Abstract

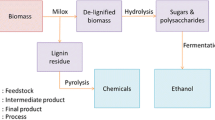

Valorization of each component of lignocellulosic biomass is critical for sustainability of biorefinery industries. Current biorefineries are confined to ethanol-centric processes and focus only on the carbohydrate-derived sugar using energy-intensive pretreatment methods, leading to deteriorated lignin quality for high-value applications. Organosolv fractionation is an effective method to improve hydrolysis efficiency of cellulose and extract a good quality lignin stream; however, hemicelluloses recovery is challenging if an acid catalyst is used. An alkali catalyst in the organosolv process, therefore, could be a promising alternative approach. We evaluated various organic solvents (glycerol, 2,3-butanediol, dimethyl sulfoxide, ethanol, butanol, isopropanol, acetonitrile, and water) for pretreatment of different biomass feedstocks, including corn stover (grass), poplar (hardwood), and Douglas fir (softwood) using sodium hydroxide as a catalyst. Results showed that an ethanol and isopropanol mixture led to 18 % more sugar released per gram of biomass than the control (conventional aqueous alkali pretreatment) for corn stover; a mixture of ethanol, butanol, and water was the next most effective solvent. For pretreatment of poplar biomass, glycerol and 2,3-butanediol were the most efficient solvents; glycerol pretreatment offers further process improvement opportunities. The organic solvents used in this experiment were not effective for Douglas fir. The quality of released sugars was statistically equal to that of synthetic sugars for 2,3-butanediol fermentation using Klebsiella oxytoca. This study opened up a promising route for high value application for all biomass components. Further research is needed to characterize the extracted lignin for quality evaluation.

Similar content being viewed by others

References

Guragain YN, Probst, KV, Vadlani, PV (2016) Fuel alcohol production. In: Corke H, Faubion J, Seethraman K, Wrigley C (eds) Encyclopedia of food grain. Elsevier, Oxford, United Kingdom. doi: 10.1016/B978-0-12-394437-5.00137-6

Hu F, Ragauskas A (2012) Pretreatment and lignocellulosic chemistry. Bioenergy Res 5:1043–1066

Casler MD, Mitchell R, Richardson J, Zalesny RS Jr (2009) Biofuels, bioenergy, and bioproducts from sustainable agricultural and forest crops. BioEnergy Res 2:77–78

Bozell JJ, Astner A, Baker D, Biannic B, Cedeno D, Elder T et al (2014) Integrating separation and conversion—conversion of biorefinery process streams to biobased chemicals and fuels. BioEnergy Res 7:856–866

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals and biorefinery concept. Prog Energy Combust 38:522–550

Beatson RP (2011) Chemicals from extractives. In: Zhu JY, Zhang X, Pan XJ (eds) Sustainable production of fuels, chemicals, and fibers from forest biomass. American Chemical Society, Washington, pp 279–297

Werpy T, Petersen G, Aden A, Bozell J, Holladay J, White J et al (2004) Top value added chemicals from biomass. Results of screening for potential candidates from sugars and synthesis gas, vol 1. US Department of Energy

Marshall J (2007) Biorefineries: curing our addiction to oil. New Sci 2611:28–31

Guragain YN, Ganesh K, Bansal S, Sathish RS, Rao N, Vadlani PV (2014) Low-lignin mutant biomass resources: effect of compositional changes on ethanol yield. Ind Crop Prod 61:1–8

Tomas-Pejo E, Oliva J, Ballesteros M (2008) Realistic approach for full-scale bioethanol production from lignocellulose: a review. J Sci Ind Res 67:874–884

Sattler SE, Palmer NA, Saballos A, Greene AM, Xin Z, Sarath G et al (2012) Identification and characterization of four missense mutations in brown midrib 12 (Bmr12), the Caffeic O-methyltransferase (COMT) of sorghum. Bioenergy Res 5:855–865

Dien BS, Sarath G, Pedersen JF, Sattler SE, Chen H, Funnell-Harris DL et al (2009) Improved sugar conversion and ethanol yield for forage sorghum (Sorghum bicolor L. Moench) lines with reduced lignin contents. Bioenergy Res 2:153–164

Yuan T, Sun S, Xu F, Sun R (2011) Characterization of lignin structures and lignin–carbohydrate complex (LCC) linkages by quantitative 13C and 2D HSQC NMR spectroscopy. J Agric Food Chem 59:10604–10614

Laskar DD, Yang B, Wang H, Lee J (2013) Pathways for biomass‐derived lignin to hydrocarbon fuels. Biofuels Bioprod Biorefin 7:602–626

Guragain YN, Herrera AI, Vadlani PV, Prakash O (2015) Lignins of bioenergy crops: a review. Nat Prod Commun 10:201–208

Ragauskas AJ, Beckham GT, Biddy MJ, Chandra R, Chen F, Davis MF et al (2014) Lignin valorization: improving lignin processing in the biorefinery. Science 344:1246843

Thring RW, Chornet E, Overend RP (1990) Recovery of a solvolytic lignin: effects of spent liquor/acid volume ratio, acid concentration and temperature. Biomass 23:289–305

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82:815–827

da Costa SL, Chundawat SP, Balan V, Dale BE (2009) ‘Cradle-to-grave’ assessment of existing lignocellulose pretreatment technologies. Curr Opin Biotechnol 20:339–347

Sun F, Chen H (2008) Enhanced enzymatic hydrolysis of wheat straw by aqueous glycerol pretreatment. Bioresour Technol 99:6156–6161

Guragain YN, De Coninck J, Husson F, Durand A, Rakshit SK (2011) Comparison of some new pretreatment methods for second generation bioethanol production from wheat straw and water hyacinth. Bioresour Technol 102:4416–4424

Diner BA, Fan J (2012) Organic solvent pretreatment of biomass to enhance enzymatic saccharification. US Patent US 2012/0270269 A1

Mosier N, Wyman C, Dale B, Elander R, Lee Y, Holtzapple M et al (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Alvira P, Tomás-Pejó E, Ballesteros M, Negro M Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Balakshin MY, Capanema EA, Chen C, Gracz HS (2003) Elucidation of the structures of residual and dissolved pine kraft lignins using an HMQC NMR technique. J Agric Food Chem 51:6116–6127

Li J, Gellerstedt G (2008) Improved lignin properties and reactivity by modifications in the autohydrolysis process of aspen wood. Ind Crop Prod 27:175–181

Xin F, Basu A, Weng MC, Yang K, He J (2015) Production of 2, 3-butanediol from sucrose by a Klebsiella species. BioEnergy Res 1–8. doi: 10.1007/s12155-015-9653-7

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D et al Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory (NREL) Laboratory Analytical Procedures (LAP) for standard biomass analysis 2007

Guragain YN, Wilson J, Staggenborg S, McKinney L, Wang D, Vadlani PV (2013) Evaluation of pelleting as a pre-processing step for effective biomass deconstruction and fermentation. Biochem Eng J 77:198–207

Rawat R, Kumbhar B, Tewari L (2013) Optimization of alkali pretreatment for bioconversion of poplar (Populus deltoides) biomass into fermentable sugars using response surface methodology. Ind Crop Prod 44:220–226

Jansen NB, Flickinger MC, Tsao GT (1984) Production of 2, 3‐butanediol from D‐xylose by Klebsiella oxytoca ATCC 8724. Biotechnol Bioeng 26:362–369

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of extractives in biomass. Laboratory Analytical Procedure (LAP) 1617

Chandel AK, Da Silva SS, Singh OV (2013) Detoxification of lignocellulose hydrolysates: biochemical and metabolic engineering toward white biotechnology. Bioenergy Res 6:388–401

Küçük MM (2005) Delignification of biomass using alkaline glycerol. Energy Sources 27:1245–1255

Ji X, Nie Z, Huang H, Ren L, Peng C, Ouyang P (2011) Elimination of carbon catabolite repression in Klebsiella oxytoca for efficient 2, 3-butanediol production from glucose-xylose mixtures. Appl Microbiol Biotechnol 89:1119–1125

Acknowledgments

This work was funded by the Development Initiative Competitive Grants Program (BRDI; grant number: 2012-10008-20263), and the Small Business Innovation Research (SBIR), Department of Navy, grant number: N68335-13-C-0174. The authors are also grateful to Novozymes Inc. for the donation of enzyme samples. Author PVV thanks the Lortscher Endowment for their support. The authors are thankful to Edenspace Inc., Manhattan, Kansas, for proving the poplar sample and Dr. Michael Wolcott, Washington State University, Pullman, Washington for the Douglas fir sample. This manuscript is contribution number 16-106-J from the Kansas Agricultural Experiment Station.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• Alkaline organic solvent pretreatment is an effective method for valorization of each component of lignocellulosic biomass.

• Effectiveness of various organic solvents differed significantly among biomass types.

• A mixture of ethanol and isopropanol was a promising solvent system for corn stover (grass), and glycerol was the most favorable solvent for poplar (hardwood), while none of the solvents used in this study were effective for Douglas fir (softwood).

• The quality of released sugar was statistically equal to synthetic sugar for 2,3-butanediol fermentation.

Rights and permissions

About this article

Cite this article

Guragain, Y.N., Bastola, K.P., Madl, R.L. et al. Novel Biomass Pretreatment Using Alkaline Organic Solvents: A Green Approach for Biomass Fractionation and 2,3-Butanediol Production. Bioenerg. Res. 9, 643–655 (2016). https://doi.org/10.1007/s12155-015-9706-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9706-y