Abstract

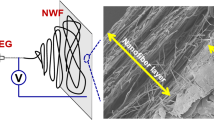

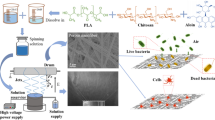

We have designed an efficient wound dressing fabric consisting of physically attached multicompartment (three layers) electrospun nanofibrous mats. Electrospining technique enables abundant porosity and large surface area into the fabric, ensuring enhanced water absorption and cell respiration purposes. Blend of water insoluble, biocompatible, antifungal, bactericidal, and glutinous chitosan with flexible polyethylene oxide (PEO) and herbomettalic mica has been used as the inner layer. Oxygen permeable, tissue compatible, and flexible thermoplastic polyurethane (TPU) has been used as the outer layer. Using some facile chemical approaches, blends of natural polysaccharide pullulan/polyvinyl alcohol (PVA), and in situ polymerized poly (acrylic acid-co-acrylamide)/PVA have been synthesized to fabricate the superabsorbent polymeric materials (SPM) based middle layers of the No. 1 and No. 2 dressings, respectively. The blend ratio, solution viscosity, and electrospinning conditions (i.e., voltage, injection rate, tip-to-collector distance, etc.) have been optimized to prepare each layers of the desired fabrics. Scanning electron microscope (SEM) images, water uptake measurements, and mechanical and thermal properties have been considered to characterize the fabric properties. Because of the more polar functional groups (i.e., -COOH, -CONH2, and -OH) and more crosslinking within the middle layer by glutaraldehyde, No. 2 fabric shows excellent mechanical property (i.e., tensile strength of > 11 MPa), faster (110 seconds) and higher (95%) fluid absorption efficacy, and better reusability (only 16% of water retention after drying for 7 days at room temperature) than No. 1 fabric. No. 1 fabric, in contrast, mainly consisting of H-bonding among the polymers having only -OH functional group, shows < 10 MPa of tensile strength, 75% fluid absorption within 150 seconds and poor reusability (27% of water retention).

Similar content being viewed by others

References

D. Huber, G. Tegl, A. Mensah, B. Beer, M. Baumann, N. Borth, and G. M. Guebitz, ACS Appl. Mater. Interfaces, 9, 15307 (2017).

B. V. Worley, R. J. Soto, P. C. Kinsley, and M. H. Schoenfisch, ACS Biomater. Sci. Eng., 2, 426 (2016).

E. A. Kamoun, E. R. S. Kenawy, and X. Chen, J. Adv. Res., 8, 217 (2017).

I. Bano, M. Arshad, T. Yasin, M. A. Ghauri, and M. Younus, Int. J. Biol. Macromol., 102, 380 (2017).

A. R. Unnithan, A. R. Sasikala, C. H. Park, and C. S. Kim, in Polyurethane Polymers, S. Thomas, J. Datta, J. T. Haponiuk, and A. Reghunadhan, Eds., Elsevier, New York, 2017, Chap. 9, pp. 233–246.

S. P. Miguel, D. R. Figueira, D. Simões, M. P. Ribeiro, P. Coutinho, P. Ferreira, and I. J. Correia, Colloids Surf. B, 169, 60 (2018).

E. Caló, L. Ballamy, and V. V. Khutoryanskiy, Hydrogels in Wound Management in Hydrogels: Design, Synthesis and Application in Drug Delivery and Regenerative Medicine, CRC Press, UK, 2018.

W. Xu, Q. Song, J. F. Xu, M. J. Serpe, and X. Zhang, ACS Appl. Mater. Interfaces, 9, 11368 (2017).

Y. Xiao, L. A. Reis, N. Feric, E. J. Knee, J. Gu, S. Cao, and M. Radisic, Proc. Natl. Acad. Sci. U.S.A., 113, E5792 (2016).

M. S. Brown, B. Ashley, and A. Koh, Front. Bioeng. Biotechnol., 6, 47 (2018).

E. M. Ahmed, J. Adv. Res., 6, 105 (2015).

M. Pakravan, M. C. Heuzey, and A. Ajji, Biomacromolecules, 13, 412 (2012).

J. Lin, C. Li, Y. Zhao, J. Hu, and L. M. Zhang, ACS Appl. Mater. Interfaces, 4, 1050 (2012).

A. K. Azad, N. Sermsintham, S. Chandrkrachang, and W. F. Stevens, J. Biomed. Mater. Res., Part B, 69, 216 (2004).

Q. Chen, Z. X. Xin, P. Saha, and J. K. Kim, J. Polym. Eng., 37, 461 (2017).

W. Xu, Z. Wang, Y. Liu, L. Wang, Z. Jiang, T. Li, W. Zhang, and Y. Liang, Carbohydr. Polym., 192, 240 (2018).

J. P. Chen, G. Y. Chang, and J. K. Chen, Colloids Surf. A, 313, 183 (2008).

M. Ignatova, N. Manolova, N. Markova, and I. Rashkov, Macromol. Biosci., 9, 102 (2009).

S. Lu, W. Gao, and H. Y. Gu, Burns, 34, 623 (2008).

M. N. R. Kumar, React. Funct. Polym., 46, 1 (2000).

T. T. Yuan, A. M. D. Foushee, M. C. Johnson, A. R. Jockheck–Clark, and J. M. Stahl, Nanoscale Res. Lett., 13, 88 (2018).

A. Wijenayake, A. Pitawala, R. Bandara, and C. Abayasekara, J. Ethnopharmacol., 155, 1001 (2014).

A. U. Wijenayake, C. L. Abayasekara, H. M. T. G. A. Pitawala, and B. M. R. Bandara, BMC Complement. Altern. Med., 16, 365 (2016).

P. M. Claesson and B. W. Ninham, Langmuir, 8, 1406 (1992).

F. Kong, S. Wang, W. Gao, and P. Fatehi, RSC Adv., 8, 12322 (2018).

S. Shukla and A. K. Bajpai, J. Appl. Polym. Sci., 102, 84 (2006).

D. Ma, B. Zhu, B. Cao, J. Wang, and J. Zhang, J. Macromol. Sci., Part B: Phys., 55, 1124 (2016).

M. J. Zohuriaan–Mehr and K. Kabiri, Iran. Polym. J., 17, 451 (2008).

H. Byun, B. Hong, S. Y. Nam, S. Y. Jung, J. W. Rhim, S. B. Lee, and G. Y. Moon, Macromol. Res., 16, 189 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Acknowledgments: This work was supported by the Gyeongsang National University Fund for Professors on Sabbatical Leave, 2017 and Materials and Components Technology Development Program of MOTIE/KEIT (10067683, Development of Manufacturing Technology of High Barrier Elastomeric Material).

Rights and permissions

About this article

Cite this article

Chen, Q., Sinha, T.K., Li, H. et al. A Facile Approach towards Fabrication of Electrospun Nanofibrous Mats based Multicompartment Wound Dressing Fabric. Macromol. Res. 26, 1265–1272 (2018). https://doi.org/10.1007/s13233-019-7028-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-019-7028-1