Ham S, Lee SH, Choi K-Y, Yang Y-H (2021) Rhodococcus sp. YHY01 a microbial cell factory for the valorization of waste cooking oil into lipids a feedstock for biodiesel production. Fuel 301:121070

Nigam PS, Singh A (2011) Production of liquid biofuels from renewable resources. Prog Energy Combust Sci 37:52–68

C. Ratledge, J.P. Wynn, The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms, in: A.I. Laskin, J.W. Bennett, G.M. Gadd (Eds.) Advances in Applied Microbiology, Academic Press 2002, pp. 1–52.

Cho HU, Park JM (2018) Biodiesel production by various oleaginous microorganisms from organic wastes. Biores Technol 256:502–508

Subhash GV, Mohan SV (2011) Biodiesel production from isolated oleaginous fungi Aspergillus sp. using corncob waste liquor as a substrate. Bioresour Technol 102:9286–9290

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80:749–756

Bhatia SK, Vivek N, Kumar V, Chandel N, Thakur M, Kumar D, Yang Y-H, Pugazendhi A, Kumar G (2020) Molecular biology interventions for activity improvement and production of industrial enzymes. Bioresour Technol 324: 124596

Lopes M, Miranda SM, Belo I (2020) Microbial valorization of waste cooking oils for valuable compounds production–a review. Crit Rev Environ Sci Technol 50:2583–2616

Lopes M, Miranda SM, Alves JM, Pereira AS, Belo I (2019) Waste cooking oils as feedstock for lipase and lipid-rich biomass production. Eur J Lipid Sci Technol 121:1800188

Max B, Salgado JM, Rodríguez N, Cortés S, Converti A, Domínguez JM (2010) Biotechnological production of citric acid. Braz J Microbiol 41:862–875

Wang Q, Huang X, Long Y, Wang X, Zhang H, Zhu R, Liang L, Teng P, Zheng H (2013) Hollow luminescent carbon dots for drug delivery. Carbon 59:192–199

Kamzolova SV, Lunina JN, Morgunov IG (2011) Biochemistry of citric acid production from rapeseed oil by Yarrowia lipolytica yeast. J Am Oil Chem Soc 88:1965–1976

Liu X, Lv J, Xu J, Zhang T, Deng Y, He J (2015) Citric acid production in Yarrowia lipolytica SWJ-1b yeast when grown on waste cooking oil. Appl Biochem Biotechnol 175:2347–2356

Fouda A, Khalil A, El-Sheikh H, Abdel-Rhaman E, Hashem A (2015) Biodegradation and detoxification of bisphenol-A by filamentous fungi screened from nature. J Adv Biol Biotechnol 2: 123–132

Hasanin MS, Hashem AH (2020) Eco-friendly, economic fungal universal medium from watermelon peel waste. J Microbiol Methods 168:105802

Dacrory S, Hashem AH, Hasanin M (2021) Synthesis of cellulose based amino acid functionalized nano-biocomplex: characterization, antifungal activity, molecular docking and hemocompatibility. Environ Nanotechnol Monit Manag 15:100453

Hasanin M, Al Abboud MA, Alawlaqi MM, Abdelghany TM, Hashem AH (2021) Ecofriendly synthesis of biosynthesized copper nanoparticles with starch-based nanocomposite: antimicrobial, antioxidant, and anticancer activities. Biol Trace Element Res 1–14

Suleiman W, El-Skeikh H, Abu-Elreesh G, Hashem A (2018) Isolation and screening of promising oleaginous Rhizopus sp and designing of Taguchi method for increasing lipid production. J Innov Pharm Biol Sci 5:8–15

Miao X, Wu Q (2006) Biodiesel production from heterotrophic microalgal oil. Biores Technol 97:841–846

Suleiman W, El-Sheikh H, Abu-Elreesh G, Hashem A (2018) Recruitment of Cunninghamella echinulata as an Egyptian isolate to produce unsaturated fatty acids. Res J Pharm Biol Chem Sci 9:764–774

Hung T-C, Giridhar R, Chiou S-H, Wu W-T (2003) Binary immobilization of Candida rugosa lipase on chitosan. J Mol Catal B Enzym 26:69–78

Marier J, Boulet M (1958) Direct determination of citric acid in milk with an improved pyridine-acetic anhydride method. J Dairy Sci 41:1683–1692

El-Gamal MS, Desouky SE-S, Abdel-Rahman MA, Khattab A-RM (2018) Optimization of citric acid production from sugar cane molasses using a fungal isolate, Aspergillus fumigatus Na-1, Elect. J Biotechnol 15:519–532

Papanikolaou S, Galiotou-Panayotou M, Fakas S, Komaitis M, Aggelis G (2008) Citric acid production by Yarrowia lipolytica cultivated on olive-mill wastewater-based media. Biores Technol 99:2419–2428

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrika 33:305–325

Ahmed NE, Salem SS, Hashem AH (2021) Statistical optimization, partial purification, and characterization of phytase produced from Talaromyces purpureogenus NSA20 using potato peel waste and its application in dyes de-colorization. Biointerface Research in Applied Chemistry 12(4): 4417-4431

Hendy M, Hashem A, Sultan M, El-Ghamery A, Abdelraof M (2021) L-methionine γ-lyase from Thermo-tolerant fungi: isolation, identification of the potent producers, and statistical optimization of production via response surface methodology, Egyptian Journal of Chemistry (In Press)

Hashem AH, Suleiman WB, Abu-elreesh G, Shehabeldine AM, Khalil AMA (2020) Sustainable lipid production from oleaginous fungus Syncephalastrum racemosum using synthetic and watermelon peel waste media. Bioresour Technol Rep 12:100569

Hashem AH, Suleiman WB, Abu-Elrish GM, El-Sheikh HH (2020) Consolidated bioprocessing of sugarcane bagasse to microbial oil by newly isolated oleaginous fungus: Mortierella wolfii. Arab J Sci Eng 46(4): 1–13

Xiaoyan L, Yu X, Lv J, Xu J, Xia J, Wu Z, Zhang T, Deng Y (2017) A cost-effective process for the coproduction of erythritol and lipase with Yarrowia lipolytica M53 from waste cooking oil. Food Bioprod Process 103:86–94

Helal SE, Abdelhady HM, Abou-Taleb KA, Hassan MG, Amer MM (2017) Evaluation of factors affecting the fungal lipase production using one factor at a time approach and response surface methodology. Egypt J Microbiol 52:1–16

Ferreira AN, Ribeiro DDS, Santana RA, Santos Felix AC, Alvarez LDG, Lima EdO, De Freitas JS, Valasques Junior GL, Franco M, Nascimento Junior BBD (2017) Production of lipase from Penicillium sp using waste oils and Nopalea cochenillifera. Chem Eng Commun 204:1167–1173

Francisco JCE, Rivera WL, Vital PG (2020) Influences of carbohydrate, nitrogen, and phosphorus sources on the citric acid production by fungal endophyte Aspergillus fumigatus P3I6. Prep Biochem Biotechnol 50:292–301

Wang J, Luo T, Li S, Zhao J (2012) The powerful applications of polyunsaturated fatty acids in improving the therapeutic efficacy of anticancer drugs. Expert Opin Drug Deliv 9:1–7

Hashem AH, Hasanin MS, Khalil AMA, Suleiman WB (2019) Eco-green conversion of watermelon peels to single cell oils using a unique oleaginous fungus: Lichtheimia corymbifera AH13. Waste and Biomass Valorization 11(11): 5721–5732

Niu Y, Wu J, Wang W, Chen Q (2019) Production and characterization of a new glycolipid, mannosylerythritol lipid, from waste cooking oil biotransformation by Pseudozyma aphidis ZJUDM34. Food Sci Nutr 7:937–948

Awad GE, Mostafa H, Danial EN, Abdelwahed NA, Awad HM (2015) Enhanced production of thermostable lipase from Bacillus cereus ASSCRC-P1 in waste frying oil based medium using statistical experimental design. J Appl Pharm Sci 5:007–015

Taskin M, Ucar MH, Unver Y, Kara AA, Ozdemir M, Ortucu S (2016) Lipase production with free and immobilized cells of cold-adapted yeast Rhodotorula glutinis HL25, Biocatalysis and Agricultural. Biotechnology 8:97–103

Calvey CH, Su Y-K, Willis LB, McGee M, Jeffries TW (2016) Nitrogen limitation, oxygen limitation, and lipid accumulation in Lipomyces starkeyi. Biores Technol 200:780–788

Hossain M, Brooks J, Maddox I (1984) The effect of the sugar source on citric acid production by Aspergillus niger. Appl Microbiol Biotechnol 19:393–397

Rohr M, Kubicek CP (1981) Regulatory aspects of citric acid fermentation by Aspergillus niger. Process Biochem 16:34

Laffey SF, Butler G (2005) Phenotype switching affects biofilm formation by Candida parapsilosis. Microbiology 151:1073–1081

El-Gamal MS, Desouky SE-S, Abdel-Rahman MA, Khattab A-RM (2018) High-temperature citric acid production from sugar cane molasses using a newly isolated thermotolerant yeast strain, Candida parapsilosis NH-3. Int J Adv Res Biol Sci 5:187–211

Acknowledgements

The authors would also like to acknowledge the facilities available at the Faculty of Science (Boys), Al-Azhar University, and National Research Centre, Cairo, Egypt, for providing the necessary research facilities.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hashem, A.H., Khattab, A.M. & Abdelraof, M. A facile one-pot bioconversion of frying oil waste to single cell oils and related products using fungi via response surface methodology. Biomass Conv. Bioref. 13, 16711–16721 (2023). https://doi.org/10.1007/s13399-021-02165-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02165-7