Abstract

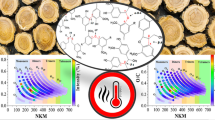

In order to strengthen the bio-based economy, it is necessary to produce value-added products by processing all fractions of the biomass, especially lignin. Isolation of lignin at atmospheric pressure and lower temperature will make it possible to recover lignin and use it for different purposes. In the present study, lignins were recovered from wood sawdust by applying six different organosolv treatments at atmospheric pressure. The lignins (ethanol organosolv lignin (EOL), alkaline glycerol organosolv lignin (AGOL), acetic acid organosolv lignin (AAOL), formic acid/acetic acid/water organosolv lignin (FAWOL 1 (40/40/20, v/v/v), FAWOL 2 (50/30/20, v/v/v), FAWOL 3 (30/50/20, v/v/v)) were compared in terms of yield, thermal properties, weight-average molecular weight, and fast pyrolysis properties. The effect of isolation method on lignin yield and structure was remarkable. Organosolv treatments at atmospheric conditions resulted in precipitation yields between 6.6% (ethanol organosolv) and 42% (alkaline glycerol organosolv). The lignin precipitated with the highest yield (AGOL) actually had the highest ash content (3.9%) and the lignin precipitated with the lowest yield (EOL) had the lowest ash content (1.2%). According to FTIR analysis, all lignins exhibited peaks at similar wavelengths but with different intensities. The weight-average molecular weight of lignins ranged between 1373 g/mol (AGOL) and 7400 g/mol (FAWOL 1). The polydispersity index of lignins ranged between 7.3 (FAWOL 1) and 2.5 (EOL and AAOL), where the lignins isolated from formic acid/acetic acid/water liquors showed higher polydispersity index compared to other lignins. Pyrolysis gas chromatography/mass spectrometry (Py-GC/MS) revealed that pyrolysis product distribution was strongly affected from the isolation method. The most abundant phenolic compound, which was observed in all lignins, was 2-methoxy-4-methylphenol (4-methylguaiacol), which was followed by 2-methoxy-4- (2-propenyl) phenol (eugenol) and guaiacol, respectively. It has been observed that each lignin is a good candidate for a different end-use due to their own characteristics.

Similar content being viewed by others

References

Den W, Sharma VK, Lee M, Nadadur G, Varma RS (2018) Lignocellulosic biomass transformations via greener oxidative pretreatment processes: access to energy and value-added chemicals. Front Chem 6:141. https://doi.org/10.3389/fchem.2018.00141

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6:4497–4559

Kandhola G, Djioleu A, Carrier DJ, Kim J-W (2017) Pretreatments for enhanced enzymatic hydrolysis of pinewood: a review. BioEnergy Res 10:1138–1154. https://doi.org/10.1007/s12155-017-9862-3

Peretti SW, Barton R and Mendonca RT (2016) Commercializing biobased products: opportunities, challenges, benefits, and risks. In: Snyder SW (ed) Lignin as feedstock for fibers and chemicals. RSC green chemistry no. 43. The Royal Society of Chemistry

Sun Z, Fridrich B, de Santi A, Elangovan S, Barta K (2018) Bright side of lignin depolymerization: toward new platform chemicals. Chem Rev 118:614–678. https://doi.org/10.1021/acs.chemrev.7b00588

Henriksson G, Li J, Zhang L and Lindström ME (2010) Thermochemical conversion of biomass to liquid fuels and chemicals. In: Crocker M (ed) RSC Energy and Environment Series No. 1, Royal Society of Chemistry, London

Azadi P, Inderwildi OR, Farnood R, King DA (2013) Liquid fuels, hydrogen and chemicals from lignin: a critical review. Renew Sust Energ Rev 21:506–523. https://doi.org/10.1016/j.rser.2012.12.022

Koumba-Yoya G, Stevanovic T (2017) Study of organosolv lignins as adhesives in wood panel production. Polymers 9:46. https://doi.org/10.3390/polym9020046

Mu L, Wu J, Matsakas L, Chen M, Vahidi A, Grahn M, Rova U, Christakopoulos P, Zhu J, Shi Y (2018) Lignin from hardwood and softwood biomass as a lubricating additive to ethylene glycol. Molecules 23:537. https://doi.org/10.3390/molecules23030537

Chen J, Kazzaz AE, Mazandarani NA, Feizi ZH, Fatehi P (2018) Production of flocculants, adsorbents, and dispersants from lignin. Molecules 23:868. https://doi.org/10.3390/molecules23040868

Witzler M, Alzagameem A, Bergs M, El Khaldi-Hansen B, Klein SE, Hielscher KB, Kreyenschmidt J, Tobiasch E, Schulze M (2018) Lignin-derived biomaterials for drug release and tissue engineering. Molecules 23:1885. https://doi.org/10.3390/molecules23081885

Gellerstedt G, Tomani P, Axegard P and Backlund B (2013) Integrated Forest biorefineries. In: Christopher L (ed) RSC Green Chemistry No. 18, The Royal Society of Chemistry, London

Hosseinaei O, Harper DP, Bozell JL, Rials TG (2016) Role of physicochemical structure of organosolv hardwood and herbaceous lignins on carbon fiber performance. ACS Sustain Chem Eng 4:5785–5798. https://doi.org/10.1021/acssuschemeng.6b01828

Suhas CPJM, Carrott MMLR (2007) Lignin-from natural adsorbent to activated carbon: a review. Bioresour Technol 98:2301–2312. https://doi.org/10.1016/j.biortech.2006.08.008

Wettstein SG, Alonso DM, Gürbüz EI, Dumesic JA (2012) A roadmap for conversion of lignocellulosic biomass to chemicals and fuels. Curr Opin Chem Eng 1:218–224

Tian D, Chandra RP, Lee J-S, Lu C, Saddler JN (2017) A comparison of various lignin-extraction methods to enhance the accessibility and ease of enzymatic hydrolysis of the cellulosic component of steam-pretreated poplar. Biotechnol Biofuels 10:157. https://doi.org/10.1186/s13068-017-0846-5

Ayyachamy M, Cliffe FE, Coyne JM, Collier J, Tuohy MG (2013) Lignin: untapped biopolymers in biomass conversion technologies. Biomass Convers Biorefin 3:255–269. https://doi.org/10.1007/s13399-013-0084-4

Capolupo L, Faraco V (2016) Green methods of lignocellulose pretreatment for biorefinery development. Appl Microbiol Biotechnol 100:9451–9467. https://doi.org/10.1007/s00253-016-7884-y

Kim J-Y, Choi JW (2019) Effect of molecular size of lignin on the formation of aromatic hydrocarbon during zeolite catalyzed pyrolysis. Fuel 240:92–100

Huang Y, Liu H, Yuan H, Zhuang X, Yuan S, Yin X, Wu C (2018) Association of chemical structure and thermal degradation of lignins from crop straw and softwood. J Anal Appl Pyrol 134:25–34. https://doi.org/10.1016/j.jaap.2018.04.008

Gonçalves AR, Benar P (2001) Hydroxymethylation and oxidation of Organosolv lignins and utilization of the products. Bioresour Technol 79:103–111

Zhang K, Pei Z, Wang D (2016) Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Bioresour Technol 199:21–33

Cheng F, Zhao X, Hu Y (2018) Lignocellulosic biomass delignification using aqueous alcohol solutions with the catalysis of acidic ionic liquids: a comparison study of solvents. Bioresour Technol 249:969–975

Shui T, Feng S, Yuan Z, Kuboki T, Xu C (2016) Highly efficient organosolv fractionation of cornstalk into cellulose and lignin in organic acids. Bioresour Technol 218:953–961

Thies MC, Klett AS (2016) Recovery of Low-Ash and Ultrapure Lignins from Alkaline Liquor By-Product Streams. In: Fang Z, Smith RL (eds) Production of Biofuels and Chemicals from Lignin. Springer, Singapore. https://doi.org/10.1007/978-981-10-1965-4_3

Wildschut J, Smit AT, Reith JH, Huijgen WJJ (2013) Ethanol-based organosolv fractionation of wheat straw for the production of lignin and enzymatically digestible cellulose. Bioresour Technol 135:58–66

Schulze P, Leschinsky M, Seidel-Morgenstern A, Lorenz H (2019) Continuous separation of lignin from organosolv pulping liquors: combined lignin particle formation and solvent recovery. Ind Eng Chem Res 58:3797–3810. https://doi.org/10.1021/acs.iecr.8b04736

Geng A, Xin F, Ip J (2012) Ethanol production from horticultural waste treated by a modified organosolv method. Bioresour Technol 104:715–721

Sun F, Chen H (2008) Organosolv pretreatment by crude glycerol from oleochemicals industry for enzymatic hydrolysis of wheat straw. Bioresour Technol 99:5474–5479

Moniz P, Lino J, Duarte LC, Roseiro LB, Boeriu CG, Pereira H, Carvalheiro F (2015) Fractionation of hemicelluloses and lignin from rice straw by combining autohydrolysis and optimized mild organosolv delignification. Bioresources 10(2):2626–2641

Bauer S, Sorek H, Mitchell VD, Ibańez AB, Wemmer DE (2012) Characterization of Miscanthus giganteus lignin isolated by ethanol organosolv process under reflux condition. J Agric Food Chem 60:8203–8212. https://doi.org/10.1021/jf302409d

Novo LP, Gurgel LVA, Marabezi K, Curvelo AADS (2011) Delignification of sugarcane bagasse using glycerol-water mixtures to produce pulps for saccharification. Bioresour Technol 102:10040–10046

Xu F, Sun J-X, Sun R, Fowler P, Baird MS (2006) Comparative study of organosolv lignins from wheat straw. Ind Crop Prod 23:180–193

American Society for Testing and Materials (ASTM) (2013) E871–82 Standard test method for moisture analysis of particulate wood fuels

American Society for Testing and Materials (ASTM) (2015) E1755–01 Standard test method for ash in biomass

American Society for Testing and Materials (ASTM) (2016) E1690–08 Standard test method for determination of ethanol extractives in biomass

TAPPI (2006) TAPPI Test method T 222 om-02-acid insoluble lignin in wood and pulp

Zhao X, Liu D (2010) Chemical and thermal characteristics of lignins isolated from Siam weed stem by acetic acid and formic acid delignification. Ind Crop Prod 32:284–291. https://doi.org/10.1016/j.indcrop.2010.05.003

Guragain YN, Bastola KP, Madl RL, Vadlani PV (2016) Novel biomass pretreatment using alkaline organic solvents: a green approach for biomass fractionation and 2,3-Butanediol production. Bioenergy Res 9:643–655. https://doi.org/10.1007/s12155-015-9706-y

Tolbert A, Akinosho H, Khunsupat R, Naskar AK, Ragauskas AJ (2014) Characterization and analysis of the molecular weight of lignin for biorefining studies. Biofuels Bioprod Biorefin 8:836–856. https://doi.org/10.1002/bbb.1500

Schulze P, Seidel-Morgenstern A, Lorenz H, Leschinsky M, Unkelbach G (2016) Advanced process for precipitation of lignin from ethanol organosolv spent liquors. Bioresour Technol 199:128–134. https://doi.org/10.1016/j.biortech.2015.09.040

Bär J, Phongpreecha T, Singh SK, Yılmaz MK, Foster CE, Crowe JD, Hodge DB (2018) Deconstruction of hybrid poplar to monomeric sugars and aromatics using ethanol organosolv fractionation. Biomass Convers Biorefin 8:813–824. https://doi.org/10.1007/s13399-018-0330-x

Katzen R, Frederickson RE, Brush BF (1980) Alcohol pulping appears feasible for small incremental capacity. Pulp Paper 54(8):144–149

Pan X, Xie D, Yu RW, Lam D, Saddler JN (2007) Pretreatment of lodgepole pine killed by mountain pine beetle using the ethanol organosolv process: fractionation and process optimization. Ind Eng Chem Res 46(8):2609–2617

Fernando EF, Vallejos EM, Area MC (2010) Lignin recovery from spent liquors from ethanol- water fractionation of sugar cane bagasse. Cellul Chem Technol 44(9):311–318

Rohde V, Hahn T, Wagner M, Böringer S, Tübke B, Brosse N, Dahmen N, Schmiedl D (2018) Potential of a short rotation coppice poplar as a feedstock for platform chemicals and lignin-based building blocks. Ind Crop Prod 123:698–706

Panamgama LA, Peramune P.R.U.S.K (2018) Coconut coir pith lignin: a physicochemical and thermal characterization. Int J Biol Macromol 113: 1149–1157

Sun FF, Wang L, Hong J, Ren J, Du F, Hu J, Zhang Z, Zhou B (2015) The impact of glycerol organosolv pretreatment on the chemistry and enzymatic hydrolyzability of wheat straw. Bioresour Technol 187:354–361

Sun FF, Tang S, Liu R, Tang Y, Wang R, Zhang Z, Gao Z, Li H, Li C, Xiao Z (2016) Biorefining fractionation of the Camellia oleifera Abel hull into diverse bioproducts with a two-stage organosolv extraction. Ind Crop Prod 94:790–799. https://doi.org/10.1016/j.indcrop.2016.09.062

Meighan BN et al (2017) Two-stage fractionation of sugarcane bagasse by autohydrolysis and glycerol organosolv delignification in a lignocellulosic biorefinery concept. Ind Crop Prod 108:431–441. https://doi.org/10.1016/j.indcrop.2017.06.049

Romaní A, Ruiz HA, Pereira FB, Domingues L, Teixeira JA (2013) Fractionation of Eucalyptus globulus wood by glycerol-water pretreatment: optimization and modeling. Ind Eng Chem Res 52:14342–14352. https://doi.org/10.1021/ie402177f

Todaka M, Kowhakul W, Masamoto H, Shigematsu M (2019) Delignification of softwood by glycerol from biodiesel by-product I: model reaction using glycerol and fatty acid sodium soap mixture for pretreatment on bioethanol production. J Wood Sci 65:49–49. https://doi.org/10.1186/s10086-019-1829-x

Saberikhah E, Rovshandeh JM, Rezayati-Charani P (2011) Organosolv pulping of wheat straw by glycerol. Cell Chem Technol 45(1–2):67–75

Scheepers JJ, Muzenda E (2015) Glycerol-a viable solvent for absorption of highly polar solutes I: behaviour of molecular interactions. J Clean Energy Technol 3(4):282–286. https://doi.org/10.7763/JOCET.2015.V3.209

Fernández-Rodríguez J, Erdocia X, Sánchez C, Alriols MG, Labidi J (2017) Lignin depolymerization for phenolic monomers production by sustainable processes. J Energy Chem 26:622–631

Avelino F, Silva KT, Mazzetto SE, Lomonaco D (2019) Tailor-made organosolv lignins from coconut wastes: effects of green solvents in microwave-assisted processes upon their structure and antioxidant activities. Bioresour Technol Rep 7:100219

Espinoza-Acosta JL, Torres-Chávez PI, Carvajal-Millán E, Ramírez-Wong B, Bello-Pérez LA, Montaño-Leyva B (2014) Ionic liquids and organic solvents for recovering lignin from lignocellulosic biomass. Bioresources 9(2):3660–3687

Monteil-Rivera F, Phuong M, Ye M, Halasz A, Hawari J (2013) Isolation and characterization of herbaceous lignins for applications in biomaterials. Ind Crop Prod 41:356–364

Ma Z, Wang J, Zhou H, Zhang Y, Yang Y, Liu X, Ye J, Chen D, Wang S (2018) Relationship of thermal degradation behavior and chemical structure of lignin isolated from palm kernel shell under different process severities. Fuel Process Technol 181:142–156. https://doi.org/10.1016/j.fuproc.2018.09.020

Li S-X, Li M-F, Bian J, Wu X-F, Peng F, Ma M-G (2019) Preparation of organic acid lignin submicrometer particle as a natural broad-spectrum photo-protection agent. Int J Biol Macromol 132:836–843

Wang S, Ru B, Lin H, Sun W, Luo Z (2015) Pyrolysis behaviors of four lignin polymers isolated from the same pine wood. Bioresour Technol 182:120–127. https://doi.org/10.1016/j.biortech.2015.01.127

El Khaldi-Hansen B, Schulze M, Kamm B (2016) Qualitative and quantitative analysis of lignins from different sources and isolation methods for an application as a biobased chemical resource and polymeric material. In: Vaz S Jr (ed) Analytical Techniques and Methods for Biomass. Springer, Switzerland

Zhang L, Yan L, Wang Z, Laskar DD, Swita MS, Cort JR, Yang B (2015) Characterization of lignin derived from water-only and dilute acid flowthrough pretreatment of poplar wood at elevated temperatures. Biotechnol Biofuels 8:203. https://doi.org/10.1186/s13068-015-0377-x

Romaní A, Ruiz HA, Teixeira JA, Domingues L (2016) Valorization of Eucalyptus wood by glycerol-organosolv pretreatment within the biorefinery concept: an integrated and intensified approach. Renew Energy 95:1–9. https://doi.org/10.1016/j.renene.2016.03.106

Wang K, Bauer S, Sun R (2012) Structural transformation of Miscanthus × giganteus lignin fractionated under mild formosolv, basic organosolv, and cellulolytic enzyme conditions. J Agric Food Chem 60:144–152. https://doi.org/10.1021/jf2037399

Sequeiros A, Labidi J (2017) Characterization and determination of the S/G ratio via Py-GC/MS of agricultural and industrial residues. Ind Crops Prod I 97:469–476. https://doi.org/10.1016/j.indcrop.2016.12.056

Maniet G, Schmetz Q, Jacquet N, Temmerman M, Gofflot S, Richel A (2017) Effect of steam explosion treatment on chemical composition and characteristic of organosolv fescue lignin. Ind Crop Prod 99:79–85

Perez-Cantu L, Schreiber A, Schütt F, Saake B, Kirsch C, Smirnova I (2013) Comparison of pretreatment methods for rye straw in the second generation biorefinery: effect on cellulose, hemicellulose and lignin recovery. Bioresour Technol 142:428–435

Wörmeyer K, Ingram T, Saake B, Brunner G, Smirnova I (2011) Comparison of different pretreatment methods for lignocellulosic materials. Part II: influence of pretreatment on the properties of rye straw lignin. Bioresour Technol 102:4157–4164

Vanderghem C, Richel A, Jacquet N, Blecker C, Paquot M (2011) Impact of formic/acetic acid and ammonia pre-treatments on chemical structure and physico-chemical properties of Miscanthus x giganteus lignins. Polym Degrad Stab 96:1761–1770. https://doi.org/10.1016/j.polymdegradstab.2011.07.022

Wild PJ, Huijgen WJJ, Heeres HJ (2012) Pyrolysis of wheat straw-derived organosolv lignin. J Anal Appl Pyrol 93:95–103

Naidu DS, Hlangothi SP, John MJ (2018) Bio-based products from xylan: a review. Carbohydr Polym 179:28–41

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Azeez AM, Meier D, Odermatt J, Willner T (2010) Fast pyrolysis of African and European lignocellulosic biomasses using Py-GC/MS and fluidized bed reactor. Energy Fuel 24:2078–2085

Zhang M, Resende FLP, Moutsoglou A, Raynie DE (2012) Pyrolysis of lignin extracted from prairie cordgrass, aspen, and Kraft lignin by Py-GC/MS and TGA/FTIR. J Anal Appl Pyrol 98:65–71

Custodis VBF, Bährle C, Vogel F, van Bokhoven JA (2015) Phenols and aromatics from fast pyrolysis of variously prepared lignins from hard- and softwoods. J Anal Appl Pyrol 115:214–223. https://doi.org/10.1016/j.jaap.2015.07.018

Chen W-H, Wang C-W, Ong HC, Show PL, Hsieh T-H (2019) Torrefaction, pyrolysis and two-stage thermodegradation of hemicellulose, cellulose and lignin. Fuel 258:116168. https://doi.org/10.1016/j.fuel.2019.116168

Lourenço A, Rencoret J, Chemetova C, Gominho J, Gutiérrez A, del Río JC, Pereira H (2016) Lignin composition and structure differs between xylem, phloem and Phellem in Quercus suber L. Front Plant Sci 7:1612. https://doi.org/10.3389/fpls.2016.01612

Shen D, Zhao J, Xia R (2016) Catalytic transformation of lignin to aromatic hydrocarbons over solid-acid catalyst: effect of lignin sources and catalyst species. Energy Convers Manag 124:61–72. https://doi.org/10.1016/j.enconman.2016.06.067

Moghaddam L, Rencoret J, Maliger VR, Rackemann DW, Harrison MD, Gutieŕrez A, del Río J, Doherty W (2017) Structural characteristics of bagasse furfural residue and its lignin component. An NMR, Py-GC/MS, and FTIR study. ACS Sustain Chem Eng 5:4846–4855. https://doi.org/10.1021/acssuschemeng.7b00274

Chen L, Wang X, Yang H, Lu Q, Li D, Yang Q, Chen H (2015) Study on pyrolysis behaviors of non-woody lignins with TG-FTIR and Py-GC/MS. J Anal Appl Pyrol 113:499–507. https://doi.org/10.1016/j.jaap.2015.03.018

Sjöström E (1993) Wood Chemistry-Fundamentals and Applications. Academic Press, San Diego

Pakdel H, Zhang H, Roy C (1994) Production and characterization of carboxylic acids from wood, part II: high molecular weight fatty and resin acids. Bioresour Technol 47:45–53

Funding

This research was financially supported by Yalova University Scientific Research Unit [Project No: 2017/AP/146].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 5789 kb)

Rights and permissions

About this article

Cite this article

Başakçılardan Kabakcı, S., Tanış, M.H. Pretreatment of lignocellulosic biomass at atmospheric conditions by using different organosolv liquors: a comparison of lignins. Biomass Conv. Bioref. 11, 2869–2880 (2021). https://doi.org/10.1007/s13399-020-00677-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00677-2