Abstract

This paper presents a study on Hybrid Electrically Conductive Adhesive (HECA) properties as an in-depth analysis regarding hybrid filler ratio at low filler range. It is well established that the hybridization approach exhibits excellent functional properties of HECA. Still, the highest potential ability of the proposed HECA concerning relative amounts of involving fillers is the least being discovered. In this work, silver micro-flake (AgMF) and multiwalled carbon nanotube (MWCNT) conductive fillers were incorporated from 3 to 15 wt.%, while AgMF: MWCNT filler ratio is varied between 0.006 up to 0.2 to choose the best combination. Here, a planetary centrifugal mixer with different mixing time and sequence were considered to identify the most effective mixing method. The functional properties of HECA were characterized in terms of a four-point probe electrical test and a lap shear test via tensile mode. The morphological study suggests that a shorter centrifugal mixing period allows an adequate dispersion of the micro-nano fillers in the HECA system and revealed superior interfacial bonding between the fillers at the optimum ratio. Interestingly, electrical resistivity at critical concentration showed an optimum ratio by incorporating only 2.5% AgMF in the hybrid fillers to yield a 42.62% reduction. However, the significant effects of hybridization are observed until the percolation threshold of HECA at 9 wt% only, followed by a 38.5% reduction beyond this limit. Moreover, the lap shear strength is most reliable at a total filler of 6 wt%, an indication of an excellent filler-binder load distribution.

Graphic Abstract

Similar content being viewed by others

References

Zhong, T., Jin, N., Yuan, W., Zhou, C., Gu, W., Cui, Z.: Printable stretchable silver ink and application to printed RFID tags for wearable electronics. Materials (Basel). 12, 1–14 (2019)

Tomotoshi, D., Kawasaki, H.: Surface and interface designs in copper-based conductive inks for printed/flexible electronics. Nanomaterials 10, 1–53 (2020)

Cadirli, E., Boyuk, U., Kaya, H., Marasli, N., Aksoz, S., Ocak, Y.: Dependence of electrical resistivity on temperature and sn content in pb-sn dependence of electrical resistivity on temperature and sn content in pb-sn solders. J. Electron. Mater. 40, 195–200 (2011)

Chen, X., Bao, R., Yi, J., Fang, D., Tao, J.: Enhancing mechanical properties of pure copper-based materials with Cr x O y nanoparticles and CNT hybrid reinforcement. J. Mater. Sci (2020). https://doi.org/10.1007/s10853-020-05440-6

Yong-Chan, C., Jin, C.B., Jae, W.C., Byoung, C.C.: The preparation and characterization of an epoxy polyurethane hybrid polymer using bisphenol a and epichlorohydrin. Fibers Polym. 21, 447 (2020)

Masaebi, N., Jamaleddin, S., Iraj, P.: Electrically conductive nanocomposite adhesives based on epoxy resin filled with silver coated nanocarbon black. J. Mater. Sci. Mater. Electron. 29, 11840–11851 (2018)

Perets, Y., Aleksandrovych, L., Melnychenko, M., Lazarenko, O., Vovchenko, L.: The electrical properties of hybrid composites based on multiwall carbon nanotubes with graphite nanoplatelets. Nanoscale Res. Lett. 12, 406 (2017)

Zoalfokkar, K.M.A.: Preparation and properties of epoxy adhesives blends. J. Univ. 4, 1126 (2018)

Suriati, G., Mariatti, M., Azizan, A.: Silver-filled epoxy composites: effect of hybrid and silane treatment on thermal properties. Polym. Bull. 70, 311–323 (2012)

Navidfar, A., Sancak, A., Yildirim, K.B., Trabzon, L.: A study on polyurethane hybrid nanocomposite foams reinforced with multiwalled carbon nanotubes and silica nanoparticles. Polym. Plast. Technol. Eng. 2559, 1463 (2017)

Marcq, F., Demont, P., Monfraix, P., Peigney, A., Laurent, C., Falat, T., Courtade, F., Jamin, T.: Carbon nanotubes and silver flakes filled epoxy resin for new hybrid conductive adhesives. Microelectron. Reliab. 51, 1230–1234 (2011)

Luo, J., Cheng, Z., Li, C., Wang, L., Yu, C., Zhao, Y., Chen, M., Li, Q., Yao, Y.: Electrically conductive adhesives based on thermoplastic polyurethane filled with silver flakes and carbon nanotubes. Compos. Sci. Technol. 129, 191–197 (2016)

Huat, S.J., Fadzullah, S.H.S.M., Nasaruddin, M.M., Masripan, N.A., Mansor, M.R., Salim, M.A.: Functional properties of hybrid MWCNT-Ag filled epoxy electrically conductive adhesive. Proc. Mech. Eng. Res. Day 2019, 84–85 (2019)

Wen, J., Tian, Y., Hang, C., Zheng, Z., Zhang, H., Mei, Z., Hu, X., Tian, Y.: Fabrication of novel printable electrically conductive adhesives ( ECAs ) with excellent conductivity and stability enhanced by the addition of polyaniline nanoparticles. Nanomater. 9, 960 (2019)

Ma, H., Li, Z., Tian, X., Yan, S., Li, Z., Guo, X., Ma, Y., Ma, L.: Silver Flakes and silver dendrites for hybrid electrically conductive adhesives with enhanced conductivity. J. Electron. Mater. 47, 2929–2939 (2018)

Zhu, J., Jin, H., Zhou, M., Zhang, X.: Electrical property of electrically conductive adhesives filled with micro-sized ag flakes and modified by dicarboxylic acids. In: International Conference on Electronic Packaging Technology (ICEPT 2016), 923–926 (2016)

Qiao, W., Bao, H., Li, X., Jin, S., Gu, Z.: Research on electrical conductive adhesives filled with mixed filler. Int. J. Adhes. Adhes. 48, 159–163 (2014)

Dong, H., Li, X., Dong, Y., Guo, S., Zhao, L.: A novel preparation method of electrically conductive adhesives by powder spraying process. Materials (Basel) 12, 1–14 (2019)

Fadzullah, S.H.S.M., Adnan, Z., Omar, G., Mustafa, Z., Masripan, N.A.B., Mansor, M.R., Salim, M.A.: Effect of hybridization on the functional properties of AgMF: MWCNT-filled electrically conductive adhesive. J. Electron. Mater. 49, 6572–6581 (2020)

Gabr, M.H., Phong, N.T., Okubo, K., Uzawa, K., Kimpara, I., Fujii, T.: Thermal and mechanical properties of electrospun nano-celullose reinforced epoxy nanocomposites. Polym. Test. 37, 51–58 (2014)

dal Lago, E., Cagnin, E., Boaretti, C., Roso, M., Lorenzetti, A., Modesti, M.: Influence of different carbon-based fillers on electrical and mechanical properties of a PC/ABS blend. Polymers (Basel) 12, (2020)

Jiang, B., Liu, C., Zhang, C., Wang, B., Wang, Z.: The effect of non-symmetric distribution of fiber orientation and aspect ratio on elastic properties of composites. Compos. Part B Eng. 38, 24–34 (2007)

Nasaruddin M.M.: Reliability performance of epoxy based electrically conductive adhesive with varying multiwalled carbon nanotube. MSc Thesis. Universiti Teknikal Malaysia Melaka, Melaka, Malaysia (2019)

Bitenieks, J., Merijs, Meri, R., Zicans, J., Berzins, R., Umbraško, J., Rekners, U.: Rheological, mechanical and adhesion properties of two component adhesive based on modified silyl terminated polyether polymer and epoxy resin. IOP Conf. Series: Materials Science and Engineering (2016) https://doi.org/10.1088/1757-899X/111/1/012018

Szabelski, J.: Effect of incorrect mix ratio on strength of two component adhesive Butt-Joints tested at elevated temperature. MATEC Web Conf. 244, 1–12 (2018)

Ghaleb, Z.A., Mariatti, M., Ariff, Z.M., Ervina, J.: Preparation and properties of amine functionalized graphene filled epoxy thin film nano composites for electrically conductive adhesive. J. Mater. Sci. Mater. Electron. 29, 3160–3169 (2018)

Poh, C.L., Mariatti, M., Ahmad Fauzi, M.N., Sidek, O., Chuah, T.P., Chow, S.C.: Dielectric and thermal properties of treated and untreated MWCNT filled DER 332 Epoxy and OP392 Epoxy. Procedia Chem. 19, 865–870 (2016)

Anuar, S.K., Mariatti, M., Azizan, A., Mang, N.C., Tham, W.T.: Effect of different types of silver and epoxy systems on the properties of silver/epoxy conductive adhesive. J. Mater. Sci. Mater. Electron. 22, 757–764 (2011)

Chan, K.L., Mariatti, M., Lockman, Z., Sim, L.C.: Effects of the size and filler loading on the properties of copper- and silver-nanoparticle-filled epoxy composites. J. Appl. Polym. Sci. 121, 3145 (2011)

Burton, B., Alexander, D., Klein, H., Garibay-Vasquez, A., Pekarik, A., Henkee, C.: Epoxy Formulations Using JEFFAMINE ® Polyetheramines. https://vdocuments.mx/epoxy-formulations-using-jeffamine-polyetheramines.htmlpolyetheramines%20(1).pdf. (2005). Accessed 15 October 2020.

Liang, M., Wong, K.L.: Study of mechanical and thermal performances of epoxy resin filled with micro particles and nanoparticles. Energy Procedia 110, 156–161 (2017)

Ekrem, M., Ataberk, N., Avcı, A., Akdemir, A.: Improving electrical and mechanical properties of a conductive nano adhesiv. J. Adhes. Sci. Technol. 31, 699 (2016)

Mette, C., Stammen, E., Dilger, K.: Structural electrically conductive adhesives. J Adhes. Soc. Jpn. 51, 274 (2015)

Sancaktar, E., Bai, L.: Electrically conductive epoxy adhesives. Polymers (Basel) 3, 427–466 (2011)

Daud, N., Shanks, R.A.: Centrifugal preparation of high filler content epoxy-calcite/talc- nanosilica hybrid composites. In: ECCM 2012 - Compos. Venice, Proc. 15th Eur. Conf. Compos. Mater. 24 (2012)

Wei, J., Atif, R., Vo, T., Inam, F.: Graphene nanoplatelets in epoxy system : dispersion, reaggregation, and mechanical properties of nanocomposites. J. Nanomater. 2015, 1 (2015)

Masripan, N.A.B., Lim, S.J., Omar, G., Salim, M.A., Akop, M.Z., Kamarolzaman, A.A., Tamaldin, N., Nurfaizey, A., Nadlene, R., Fadzullah, S.H.S.M., Saad, A.M., Jasmee, S., Ramli, M.B., Nordin, M.N.A.: Effect of tensile load on electrical resistivity of stretchable conductive ink ( SCI ). J. Mech. Sci. Technol. 11, 30–35 (2019)

ASTM International.: ASTM F390-98 Sheet Resistance of Thin Metallic Films With a Collinear Four-Probe Array. American Society for Testing Material F390-98 (2003)

Berni, A., Mennig, M., Schmidt, H.: Doctor blades. In: Aegerter, M.A., et al. (eds.) Sol-Gel Technologies for Glass Producers and Users, pp. 89–92. Springer, New York (2004)

Taghavi, G., Fox, D., Krishnan, L., Cobley, A.J.: Functionalised copper nanoparticle catalysts for electroless copper plating on textiles. Surf. Coat. Technol. (2020). https://doi.org/10.1016/j.surfcoat.2020.125971

Krawczak, E., Gułkowski, S.: Electrical properties of aluminum contacts deposited by DC sputtering method for photovoltaic applications. E3S Web Conf. 19, 1 (2017)

ASTM International. ASTM D 1002 - Lap Shear Strength of Adhesively Bonded Metal Specimens. American Society for Testing Material D 1002 (2005)

Liang, M., Wong, K.L., Shanks, R., Bansal, V.: Study of dielectric and mechanical properties of epoxy/sio2 nanocomposite prepared by different processing techniques. In: 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM) 48–51 (2015)

Banerjee, P., Bhattacharjee, Y.: Lightweight epoxy-based composites for EMI shielding applications. J. Electron. Mater. 49, 1702 (2019)

Gursel, A., Mohamad, A.A., Mohd Nazerib, M.F.: Adhesion mechanism and failure modes in adhesively bonded joints. In: International Conference on Material Science and Technology in Kızılcahamam/ANKARA (IMSTEC) 108–114 (2019)

Nasaruddin, M.M., Fadzullah, S.H.S.M., Omar, G.: Preliminary investigation on multi-walled carbon nanotubes filled epoxy composite as electrically conductive adhesive. Int. J. Recent Technol. Eng. 8, 28–32 (2019)

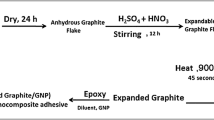

Yu, L., Kang, H., Lim, Y., Lee, C.S., Shin, K., Park, J.S., Han, J.H.: Electrically conductive epoxy nanocomposites with expanded graphite/carbon nanotube hybrid fillers prepared by direct hybridization. J. Nanosci. Nanotechnol. 14, 9139–9142 (2014)

Srinivas, K., Bhagyashekar, M.S., Darshan, B.G.: Effect of fillers on electrical conductivity of epoxy composites. J. Polym. Compos. 6, 25–30 (2018)

Nasaruddin, M.M., Fadzullah, S.H.S.M., Omar, G., Mustafa, Z., Ramli, M., Akop, M.Z., Mohamad, I.S., Çoşut, B.: The effect of aspect ratio on multiwalled carbon nanotubes filled epoxy composite as electrically conductive adhesive. J. Adv. Manuf. Technol. 13, 133–144 (2019)

Fadzullah, S.H.S.M., Nasaruddin, M.M., Mustafa, Z.: The effect of chemical surface treatment on mechanical performance of electrically conductive adhesives. J. Novel Carbon Res. Sci. Green Asia Strategy 7, 444–451 (2020)

Liang, M., Wong, K.L.: Electrical performance of epoxy resin filled with micro particles and nanoparticles. In: 1st International Conference on Energy and Power, Energy Procedia 110, 162–167 (2017)

Shakuntala, O., Raghavendra, G., Samir Kumar, A.: Effect of filler loading on mechanical and tribological properties of wood apple shell reinforced epoxy composite. Adv. Mater. Sci. Eng. 2014, 1–9 (2014)

Tian, J., Yang, C., Yang, J., Hao, S.: The correlated effects of filler loading on the curing reaction and mechanical properties of graphene oxide reinforced epoxy nanocomposites. J. Mater. Sci. 56, 3723–3737 (2020)

Acknowledgements

The authors would like to acknowledge the financial support from Zamalah Scheme under Universiti Teknikal Malaysia Melaka (UTeM) for this research work.

Funding

Zamalah Scheme scholarship from Universiti Teknikal Malaysia Melaka (UTeM).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Adnan, Z., Fadzullah, S.H.S.M., Omar, G. et al. Hybrid Electrically Conductive Adhesive (HECA) Properties as a Function of Hybrid Filler Ratio with Increasing Total Filler Loading. Electron. Mater. Lett. 17, 369–383 (2021). https://doi.org/10.1007/s13391-021-00285-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-021-00285-w