Abstract

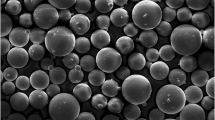

This work compares two metal additive manufacturing processes, selective laser melting (SLM) and electron beam melting (EBM), based on microstructural and mechanical property evaluation of Ti6Al4V parts produced by these two processes. Tensile and fatigue bars conforming to ASTM standards were fabricated using Ti6Al4V ELI grade material. Microstructural evolution was studied using optical and scanning electron microscopy. Tensile and fatigue tests were carried out to understand mechanical properties and to correlate them with the corresponding microstructure. The results show differences in microstructural evolution between SLM and EBM processed Ti6Al4V and their influence on mechanical properties. The microstructure of SLM processed parts were composed of an α′ martensitic phase, whereas the EBM processed parts contain primarily α and a small amount of β phase. Consequently, there are differences in tensile and fatigue properties between SLM- and EBM-produced Ti6Al4V parts. The differences are related to the cooling rates experienced as a consequence of the processing conditions associated with SLM and EBM processes.

Similar content being viewed by others

References

F. Abe, K. Osakada, M. Shiomi, K. Uematsu, and M. Matsumoto, The Manufacturing of Hard Tools from Metallic Powders by Selective Laser Melting, J. Mater. Process. Technol., 2001, 111, p 210–213

S.M. Gaytan, L.E. Murr, E. Martinez, J.L. Martinez, B.I. Machado, D.A. Ramirez, F. Medina, S. Collins, and R.B. Wicker, Comparison of Microstructures and Mechanical Properties for Solid and Mesh Cobalt-Base Alloy Prototypes Fabricated by Electron Beam Melting, Metall. Mater. Trans. A, 2010, 41A, p 3216–3227

E. Brinksmeier, G. Levy, D. Meyer, and A.B. Spierings, Surface Integrity of Selective-Laser-Melted Components, CIRP Ann. Manuf. Technol., 2010, 59(1), p 601–606

J.P. Kruth, G. Levy, F. Klocke, and T.H.C. Childs, Consolidation Phenomena in Laser and Powder-Bed Based Layered Manufacturing, CIRP Ann. Manuf. Technol., 2007, 56, p 730–759

M.F. Zah and S. Lutzmann, Modelling and Simulation of Electron Beam Melting, Prod. Eng. Res. Dev., 2010, 4, p 15–23

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, and R.B. Wicker, Microstructures and Mechanical Properties of Electron Beam-Rapid Manufactured Ti-6Al-4V Biomedical Prototypes Compared to Wrought Ti-6Al-4V, Mater. Charact., 2009, 60, p 96–109

L. Thijs, F. Verhaeghe, T. Craeghs, J.V. Humbeeck, and J.P. Kruth, A Study of the Microstructural Evolution During Selective Laser Melting of Ti-6Al-4V, Acta Mater., 2010, 58, p 3303–3312

B. Song, S. Dong, B. Zhang, H. Liao, and C. Coddet, Effects of Processing Parameters on Microstructure and Mechanical Property of Selective Laser Melted Ti6Al4V, Mater. Des., 2012, 35, p 120–125

I. Yadroitsev, P. Bertrand, and I. Smurov, Parametric Analysis of the Laser Melting Process, Appl. Surf. Sci., 2007, 253(19), p 8064–8069

R. Morgan, C.J. Sutcliffe, and W. O’Neill, Density Analysis of Direct Metal Laser Remelted 316L Stainless Steel Cubic Primitives, J. Mater. Sci., 2004, 39(4), p 1195–1205

E. Yasa, J. Deckers, and J.P. Kruth, The Investigation of the Influence of Laser Re-Melting on Density, Surface Quality and Microstructure of Selective Laser Melting Parts, Rapid Prototyp. J., 2011, 17(5), p 312–327

S.S. Al-Bermani, M.L. Blackmore, W. Zhang, and I. Todd, The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V, Metall. Mater. Trans. A., 2010, 41A, p 3422–3432

L. Facchini, E. Magalini, P. Robotti, and A. Molinari, Microstructure and Mechanical Properties of Ti-6Al-4V Produced by Electron Beam Melting of Pre-Alloyed Powders, Rapid Prototyp. J., 2009, 15(3), p 171–178

B. Vrancken, L. Thijis, J.P. Kruth, and J.V. Humbeeck, Heat Treatment of Ti6Al4V Produced by Selective Laser Melting—Microstructure and Mechanical Properties, J. Alloy Compd., 2012, 541, p 177–185

ASM Handbook, Vol. 1, ASM International, Materials Park, OH, 1993, p 2071

T. Vilaro, C. Colin, and J.D. Bartout, As-Fabricated and Heat Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting, Metall. Mater. Trans. A., 2011, 42, p 3190

L. Facchini, E. Magalini, P. Robotti, A. Molinari, S. Hogess, and K. Wissenbach, Ductility of Ti-6Al-4V Alloy Produced by Selective Laser Melting of Pre-Alloyed Powders, Rapid Prototyp. J., 2010, 16(6), p 450–459

G. Chahine, M. Koike, T. Okabe, P. Smith, and R. Kovacevic, The Design and Production of Ti-6Al-4V ELI, Customized Dental Implants, JOM, 2008, 60(11), p 50–55

G.E. Dieter, Mechanical Metallurgy, McGraw Hill, New York, 1986

M. Erdogan and S. Tekeli, The Effect of Martensitic Particle Size on Tensile Fracture of Surface-Carburized AISI, 8620 Steel with Dual Phase Core Microstructure, Mater. Des., 2002, 23, p 597–604

T.S. Srivatsana, M. Kuruvilla, and L. Park, A Study at Understanding the Mechanisms Governing the High Cycle Fatigue and Final Fracture Behavior of the Titanium Alloy: Ti-4Al-2.5V, Mater. Sci. Eng. A., 2010, 527, p 435–448

S.G. Ivanova, R.R. Biederman, and R.D. Sisson, Jr., Investigation of Fatigue Crack Initiation in Ti-6Al-4V During Tensile-Tensile Fatigue, J. Mater. Eng. Perform., 2002, 11(2), p 226–231

R.K. Nalla, B.L. Boyce, J.P. Campbell, J.O. Peters, and R.O. Ritchie, Influence of Microstructure on High-Cycle Fatigue of Ti-6Al-4V: Bimodal vs. Lamellar Structures, Metall. Mater. Trans. A., 2002, 33A, p 899–918

J. Oh, N.J. Kim, S. Lee, and W. Lee, Correlation of Fatigue Properties and Microstructure in Investment Cast Ti-6Al-4V, Mater. Sci. Eng. A., 2003, 340, p 232–242

Acknowledgments

The authors acknowledge the Office of Naval Research (ONR), USA for support through grant #’s N00014-09-1-0147, N00014‐10‐1‐0800, and N00014-11-1-0689.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rafi, H.K., Karthik, N.V., Gong, H. et al. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. of Materi Eng and Perform 22, 3872–3883 (2013). https://doi.org/10.1007/s11665-013-0658-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0658-0